Low idle HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 66 of 1395

lgnition System

5.

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

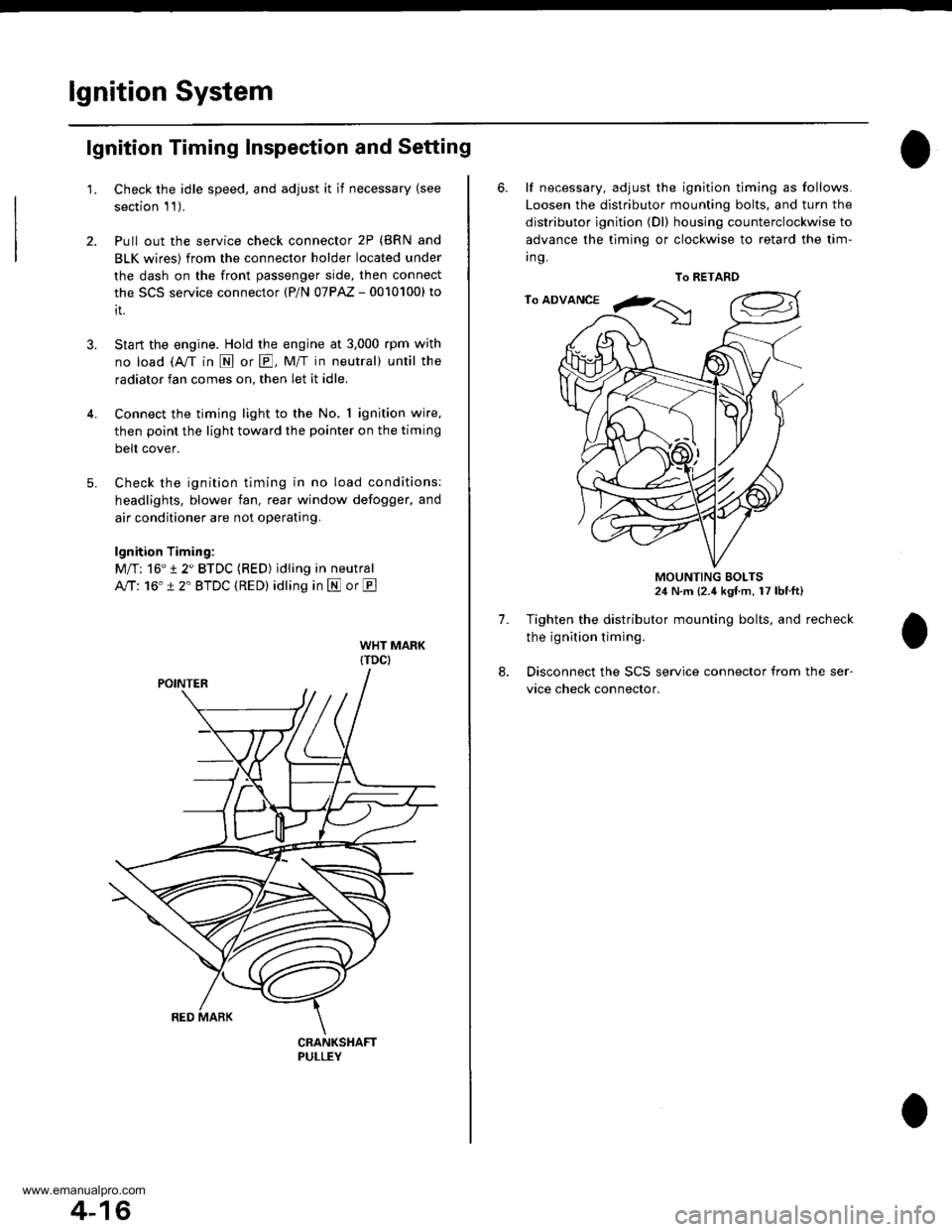

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 123 of 1395

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

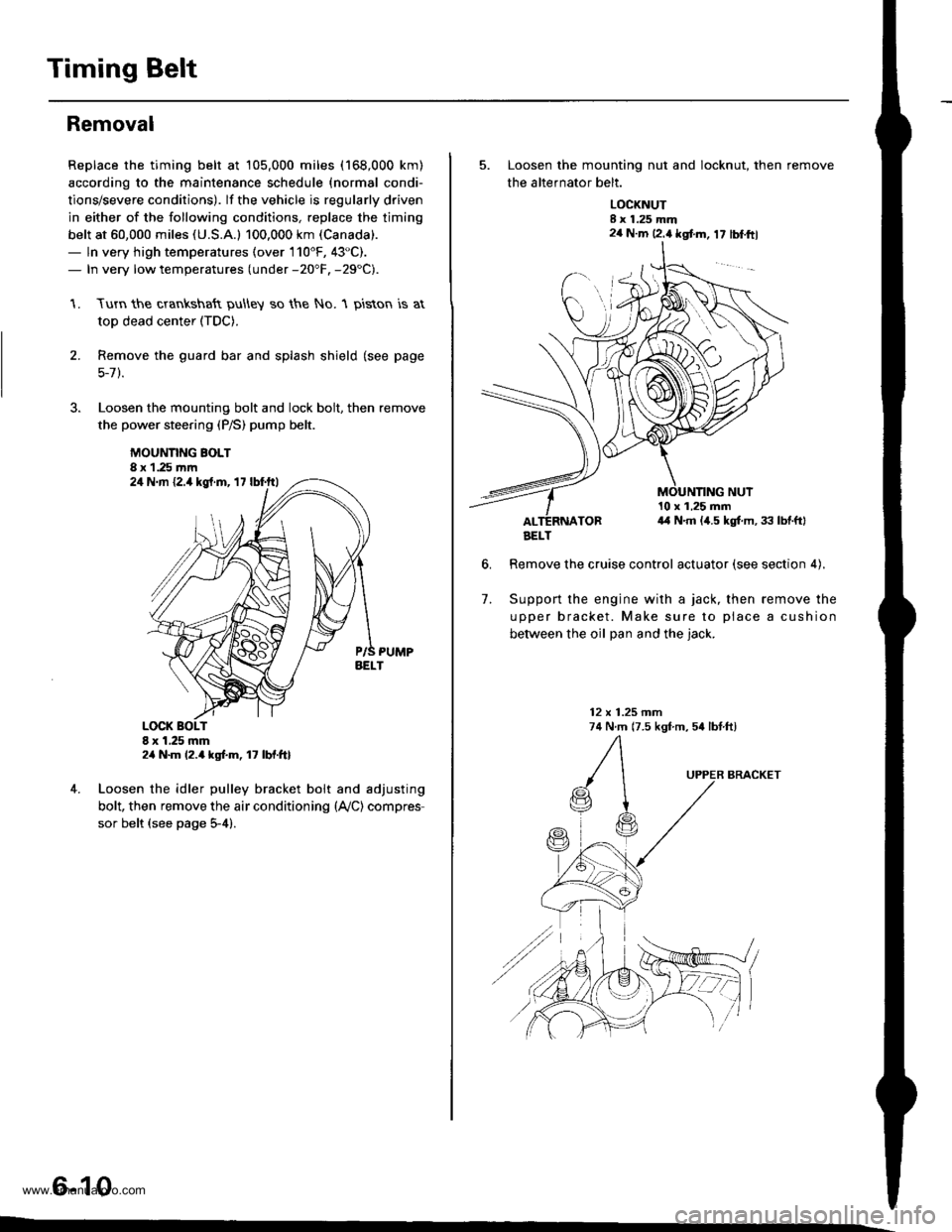

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 126 of 1395

CKF Sensor

Replacement

1.

