windows HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1016 of 1395

22.

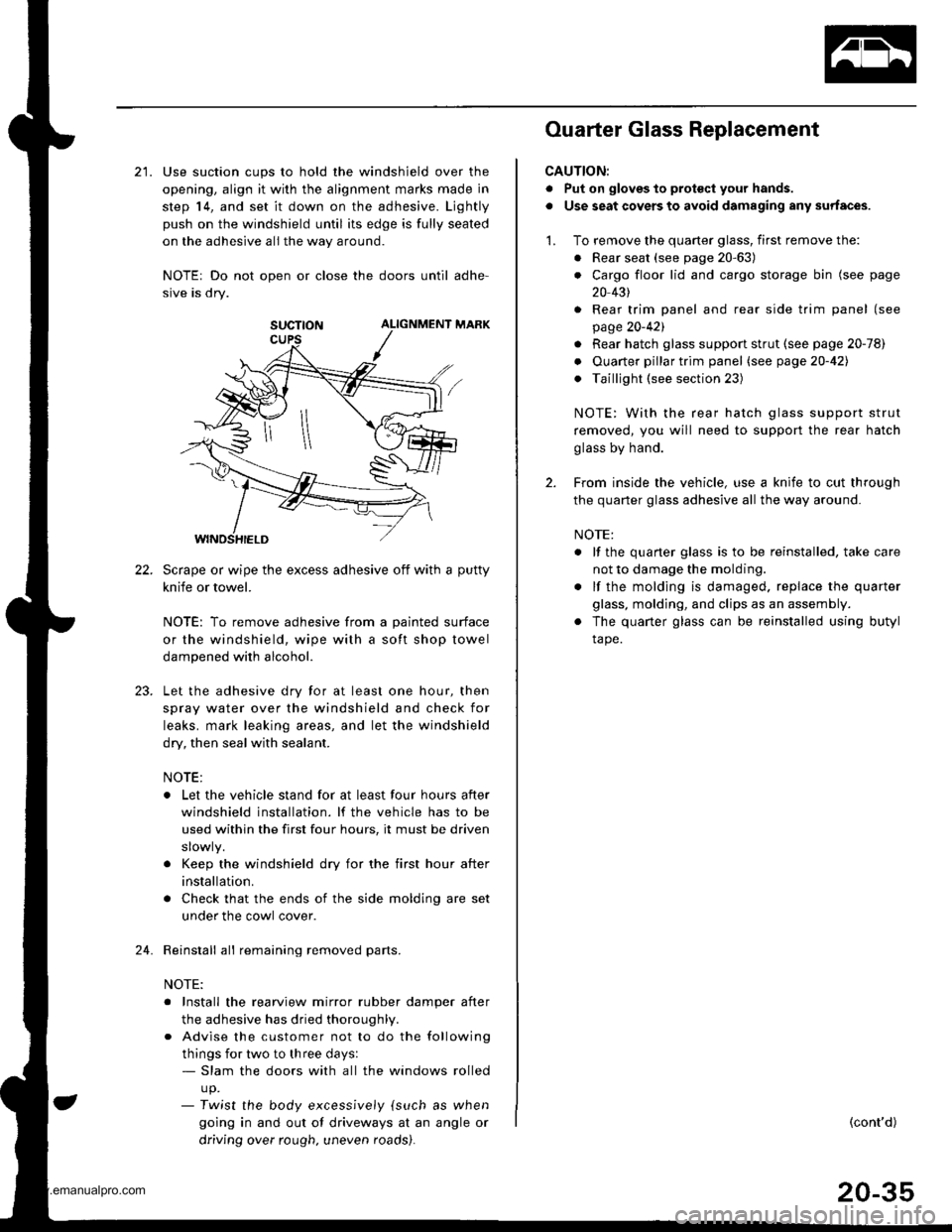

21. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 14, and set it down on the adhesive. Ljghtly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTEr Do not open or close the doors until adhe-

sive is dry.

SUCTTON ALIGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the windshield, wipe with a soft shop towel

dampened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the windshield and check for

leaks. mark leaking areas, and let the windshield

dry, then seal with sealant.

NOTE:

. Let the vehicle stand for at least four hours after

windshield installation. lf the vehicle has to be

used within the first four hours, it must be driven

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl,.

