Cylinder HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 943 of 1395

10.

11,

Connect the parking brake cable to the parking

brake lever,

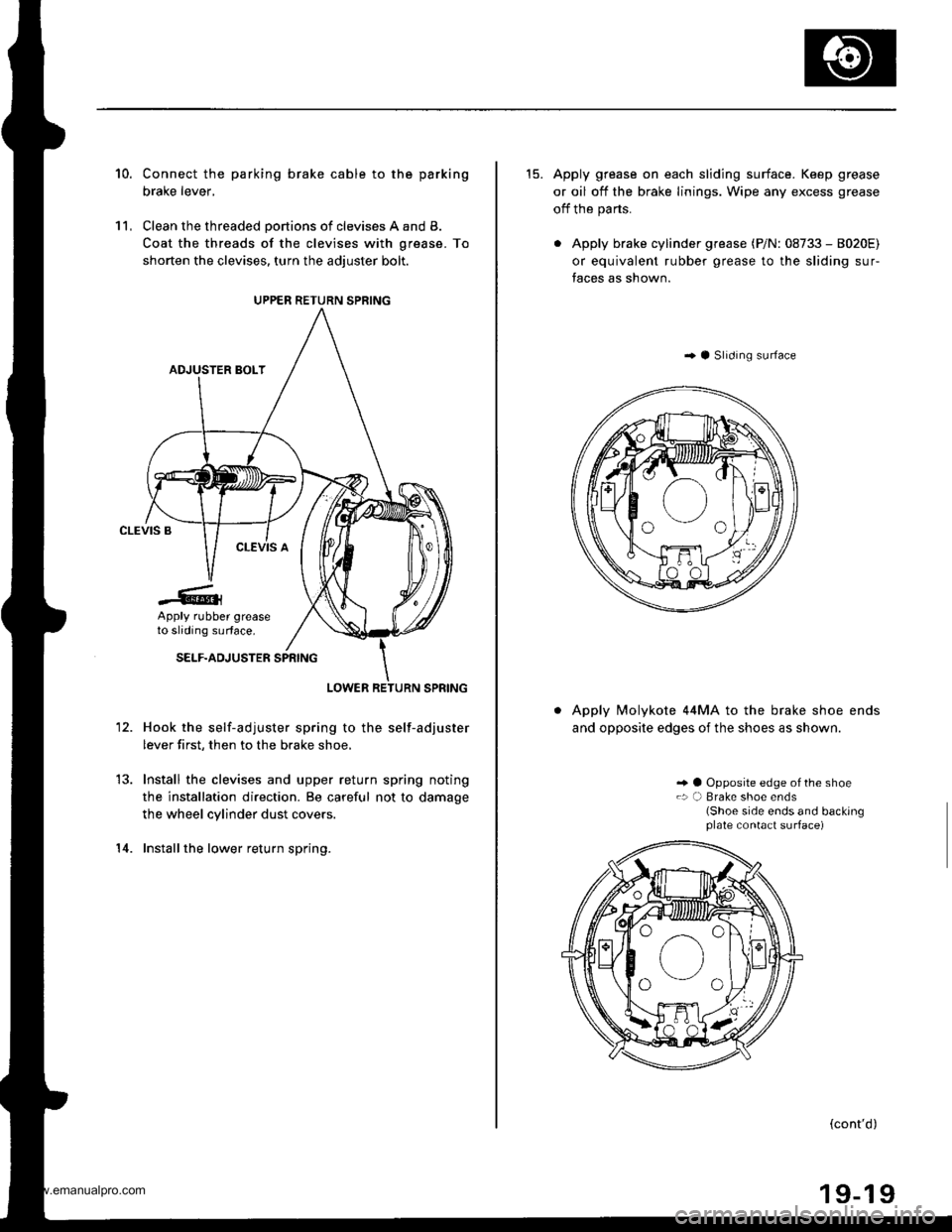

Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shorten the clevises, turn the adiuster bolt.

Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe,

Install the clevises and upper return spring noting

the installation direction. Be careful not to damage

the wheel cylinder dust covers.

Installthe lower return spring.

12.

14.

UPPER RETURN SPRING

Apply rubber greaseto sliding surface.

15. Apply grease on each sliding surface. Keep grease

or oil off the brake linings. Wipe any excess grease

off the parts.

. Apply brake cylinder grease (P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

..4 Slrdrng surface

Apply Molykote 44MA to the brake shoe ends

and opposite edges of the shoes as shown.

.. a Opposite edge of the shoe.: a) Brake shoe ends(Shoe side ends and backingplate contact surface)

(cont'd)

www.emanualpro.com

Page 944 of 1395

Rear Drum Brakes

Brake Shoes Replacement (cont'd)