|o|'ln PUUCY BMCKET SOLIl0 r 1.25 mm14 .m 14.5 kgl.m,3:' lbtftl

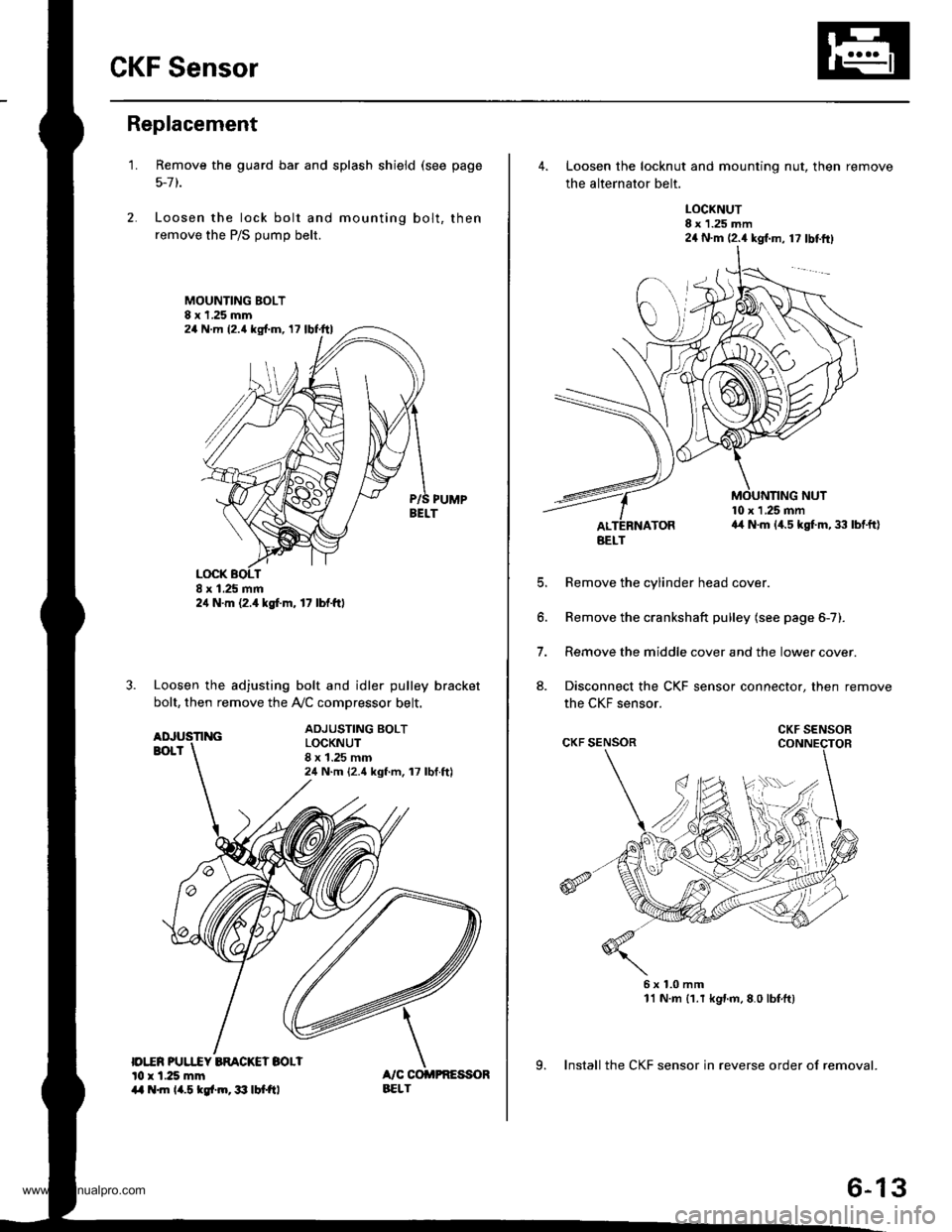

Remove the guard bar and splash shield (see page

5-7 t.

Loosen the lock bolt and mounting bolt, then

remove the P/S pump belt.

MOUNTING BOLT8 x 1.25 mm

PUMPBELT

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the Ay'C comDressor belt.

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ft)

24 N.m (2.{ kgf.m, 17 lbf.ttl

24 N.m 12.4 lgf.m, 17 lbl.ftl

4. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgl.m, 17 lbtftl

10 x 1 .25 mma4 N.m (4.5 kgt m, 33 lbtft)

E

6.

7.

aJ.

Remove the cylinder head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and the lower cover.

Disconnect the CKF sensor connector, then remove

the CKF sensor.

6x1.0mm11 N.m {1.r kgnm,8.0 lbfft)

9. Install the CKF sensor in reverse order of removal.

BELT

CKF SENSOR

6-13

www.emanualpro.com

Page 129 of 1395

Gylinder Head

Removal

Engine removal is not required for this procedure.

l!@ Make sure iacks and safety stands are

placed properly, and hoist blackels ale attachgd to the

correct position on the engine.

NOTE:

o Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage, unplug the wiring connectors care-

fully while holding the connector portion.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F (38'C)

before loosening the retaining bolts.

. Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

2.

4.

5.

