vehicle stab HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 402 of 1395

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

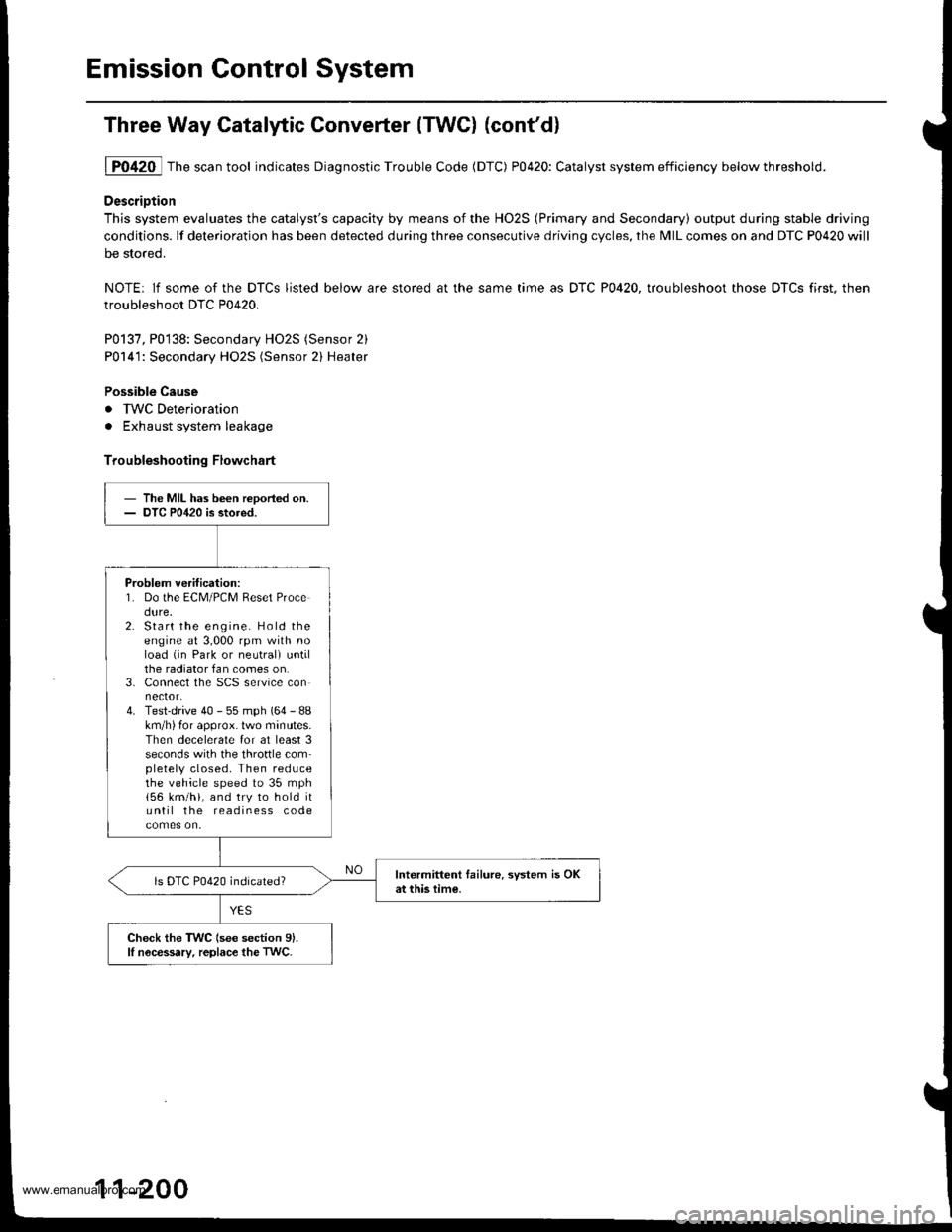

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 906 of 1395

Front Suspension

Suspension Arms Replacement

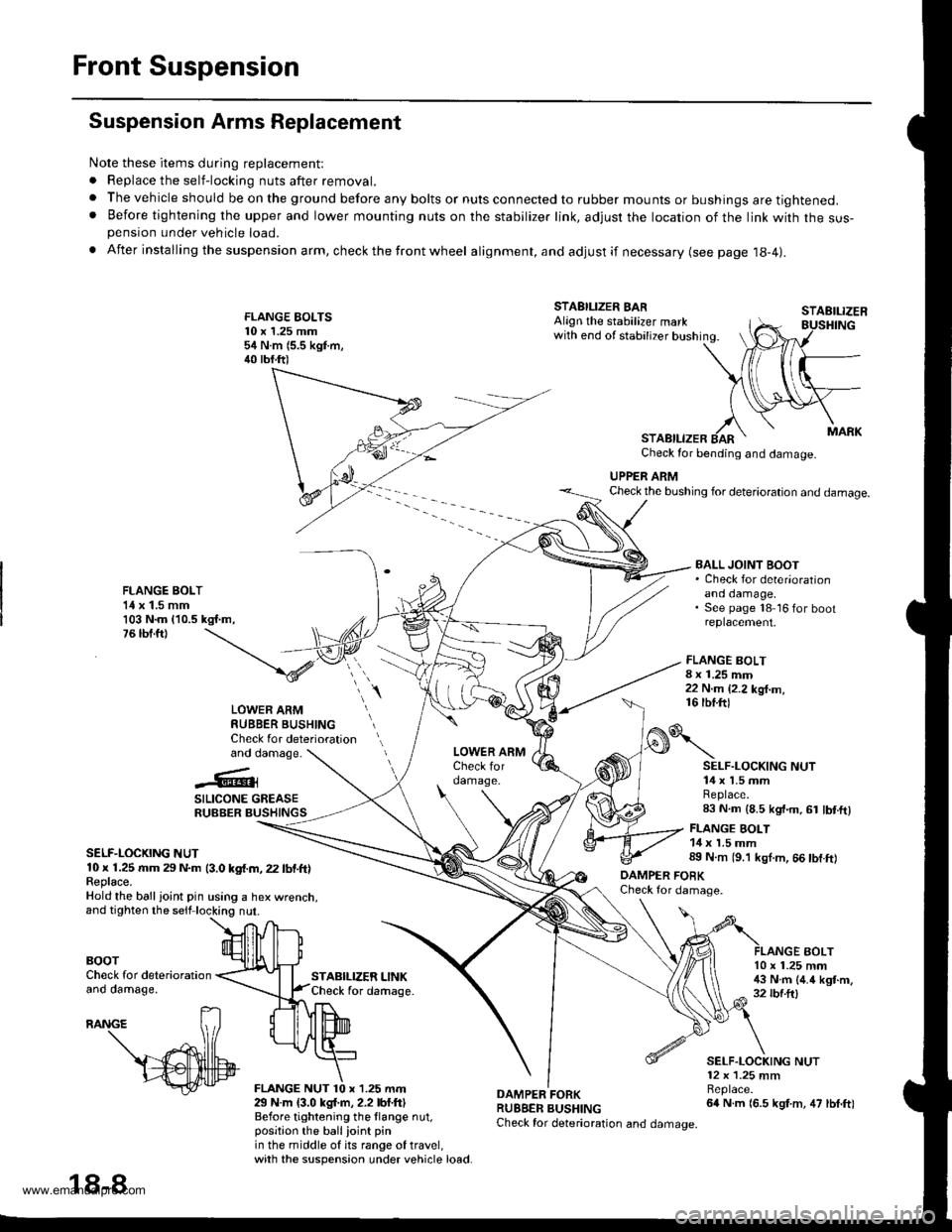

Note these items during replacement:

. Replace the self-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.. Before tightening the upper and lower mounting nuts on the stabilizer link, adjusr the location of the link with the sus-pension under vehicle load.

. After insta lling the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4|.

FLANGE EOLTS10 x 1.25 mm54 N.m (5.5 kgf.m,40 tbf.ft)

STABILIZER LINKCheck for daftage.

FLANGE BOLT8 x 1.25 mm22 N.m {2.2 kg{.m,16 tbf.ftl

STAEILIZER

AOLT

STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

STABILIZERCheck for bending and damage.

UPPER ARMCheck the bushing for deterioration and damage.

