connector a HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 14 of 1395

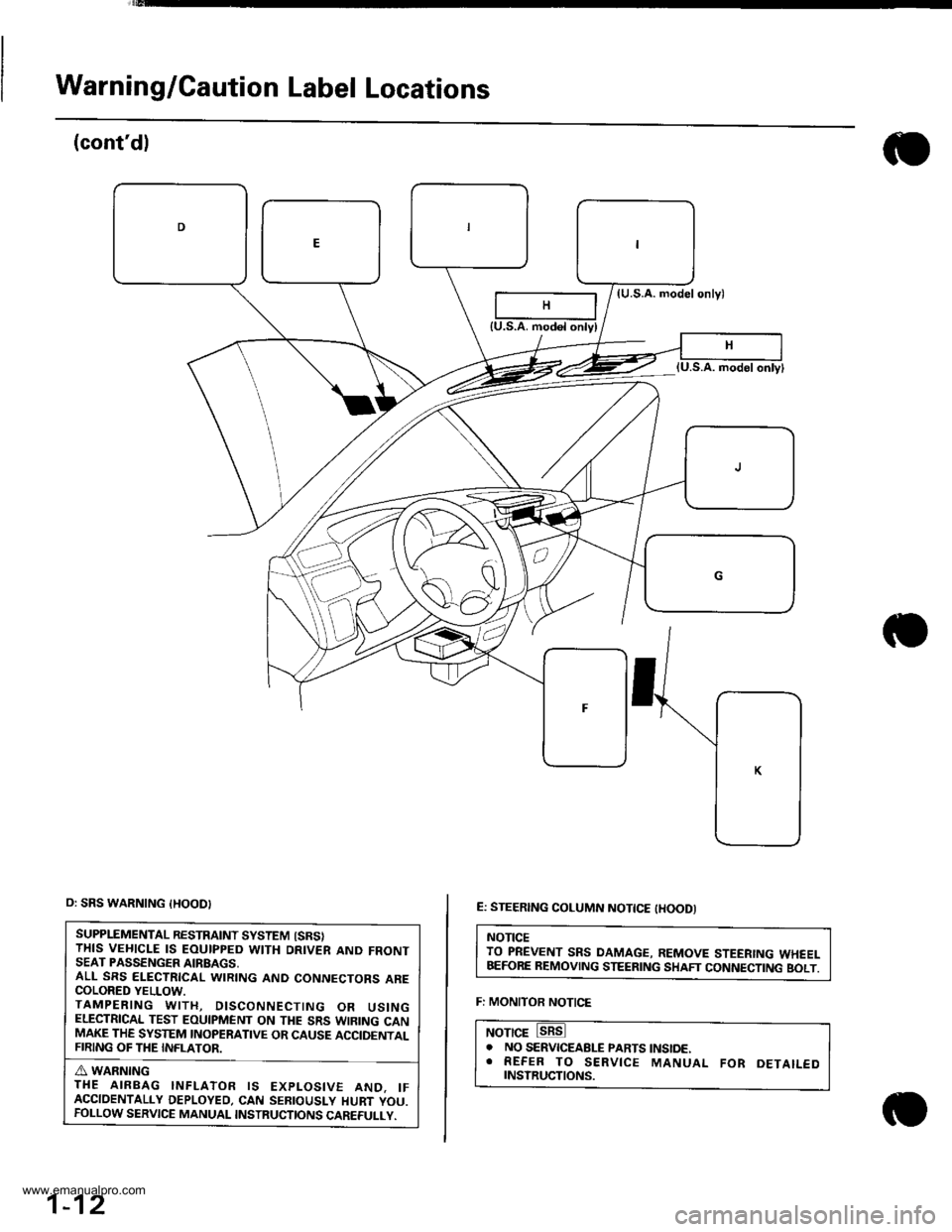

Warning/Caution Label Locations

(cont'dl

(U.S.A. modelonlyl

E: STEERING COLUMN NOTTCE tHOODI

NOTICETO PREVENT SRS DAMAGE, REMOVE STEERING WHEELBEFORE REMOVING STEERING SHAFT CONNECTING BOLT.

F: MONITOR NOTICE

NOTICE. NO SERVICEABLE PARTS tNStoE.. REFER TO SERVICE MANUAL FoR DETAILEDrNsrRucTtoNs.

{U.S.A. modol onlyl

o: SRS WARNING {HOOD}

SUPPLEMENTAL RESTRAINT SYSTEM {SRSITHIS VEHICLE IS EOUIPPED WITH DRIVER AND FRONTSEAT PASSENGER AIRBAGS,ALL SRS ELECTRICAL WIRING AND CONNECTORS ARECOLORED YELLOW.TAMPERING WITH, DISCONNECTING OR USINGELECTRICAL TEST EOUIPMENT ON THE SRS WIRING CANMAKE THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTALFIRING OF THE INFLATOR.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND. IFACCIDENTALLY DEPLOYED, CAN SEBIOUSLY HURT YOU.FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

