ignition HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 54 of 1395

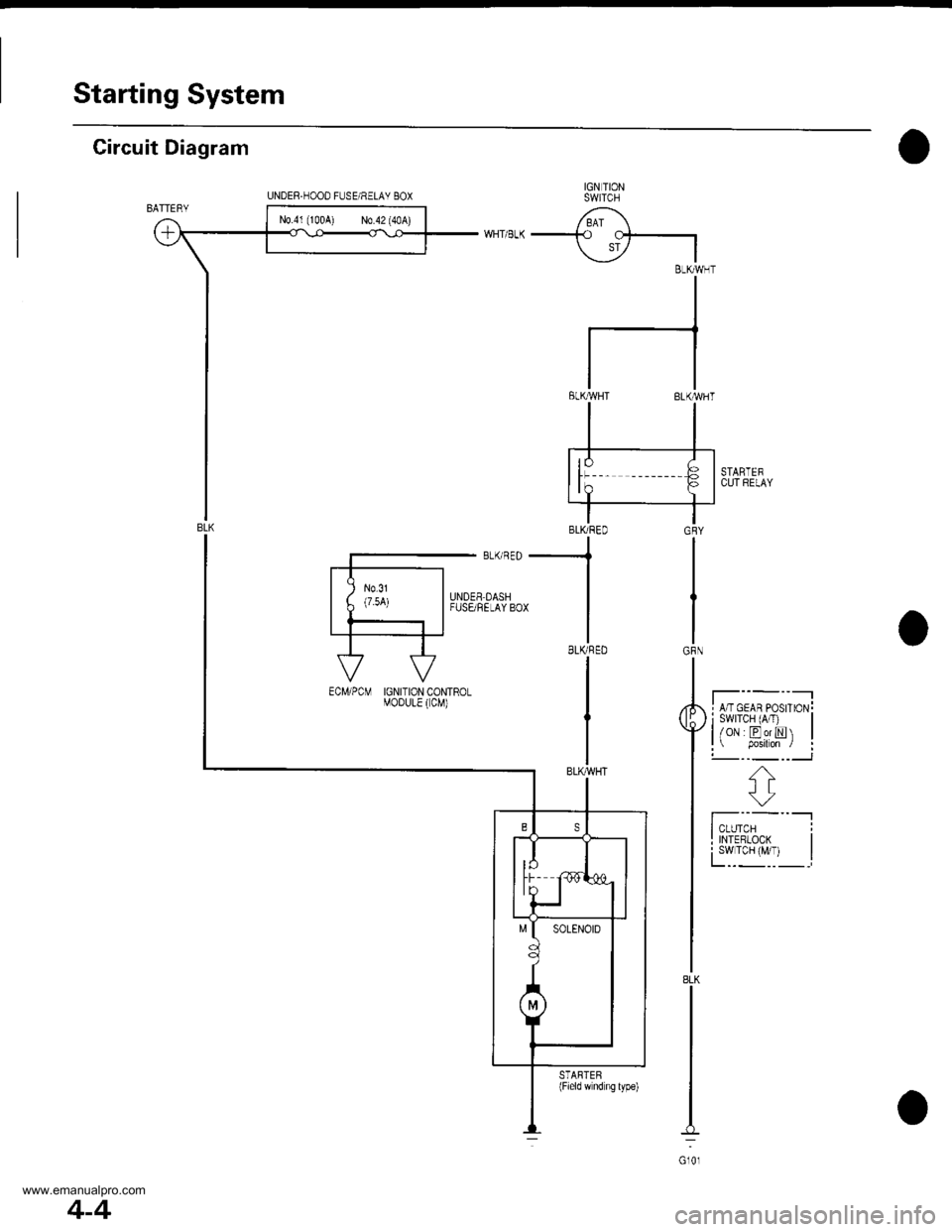

Starting System

Circuit Diagram

IGN TIONSWITCH

/ BAI \-+o cf-.|

\i7 IBLKMHT

II

I

tl

tlELKMHT BLK'WHT

STARTEFCUl RELAY

I A/T GEAR PosrroN!i swrTcH (A/T) |l/oN EorN |l p.siton / :!-- -_ --___J

f';--"-lI TNTERLooK I

fYl""yl, I

GRY

IGRN

8LK

Gl0l

UNDER.HOOD FUSE/RELAY 8OX

N0.41 (100A) N0.42 (40A)

-.1

BLKRED

I

IGNITION CONTROLMOoULE ( CM)

STARTEB(Field wnd ng lype)