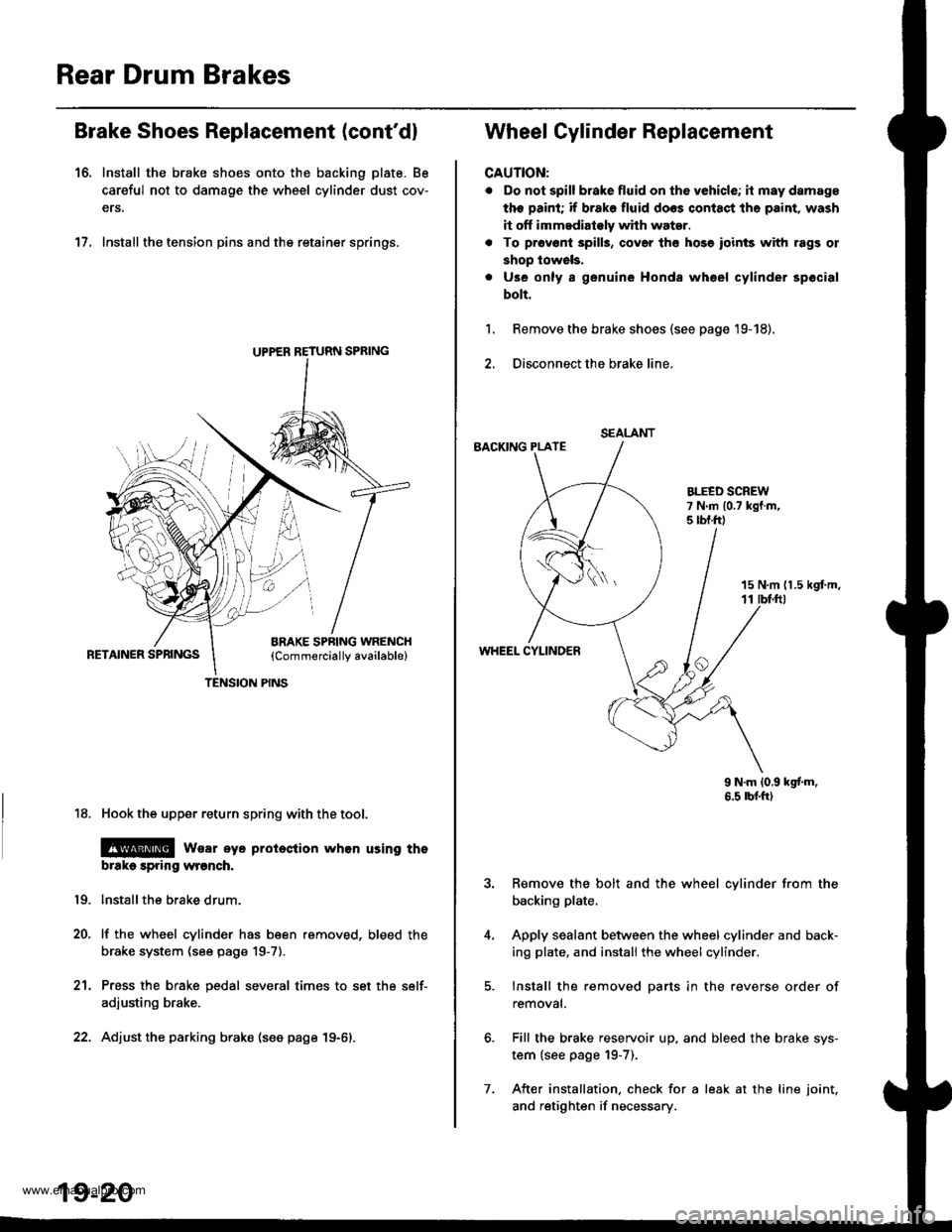

16. Install the brake shoes onto the backing plate. Be

careful not to damage the wheel cylinder dust cov-

ers.

17. Install the tension pins and the retainer springs.

18. Hook the upper return spring with the tool.

@ wsar eye proieclion whon using tho

brtko spring wronch.

lnstallthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7).

Press the brake pedal several times to set the self-

adjusting brake.

Adjust the parking brako (see page 19-6).

19.

20.

21.

UPPER RETURN SPRING

TENSION PINS

19-20

7.

SEALANT

Wheel Cylinder Replacement

CAUTION:

. Do not spill brake fluid on th6 vehicle; it may damage

the paint; if brako fluid doos contact tho paint, wash

it off immedialely whh water.

. To pr6v6ni 3pills, cov6r th6 hose ioinls with rags ol

shop lowels,

. Use only a genuine Honda whoel cylinder spocial

bolt.

Remove the brake shoes {see page '19-18).

Disconnect the brake line,

BACKING PLATE

1.

15 N,m 11.5 kgt m,11 tbf.ftl

WHEEL CYLINDER

9 N.m 10,9 kgf'm.6.5 rbtft)

Remove the bolt and the wheel cylinder from the

backing plate.

Apply sealant between the wheel cylinder and back-

ing plate, and install the wheel cylinder.

Install the removed parts in the reverse order of

removal.

Fill the brake reservoir up. and bleed the brake sys-

tem {see page 19-7).

After installation. check for a leak at the line joint.

and retighten if necessary.