1-12

www.emanualpro.com

Page 52 of 1395

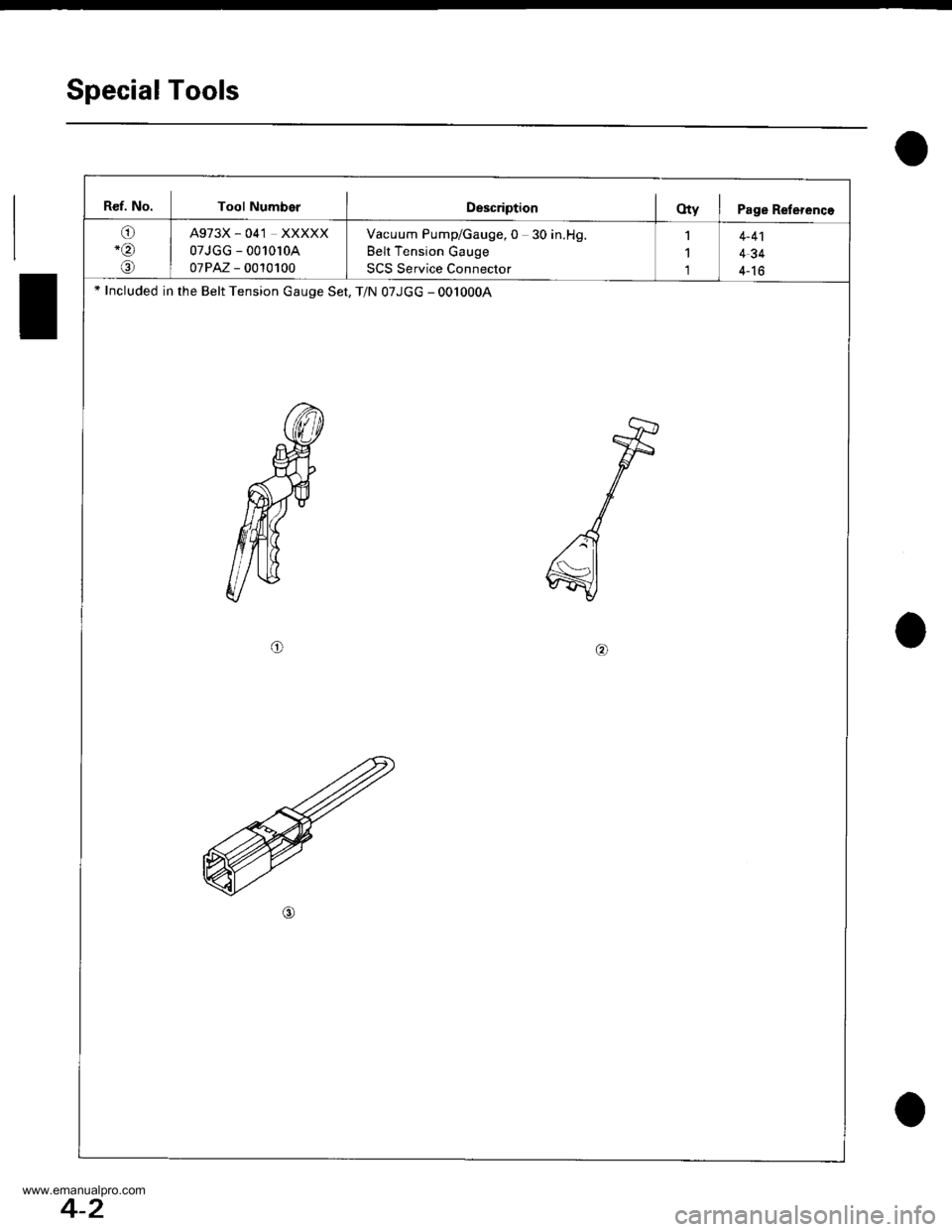

Special Tools

Ref. No.Tool NumberDescriptionOty I Page Reference

o-o

o

A973X - 041 XXXXX

07JGG - 001010A

07PAZ - 0010100

Vacuum Pump/Gauge, 0 30 in.Hg.