4-4

www.emanualpro.com

Page 55 of 1395

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

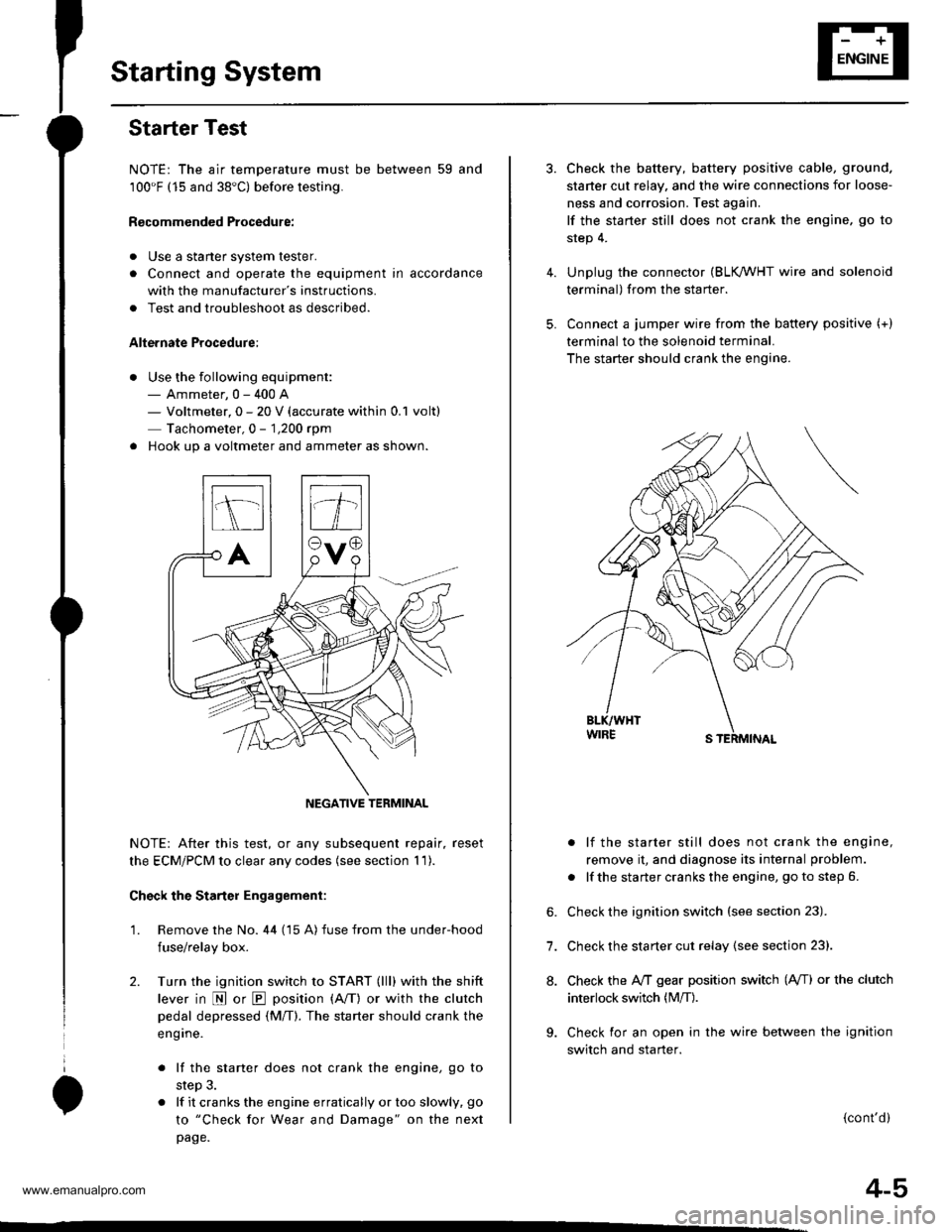

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 56 of 1395

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

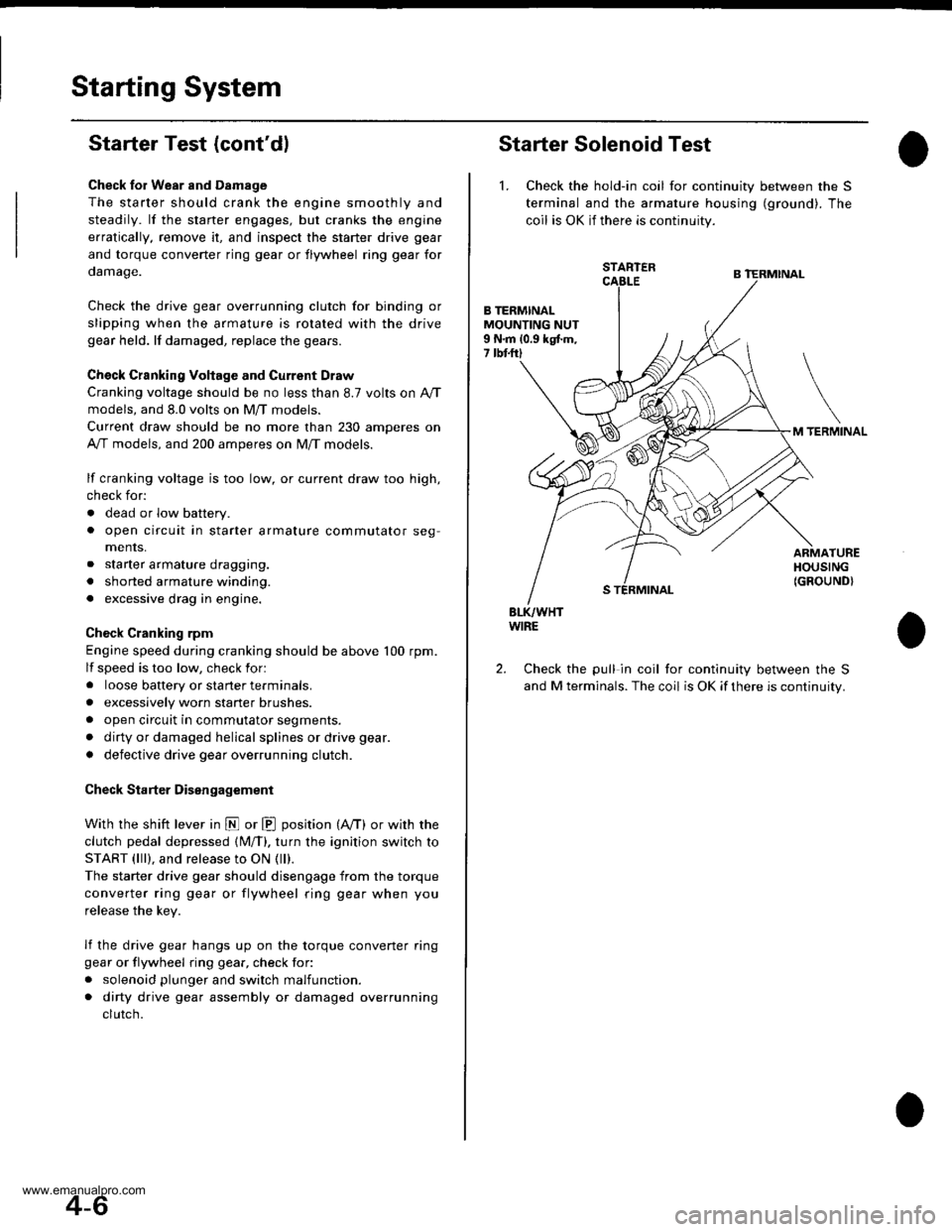

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 64 of 1395

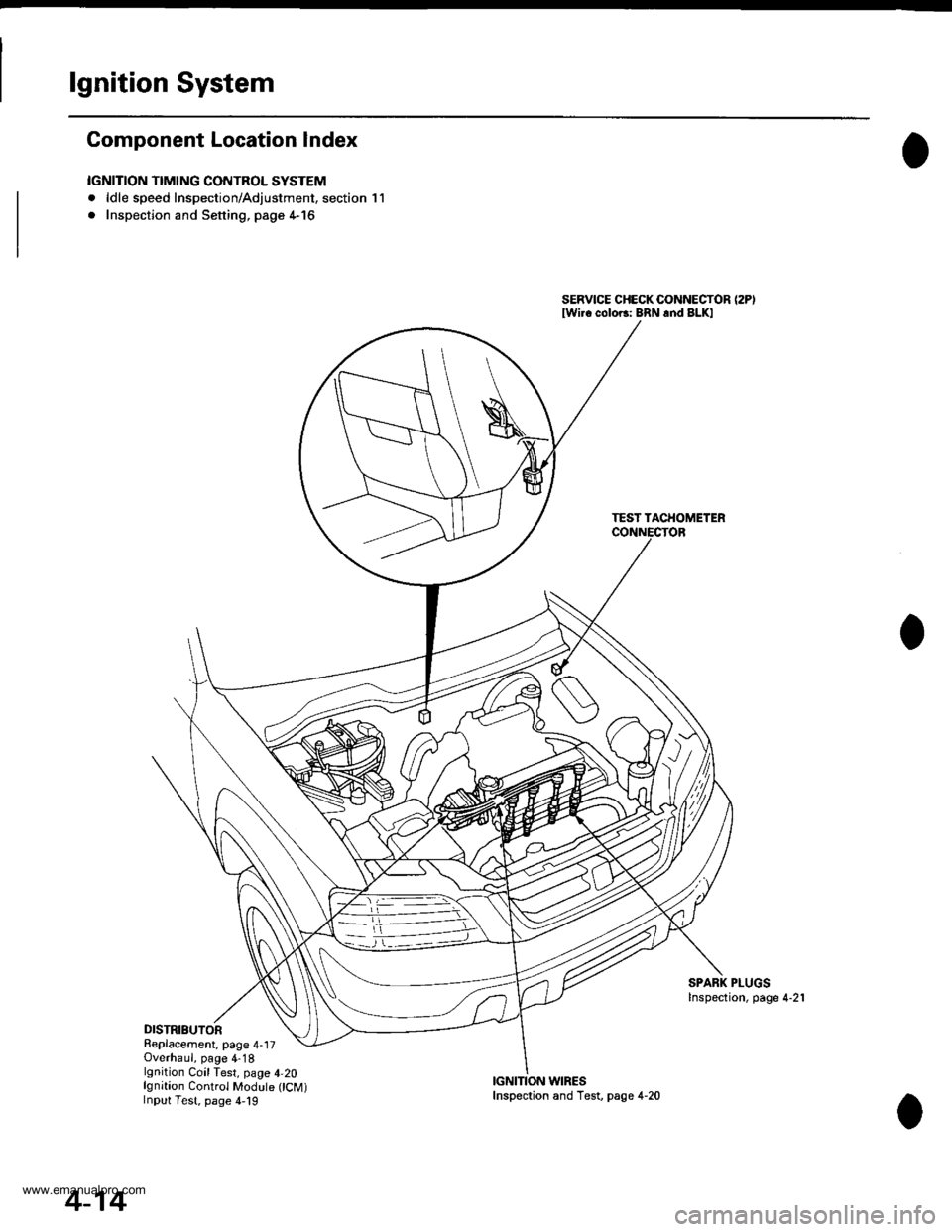

lgnition System

Component Location Index

IGNITION TIMING CONTROL SYSTEM

. ldle speed Inspection/Adjustment, section 11

. Inspection and Sening. page 4-16