www.emanualpro.com

Page 945 of 1395

Brake Hoses/Lines

Inspection/Torque Specif ications

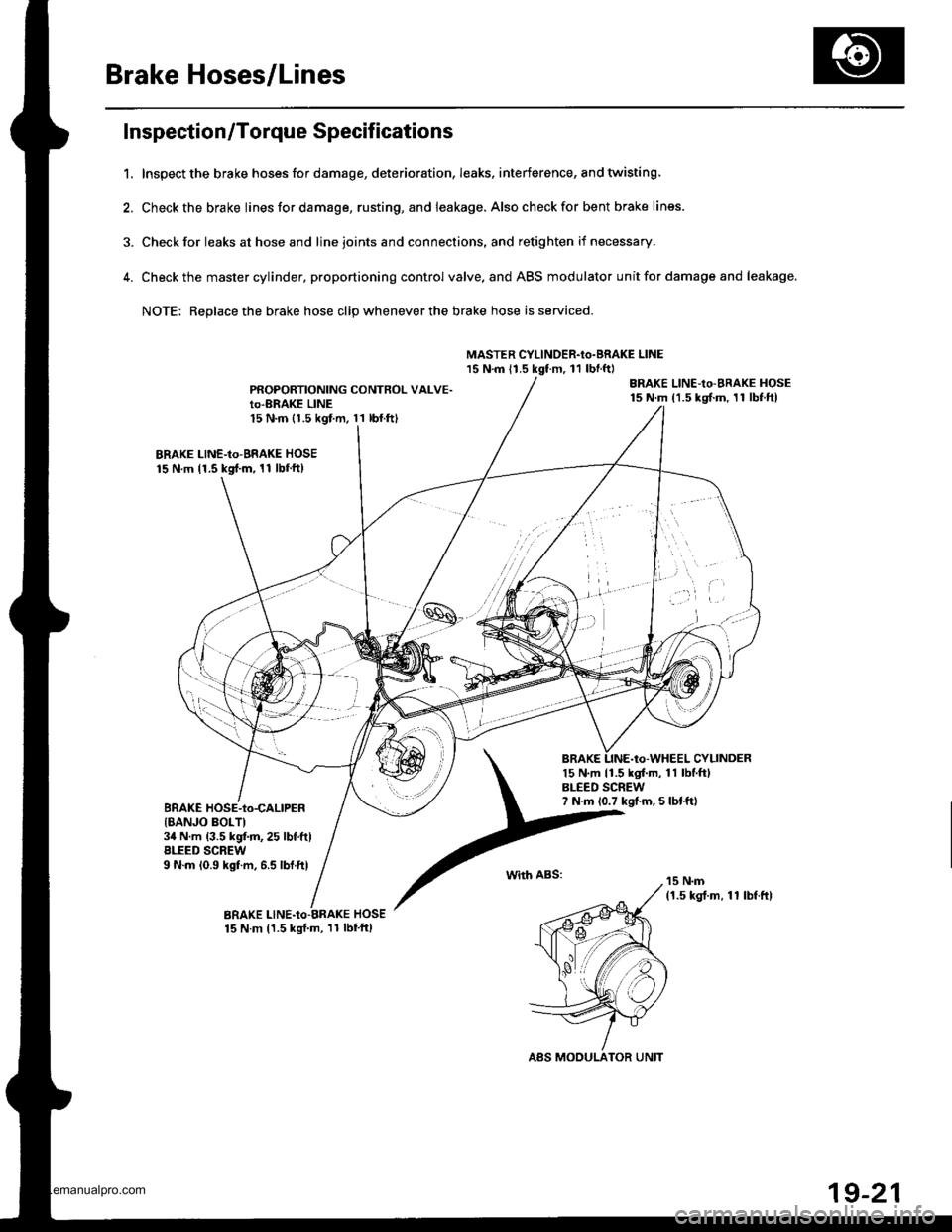

1. Inspect the brake hoses for damage, deterioration, leaks, interference, and twisting

2. Check the brake Iines for damage, rusting, and leakage. Also check for bent brake lines.

3. Check for leaks at hose and line joints and connections, and retighten if necessary.

4. Checkthe master cylinder, proportioning control valve. and ABS modulator unit for damage and leakage.

NOTE: Replace the brake hose clip whenever the brake hose is serviced.

MASTER CYLINOER.Io.BRAKE LINE15 N.m 11.5 kgt m, 11 lbnftl

PROPORTIONING CONTROL VALVE.Io-BRAKE LINE15 N.m (1.5 kgf.m. 11 lbl.ftl

BRAKE LINE-Io-BRAKE HOSE15 N.m 11.5 kgd.m, 11 lbf'ft)

CYLINDER15 N.m 11.5 kgf.m, 11 lbf.ft)BLEED SCREW7 N.m 10.7 kgf.m, 5 lbt.fttBRAKE HOSE-to-CALIPER{8ANJO BOLTI34 N.m (3.5 kgf.m,25 lbf.ftlBLEED SCREW9 N.m 10.9 kgf.m, 6.5 lbf.ftlwith ABS:

19-21

www.emanualpro.com

Page 953 of 1395

Anti-lock Brake System (ABS)

Features/Gonstruction (cont'd)