Belt Tension Gauge

SCS Service Connector

4-41

434

4-16* Included in the Belt Tension Gauge Set, T/N 07JGG - 0010004

o@

o

4-2

www.emanualpro.com

Page 55 of 1395

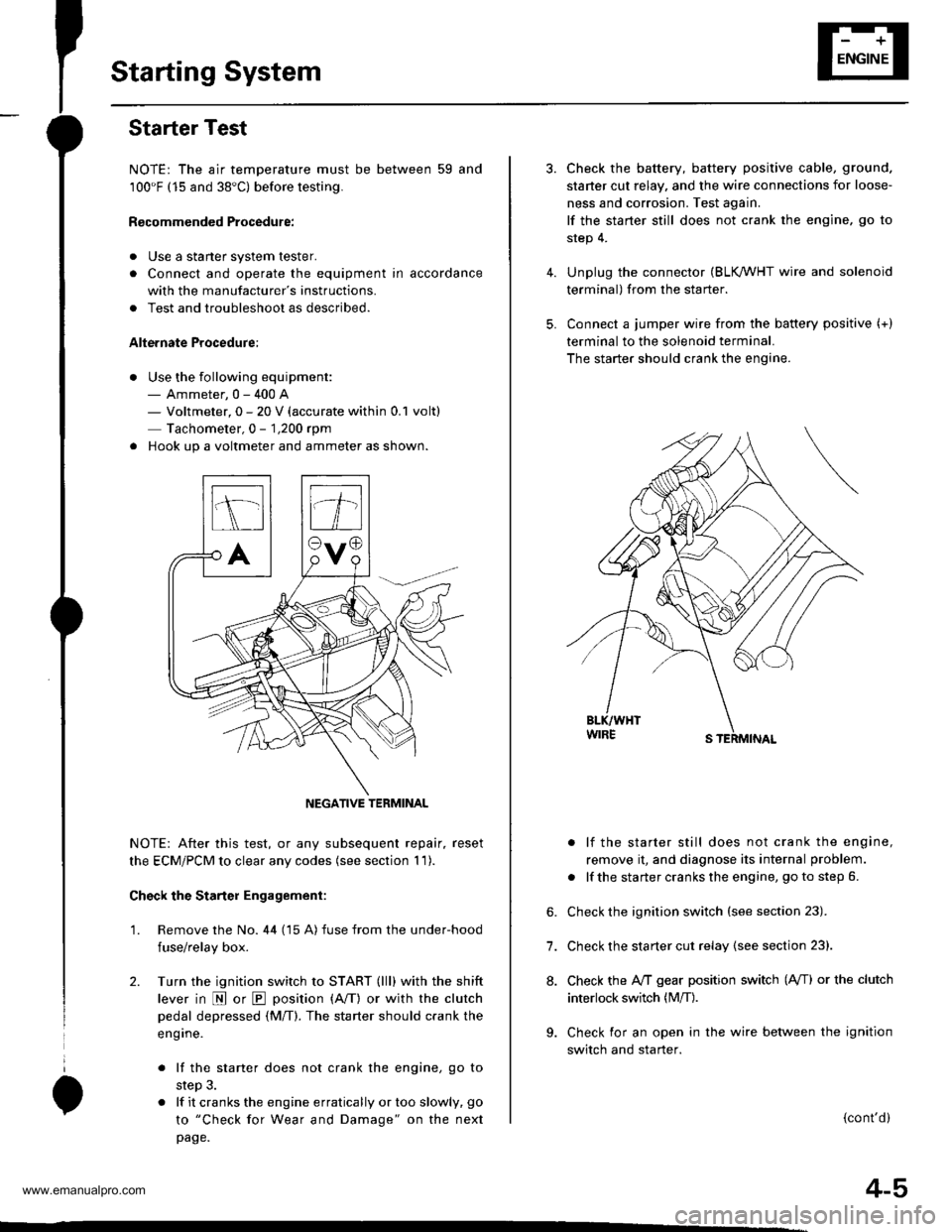

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 64 of 1395

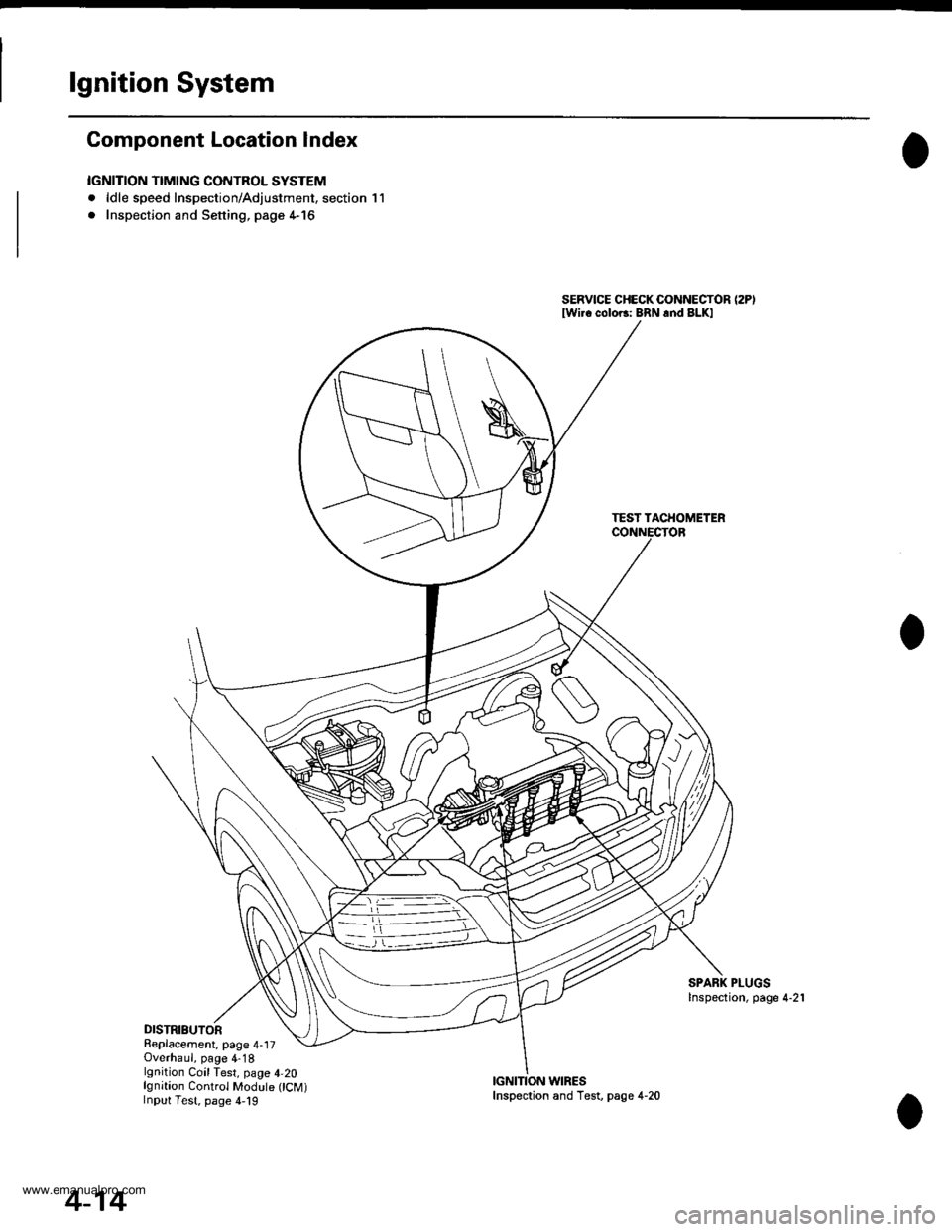

lgnition System

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. ldle speed Inspection/Adjustment, section 11

. Inspection and Sening. page 4-16

DISTRIBUTORReplacement, page 4-17Overhaul, page 4-18lgnition CoilTest, page 4,20lgnition Control Module CM)Input Test, page 4,19

SERVICE CHECK CONNECTOR (2P)

lwi.c colo6: BRN rnd BLKI

TEST TACHOMETER

SPARK PLUGSInspection, page 4-21

WIRES

4-14

Inspection and Test, page 4-20

www.emanualpro.com

Page 66 of 1395

lgnition System

5.