. Advise the customer not to do the following

things for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excess,vely {such as when

going in and out of driveways at an angle or

driving over rough. uneven roads).

24.

Ouarter Glass Replacement

CAUTION:

. Put on gloves to prot€ct your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the quarter glass, first remove the:

. Rear seat (see page 20-63)

. Cargo floor lid and cargo storage bin (see page

20 431

. Rear trim panel and rear side trim panel (see

page 20-421

. Rear hatch glass support strut (see page 20-78)

. Ouarter pillar trim panel (see page20-421

. Taillight (see section 23)

NOTE: With the rear hatch glass support strut

removed, you will need to support the rear hatch

glass by hand.

2. From inside the vehicle, use a knife to cut through

the quarter glass adhesive all the way around.

NOTE:

. lf the quaner glass is to be reinstalled, take care

not to damage the molding.

. lf the molding is damaged. replace the quarter

glass, molding, and clips as an assembly.

. The quarter glass can be reinstalled using butyl

tape.

(cont'd)

20-35

www.emanualpro.com

Page 1020 of 1395

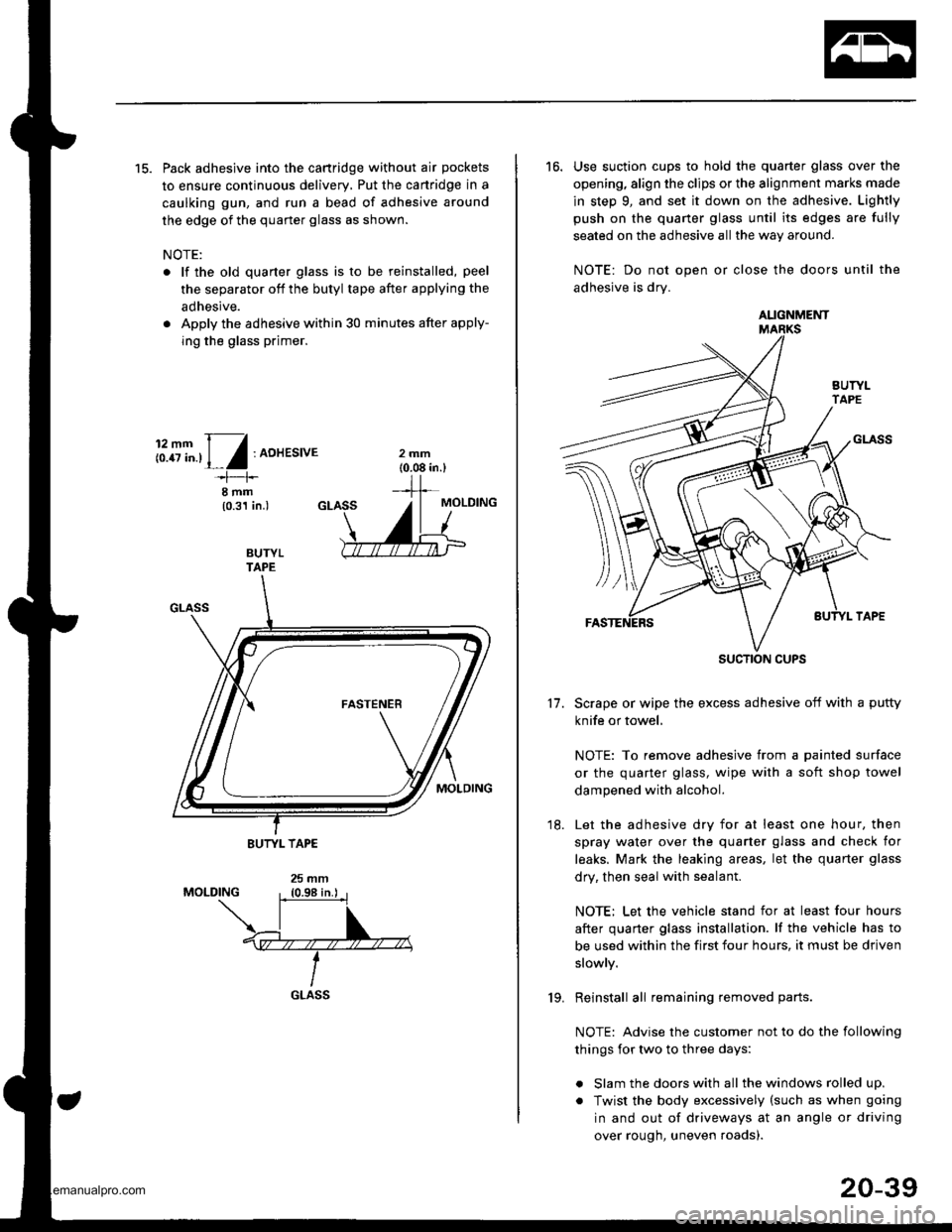

15. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery, Put the canridge in a