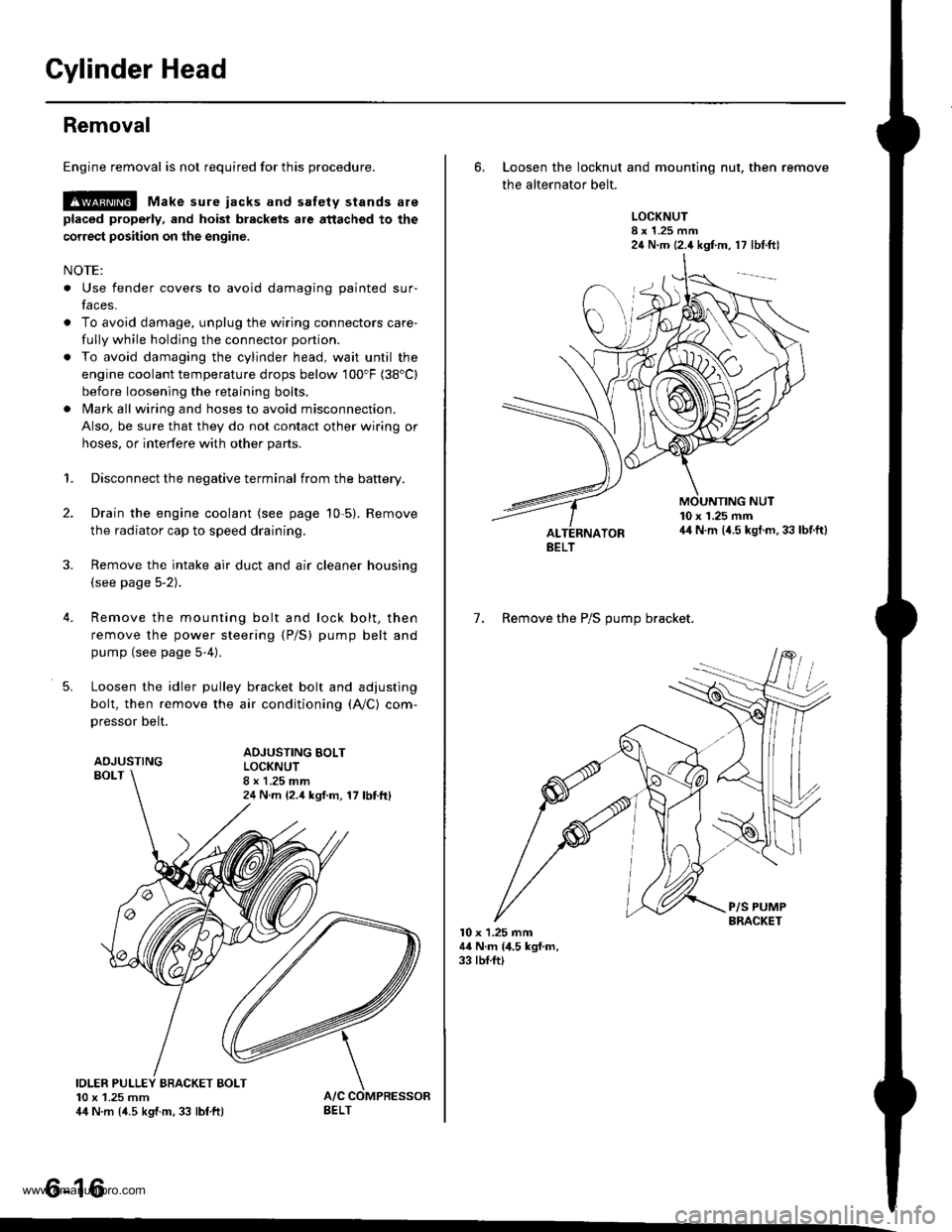

1.Disconnect the negative terminal from the battery.

Drain the engine coolant (see page 10-5). Remove

the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing(see page 5-2).

Remove the mounting bolt and lock bolt, then

remove the power steering (P/S) pump belt and

pump (see page 5-4).

Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com,

pressor belt.

ADJUSTINGBOLT

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N m {2.4 ksf.m, 17 lbttt}

IOLER PULLEY BBACKET BOLT10 x 1.25 mm44 N.m {4.5 kgtm, 33 lbf ft)

tt aAo-Io

6. Loosen the locknut and mounting nut, then remove

the alternator belt.

LOCKNUT8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbt.ftl

10 x 1.25 mm44 N.m (4.5 kgt.m. 33 lbf.ft)

7. Remove the P/S OUmo bracket.

l0 x 1.25 mm44 N.m (4.5 kgf.m,33 rbf.ft)

BELT

www.emanualpro.com

Page 266 of 1395

Troubleshooting

Troubleshooting Procedures (cont'dl

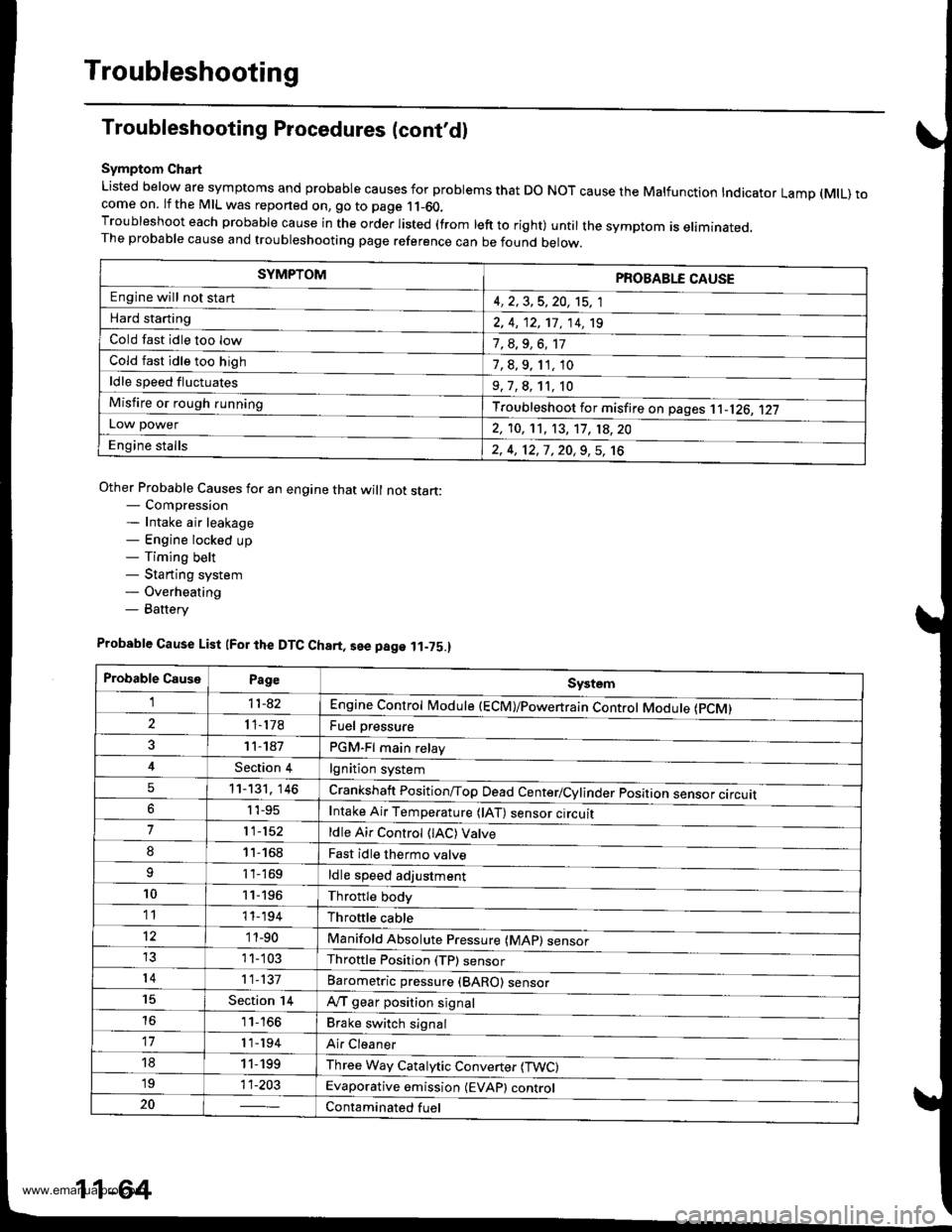

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the Malfunction Indicator Lamp (MlL) tocome on. lf the MIL was reported on, go to page 11-60.Troubleshoot each probable cause in the order listed (from left to right) until the symptom is eliminated,The probable cause and troubleshooting page reference can be found below.