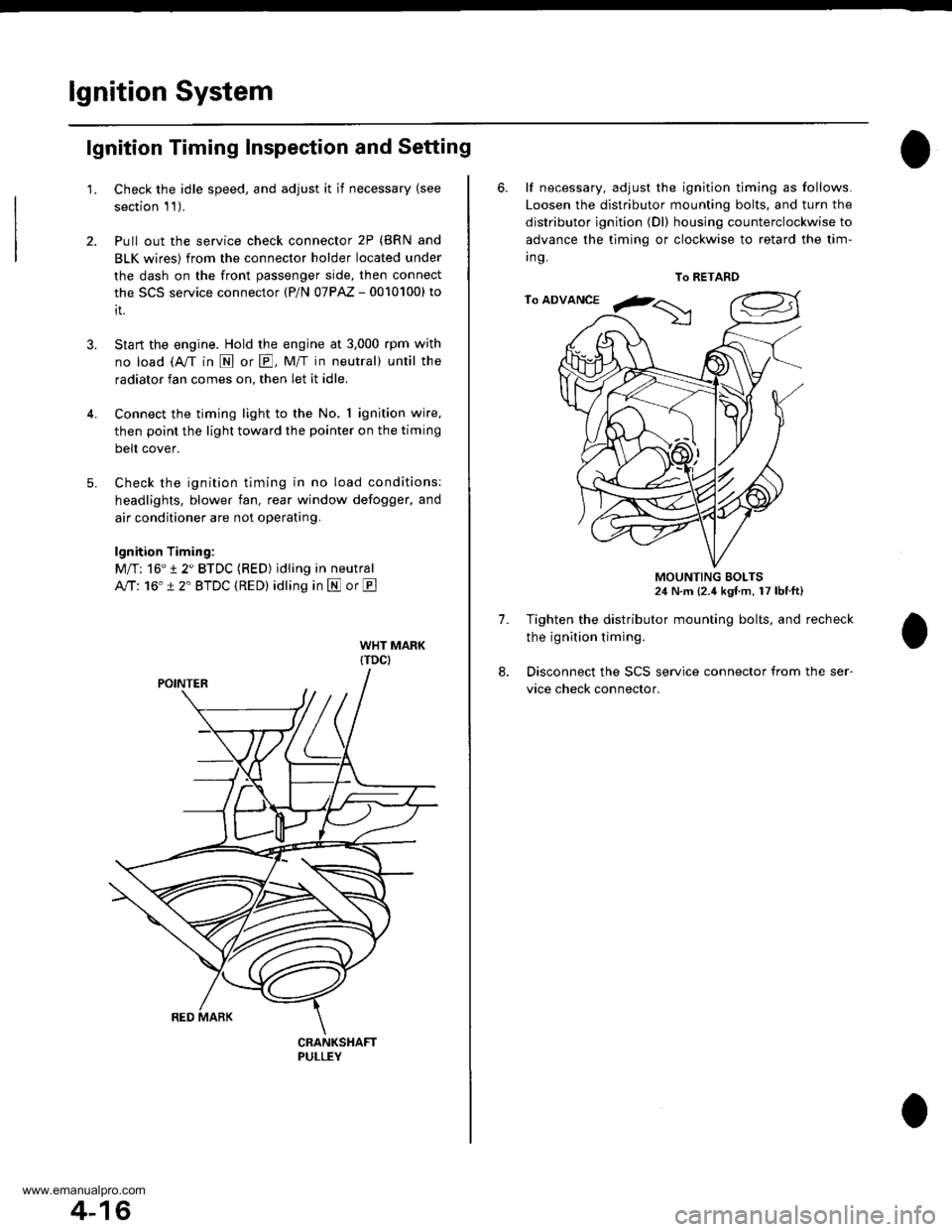

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 67 of 1395

e

o

I'

