torque HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 801 of 1395

Troubleshooting (Manual Transmissionl

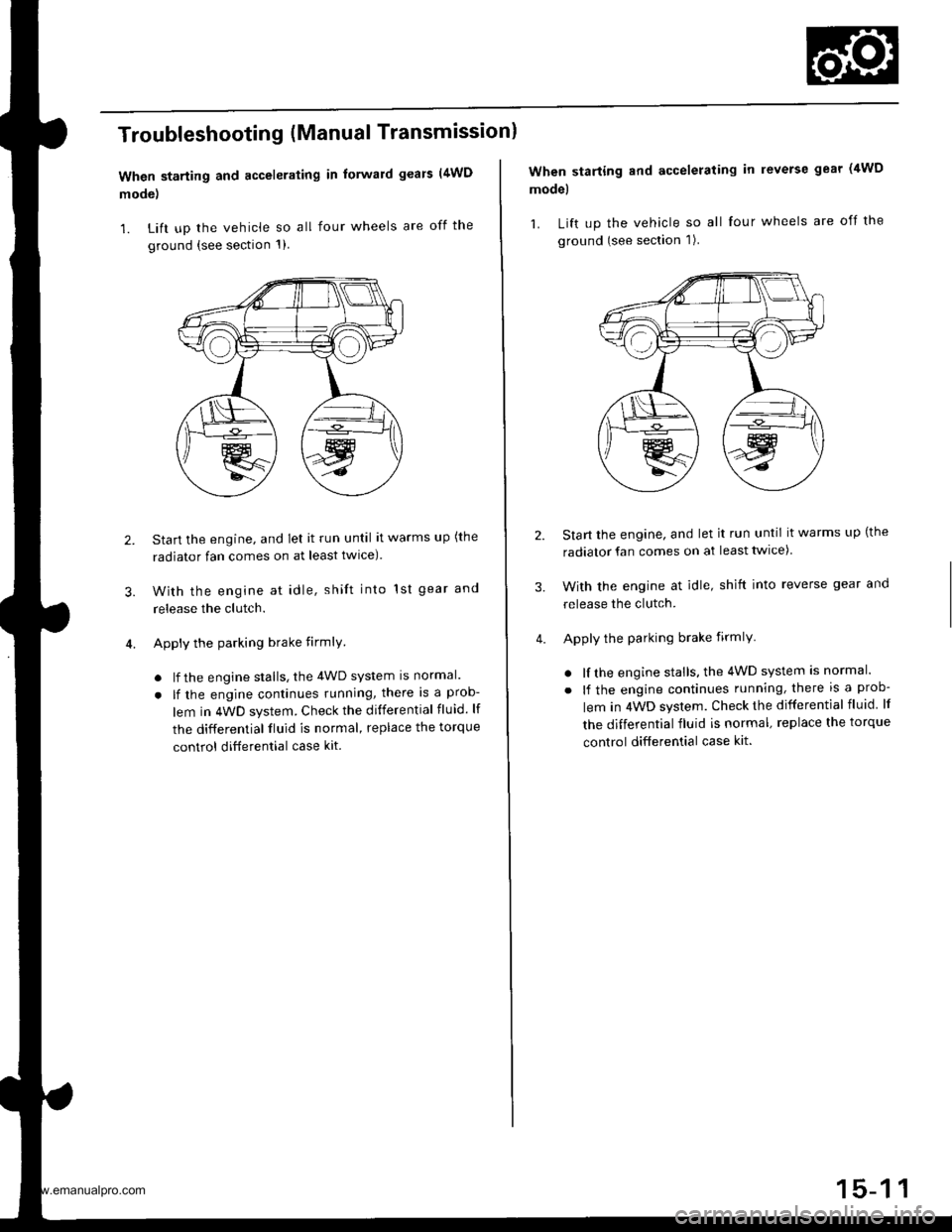

When starting and accelerating in forward gears (4WD

mode)

1. Lift up the vehicle so all four wheels are off the

ground {see section 1)

3.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twlce).