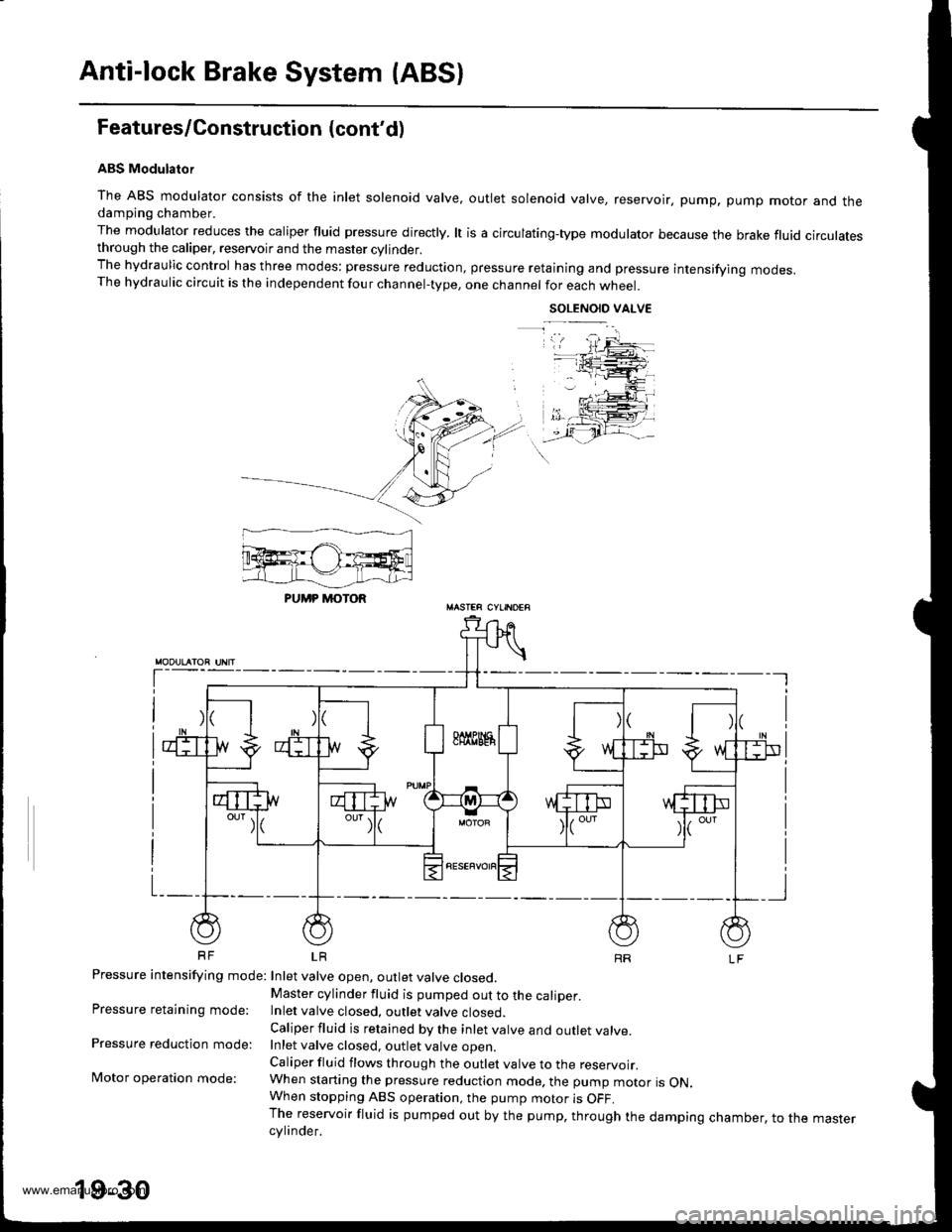

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedampjng chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fluid circulatesthrough the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensifying modes.The hydraulic circuit is the independent four channel-type, one channel for each wheel.

SOLENOID VALVE

t-

Pressure intensifying mode: Inlet valve open, outlet valve closed,

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

Master cylinder fluid is pumped out to the caliper.Inlet valve closed, outlet valve closed.

Caliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve ooen

Caliper fluid flows through the outlet valve to the reservoir.When starting the pressure reduction mode. the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercylinder.