caulking gun, and run a bead of adhesive around

the edge of the quarter glass as shown.

NOTE:

. lf the old quarter glass is to be reinstalled, peel

the separator off the butyl tape after applying the

adhesive.

. Apply the adhesive within 30 minutes after apply-

ing the glass primer.

i:.8T".,1,/:AoHEsrvE

I rnm(0.31 in.)

BUTYLTAPE

GLASS19.

20-39

16. Use suction cups to hold the quarter glass over the

opening, align the clips or the alignment marks made

in step 9, and set it down on the adhesive. Lightly

push on the quaner glass until its edges are fully

seated on the adhesive all the way around.

NOTE: Do not open or close the doors until the

adhesive is drv.

Scrape or wipe the excess adhesive off with a putty

knife or towel,

NOTE: To remove adhesive from a painted surface

or the quarter glass, wipe with a soft shop towel

dampened with alcohol.

Let the adhesive dry for at least one hour. then

spray water over the quarter glass and check for

leaks. Mark the leaking areas, let the quarter glass

dry, then seal with sealant.

NOTE: Let the vehicle stand for at least four hours

after quarter glass installation. lf the vehicle has to

be used within the first four hours, it must be driven

slowly.

Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the following

things for two to three days:

. Slam the doors with all the windows rolled up.

. Twist the body excessively (such as when going

in and out of driveways at an angle or driving

over rough, uneven roads).

11.

18.