Other Probable Causes for an engine that will not start:- Compression- Intake air leakage- Engine locked up- Timing belt- Starting system- Overheating- Battery

SYMPTOMPROBABLE CAUSE

Engine will not sta rt4, 2,3,5,20, 't5, 1

Hard starting2, 4, 12,17, 14, 't9

Cold fast idle too low7, a,9, 6, 17

Cold fast idle too high7,8,9,11,10

ldle speed fluctuates9,7,8, 't1, 10

Misfire or rough runningTroubleshoot for misfire on pages '11-126, 1|21LOl/\/ power2, 10,11, 13, '17, 18,20

Engine stalls2, 4, 12,1,20,9,5, 't6

Probable Cause List (For the DTC Ch8rt, see page ll-75.)

Probable CausePageSystem

Engine controt ruoaute (ecvtffi'I11-42

I 1-178Fuel oressure

PGM-Fl main relav

lgnition system

Crankshatt Position/Top Dead Center/Cylinder position sensor circuit

Intake Air Temperature (lAT) sensor ctrculr

ldle Air Control (lAC) Vatve

Fast idle thermo valve

ldle speed adjustment

Throttle body

Throftle cable

Manifold Absolute P."""rr"ffi

Throftle Position (TP) sensor

Barometric pressur" (gnno-

Ay'T gear position signal

Brake switch signal

Air Cleaner

Three Way Catalytic Converter (TWC)

Evaporative emission (EVAP) control

Contaminated fuel

1 1- 187

Section 4

5't1-'t31,146

6I '�t-95

711-152

81'l-168

1 1- 169

1011-196'1111-'194

12'1 'l -90

1 1- 103

1411-137

15Section 14

161 1- 166

17r 1-194

181 1,199'1911-203

20

11-64

www.emanualpro.com

Page 267 of 1395

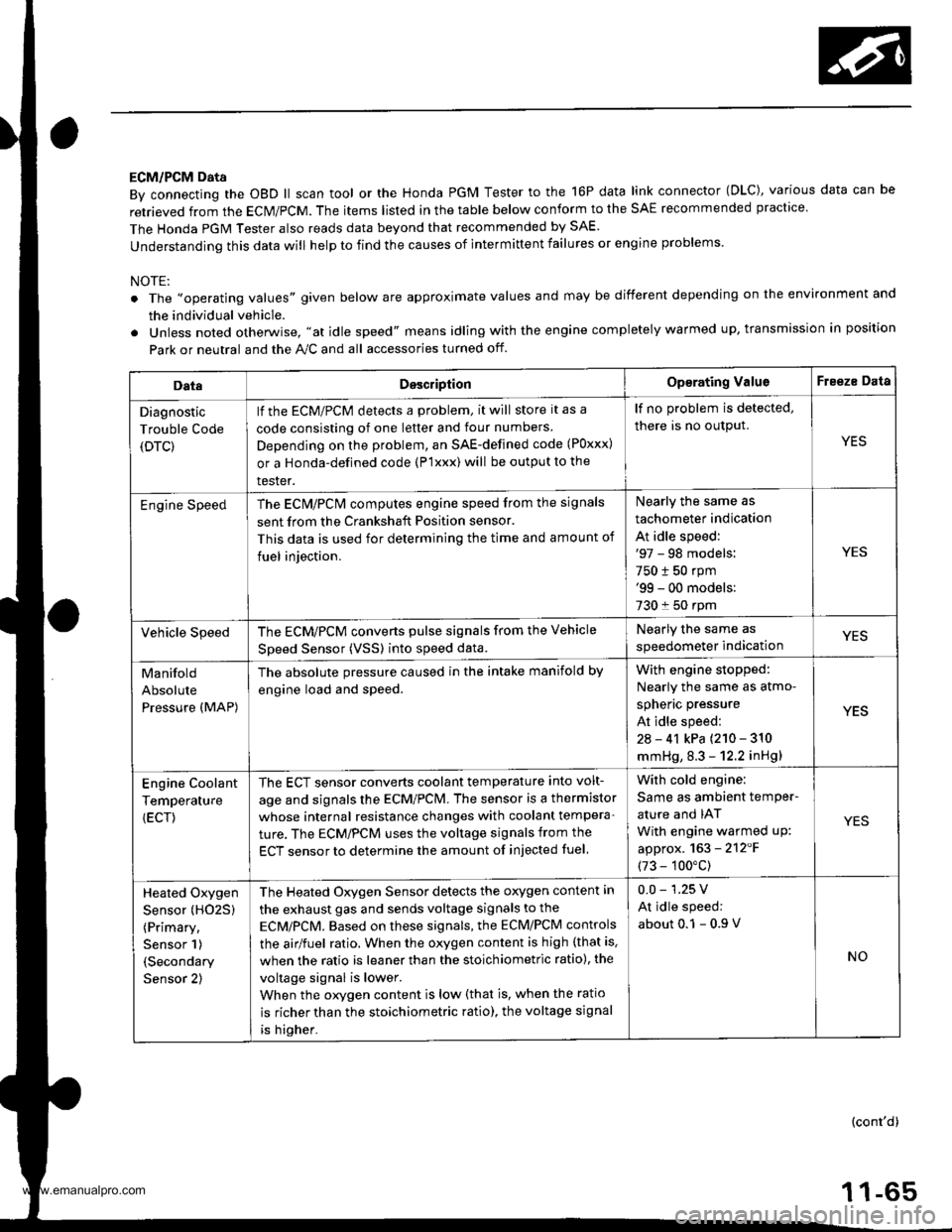

ECM/PCM Data

By connecting the OBD ll scan tool or the Honda PGM Tester to the 16P data link connector (OLC), various data can be

retrieved from the ECM/PCM. The items listed in the table below conform to the SAE recommended practice

The Honda PGM Tester also reads data beyond that recommended by SAE.

understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The ',operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise. "at idle speed" means idling with the engine completely warmed up, transmission in position

Park or neutral and the A,./C and all accessories turned otf.

DataDesc.iptionOp€rating ValuoFreeze Data

Diagnostic

Trouble Code

(DTC)

lf the ECM/PCM detects a problem, it will store it as a

code consisting of one letter and tour numbers

Depending on the problem, an SAE-defined code (Poxxx)

or a Honda-defined code (P'lxxx) will be output to the

tester.

lf no problem is detected,

there is no output.

YES

Engine SpeedThe ECN4/PCN4 computes engine speed from the signals

sent from the Crankshaft Position sensor.

This data is used for determining the time and amount of

fuel iniection.

Nearly the same as

tachometer indication

At idle speed:'97 - 98 models:

750 t 50 rpm'99 - 00 models:

730 f 50 rpm

YES

Vehicle SpeedThe ECM/PCM converts pulse signals from the Vehicle

Speed Sensor (VSSI into speed data.