PUMP MOTOR

19-30

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com

Page 989 of 1395

Doors

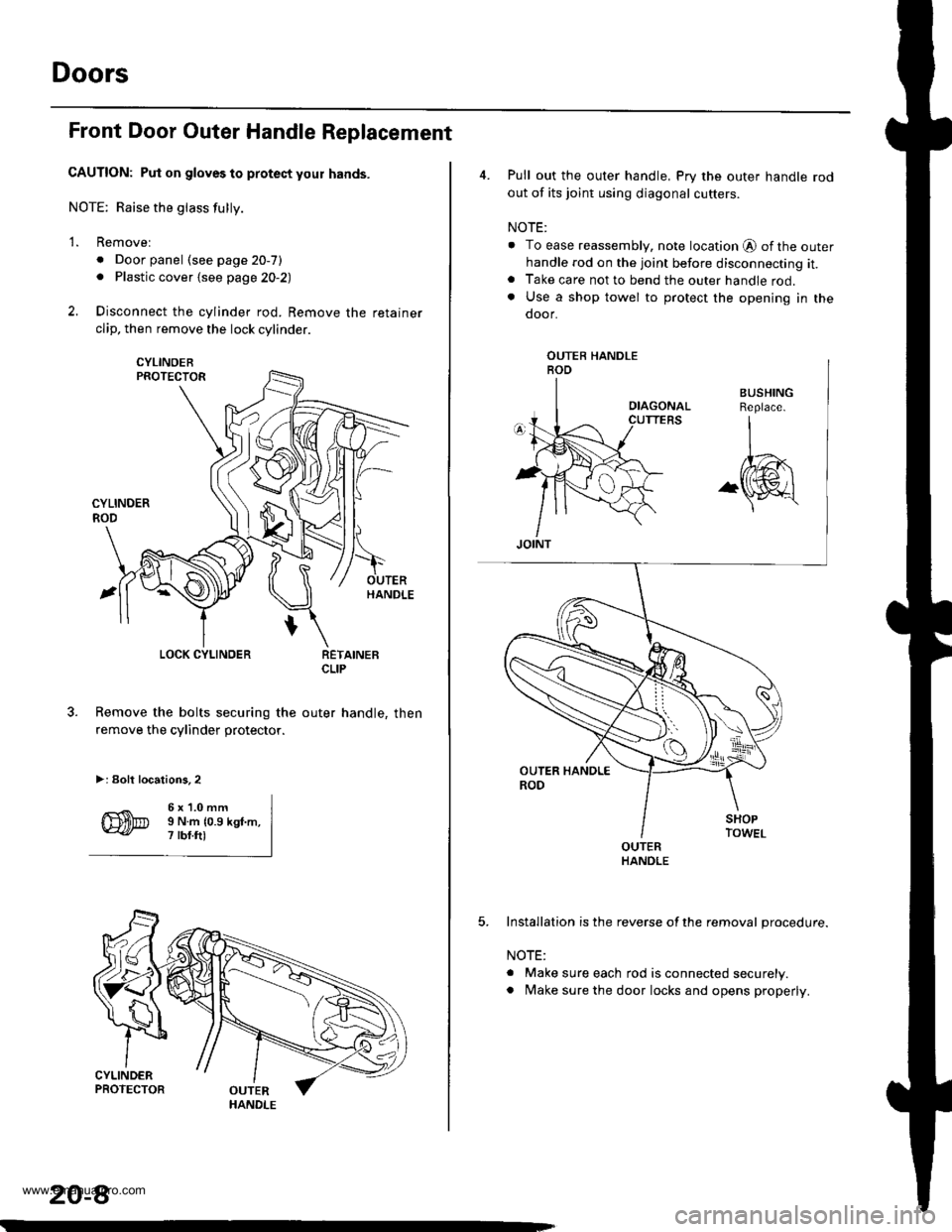

Front Door Outer Handle Replacement

CAUTION: Put on gloves to protect your hands.

NOTE; Raise the glass fully.

2.

1.Removel

. Door panel (see page 20-7). Plastic cover {see page 2O-2)

Disconnect the cylinder rod. Remove the retainer

clip, then remove the lock cylinder.

5.

6 x'1.0 mmI N.m {0.9 kgt.m,7 rbf.ftl

LOCK CYLINDER

Remove the bolts securing the

remove the cylinder protector.

>: Eolt locations,2

RETAINEBCLIP

outer handle, then

HANDLE

20-8

4. Pull out the outer handle, Pry the outer handle rod

out of its joint using diagonal cutters.

NOTE:

. To ease reassembly, note location @ ofthe outerhandle rod on the joint before disconnecting it.. Take care not to bend the outer handle rod.. Use a shop towel to protect the opening in the

door.

OUTEBHANDLE

5. Installation is the reverse of the removal procedure.

NOTE:

. Make sure each rod is connected securely.. Make sure the door locks and opens properly.