AUGNMENT

SUCTION CUPS

www.emanualpro.com

Page 1292 of 1395

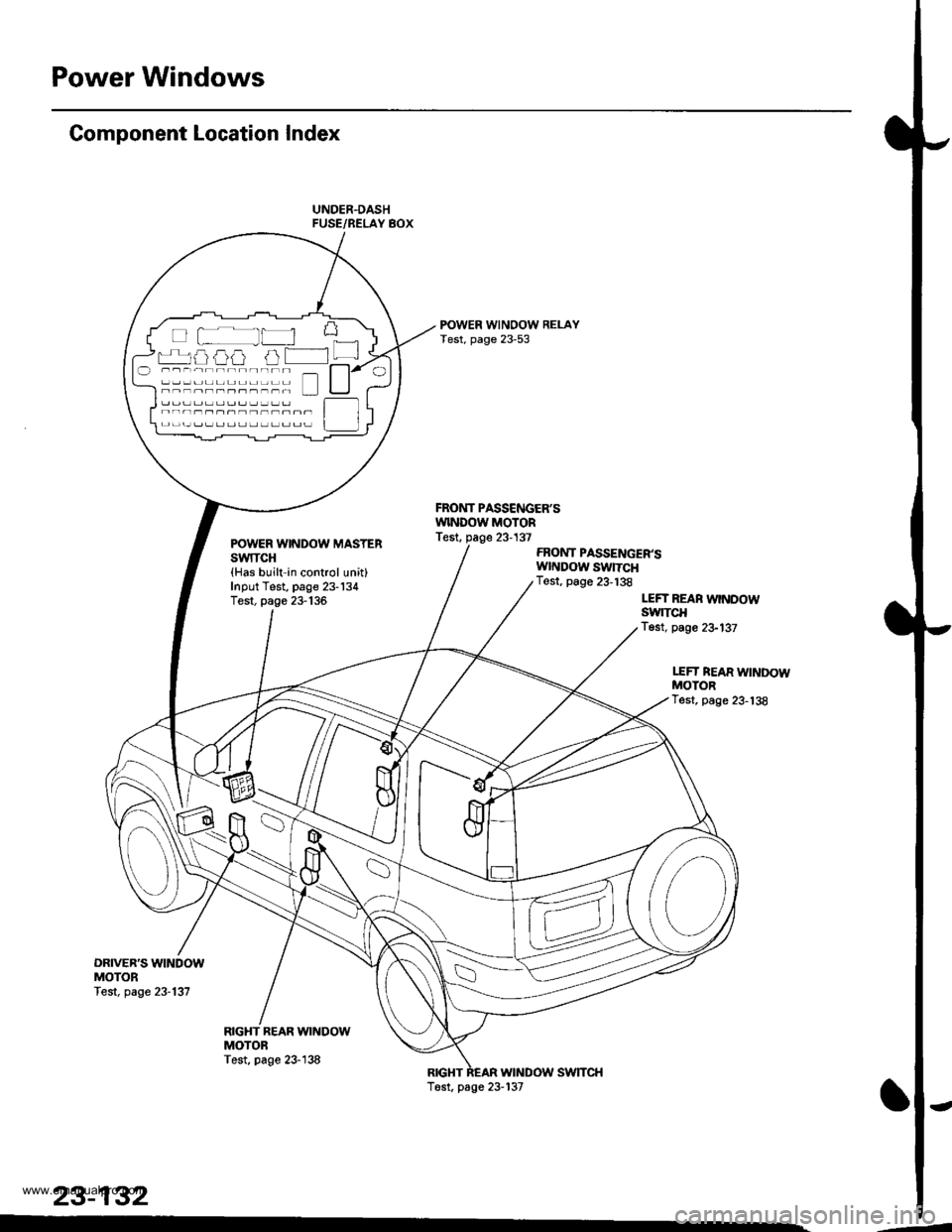

Power Windows

Component Location Index

FRONT PASSCNGER'SWINDOW MOTORTest, page 23-137POWER WINDOW MASTERSWITCH(Has built in control unit)Input Test, page 23-'134Test, page 23-135