Nearly the same as

speedometer indicationYES

Manifold

Absolute

Pressure (MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engin6 stopped:

Nearly the same as atmo-

spheric pressure

At idle speed:

2a - 41 kPa {210 - 310

mmHg, 8.3 - 12.2 inHg)

YES

Engine Coolant

Temperature

{ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM/PCM. The sensor is a thermistor

whose internal resistance changes with coolant tempera-

ture. The ECM/PCM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel

With cold engine:

Same as ambient temPer-

ature and IAT

With engine warmed uP:

approx. 163 - 2'12'F

(73 - 100"c)

YES

Heated Oxygen

Sensor (HO25)

(Primary,

Sensor 1)

(Secondary

Sensor 2)

The Heated Oxygen Sensor detects the oxygen content in

the exhaust gas and sends voltage signals to the

ECMiPCM. Based on these signals, the ECM/PCM controls

the airlfuel ratio. When the oxygen content is high (that is.

when the ratio is leaner than the stoichiometric ratio), the

voltage signal is lower.

When the orygen content is low (that is, when the ratio

is richer than the stoichiometric ratio), the voltage signal

is higher.

0.0 - 1.25 V

At idle speed:

about 0.1 - 0.9

NO

(cont'd)

1 1-65

www.emanualpro.com

Page 268 of 1395

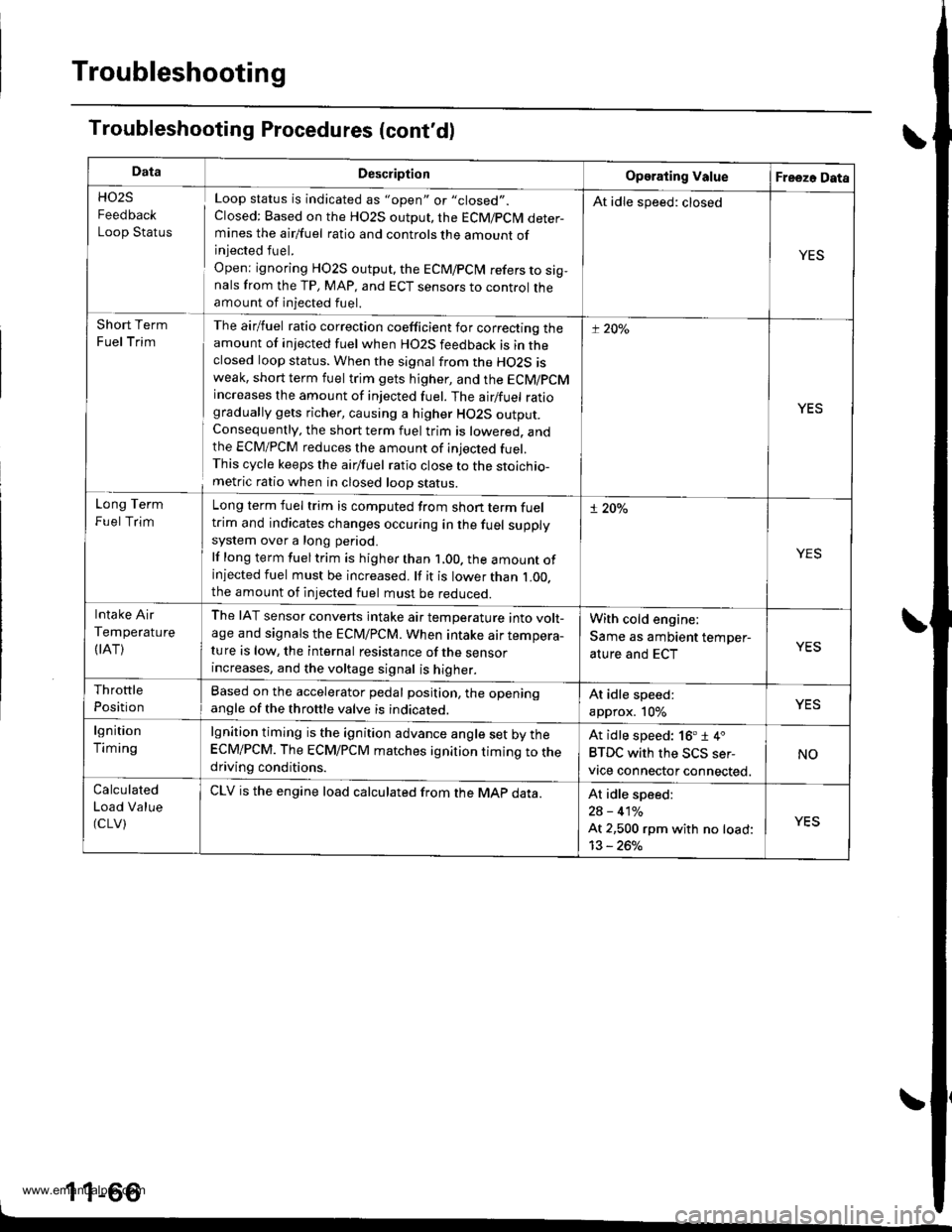

Troubleshooting

Troubleshooting Procedures (cont'd)

DataDescliptionOperating ValueFreezo Data

HO2S

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the ECM/pCM deter-mines the airlfuel ratio and controls the amount ofinjected fuel.

Open: ignoring HO2S output, the ECM/pCiM refers to sig,nals from the TP, MAP, and ECT sensors to control theamount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correction coefficient for correcting theamount of injected fuel when HO2S feedback is in theclosed loop status. When the signal from the HO2S isweak, short term fuel trim gets higher, and the ECM/PCMincreases the amount of injected fuel. The airlfuel ratiogradually gets richer, causing a higher HO2S output.Consequently. the short term fuel trim is lowered. andthe ECM/PCM reduces the amount of injected fuel.This cycle keeps the airfuel ratio close to the stoichio-metric ratio when in closed looD status.

t:20y"

YES

Long Term

Fuel Trim

Long term fuel trim is computed from shon term fueltrim and indicates changes occuring in the fuel supplysystem over a long period.

lf long term fuel trim is higher than 1,00. the amount ofinjected fuel must be increased. lf it is lower than L00.the amount of injected fuel must be reduced.

! 20%

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into volt-age and signals the ECrU/PCM. When intake air tempera-ture is low, the internal resistance of the sensorincreases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position, the openingangle of the throttle valve is indicateo.At idle speed:

approx. 10%

lgnition

Timing

lgnition timing is the ignition advance angle set by theECM/PCM. The ECM/PCM matches ignition timing to thedriving conditions.

At idle speed: 16'1 4.

BTDC with the SCS ser-

vtce connector connected.