www.emanualpro.com

Page 990 of 1395

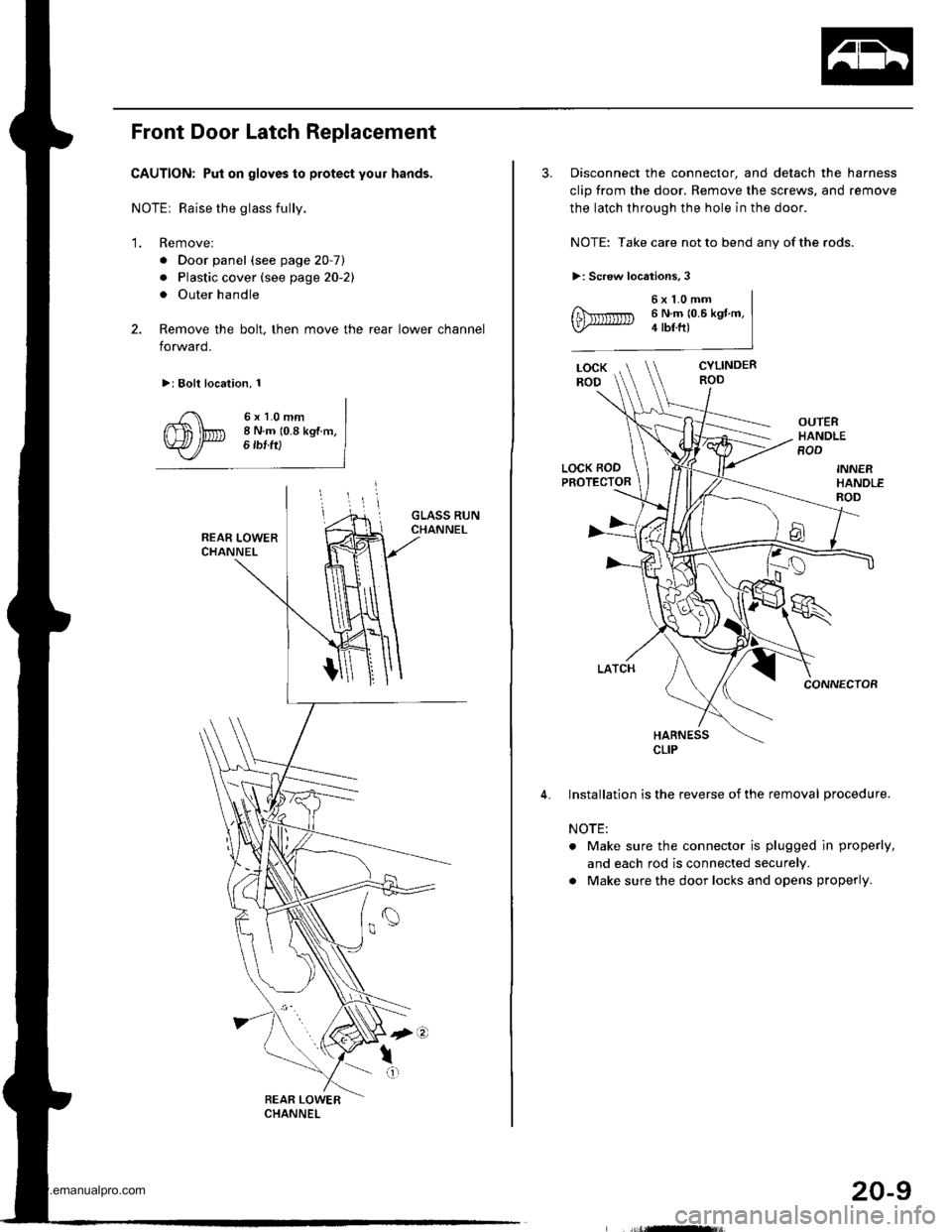

Front Door Latch Replacement

CAUTION: Put on gloves to protect your hands,

NOTEr Raise the glass fully.

'1. Remove:

. Door panel (see page 20-7)

. Plastic cover (see page 20-21

. Outer handle

2. Remove the bolt, then move the rear lower channel

forward.

>: Bolt location, 1

6xl.0mm8 N.m (0.8 kgf m,6 tbf ft)

3. Disconnect the connector, and detach the harness

clip from the door. Remove the screws, and remove

the latch through the hole in the door.

NOTE: Take care not to bend any of the rods.

>: Screw locations,3

6x1.0mm6 N.m 10.6 kgt m,4 tbf.ft)

CYLINDERROD

OUTERHANDLEROD

LOCK RODPROTECTOR

CONNECTOR

HARNESS

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is plugged in properly,

and each rod is connected securely.

a Make sure the door locks and opens properly.

CLIP

20-9

www.emanualpro.com

Page 1000 of 1395

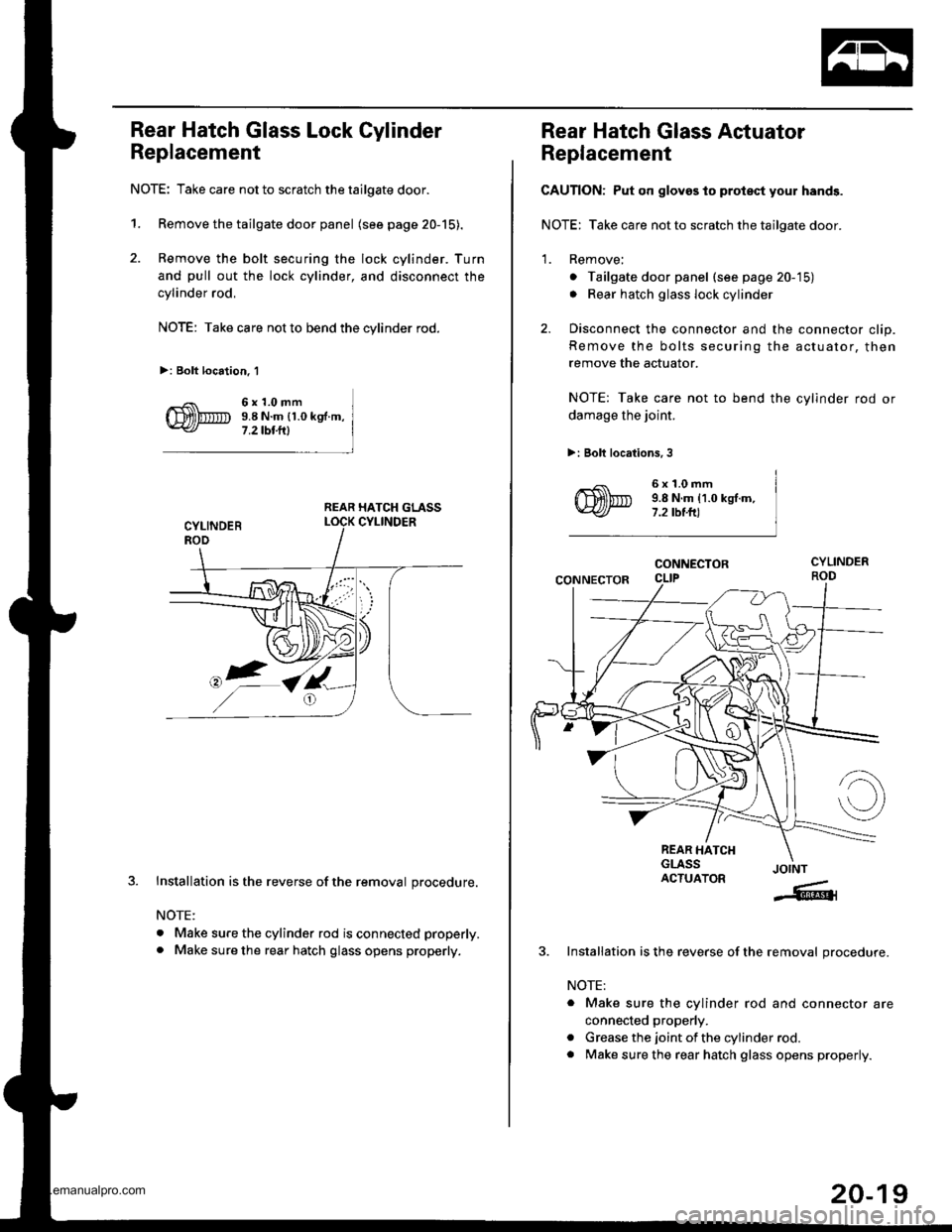

Rear Hatch Glass Lock Cylinder

Replacement

NOTE: Take care not to scratch the tailgate door.