FLANGE BOLT1{ x 1.5 mm103 N.m {10.5 kgf.m,76 tbf.ft)

BALL JOINT BOOT. Check for deter'orationano oamage,See page 18 16 for bootreplacement.

LOWER ARMRUBBER BUSHINGCheck for deteriorationand damage.

..'.{l@3

SILICONE GREASERUBBER BUSHINGS

SELF-LOCKING NUT10 x 1.25 rr|m 29 N.m (3.0 kgf.m, 22 lbf.ft)Feplace.Hold the ball ioint pin using a hex wrenct

BOOTCheck for deteriorationano oamage,

29 N.m {3.0 kgl.m, 2.2 lbf.ftlBefore tightening the llange nut,position the ballioint pinin the middle of its range of travel,with the suspension under vehicle load.

DAMPER FORKRUBBER BUSHINGCheck for deterioration and damage.

o\

DAMPER FOBKCheck for damage.

SELF.LOCKING NUT14 x 1.5 mmReplace.83 N.m (8.5 kgt.m, 61 lbt.ftl

FLANGE BOLT14 x 1.5 mm89 N.m (9.'l kgl.m, 66 tbf.ft)

10 x 1.25 mm!$ N.m (4.4 kgt.m,32 rbf.ftl

SELF.LOCKING NUT12 x 1.25 mmBeplace.64 N.m (6.5 kgt.m, 47 lbf.ft)