NO

Calculated

Load Value(cLV)

CLV is the engine load calculated from the MAp data.At idle speed:

2A - 410/o

At 2,500 rpm with no load:

13 - 260/o

YES

_

1 1_66

www.emanualpro.com

Page 269 of 1395

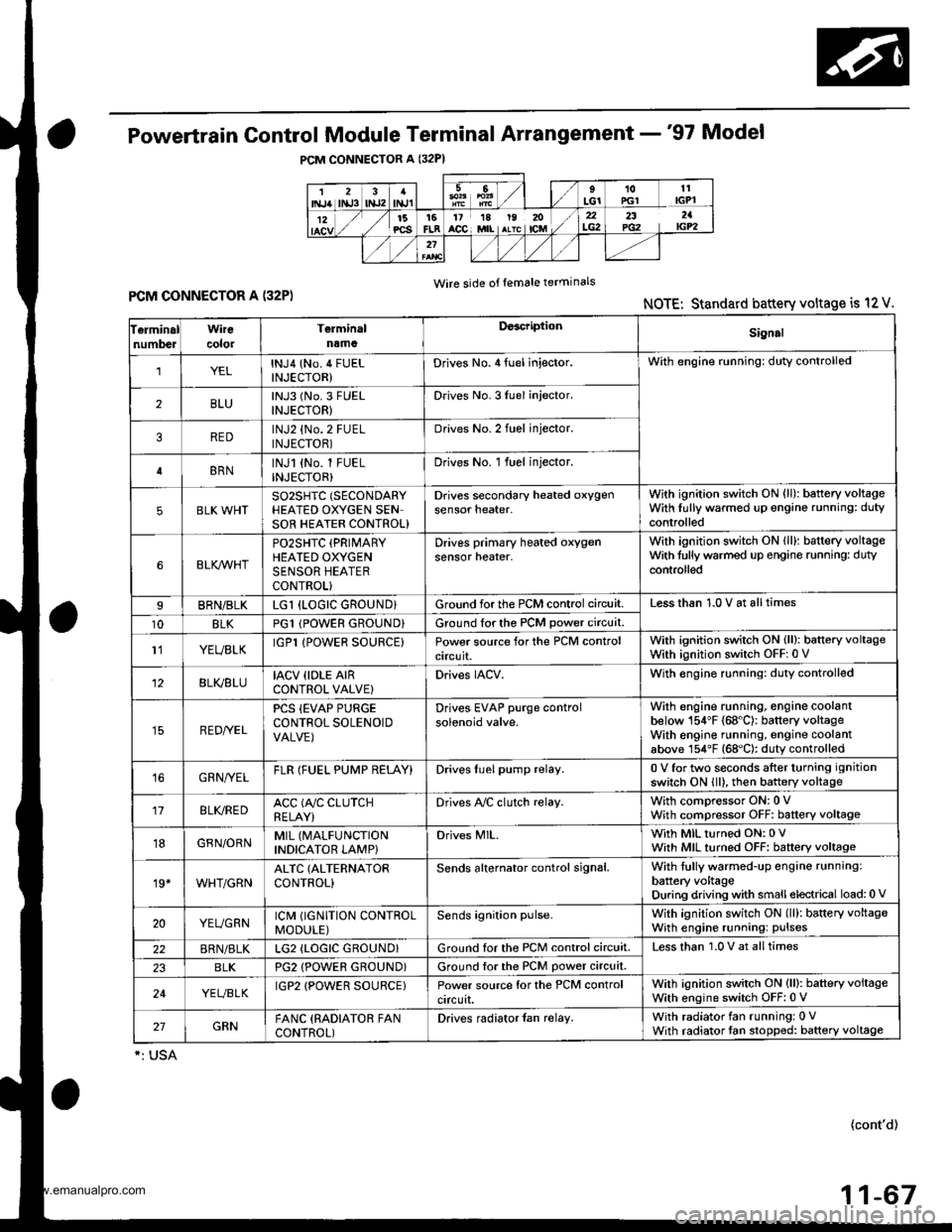

Powertrain Control Module Terminal Arrangement -'97 Model

FCM CONNECTOR A (32P)NOTE: Standard battery voltage is 12 V.

Wire side of lemale terminals

f€rminalnumlreJWirecolor

Telminalnama

DescriptionSignal

YELlNJ4 (No.4 FUELINJECTOR)Drives No. 4 {uel injector.With engine running: duty controlled

2BLUlNJ3 (No.3 FUELINJECTOR)Drives No. 3luel injector.

REDlNJ2 {No.2 FUELINJECTOR)Drives No.2 tuel injector.

BRNlNJl (No. l FUELINJECTOR)Drives No. 1 fuel injector.

5BLK WHTSO2SHIC (SECONDARY

HEATED OXYGEN SENSOR HEATER CONTROL)

D ves secondary heated oxygensensor heater.With ignition switch ON {ll): battery voltageWith fully warmed up engino running: dutycontrolled

6BLKAr'YHT

PO2SHTC (PRIMARY

HEATED OXYGENSENSOR HEATERCONTROL}

Drives primary heated oxygensensor heater,With ignition switch ON lll): battery voltagewith fully warmed up engine running: dutycontroll6d

I8RN/BLKLGl (LOGIC GROUND}Ground forthe PCM control circuit.Less than 1.0 V at all times

10BLKPG1 lPOWER GROUND}Ground for the PCM power circuit.

l1YEUELKIGPl lPOWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltageWith ignition switch OFF: 0 V

12BLI(BLUIACV {IDLE AIRCONTROL VALVE}Drives IACV.With €ngine running: duty controlled

REDryEL

PCS (EVAP PURGECONTFOL SOLENOIDVALVE)

Drives EVAP purge controlsolenoid valve.

With engine running, engine coolantbelow 154'F (68"C): battery voltageWith engine running, engine coolantabove 154"F (68"C): duty controlled

16GRN/VELFLR (FUEL PUMP RELAY)Drives Iuel pump relay.0 V for two seconds after turning ignition

switch ON lll), then battery voltage

118LI(REDACC (A,/C CLUTCHRELAY}Drives Ay'C clutch relay.With comoressor ON: 0 VWith compressor OFF: baftery voltage

18GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP}Drives MlL.With MIL turned ON: 0 VWith MIL turned OFF: baftery voltage

19*WHT/GRNALTC (ALTERNATOR

CONTROL}Sends alternator control signal.With tully warmed-up engine running:

battery voltageDuring driving with smallelectrical load:0 '

20YEUGRNICM (IGNITION CONTROLMODULE)Sends ignition pulse.With ignition switch ON (ll): baftery voltageWith engine running: pulses

22BRN/BLKLG2 (LOGIC GROUND}Ground tor the PCM control circuit.Less than 1.0 V at alltimes

23BLKPG2 {POWER GROUND}Ground lor the PCM power circuit.