DISTRIBUTORReplacement, page 4-17Overhaul, page 4-18lgnition CoilTest, page 4,20lgnition Control Module CM)Input Test, page 4,19

SERVICE CHECK CONNECTOR (2P)

lwi.c colo6: BRN rnd BLKI

TEST TACHOMETER

SPARK PLUGSInspection, page 4-21

WIRES

4-14

Inspection and Test, page 4-20

www.emanualpro.com

Page 65 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9--*.--EII

Vil

IGN TIONW]BES

SPARKPLUGS

I l: 99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top de HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9--*.--EII

Vil

IGN TIONW]BES

SPARKPLUGS

I l: 99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top de](/img/13/5778/w960_5778-64.png)

Circuit Diagram

IGNIT ONSW TCHUNDEF,DASHFUSEi RELAY BOX

6 l;;l Eci,.pcMi{Hr6-(-\9-'-'*'.--EII

V'il

IGN TIONW]BES

SPARKPLUGS

I l: '99 - 00 modelsGt01

4-15

UNDEF.HOOD FUSE/RELAY 8OX

f l-- r

TDC Top dead cenlerCKP Cran[shan poslionCYP Cylnder posrlon

TDC/CKP/CYP SENSOR

BLK/YEL

l^IGNITIONcotL

IGN]TION CONTROLMODULE (CM)

/ Has buil-if \I no|se l

i l' i--, -BLUll

ifrI BLU BLU I

ll/' i

| | resrI TACHOMETER

I I

tott"to*

LTTCHoMEIEB j'97 -'98 models

IJltfi--cMFcr,r

I

www.emanualpro.com

Page 66 of 1395

lgnition System

5.