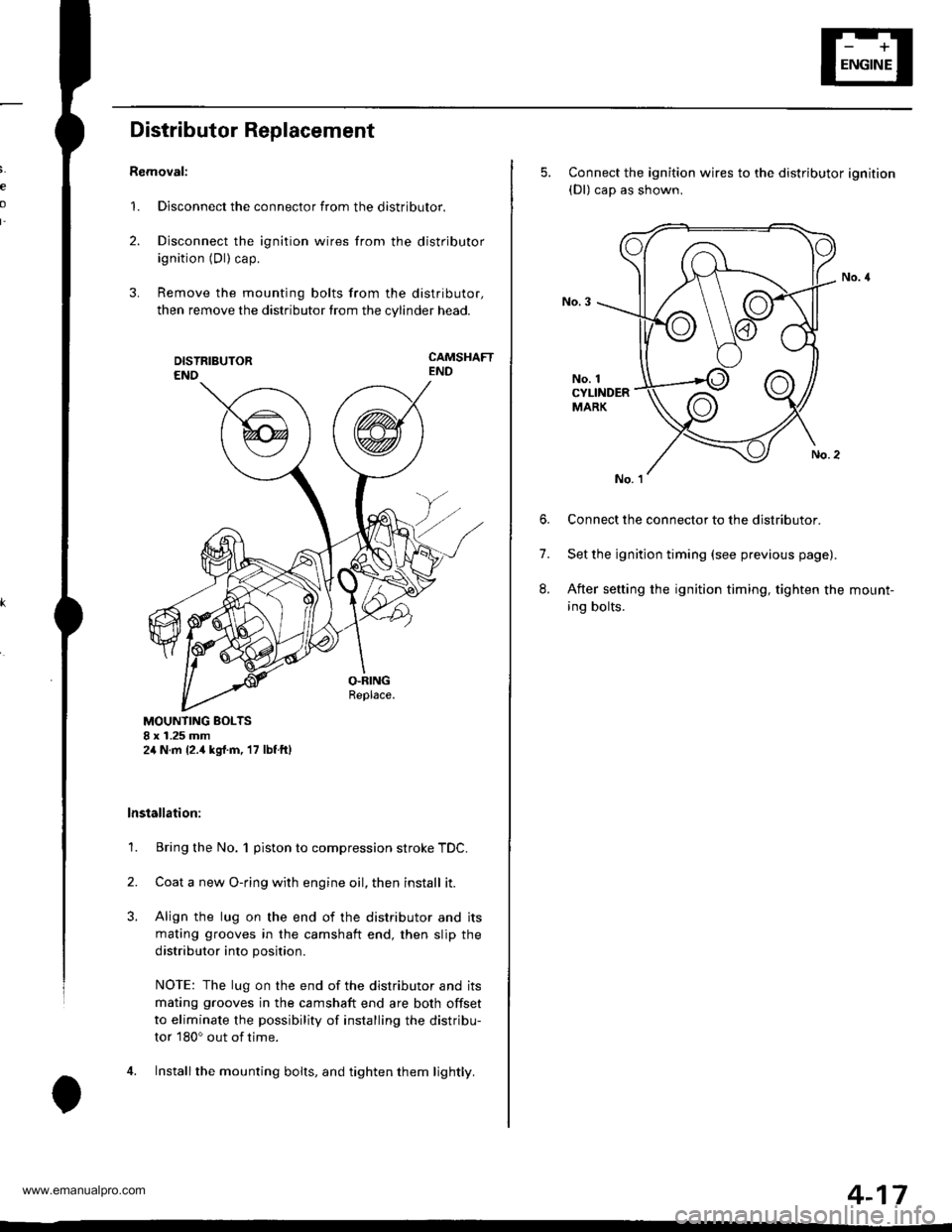

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition (Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

CAMSHAFTEND

MOUNTING BOLTS8 x 1.25 mm2,1N.m {2.,1kgrf.m, 17 lbf ftl

lnstallation:

1. Bring the No. 1 piston to compression stroke TDC.

2. Coata new O-ring with engine oil, then install it.

3. Align the lug on the end of the distributor and its

mating grooves in the camshaft end, then slip the

distributor into position.

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180o out of time.

4. Installthe mounting bolts, and tighten them lightly.

5. Connect the ignition wires to the distributor ignition(Dl) cap as shown,

No. 1CYLINDERMARK

6. Connect the connector to the distributor.

7. Set the ignition timing (see previous page).

8. After setting the ignition timing, tighten the mount-

ing bolts.

4-17

www.emanualpro.com

Page 69 of 1395

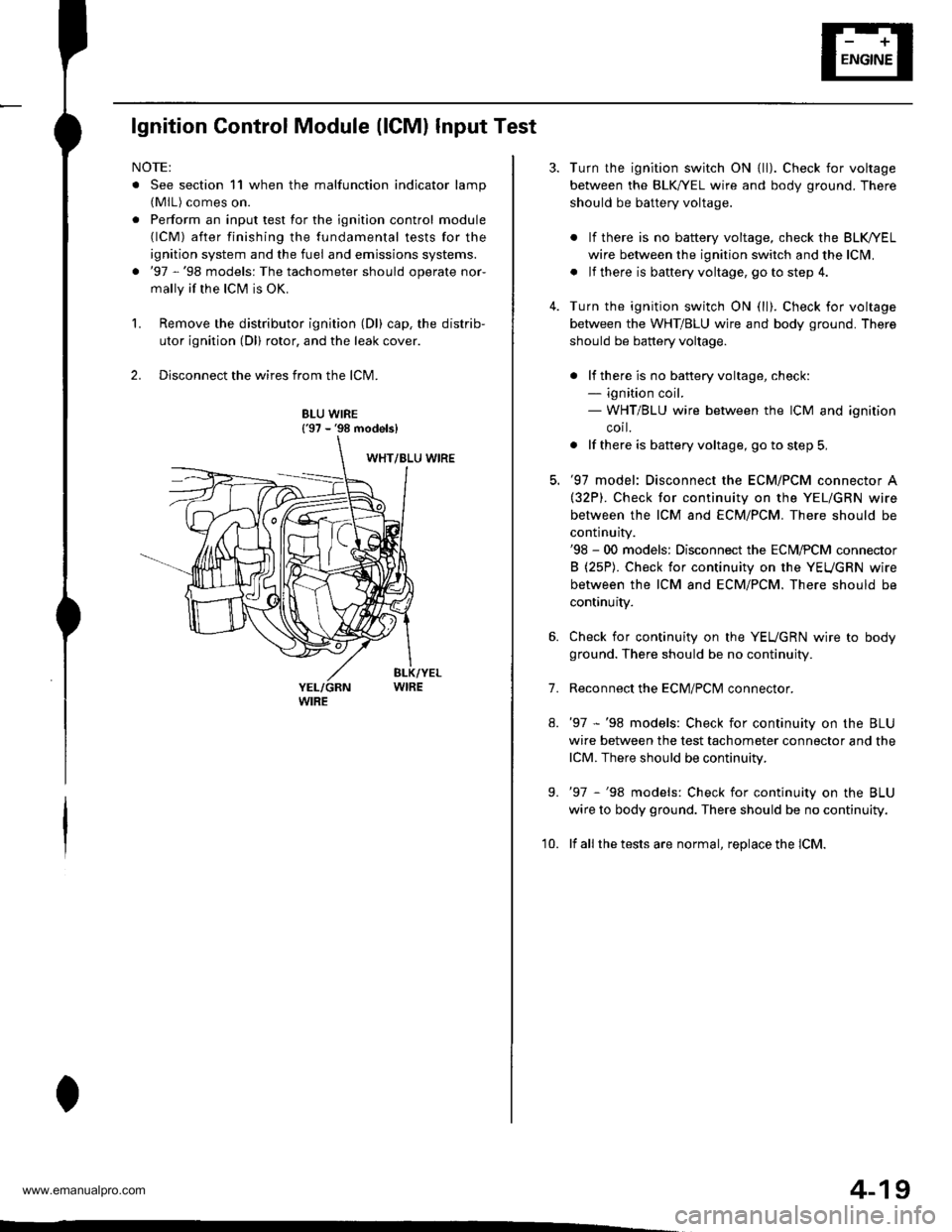

lgnition Control Module (lCMl Input Test

NOTE:

. See section 11 when the malfunction indicator lamp(MlL) comes on.

. Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems.

. '97 -'98 models: The tachometer should operate nor-

mally if the ICM is OK.

L Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor, and the leak cover.