24YEUBLKIGP2 {POWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltage

With engine switch OFF: 0 V

27GRNFANC (RADIATOR FANCONTROL)Drives radiator {an relay.With radiator fan running: 0 VWith radiator fan stopped: baftery voltage

*: USA

{cont'd)

11-67

www.emanualpro.com

Page 272 of 1395

Troubleshooting

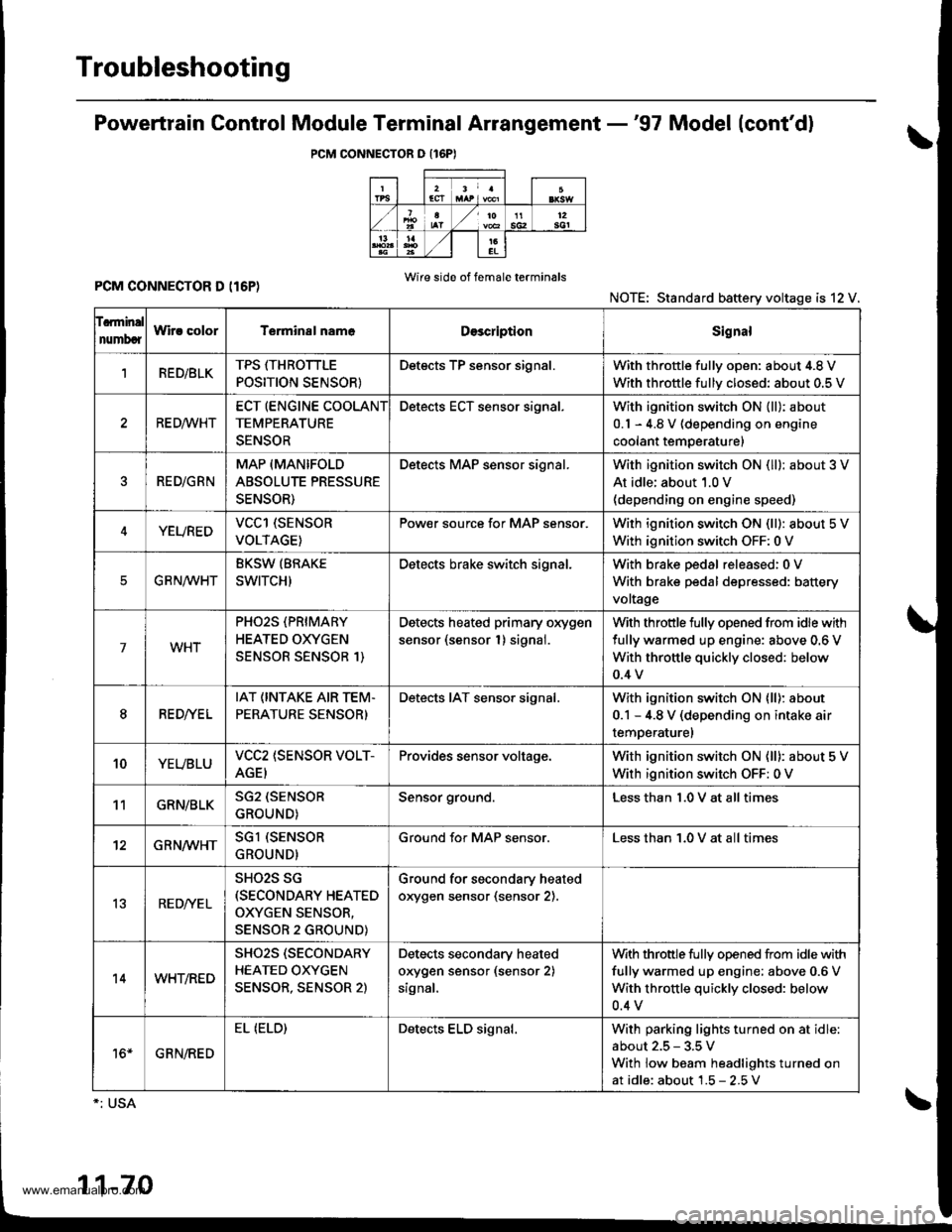

Powertrain Gontrol Module Terminal Arrangement -'97 Model (cont'd)

PCM CONNECTOR O {16PI

PCM CONNECTOR D (I6P)Wire side of f6male terminals

NOTE: Standard battery voltage is 12 V.

f.rminal

numbcrWir! colorT€rminal nam6DescriptionSignal

1RED/BLKTPS ffHROTTLE

POSITION SENSOR}

Detects TP sensor signal.With throttle fullv oDen: about 4.8 V

With throttle fullv closed: about 0.5 V

RE D,4/VHT

ECT (ENGINE COOLANT

TEMPERATURE

SENSOR

Detects ECT sensor signal.With ignition switch ON {ll): about

0.1 - 4.8 V (depending on engine

coolant temperature)

RED/GRN

MAP (MANIFOLD

ABSOLUTE PRESSURE

SENSOR)

Detects MAP sensor signal.With ignition switch ON (ll): about 3 V

At idle; about 1.0 V(depending on engine speed)

YEUREDVCCl (SENSOR

VOLTAGE)

Pow€r source for MAP sensor.With ignition switch ON (ll): about 5 V

With ignition switch OFF: 0 V

EG R N/WHT

BKSW (BRAKE

SWITCH)

Detects brake switch signal.With brake pedal released:0 V

With brake pedal depressed: battery

voltage

7WHT

PHO2S (PRIMARY

HEATED OXYGEN

SENSOR SENSOR 1)

Detects heated primary oxygen

sensor (sensor 1) signal.

With throttle fully opened from idle with

fully warmed up engine: above 0.6 V

With throttle quickly closed: below

0.4 v

8RED//E L

IAT (INTAKE AIR TEM.

PERATURE SENSOR)

Detects IAT sensor signal.With ignition switch ON lll): about

0.1 - 4.8 V (depending on intake air

temperaturel

10YEUBLUVCC2 (SENSOR VOLT-

AGEI

Provides sensor voltage.With ignition switch ON (ll): about 5 V

With ignition switch OFF: 0 V

11GRN/BLKSG2 (SENSOR

GROUND)

Sensor ground.Less than 1.0 V at all times

12GRN/WHTSGl (SENSOR

GROUND)

Ground for MAP sensor.Less than 1.0 V at all times

13RED/YE L

SHO2S SG(SECONDARY HEATED

OXYGEN SENSOR,

SENSOR 2 GROUND)

Ground for secondary heated

orygen sensor (sensor 2).

14WHT/RED

SHO2S (SECONDARY

HEATED OXYGEN

SENSOR, SENSOR 2)

Detects secondary heated

orygen sensor (sensor 2)