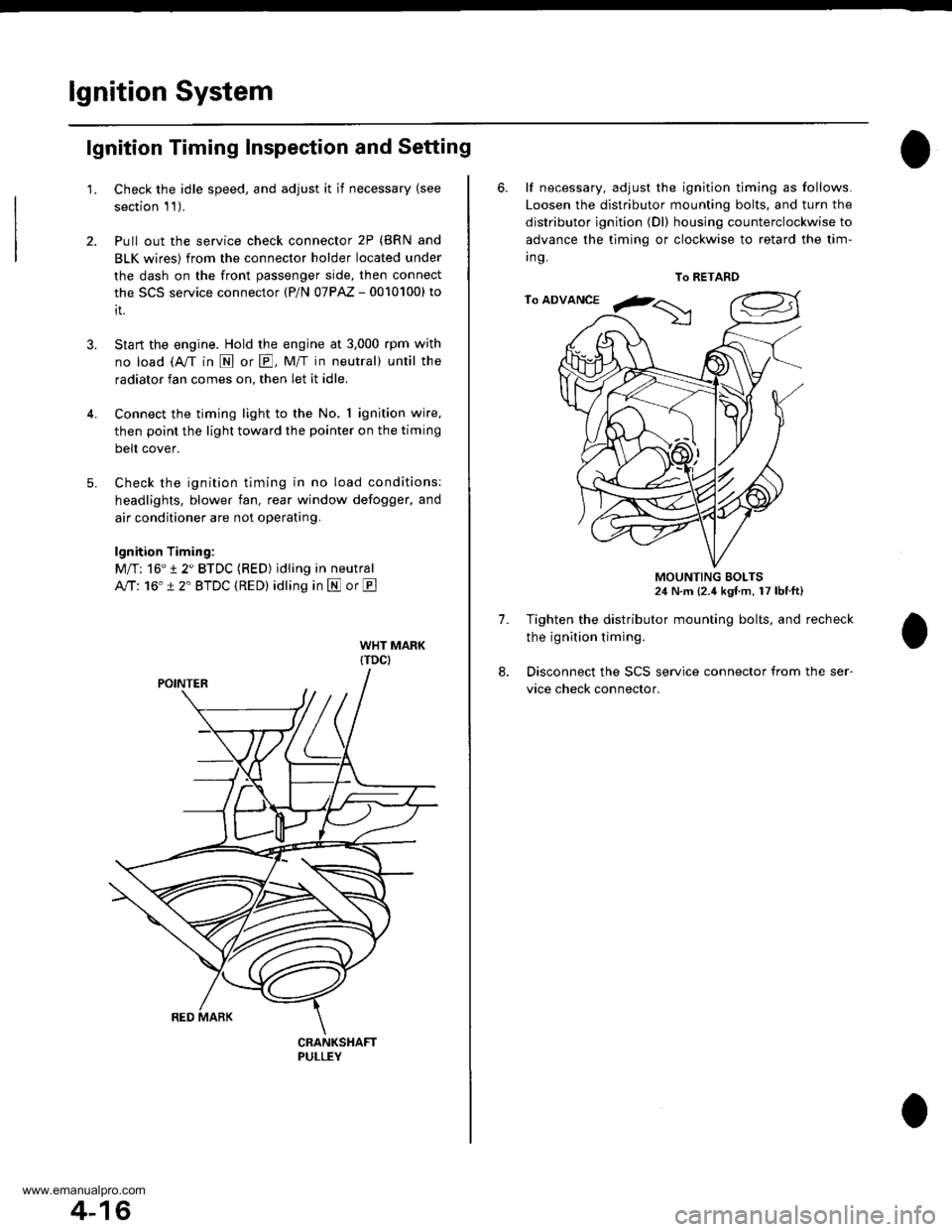

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 67 of 1395

e

o

I'

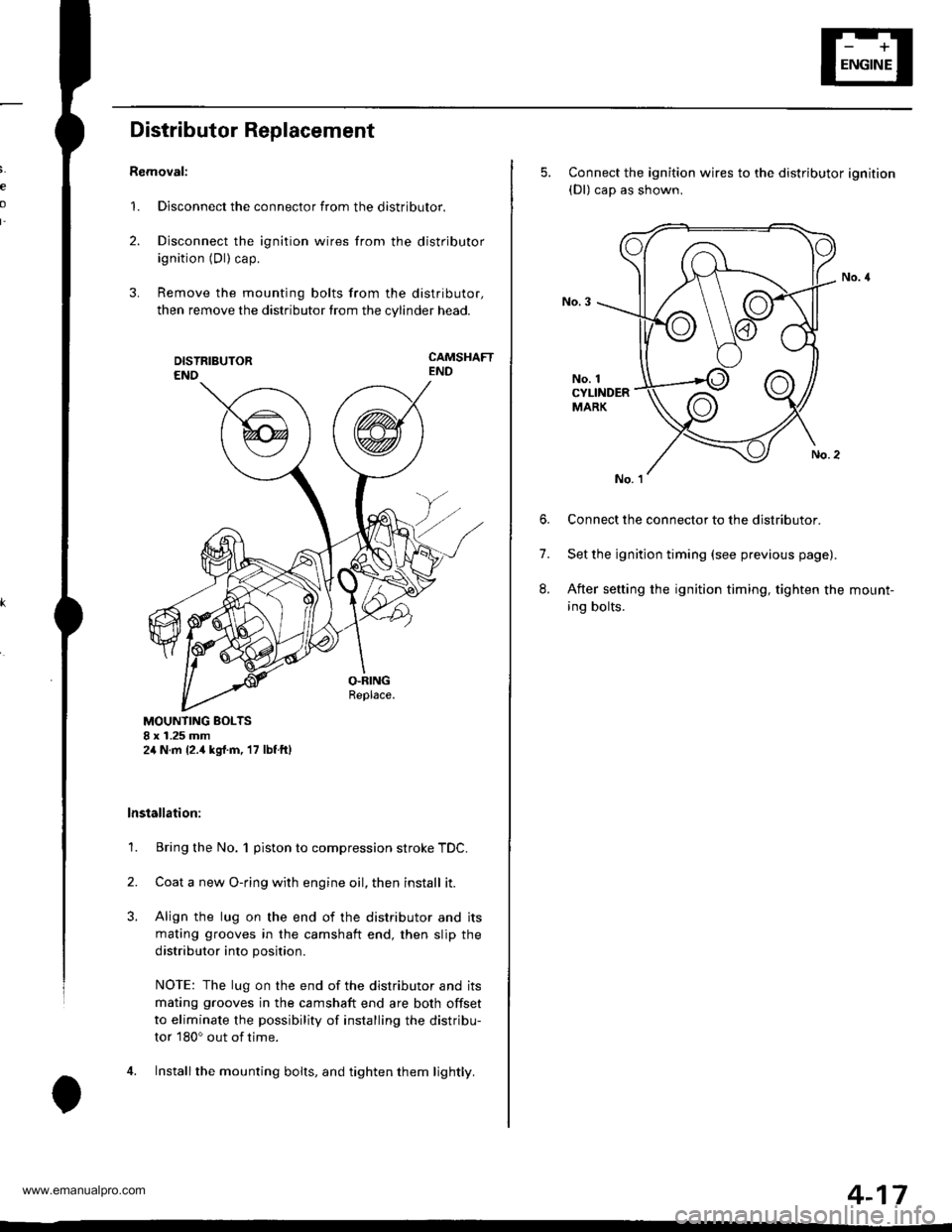

Distributor Replacement

Removal:

1. Disconnect the connector from the distributor.

2. Disconnect the ignition wires from the distributor

ignition (Dl) cap.

3. Remove the mounting bolts from the distributor,

then remove the distributor from the cylinder head.