With the engine at idle, shift into 1st gear and

release the clutch.

Apply the parking brake firmlY

. lf the engine stalls, the 4WD system is normal.

. lf the engine continues running, there is a prob-

lem in 4WD system. Check the differential fluid. lf

the differential fluid is normal, replace the torque

control ditferential case kit.

2.

When starting and accelerating in reverse gear (4WD

model

1. Lift up the vehicle so all four wheels are off the

ground (see section 1).

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice)

With the engine at idle, shift into reverse gear and

release the clutch.

Apply the parking brake firmlY

. lf the engine stalls, the 4WD system is normal.

. lf the engine continues running, there is a prob-

lem in 4WD system. Check the differential fluid lf

the differential fluid is normal, replace the torque

control differential case kit.

3.

www.emanualpro.com

Page 802 of 1395

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmission/Manual Transmission)

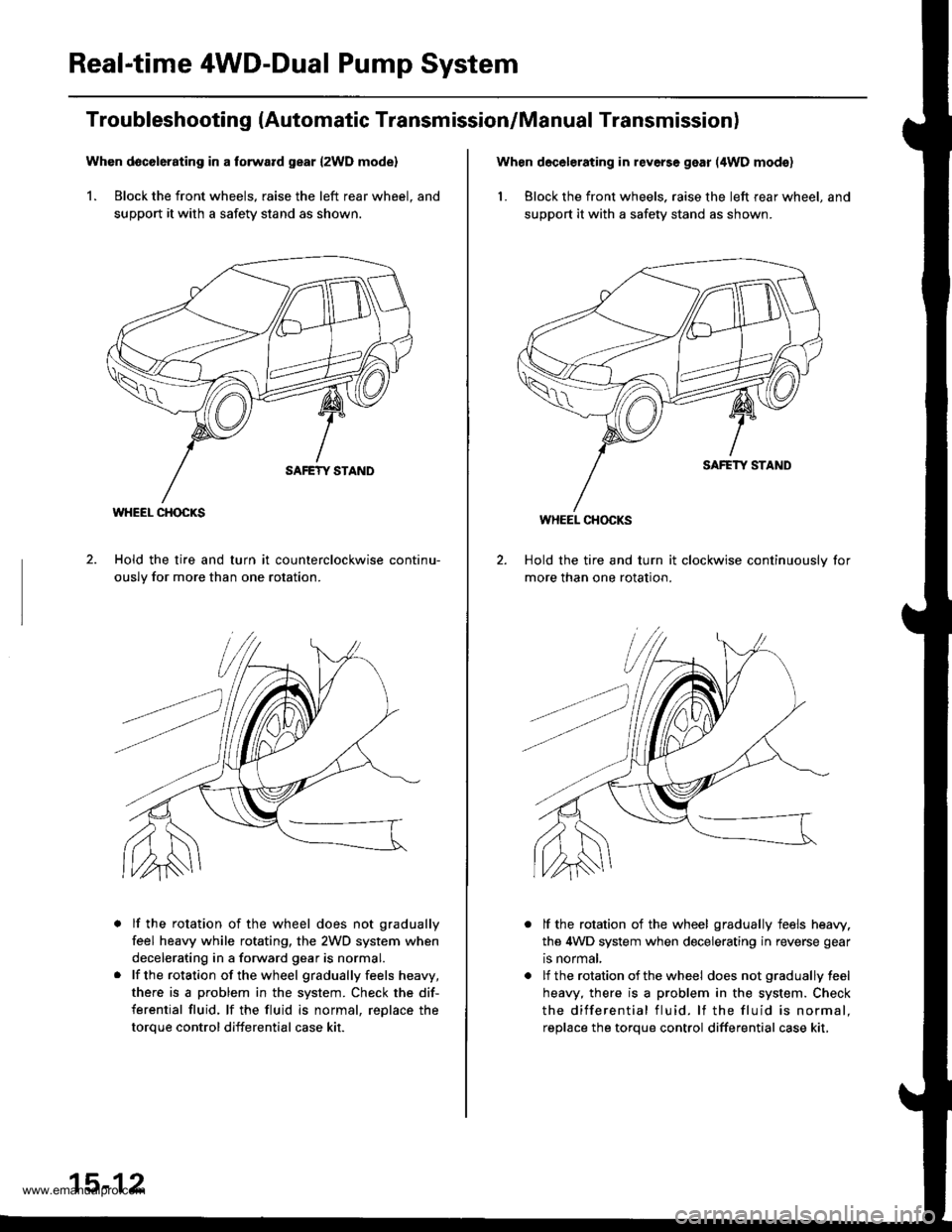

Whon d6c6l6rating in a torward gear {2WD mode}

1. Block the front wheels, raise the left rear wheel. and

support it with a safety stand as shown.

Hold the tire and turn it counterclockwise continu-

ouslv for more than one rotation.

lf the rotation of the wheel does not gradually

feel heavy while rotating, the 2WD system when

decelerating in a forward gear is normal.

lf the rotation of the wheel gradually feels heavy,

there is a problem in the system. Check the dif-

ferential fluid, lf the fluid is normal, reDlace the

toroue control differential case kit.

WHEEL CHOCKS

15-12

When decelerating in reverse gear (4WD mod€)

1. Block the front wheels. raise the left rear wheel, and

suppo( it with a safety stand as shown.

Hold the tire and turn it clockwise continuouslv for

more than one rotation.

lf the rotation of the wheel gradually feels heaw.

the 4WD system when decelerating in reverse gear

is normal,

lf the rotation of the wheel does not gradually feel

heavy, there is a problem in the system. Check

the differential fluid. lf the fluid is normal.