RIGHT REAR WINDOWMOTOBTest. page 23-138

FBOI{T PASSENGER'SWI{DOW SWTTCHTest, page 23-138

LEFT REAN WWDOWSwlTCHTest, page 23-137

LEFT REAR WINDOWMOTORTest, page 23-'t38

DRIVER'S WINDOWMOTORTest, page 23-137

RIGHTwtNDow swTcHT6sr, page 23-137

tt

L--JIJJ'JJL J 1J 15-- --------------) ------------ t_.1

--.-\-.--t

\-

23-132

.-

www.emanualpro.com

Page 1294 of 1395

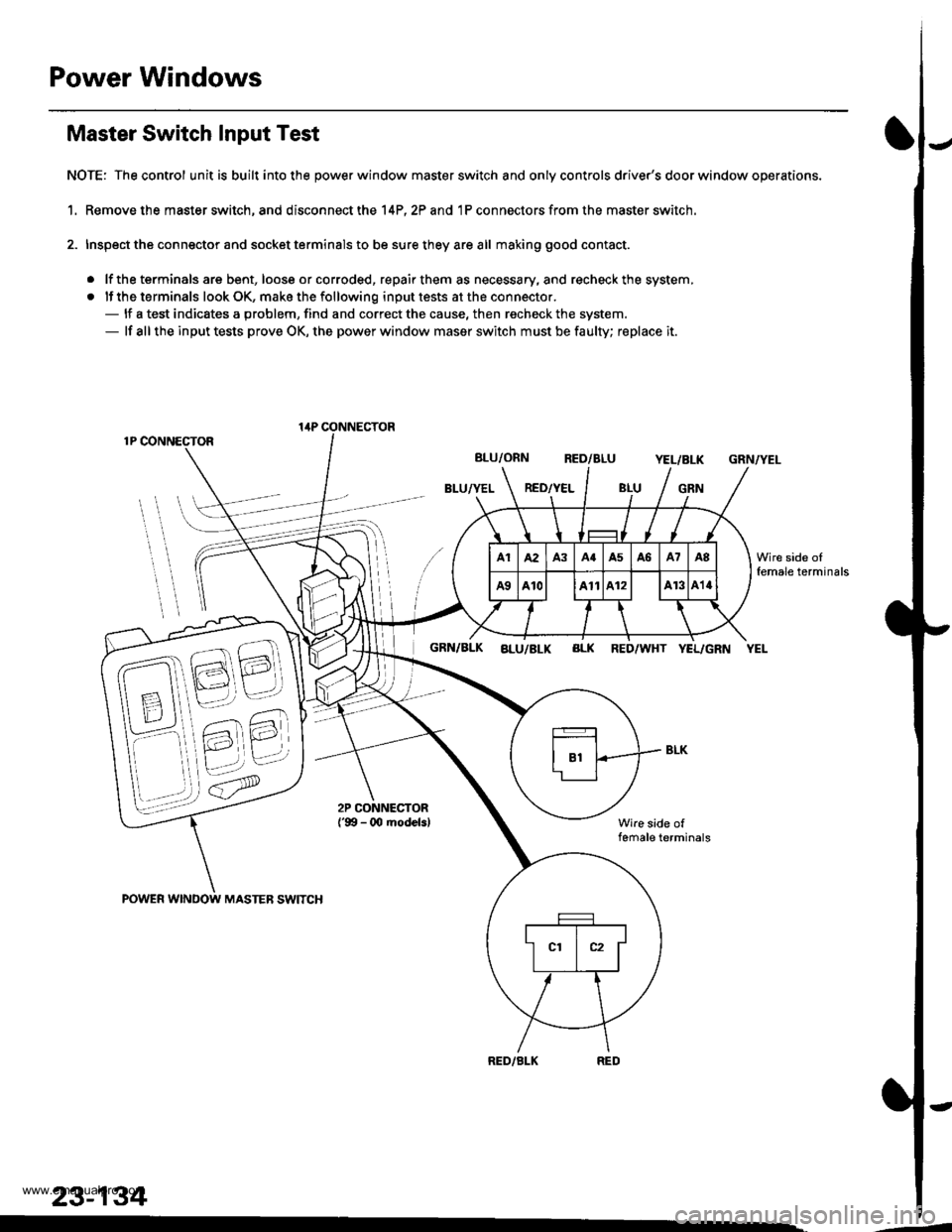

Power Windows

Master Switch Input Test

NOTE: The control unit is built into the power window master switch and only controls driver's door window operations.

1. Remove the master switch, and disconnect the 14P,2? and 1P connectors from the master switch.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system,

. lf the terminals look OK, make the following input tests at the connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the power window maser switch must be faulty; replace it.