2. Disconnect the wires from the lCM.

8LU WIRE{'97 - '98 models}

4-19

7.

Turn the ignition switch ON {ll). Check for voltage

between the BLK,^/EL wire and body ground. There

should be battery voltage.

. lf there is no battery voltage, check the BLK/rEL

wire betlveen the ignition switch and the lclvl.

. lf there is baftery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground. There

should be battery voltage.

. lf there is no batteryvoltage, check:- ignition coil.- WHT/BLU wire between the ICM and ignition

corl.

. lf there is battery voltage, go to step 5,

'97 model: Disconnect the ECM/PCM connector A(32P). Check for continuity on the YEL/GRN wire

between the ICM and ECM/PCM. There should be

continuity.'98 - 00 models: Disconnect the ECM,PCM connector

B (25P). Check for continuity on the YEUGRN wire

between the ICM and ECM/PCM. There should be

continuity.

Check for continuity on the YEUGRN wire to body

ground. There should be no continuity.

Reconnect the ECM/PClvl connector.

'97 -'98 models: Check for continuity on the BLU

wire between the test tachometer connector and the

lCM. There should be continuity.

'97 -'98 models: Check for continuity on the BLU

wire to body ground. There should be no continuity.

lf all the tests are normal, replace the lCM.

9.

'10.

www.emanualpro.com

Page 74 of 1395

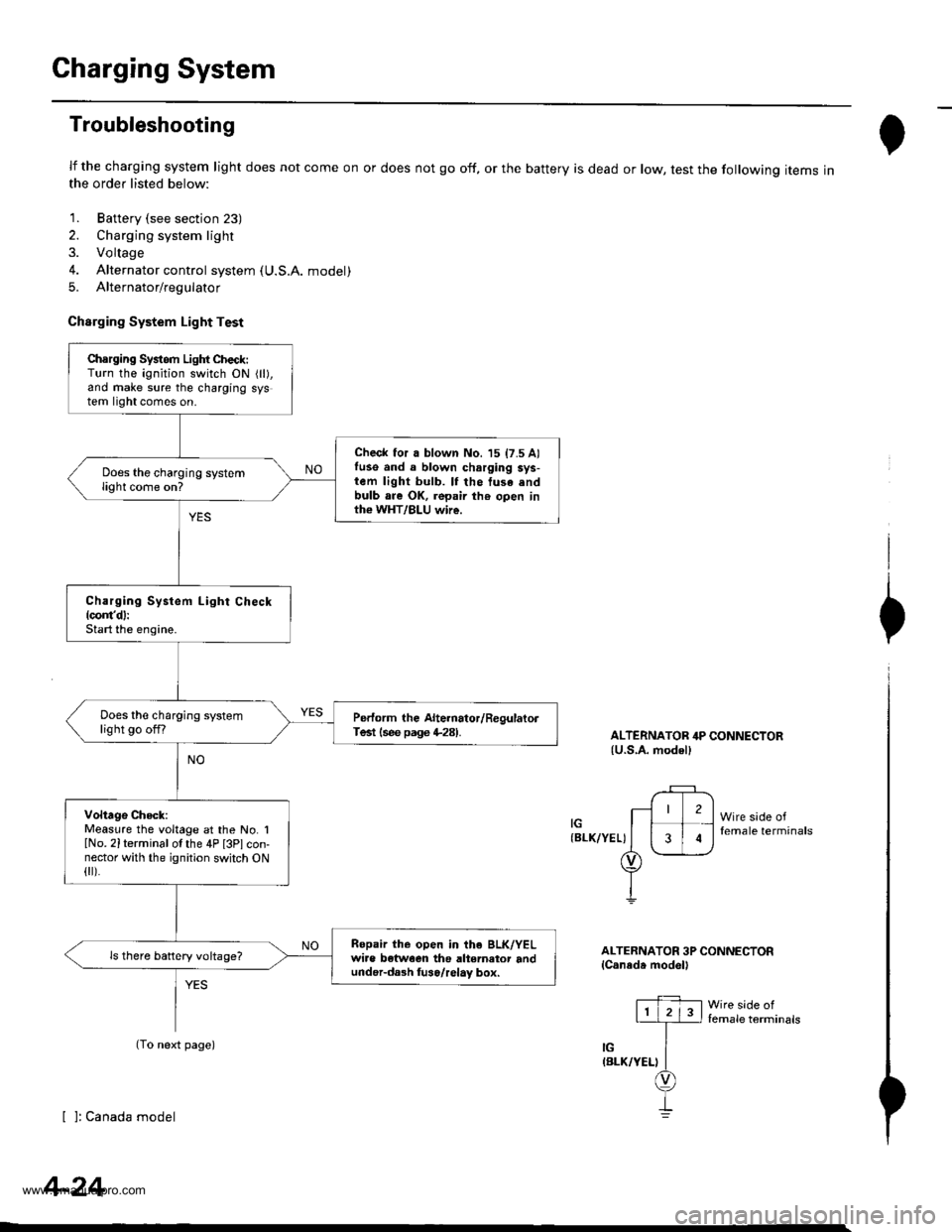

Gharging System

Troubleshooting

lf the charging system light does not come on or does not go off, or the battery is dead or low, test the following items inthe order listed below:

1. Battery (see section 23)

2. Charging system light

3. Voltage

4. Alternator control system (U.S.A. model)

5. Alternator/regulator

Charging System Light Test

ALTERNATOR 4P CONNECTOR{U.S,A. modell

(BLK/YEL)

2

3

Wire sade offemale terminals

I

I

I

ALTERNATOR 3P CONNECTORlCaneda model'

Iemale terminals

[ ]: Canada model

Chsrging Systom Light Check:Turn the ignition switch ON {ll),and make sure the charging system light comes on.

Check for a blown No. 15 17.5 Alfuse and a blown charging sys-tem light bulb. lf the tusa .ndbulb are OK, repair th€ open inth€ WHT/BLU wire.