reolace the torque control differential case kit,

WHEEL CHOCKS

www.emanualpro.com

Page 803 of 1395

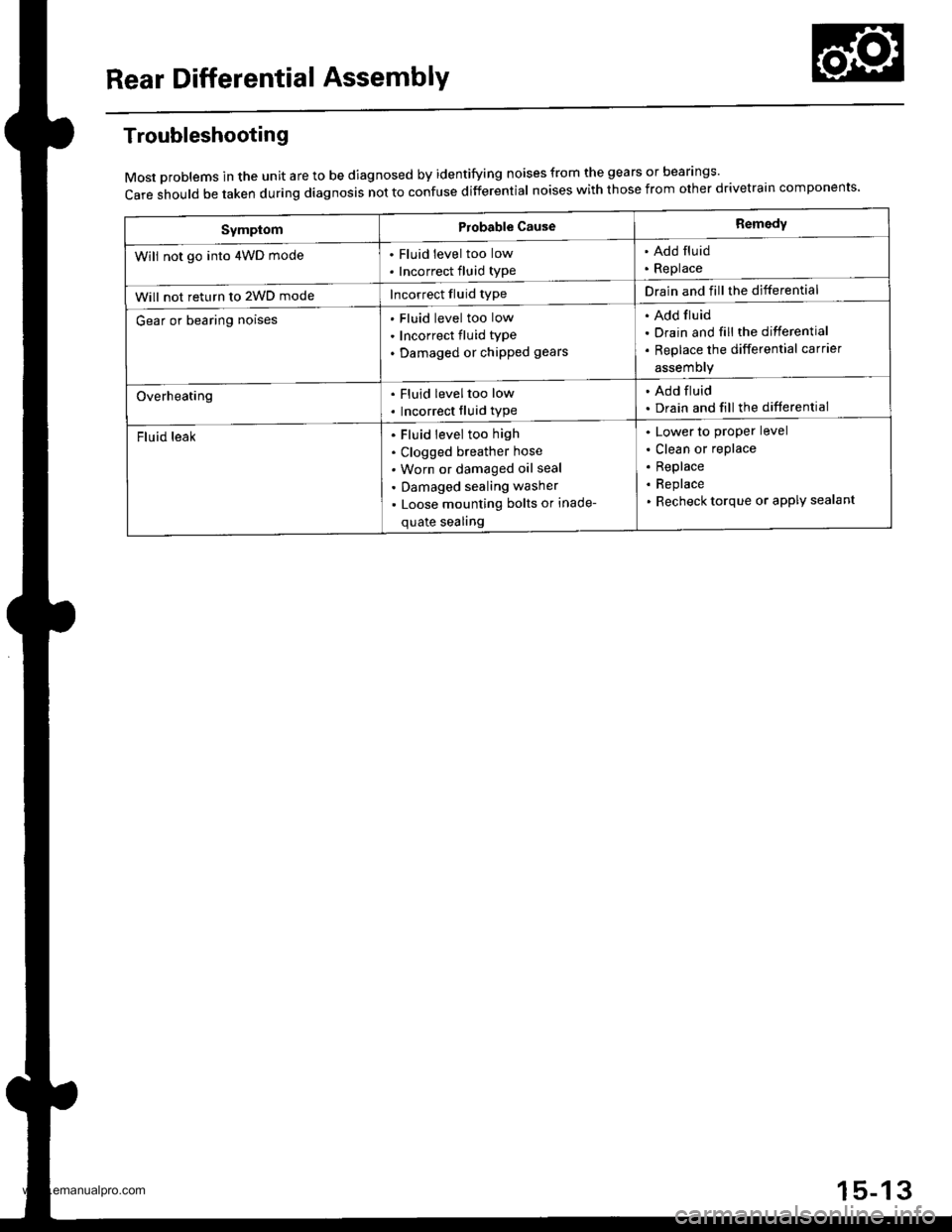

Rear Differential AssemblY

Troubleshooting

Most problems in the unit are to be diagnosed by identifying noises from the gears or bear'ngs'

care should be taken during diagnosis not to confuse differential noises with those from other drivetra'n components'