1. Remove the tailgate door panel (see page 20-15).

2. Remove the bolt securing the lock cylinder. Turn

and pull out the lock cylinder, and disconnect the

cylinder rod,

NOTE: Take care not to bend the cylinder rod.

>: Bolt location. 1

6x1.0mm9.8 N.m {1.0 kg .m,

7 .2 tbt.lll

REAR HATCH GLASS

J.Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod is connected properly.

. Make sure the rear hatch glass opens properly.

Rear Hatch Glass Actuator

Replacement

CAUTION: Put on gloves to protsct your hands.

NOTE: Take care not to scratch the tailgate door.

1. Remove;

o Tailgate door panel (see page 20-'15)

. Rear hatch glass lock cylinder

2. Disconnect the connector and the connector clip.

Remove the bolts securing the actuator, then

remove the actuator.

NOTE: Take care not to bend the cylinder rod or

damage the joint.

>: Bolt locations, 3

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 tbt.ft)

CONNECTOR

CONNECTOR

REAR HATCHGLASSACTUATORJOINT

-6{

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod and connector are

connected properly.

. Grease the joint of the cylinder rod.

. Make sure the rear hatch glass opens properly.

20-19

www.emanualpro.com

Page 1214 of 1395

lgnition Switch

Test

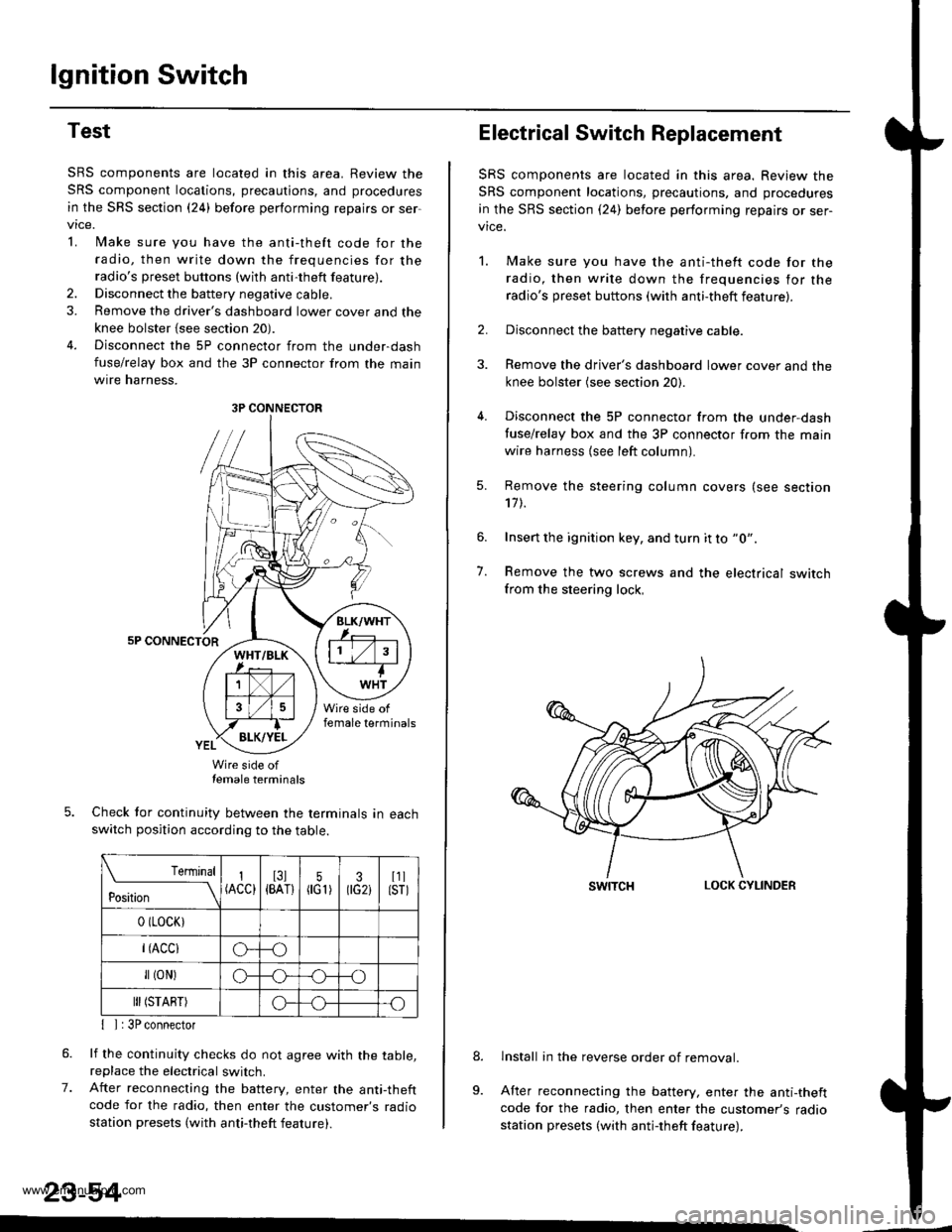

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser

vtce.

L lMake sure you have the anti-theft code for the

radio, then write down the frequencies for theradio's preset buttons (wilh anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster {see section 20).