18-8

www.emanualpro.com

Page 917 of 1395

Rear Suspension

Suspension Arms Replacement

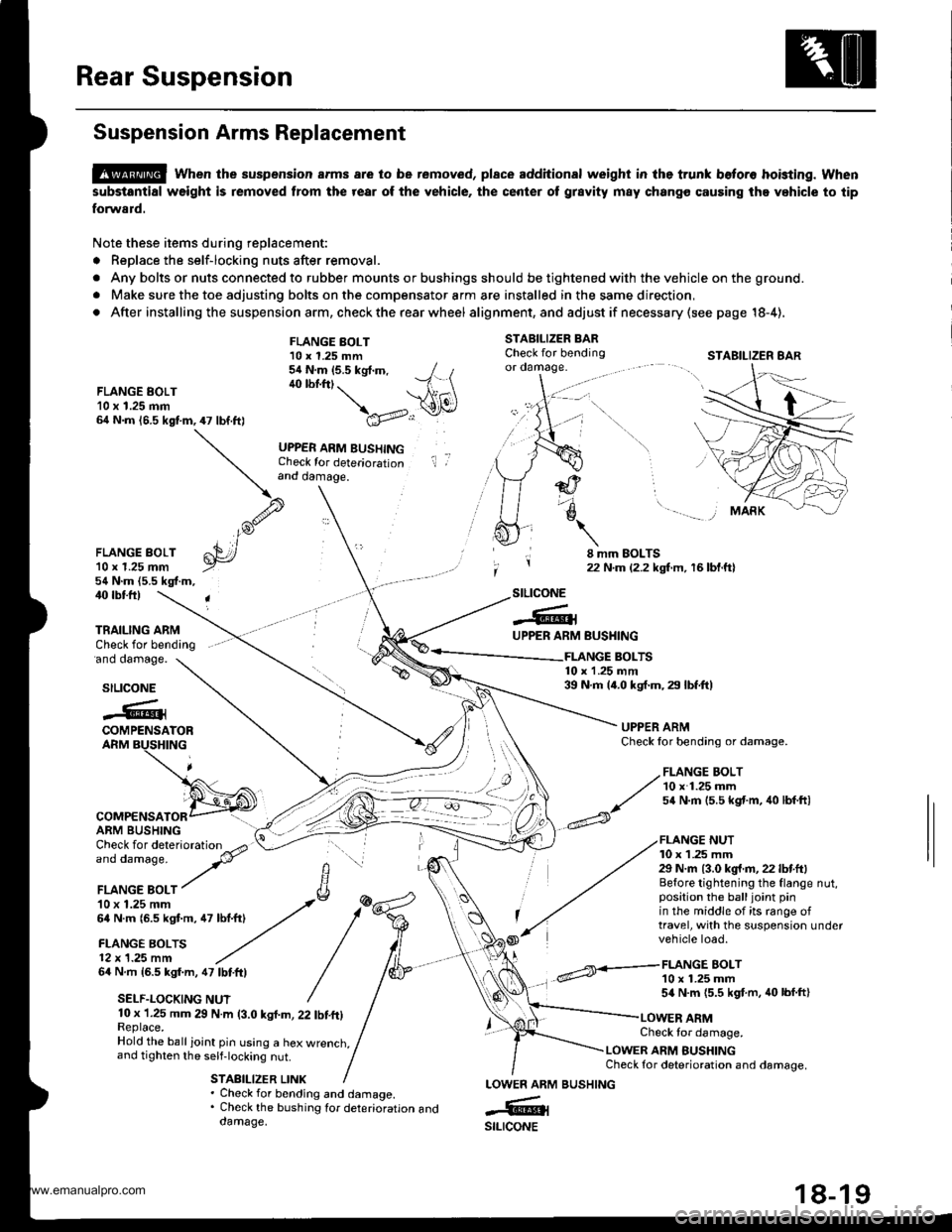

@ when the suspension arms are to be removed, plsce additional weight in lhe trunk beto.o hoisting. when

substantial weight is removed from the rear of the vehicle, the center ot grsvity m8y chango causing the vehicle to tip

forward.

Note these items during replacement:

. Replace the self-locking nuts after removal.

. Any bolts or nuts connected to rubber mounts or bushings should be tightened with the vehicle on the ground.

. Make sure the toe adjusting bolts on the compensator arm are installed in the same direction,

. After installing the suspension arm, check the rear wheel alig nment, and adjust if necessa ry (see page 18-4),

STABILIZER BARCheck for bendingor oamage.

FLANGE EOLT10 x 1.25 mm64 N.m 16.5 kgf.m,47 lbf.ft)

FLANGE BOLT10 x 1.25 mm54 N.m (5.5 kgt.m, / t40 lbf.ftt. --1 \ \A1(\

\a'v..:r

UPPER ARM BUSHINGCheck for deteriorationand damage.

il ,

FLANGE BOLT'l0 r 1.25 mm54 N.m (5.5 kgf.m,

8 mm EOLTS22 N.m {2.2 kgf.m, 16 bl.ftl

40 rbtft)

'ano oamage.

TRAILING ARMCheck for bending

stLtcoNE

-6lUPPER ARM

COMPENSATORARM BUSHING

64 N.m 16.5 kgf.m, 47 lbtftl

SELF.LOCKING NUT

BUSHING

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf.m, 40 lbf.ft}

FLANGE BOLTS10 x 1.25 mm39 N.m 14.0 kgf.m, 29 lbf.ft)stLtcoNE

.@iCOMPENSATORARM BUSHING

UPPER ARMCheck lor bending or damage.

FLANGE NUT10 x 1 .25 mm29 N.m {3.0 kg{.fl,22 lbf.ft}Before tightening the flange nut,position the balljoint pinin the middle of its range oftravel, with the suspension undervehicle load.

10 x 1.25 mm 29 N.m (3.0 kgl.m, 22 tbf.ft)Replace.Hold the ball ioint pin using a hex wrenct,,and tighten the self-locking nut.

STABILIZER LINK

Check tor damage.

LOWER ARM BUSHINGCheck for deterioration and damage.

. Check for bending and damage.. Check the bushing tor deterioration anddamage.

LOWEN ARM

-6ilstLrcoNE

STABILIZER 8AR

,/ FLANGE BOLT

// 10 x 1.25 mm

^/ s4 N.m 15.5 kst'm, 40 lbf ftl

BUSHING

www.emanualpro.com

Page 951 of 1395

Anti-lock Brake System (ABS)