SymptomProbable CauseRemedy

Will not go into 4WD mode. Fluid level too low

. Incorrect fluid type

. Add fluid. Replace

Will not return to 2WD modeIncorrect fluid typeDrain and fill the differential

Gear or bearing noisesFluid level too low

Incorrect fluid type

Damaged or chipped gears

Add fluid

Drain and fill the differential

Replace the differential carrier

assemory

Overheating. Fluid leveltoo low

. Incorrect fluid type

. Add fluid. Drain and fill the differential

Fluid leakFluid level too high

Clogged breather hose

Worn or damaged oil seal

Damaged sealing washer

Loose mounting bolts or inade-

quate sealing

Lower to proper level

Clean or replace

Replace

Replace

Recheck torque or aPPIY sealant

15-13

www.emanualpro.com

Page 808 of 1395

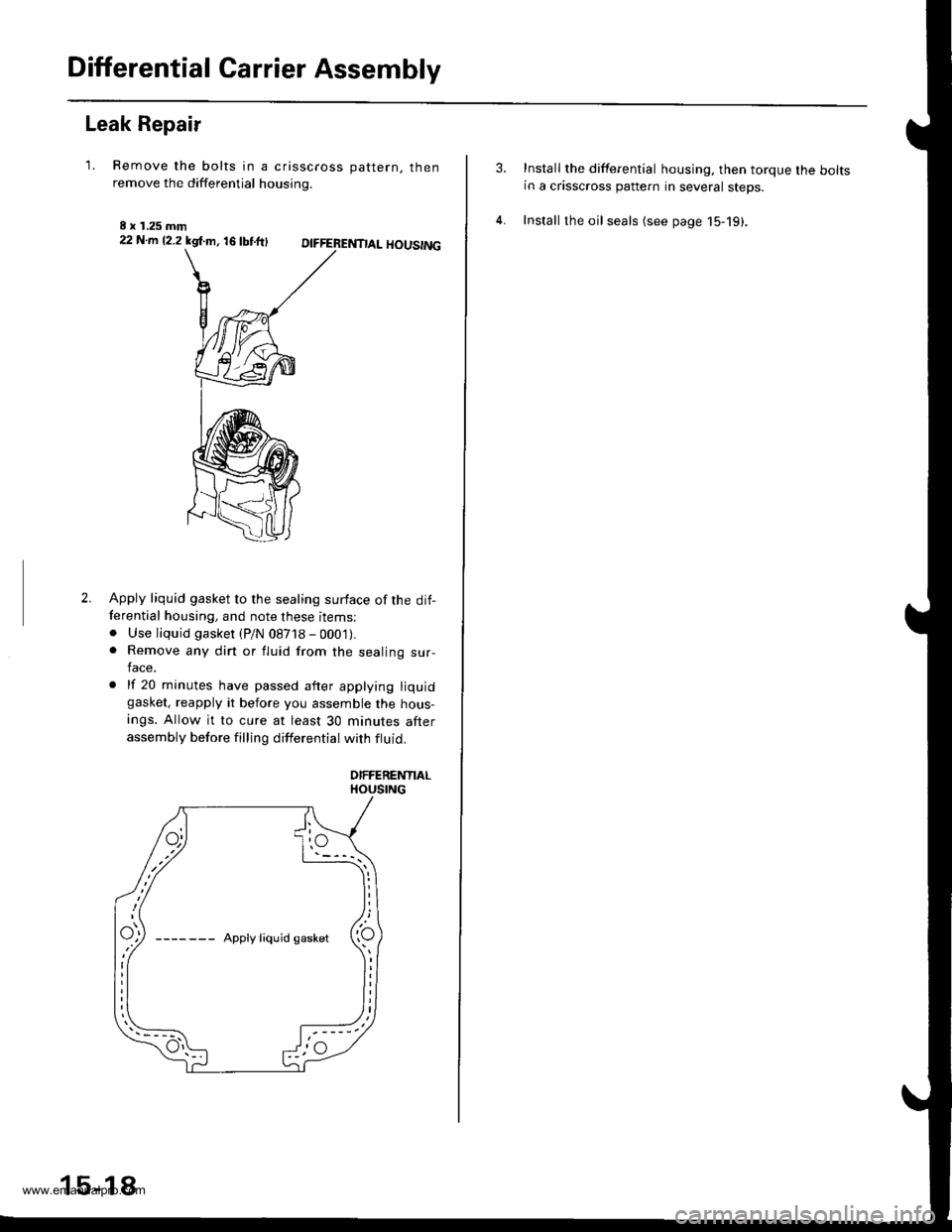

Differential Carrier Assembly

Leak Repair

'1. Remove the bolts in a crisscross oattern. thenremove the differential housing.

I x 1.25 mm22 N.m 12.2 kgl.m, 16 tbtftlDIFFERENTIAL HOUSING

2.Apply liquid gasket to the sealing surface of the dit-ferential housing, and note these items:. Use liquid gasket (P/N 08718 - 000'1).. Remove any dirt or fluid from the sealing sur-lace.

. lf 20 minutes have passed after applying liquidgasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes afterassembly before filling differential with ftuid.

DIFFERENTIALHOUSING

15-18

Install the differential housing. then torque the boltsin a crisscross pattern in several steps.

Install the oil seals (see page 15-19).