4. Disconnect the 5P connector from the under-dash

fuse/relay box and the 3P connector from the main

wtre narness,

5P CONNECTOR

Wire side oftemale terminals

Check tor continuity between the terminals in eachswitch position according to the table.

rernrnal

ros[ron \

I(ACC)I3l{BAT}5flG1)30G2iI1llsrl

0 (LocK)

r(Acclo--o

fl (oN)G_o

III (START)o--.o

7.

{ I | 3P connector

lf the continuity checks do not agree with the table,replace the electrical switch.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radio

station presets (with anti-theft feature).

23-54

3P CONNECTOR

Electrical Switch Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24) before performing repairs or ser-vice.

1. Make sure you have the anti-thett code for the

radio, then write down the frequencies for the

radio's preset buttons (with anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

4. Disconnect the 5P connector from the under,dash

tuse/relay box and the 3P connector f.om the main

wire harness {see left column).

7.

Remove the steering column covers (see section'17 t.

Insert the ignition key, and turn it to "0".

Remove the two screws and the electrical switchfrom the steering lock,

swrTcHLOCK CYLINDER

lnstall in the reverse order of removal.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radiostation presets (with antj-theft feature).

9.

www.emanualpro.com

Page 1282 of 1395

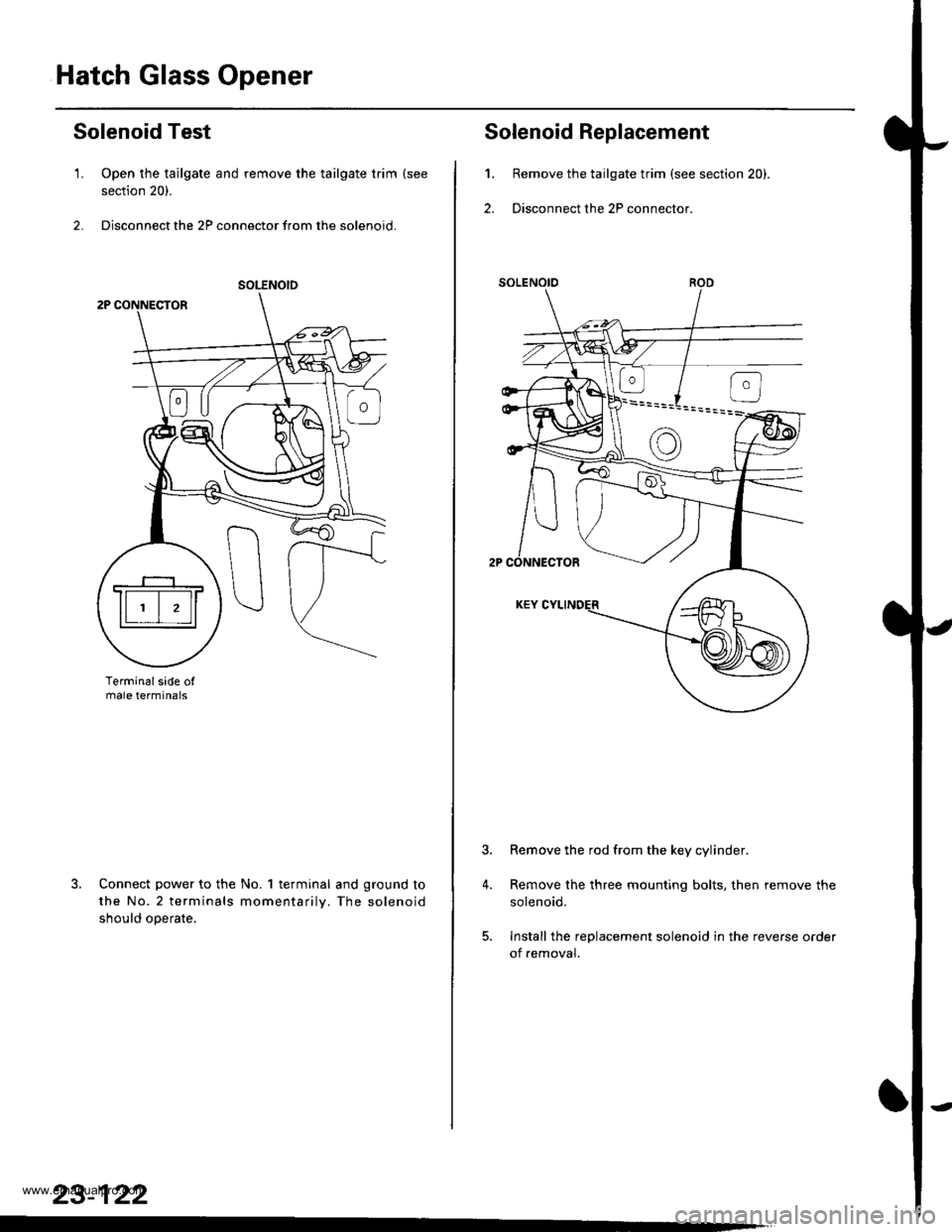

Hatch Glass Opener

Solenoid Test

1. Open the tailgate and remove the tailgate trim (see

section 20).

2. Disconnect the 2P connector from the solenoid.

Terminalsade ofmale termtnals

Connect power to the No. 1 terminal and ground to

the No.2 terminals momentarilv. The solenoid

should ooerate.

SOLENOID

23-122

't.

2.

4.

Solenoid Replacement

Remove the tailgate trim (see section 20).

Disconnect the 2P connector.

Remove the rod from the key cylinder.

Remove the three mounting bolts, then remove the

solenoid.

Install the replacement solenoid in the reverse oader

of removal.

www.emanualpro.com