Features/Construction

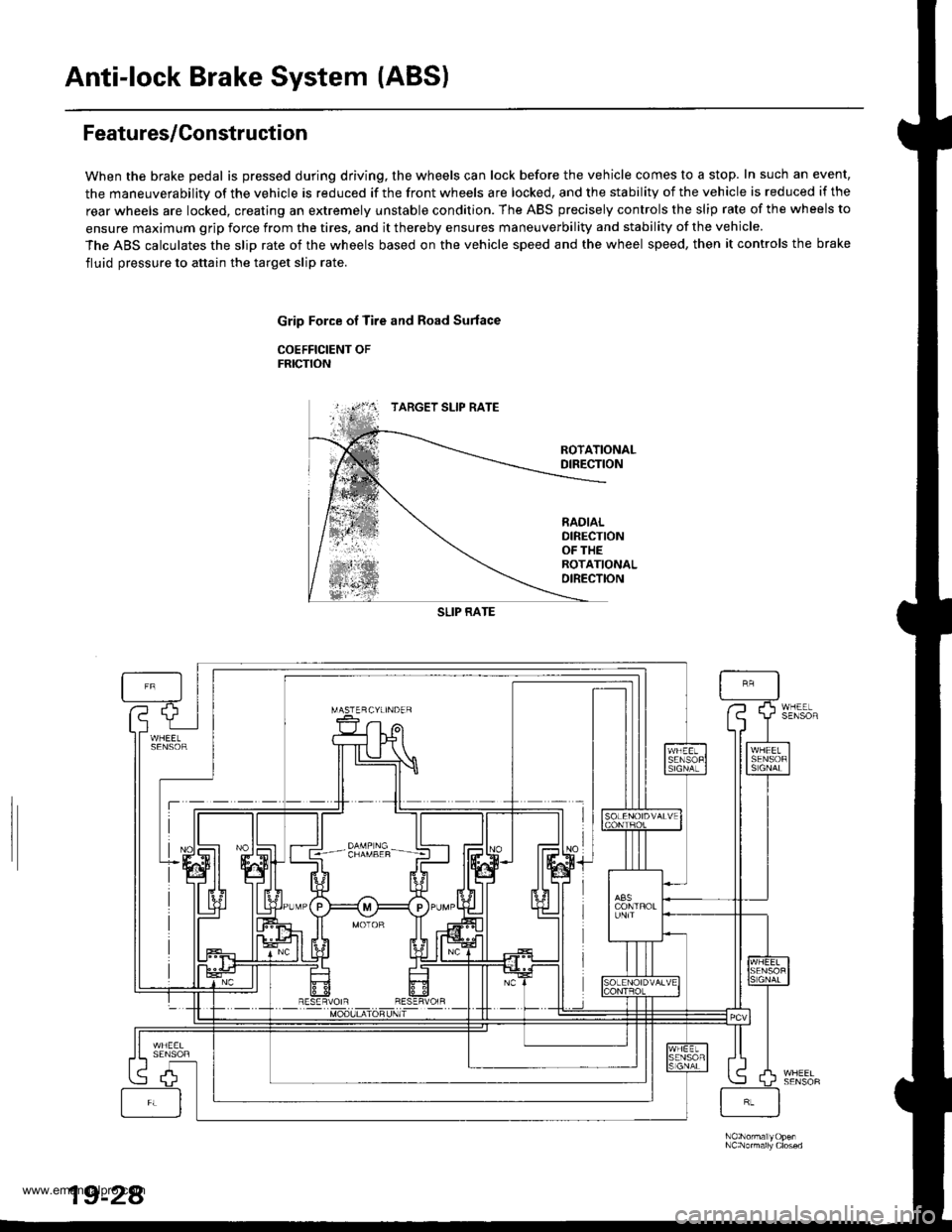

When the brake pedal is pressed during driving, the wheels can lock before the vehicle comes to a stop. In such an event,

the maneuverability of the vehicle is reduced if the front wheels are locked, and the stability of the vehicle is reduced if the

rear wheels are locked, creating an extremely unstable condition. The ABS precisely controls the slip rate of the wheels to

ensure maximum grip force from the tires, and it thereby ensures maneuverbility and stability of the vehicle.

The ABS calculates the slip rate of the wheels based on the vehicle speed and the wheel speed, then it controls the brake

fluid pressure to attain the target slip rate.

Grip Force of Tire and Road Surlace

COEFFICIENT OFFRICTION

TARGET SLIP RATE

RADIALOIRECTIONOF THEROTATIONALDIRECTION

SLIP RATE

19-24

www.emanualpro.com