www.emanualpro.com

Page 811 of 1395

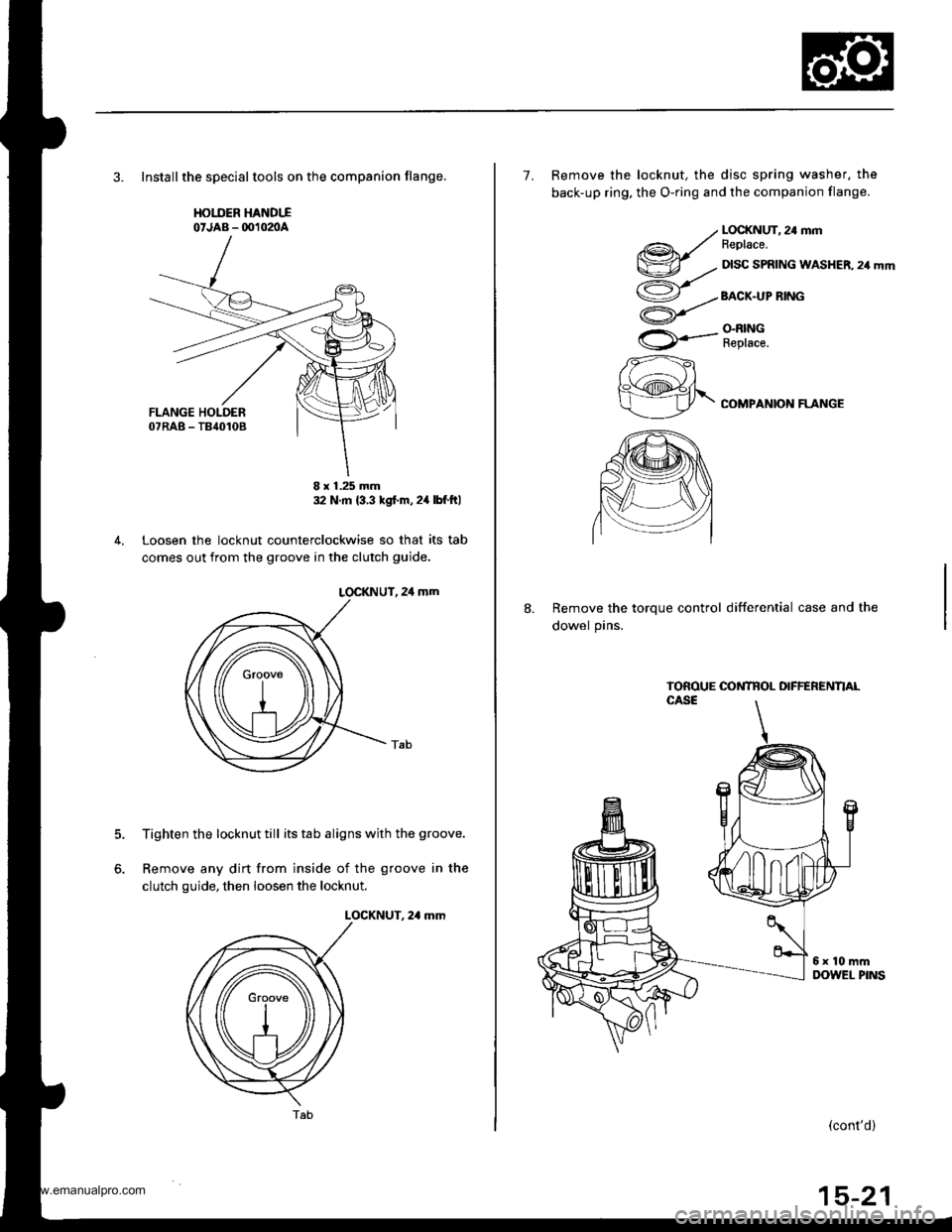

3. Installthe speclaltools on the companion flange,

HOIIIER HANDTIo'JAB - OO102nA

32 N m {3 3 tgt m,24lbf ftl

Loosen the locknut counterclockwise so that its tab

comes out from the groove in the clutch guide.

LOCKNUT, 24 mm

Tighten the locknut till its tab aligns with the groove.

Remove any dirt from inside of the groove in the

clutch guide, then loosen the locknut.

LOCKNUT. 2,1 mm

5.

6.

8 x 1.25 mm

Tab(cont'd)

7. Remove the locknut, the disc spring washer, the

back-up ring, the O-ring and the companion flange.

@r/v-.,.

ao/

U

rA*..-

zzft

h\@fr\

LOCKNUT, 24 mmFeplace.

DISC SPRING WASHER, 24 mm

BACX.UP RING

O.N|NGReplace.