CAMSHAFTEND

MOUNTING BOLTS8 x 1.25 mm2,1N.m {2.,1kgrf.m, 17 lbf ftl

lnstallation:

1. Bring the No. 1 piston to compression stroke TDC.

2. Coata new O-ring with engine oil, then install it.

3. Align the lug on the end of the distributor and its

mating grooves in the camshaft end, then slip the

distributor into position.

NOTE: The lug on the end of the distributor and its

mating grooves in the camshaft end are both offset

to eliminate the possibility of installing the distribu-

tor 180o out of time.

4. Installthe mounting bolts, and tighten them lightly.

5. Connect the ignition wires to the distributor ignition(Dl) cap as shown,

No. 1CYLINDERMARK

6. Connect the connector to the distributor.

7. Set the ignition timing (see previous page).

8. After setting the ignition timing, tighten the mount-

ing bolts.

4-17

www.emanualpro.com

Page 68 of 1395

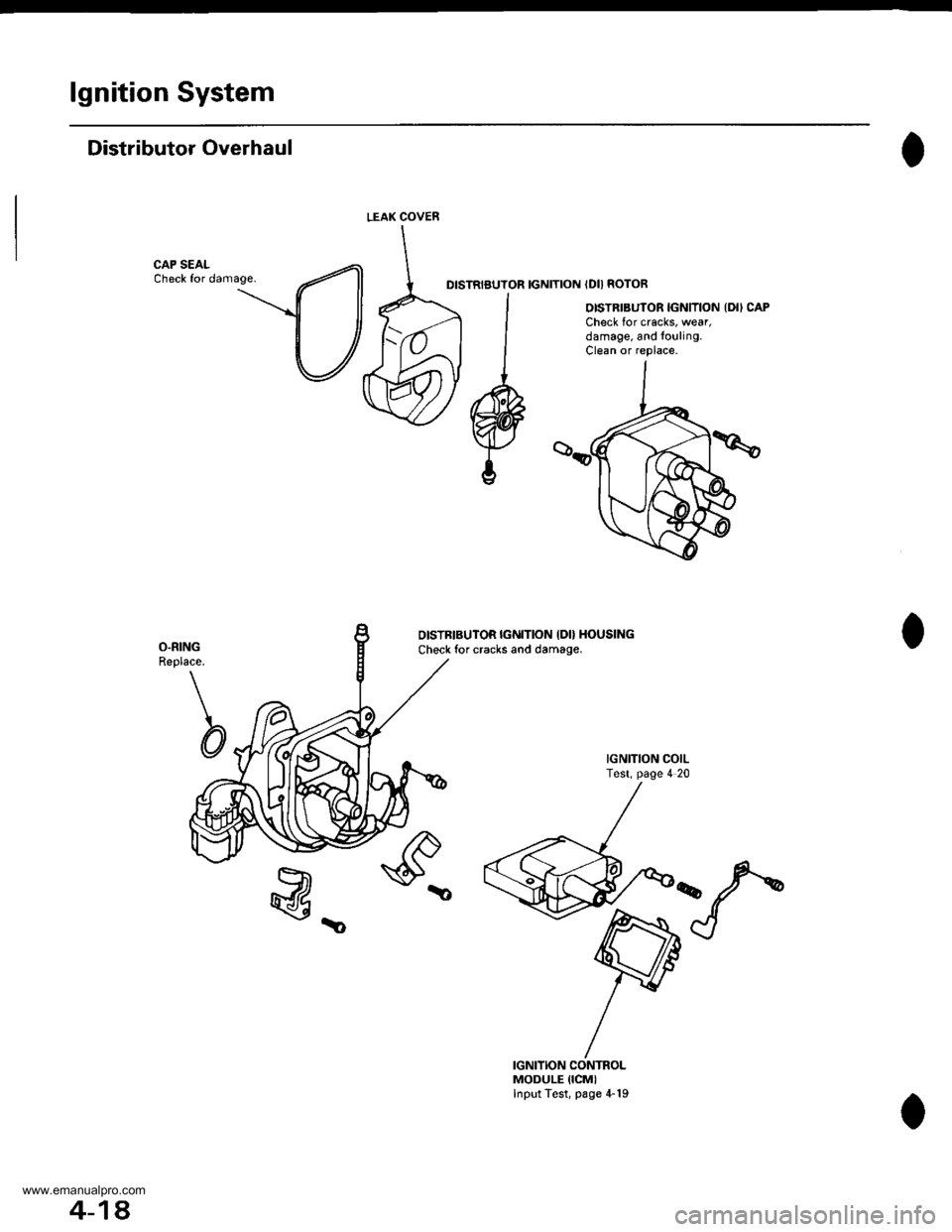

lgnition System

Distributor Overhaul

CAP SEALCheck for damage.DISTRIBUTOR IGNITION IDII ROTOR

OISTRIBUTOR IGNITION {DII CAPCheck for cracks, wear,damage, and to!ling.Clean or replace.

O.RINGReplace.

b

OISTBIBUTOR IGI{ITION IDO HOUSING

Check for cracks and damage.