1P CONNECTOR

BLU/ORN RED/BLUYEL/BLK

BLU/YEL RED/YELGRN

GRN/YEL

POWER WINDOW MASTEB SWITCH

GRN/BLK aLu/BLK BLK RED/WHT YEL/GRN YEL

Wire side offemale terminals

RED/BLK

lirP CONNECTOR

23-134

Wire side oIfemale terminals

.-

www.emanualpro.com

Page 1296 of 1395

Power Windows

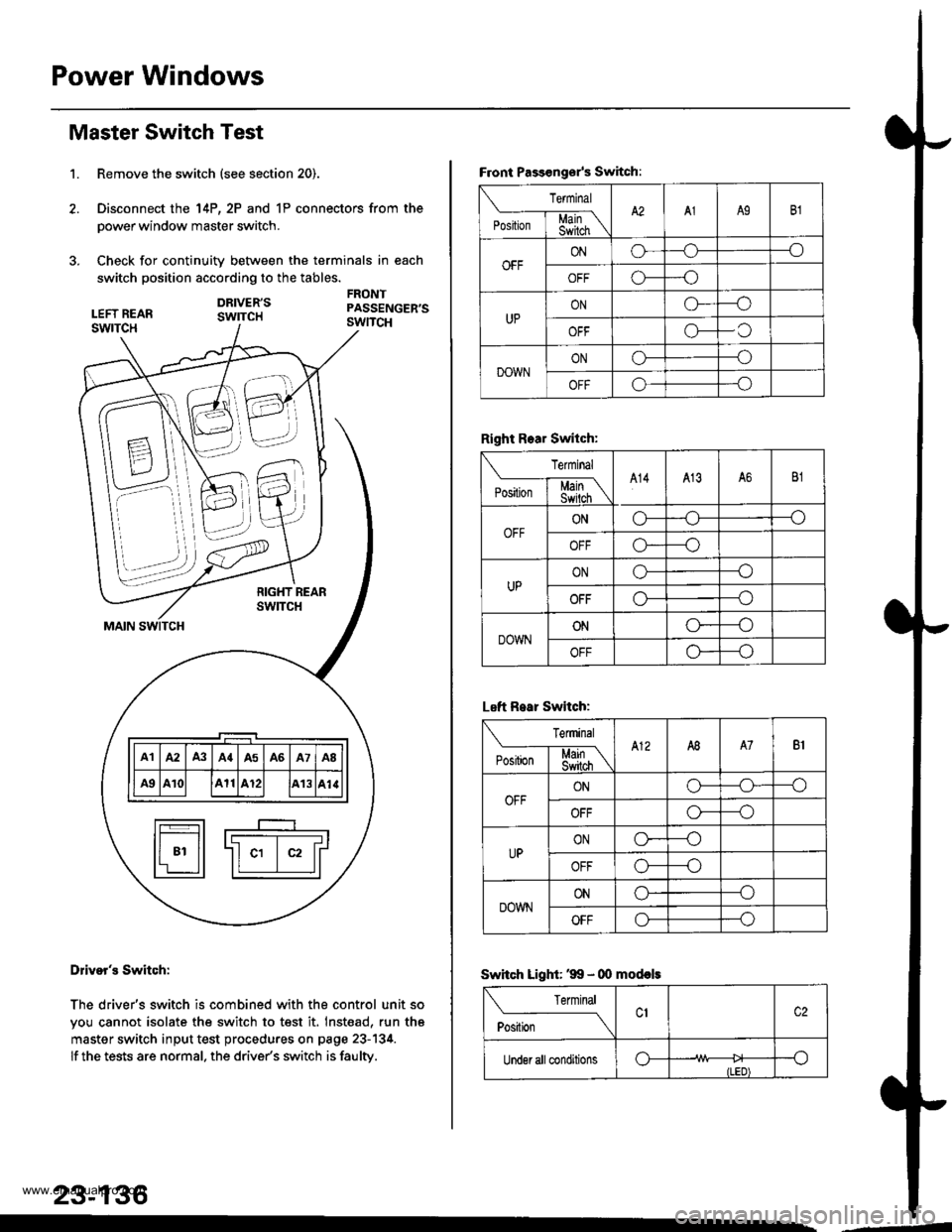

1.

Master Switch Test

Remove the switch (see section 20).

Disconnect the 14P, 2P and 1P connectors from the

power window master switch.

Check for continuity between the terminals in each

switch position according to the tables.

DRIVER'SswrTcH

FRONTPASSENGER'SswncH

B \\N

7-.i::,,,

\\'. )),,

t-_____r-__I F---T-----r-----r----r-----T---------T-----'r Illal lA2 lA3 lA{lA5 lA6 lA7 laB ll

lF#lll ae lA10l lA11lA12l lA13lal.llI r________r_____J t-t___Jl

fr---r-l r----

I t-------- -------r l

ll 81 ll -ll c1 | c2 lrl'r ll ll I llL--:J

Dliver's Switch:

The driver's switch is combined with the control unit so

you cannot isolate the switch to test it. Inst€ad, run th6

master switch input test procedures on page 23-134.

lf the tests are normal. the drive/s switch is faulty.

23-136

--d

F.ont Passongsr's Switch:

rermrnal

'**[ffiA2A1A9B1

OFFONo--_o

o---o

UPONG---o

OFFo-C

DOWNONo---o

OFFo---o

Right Rear Switch:

Terminal

'".'*l-$j[\A14413A6B1

OFFONo---o

OFFo*--o

UPONo---o

OFFo---o

DOWNONo----o

OFFo---o

Left R.ar Switch:

Terminal

e*Li*l$[\A12A8A7B1

OFFONo-o--o

OFFo---o

UPONo----o

OFFo---o

DOWNONo--_o

OFFo---o

Swhch Light: '99 - 00 mod€ls

Terminal

ti.*----_\

Under all conditionso--o

ILED)

www.emanualpro.com

Page 1298 of 1395

Power Windows

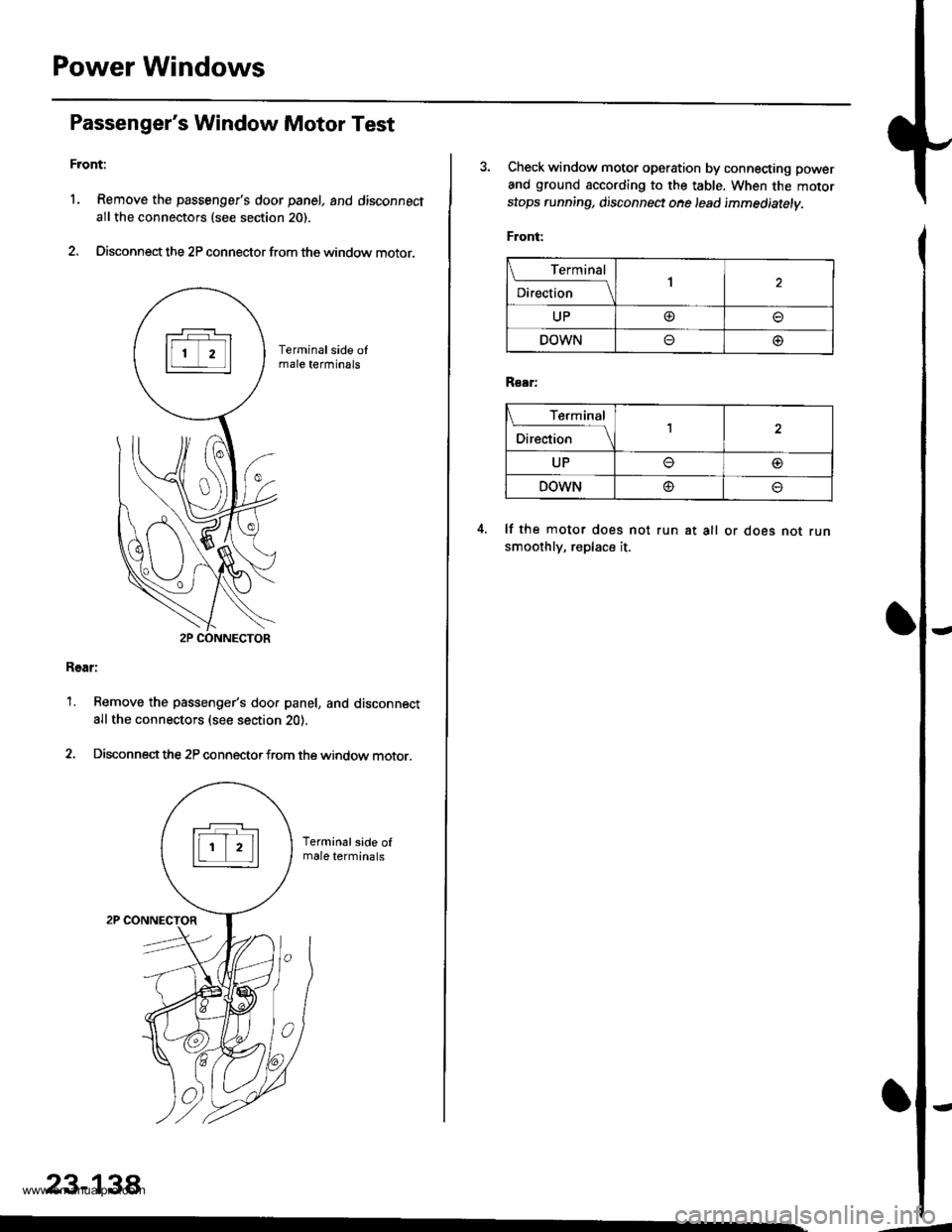

Passenger's Window Motor Test

Front:

l. Remove the passenger's door panel, and disconnect

allthe connectors (see section 20).

2. Disconnect the 2P connector from the window motor.

Rear:

1. Remove the passenger's doo. panel, and disconnect

allthe connectors (see section 20).

2. Disconnectthe 2P connectorfrom the window motor.

23-138

3. Check window motor operation by connecting power

and ground according to the table. When the motor

stops running, disconnect ohe lead immediatelv.

Front:

Terminal

;."b"

.l\

UP@

DOWNo@

R€ar:

I Terminal

;*r*

-l\

UPo@

DOWN@o

lf the motor does not run at all or does not runsmoothly, replace it.

www.emanualpro.com