Does the charging systemlight come on?

Charging System Light Check{com'd}:Start the engine.

Does the charging systemlight go offfPerform the Alte.nator/RegulatorTest lsee page +281.

Voltage Check:Measure the voltage at the No. IlNo. 2iterminal of the 4P [3Plcon-nector with the ignition switch ON{ ).

Ropair the open in the BLK/YELwiae betwoen the altemator andunder-da3h luso/relay box.

ls there battery voltage?

(To next page)

4-24

www.emanualpro.com

Page 76 of 1395

Charging System

Troubleshooting (cont'dl

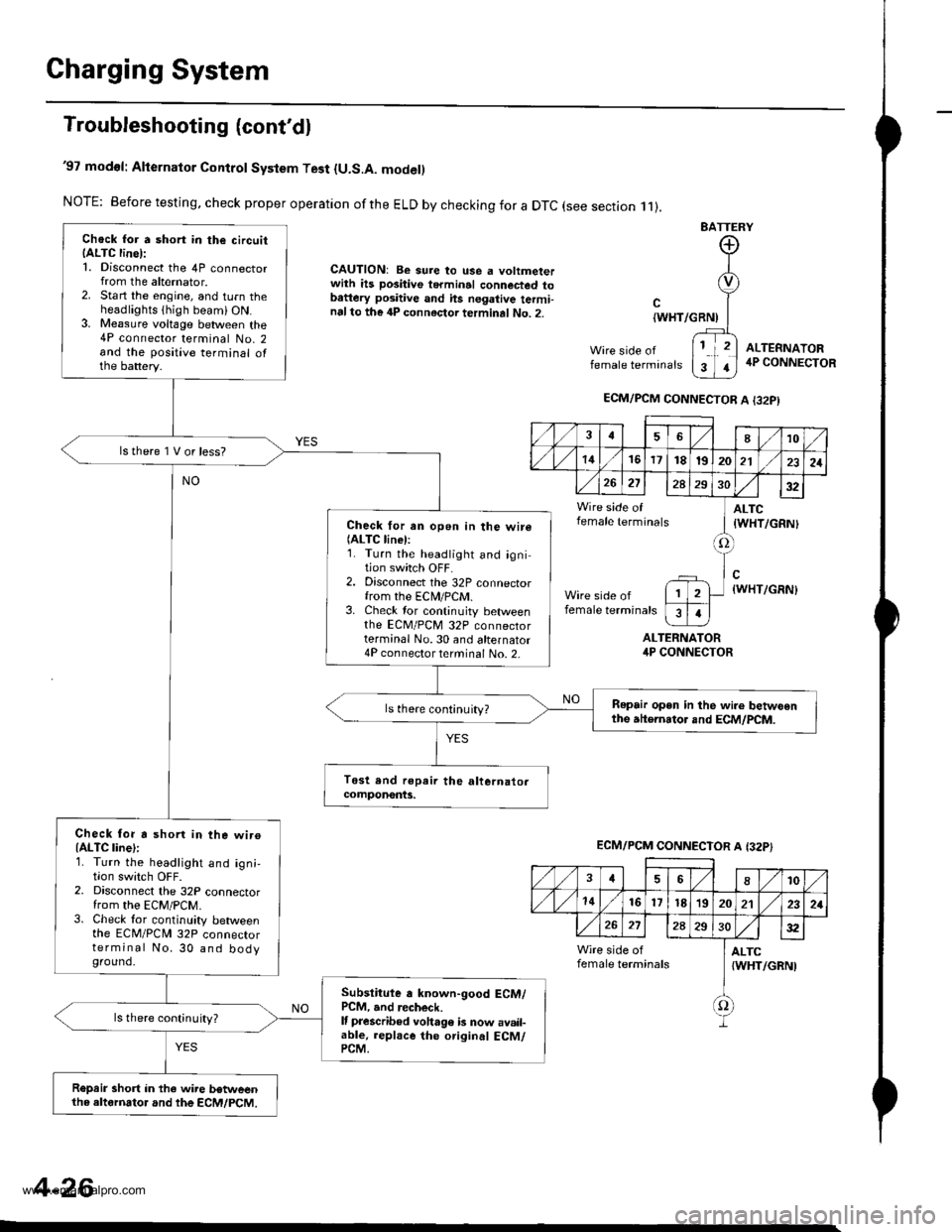

'97 modol: Alternator Control System Test {U.S.A. model)

NOTE: Before testing, check proper operation ofthe ELD by checking for a DTC (see section .11).

CAUTION: Be sure to use a voltmeterwith ils positive terminal connected tobattery positive and hs negative termi-nalto the 4P connector terminal No. 2.

BATTERY

Wire side offemale terminals

{WHT/GRNI

ALTERNATORirP CONNECTOR

ALTEFNATOR4P CONNECTOR

Chock for a short in the circuitIALTC line):1. Disconnect the 4P connectorfrom the alternator.2. Start the engine, and turn theheadlights thigh beami ON.3. Me8sure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

lstherelVorless?

Check for an open in the wire(ALTC linel:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectorfrom the ECN4/PCM.3. Check tor continuity betweenthe EcM/PcM 32P connectorterminal No.30 and alternator4P connector terminal No. 2-

Repair open in the wi.e betwoenthe atternator and ECM/PCM.ls there continuity?

Check for a shorl in the wiroIALTC line):1. Turn the headlight and ign;,I|on swrtcn UFF2. Disconnect the 32P connectorfrom the EcM/PcM.3. Check tor continuity betweenthe ECM/PCN4 32P connectorterminal No. 30 and bodyground.

Subslitute a known-good ECM/PCM, and recheck.It prescribed voha96 b now avail-able, replace the original ECM/PCM.

ls there continuity?

R€prir short in the wire betweenthe altornator and the ECM/PCM.