IGNITION COILTest, page 4 20

@_

IGNITION CONTROLMODULE {ICMIInput Test, page 4-19

LEAK COVEN

4-18.

www.emanualpro.com

Page 69 of 1395

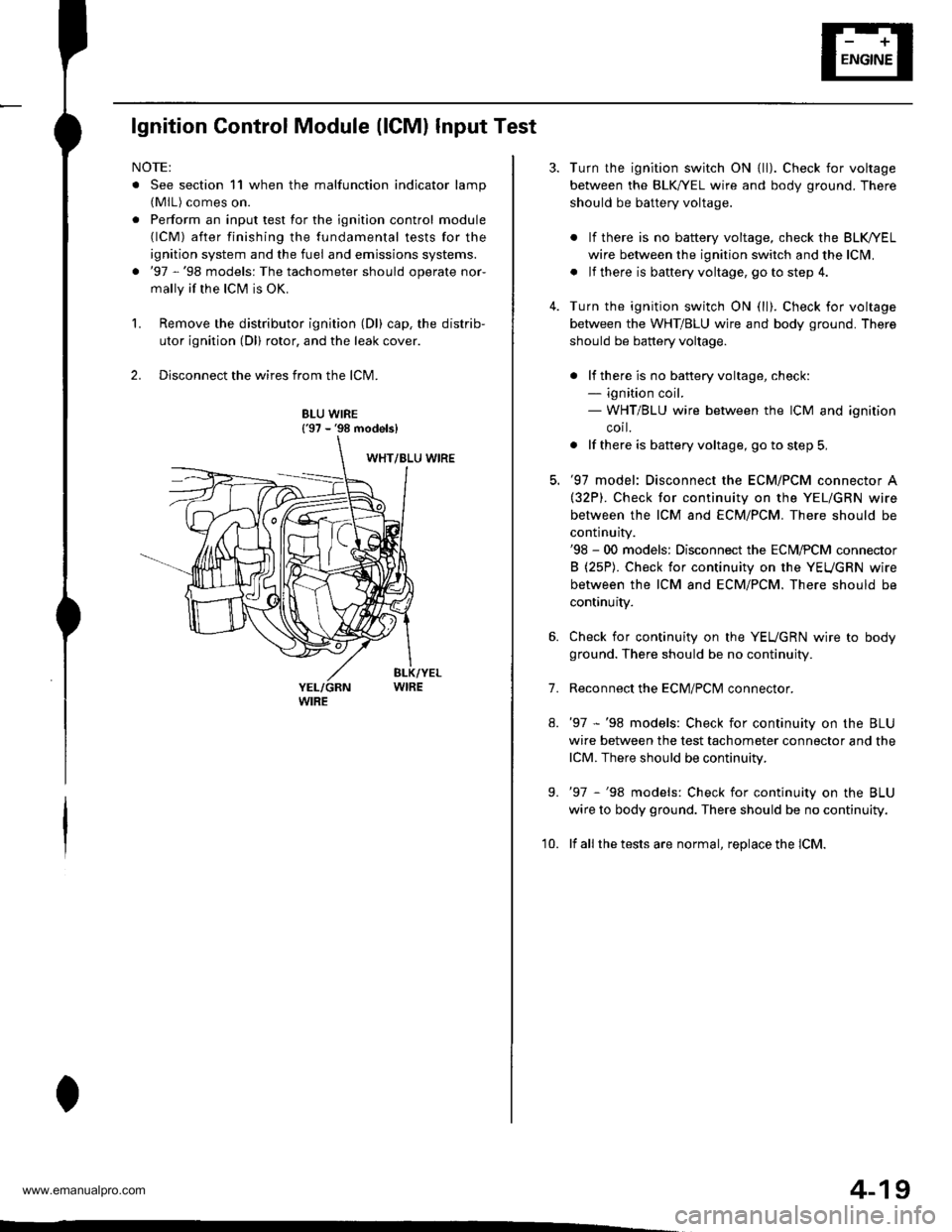

lgnition Control Module (lCMl Input Test

NOTE:

. See section 11 when the malfunction indicator lamp(MlL) comes on.

. Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems.

. '97 -'98 models: The tachometer should operate nor-

mally if the ICM is OK.

L Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor, and the leak cover.

2. Disconnect the wires from the lCM.

8LU WIRE{'97 - '98 models}

4-19

7.

Turn the ignition switch ON {ll). Check for voltage

between the BLK,^/EL wire and body ground. There

should be battery voltage.

. lf there is no battery voltage, check the BLK/rEL

wire betlveen the ignition switch and the lclvl.

. lf there is baftery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground. There

should be battery voltage.

. lf there is no batteryvoltage, check:- ignition coil.- WHT/BLU wire between the ICM and ignition

corl.

. lf there is battery voltage, go to step 5,

'97 model: Disconnect the ECM/PCM connector A(32P). Check for continuity on the YEL/GRN wire

between the ICM and ECM/PCM. There should be

continuity.'98 - 00 models: Disconnect the ECM,PCM connector

B (25P). Check for continuity on the YEUGRN wire

between the ICM and ECM/PCM. There should be

continuity.

Check for continuity on the YEUGRN wire to body

ground. There should be no continuity.

Reconnect the ECM/PClvl connector.