signal,

With throttle fully opened from idle with

fully warmed up engine; above 0.6 V

With throttle quickly closed: below

0.4 v

16*GRN/RED

EL (ELD)Detects ELD signal.With parking lights turned on at idle

about 2.5 - 3.5 V

With low beam headlights turned on

at idle: about 1.5 - 2.5V

1-70

www.emanualpro.com

Page 273 of 1395

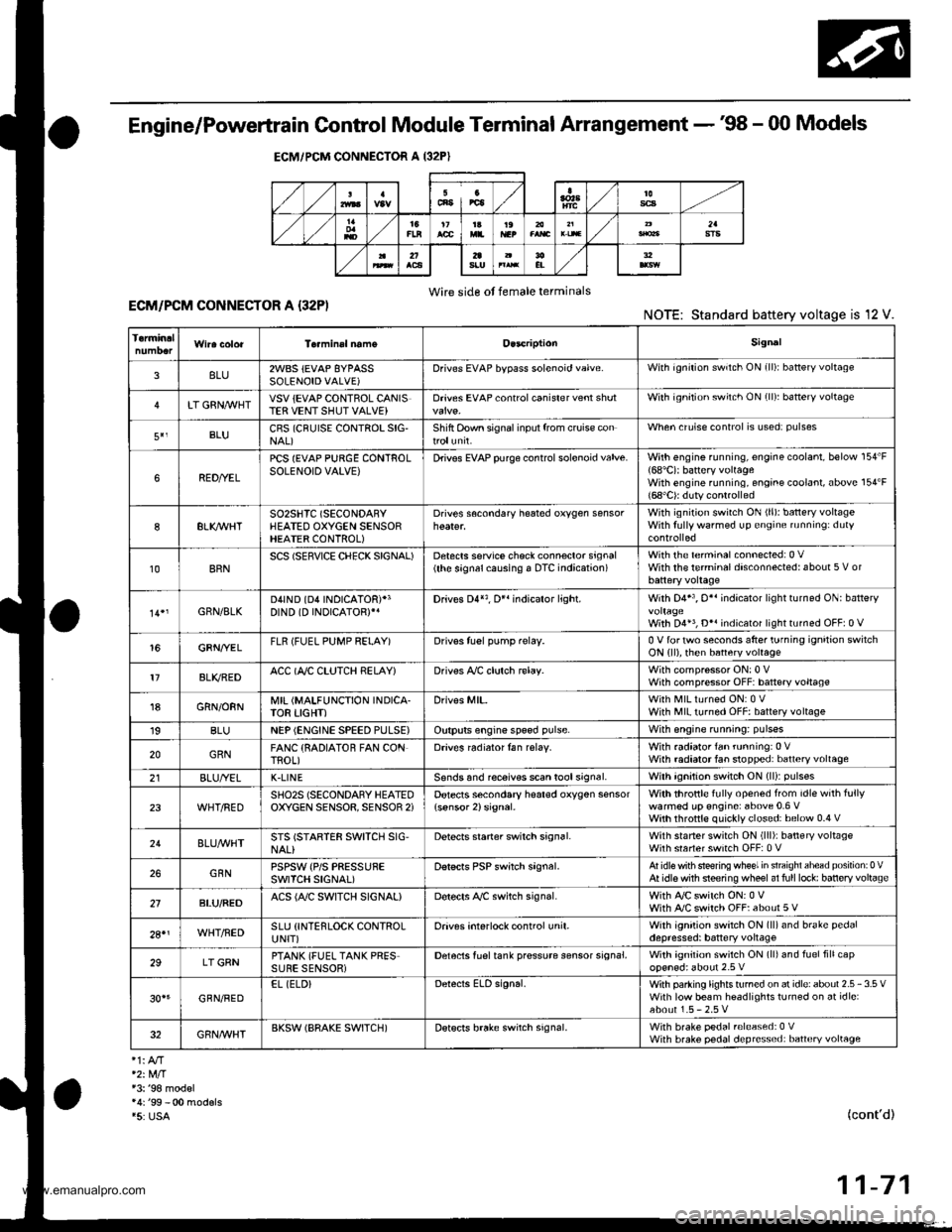

Engine/Powertrain Control Module Terminal Arrangement - 38 - 00 Models

ECM/PCM CONNECTOR A (32P}

,/./5aIsca

,/ l,/t5ItsTs

n2ls!uCI

Wire side ot female terminalsECM/FCM CONNECTOR A {32P)NOTE: Standard baftery voltage is '12 V.

D93criptionSignal

3BLU2WBS {EVAP BYPASSSOLENOID VALVE)Drives EVAP bvoass solonoid valve.With ignirion switch ON {ll)r battery voltage

LT GRNMHTVSV {EVAP CONTROL CANISTEB VENT SHUT VALVE)D.ives EVAP controlcanisler vent shutWith ig^ition switch ON (ll): battery voltage

5',BLUCRS (CRUISE CONTROL SIG'NAL)Shift Oown signalinputfrcm cruise conWhen cruise control is used: pulses

6RED/YEL

PCS (EVAP PURGE CONTROLSOLENOID VALVE)Drives EVAP purge controlsolonoid valve.With engins running, engine coolant, below 154'F(68'C)r battery voltageWith engine running, engine coolant, above 154"F{6a'C}r duty conl.olled

8ELIOWHTSO2SHTC (SECONDARVHEATED OXYGEN SENSORHEATER CONTROL)

Drives sacondary heated oxygen sensorWith ignition switch ON (ll): banery voltageWith fully warmed up engine running: duty

10BRNSCS (SERVICE CHECX SIGNAL)Detects seNics check conneclor signal(he signalcausing a DTC indicatjon)with rhe lerminal connected:0 vWith the rerminaldisconnectedrabout 5 v or

l4'rGRN/8LKD4IND (D4INDICATOR)+3DIND (D INDICATORTIDrives D4*3. Dr'indicaior light.W,rh 04' , O" indrcator light turned O batter,

With D4*3, D*. indicator light turned OFFr0 V

16GRNI/ELFLR (FUEL PUMP RELAY)Drivss fusl pump relay.0 V for iwo seconds after ru'nin9 ign'lion swilchON lll), then banery voltage

17AL|(/REDACC (I/C CLUTCH RELAY}Drives l,/C clurch rclay.With compressor ONr0 VWith compressor OFF: battery voltage

18GRN/ORNMIL (MALFUNCTION INDICA.TOR LIGHT)Driv€s MlL.With MlLturned ON:0 VWith MIL turned OFF: battery voltage

19BLUNEP (ENGINE SPEED PULSE)Outputs engine spsed pulse.With sngine runnin9: pulses

20GRNFANC {RADIATOR FAN CONTROL)Drives r6diator fan rslay.With radaator fan running:0 VWith radaatorfan stopped: battery vollage

218LU/t/ELK-LINESends and receiv€s scan toolsignal.With ignition switch ON (ll): p'rlses

23WHT/REDSHO2S (SECONDARY HEATEDOXYGEN SENSOR. SENSOR 2iDetects secondary h€at€d oxygen sensorWith throttle fully opened from idle wilh fullywalmed up engine: above 0.6 Vwith rhrottle quickly closed: below 0-4 V

21BLU/WHTSTS (STARTER SWITCH SIG,NAL}Dotocts srarter switch signal.Whh staner switch ON (lll): batlery voltageWith srarter switch OFF: 0 V

26GBNPSPSW {P/S PsESSUFESWITCH SIGNAL)Detecrs PSP switch signal.At idle with steeing wh€el in stBighl ahead position: 0 VAt idls with nee ng wheel al full lockr banory voltage

2fBLU/BEOACS (Ir'C SWTCH SIGNAL}D€tects ly'C switch signal.With Ay'C switch ON:0 VWith l/C swil€h OFF: about 5 V

2A'\WHT/NEDSLU {INTERLOCK CONTROLUNIT)Orives interlock control unil.With ignilion switch ON (ll)and brake pedaldepressed: battery vohage

29LT GRNPTANK (FUEL TANK PRES'SURE SENSOR)Detocts fueltank pressure sensor signal.With agnition switch ON (ll) and fuel fill capopensd; about 2.5 v

GBN/FEDEL (ELD}Detects ELD signal.Wirh paaing rightstumed on at idle:about 2.5 - 3.5 VWith low beam headlights tumed on at idle:about 1.5-2.5V

GRN/WHTBKSW (BRAKE SWTTCH)Dst€cts brake switch signal.Wirh brake pedal released:0 VWith brake pedal depressed: battery vollage

13: '98 modsl

15: USA(cont'd)

11-71

www.emanualpro.com