ECM/PCM CONNECTOR A I32PI

,/1./1810

./ l./t4161718t9202121

26272A293032

Wire side of ] ALTCfemale terminals I tWHT/cRNl

tlWHT/GRN)

female terminals

I

1

ECM/PCM CONNECTOR A {32P}

,/ ,/46810

,/1,/1416l7t8'1920212321

272A2S30:t2

Wire side of I ALTCfemale terminals {WHT/GRNI

f)

4-26

www.emanualpro.com

Page 77 of 1395

R'oR

l

u

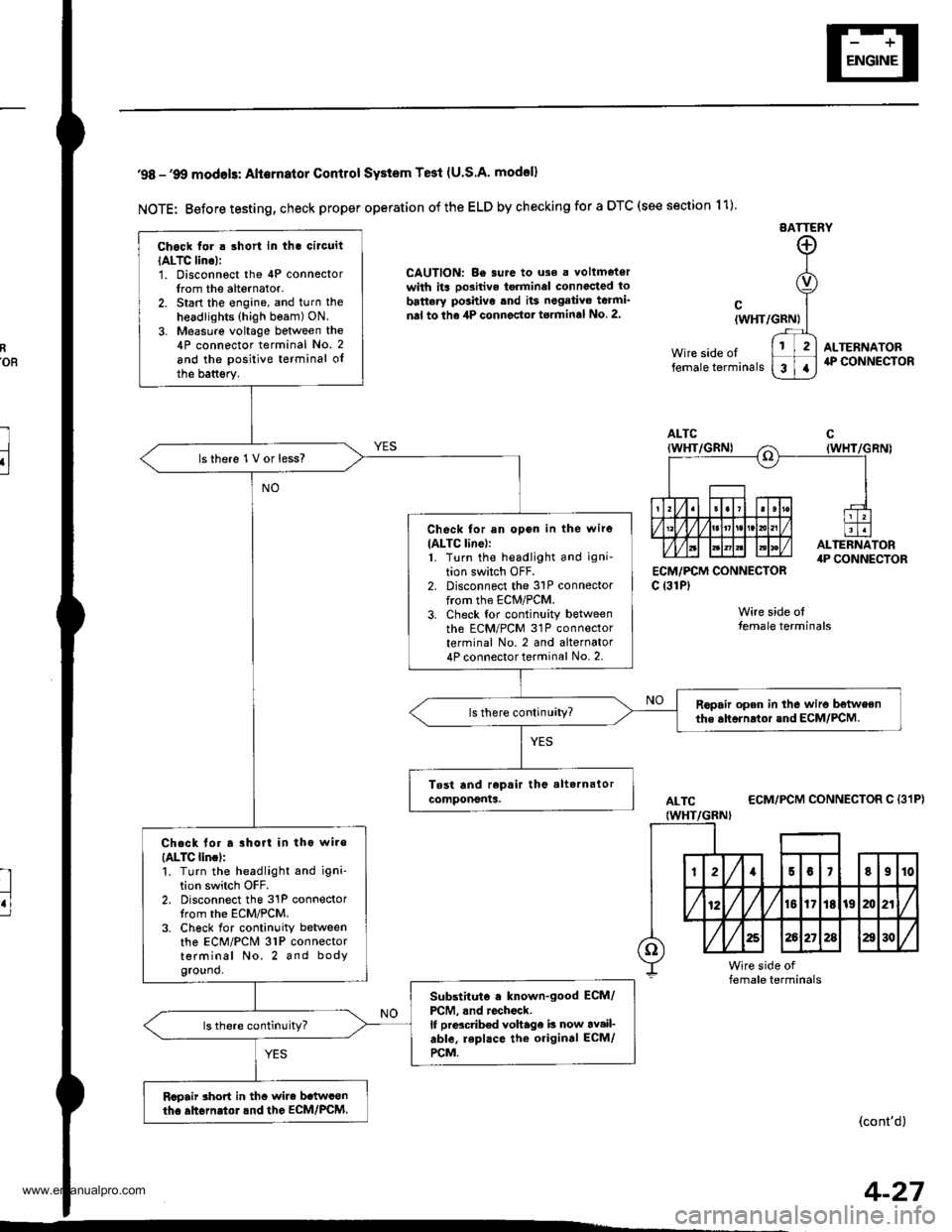

'98 -'9O modols: Alternator Contlol SYstem Te3t (U.S.A' model)

NOTE: Before testing, check proper operation of the ELD by checking for a DTC (see section 11)

EATTERY

CAUTION: Be surc to uso a voltmetorwith its oo3itive torminel connccted to

battery po3hivo tnd its negativo teami'

nal to the 4P connector torminal No 2.

ECM,/PCM CONNECTORc {31P)

Wire side olfemale terminals

cIWHT/GRN)

Wire side oltemale terminals

ALTERNATOR4P CONNECTOR

ALTC

IWHT/GBNI

ECM/PCM CONNECTOR C {31P}

(cont'd)

Chock tor . short in tha circuit

IALTC lino):1. Disconnoct the 4P connectorIrom the alternator.2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the4P connector terminal No. 2

and the positive terminal oIthe battsry.

lsthere 1V or less?

Check for an opon in the wire

IALTC line):1. Turn the headlight and igni-

tion switch OFF.2. Disconnect the 31P connectorfrom the ECM/PCM.3. Check tor continuity betweenth6 ECM/PCM 31P connectorterminal No. 2 and alternator4P connector terminal No. 2.

Ropair open in the wiro betweenthe ahornrtor and ECM/PCM.

Chack lor a rhort in tho wire

{ALTC lincl:'!. Turn the headlight and igni'tion switch OFF.2. Disconnect the 31P connectorIrom the ECM/PCM.3. Ch6ck for continuity betweenthe ECM/PCM 31P connectorterminal No. 2 and bodyground.

Substituto . known-good ECM/

PCM, .nd rochock.lf prdcdb€d voltage b now av.il-able, repl.ce the original ECM/

rcM.

Rcpair rhort in thc wire b.twconth. ahGrn.tol.nd the EcM/PcM.

4-27

www.emanualpro.com