'97 -'98 models: Check for continuity on the BLU

wire between the test tachometer connector and the

lCM. There should be continuity.

'97 -'98 models: Check for continuity on the BLU

wire to body ground. There should be no continuity.

lf all the tests are normal, replace the lCM.

9.

'10.

www.emanualpro.com

Page 70 of 1395

lgnition System

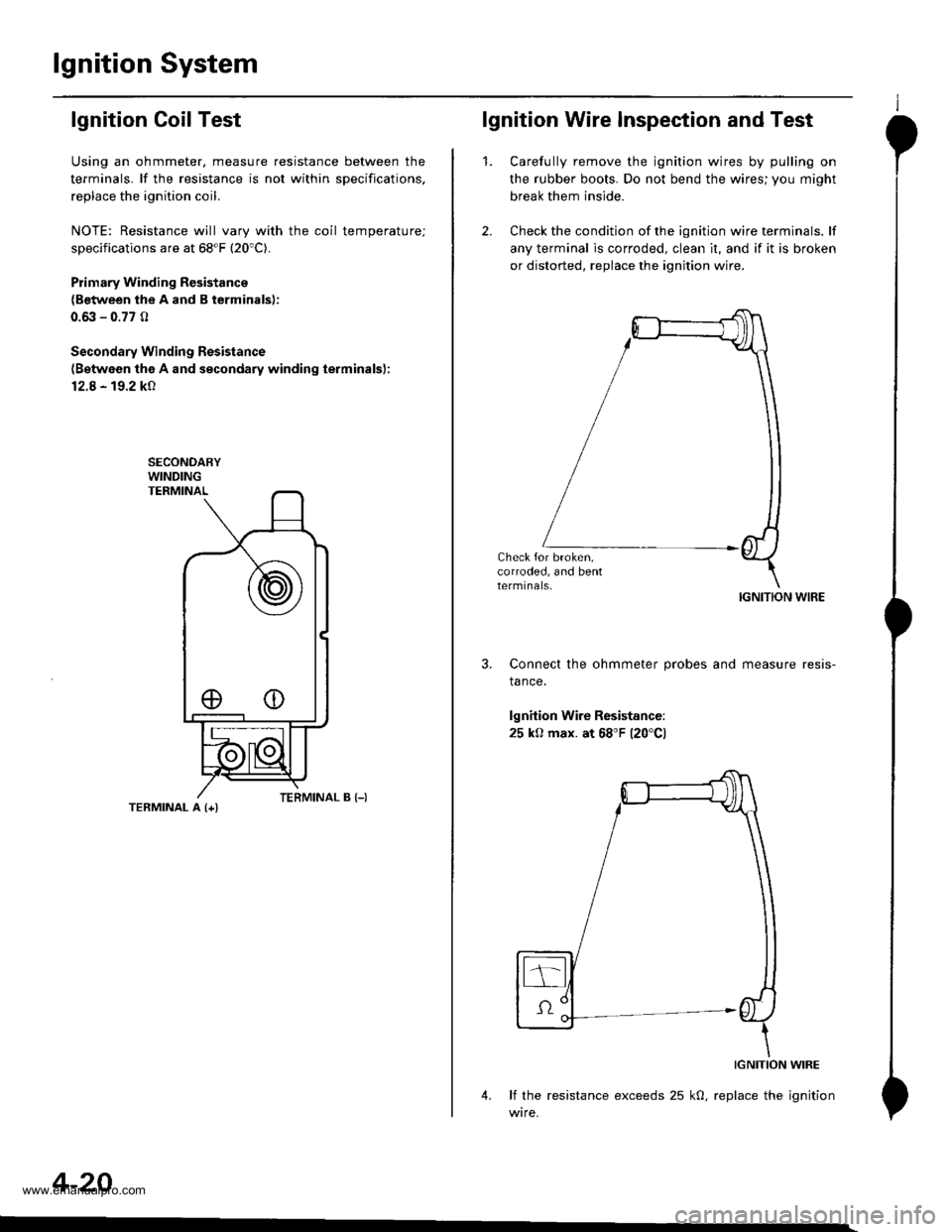

lgnition Coil Test

Using an ohmmeter, measure resistance between the

terminals. lf the resistance is not within sDecifications,

replace the ignition coil.

NOTE: Resistance will vary with the coil temperature;

specifications are at 68"F (20'C).

Plimary Winding Resistance

{Between the A and B terminals):

0.6it - 0.77 0

Secondary Winding Resistance

{Between the A and secondary winding terminals):

12.8 - 19.2 kO

TERMINAL A {+l

4-20

eo

lgnition Wire Inspection and Test

1.Carefully remove the ignition wires by pulling on

the rubber boots. Do not bend the wires; you might

break them inside.

Check the condition of the ignition wire terminals. lf

any terminal is corroded, clean it, and if it is broken

or distorted, replace the ignition wire.

IGNITION WIRE

Connect the ohmmeter probes and measure resis-

tance.

lgnition Wire Resistance:

25 kO max. at 68'F 120'Cl

IGNITION WIRE

4. lf the resistance exceeds 25 kO, replace the ignition

wire.

www.emanualpro.com