COMPANION FLANGE

8.Remove the torque control differential case and the

dowel pins.

www.emanualpro.com

Page 814 of 1395

Rear Differential Assembly

Reassembly (cont'dl

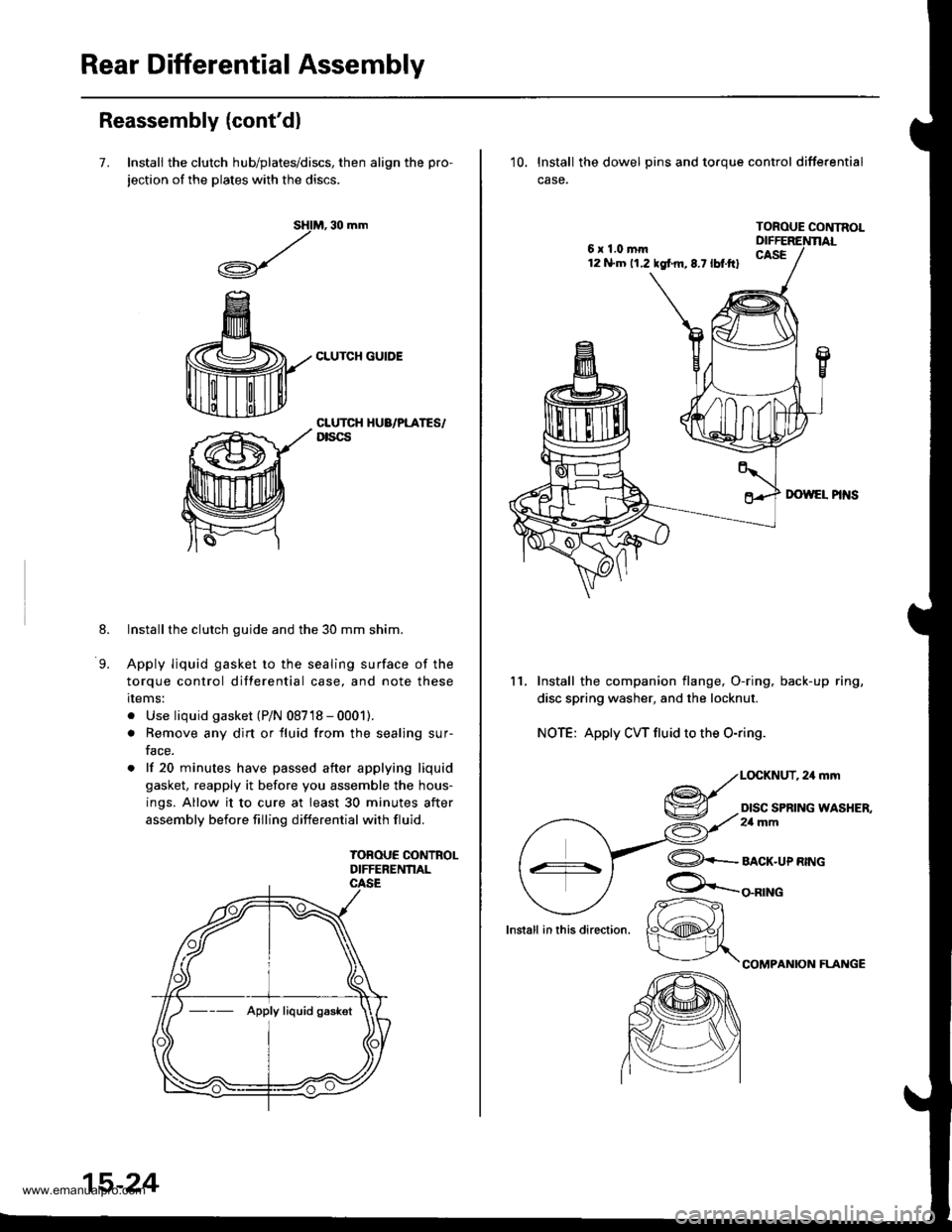

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 815 of 1395

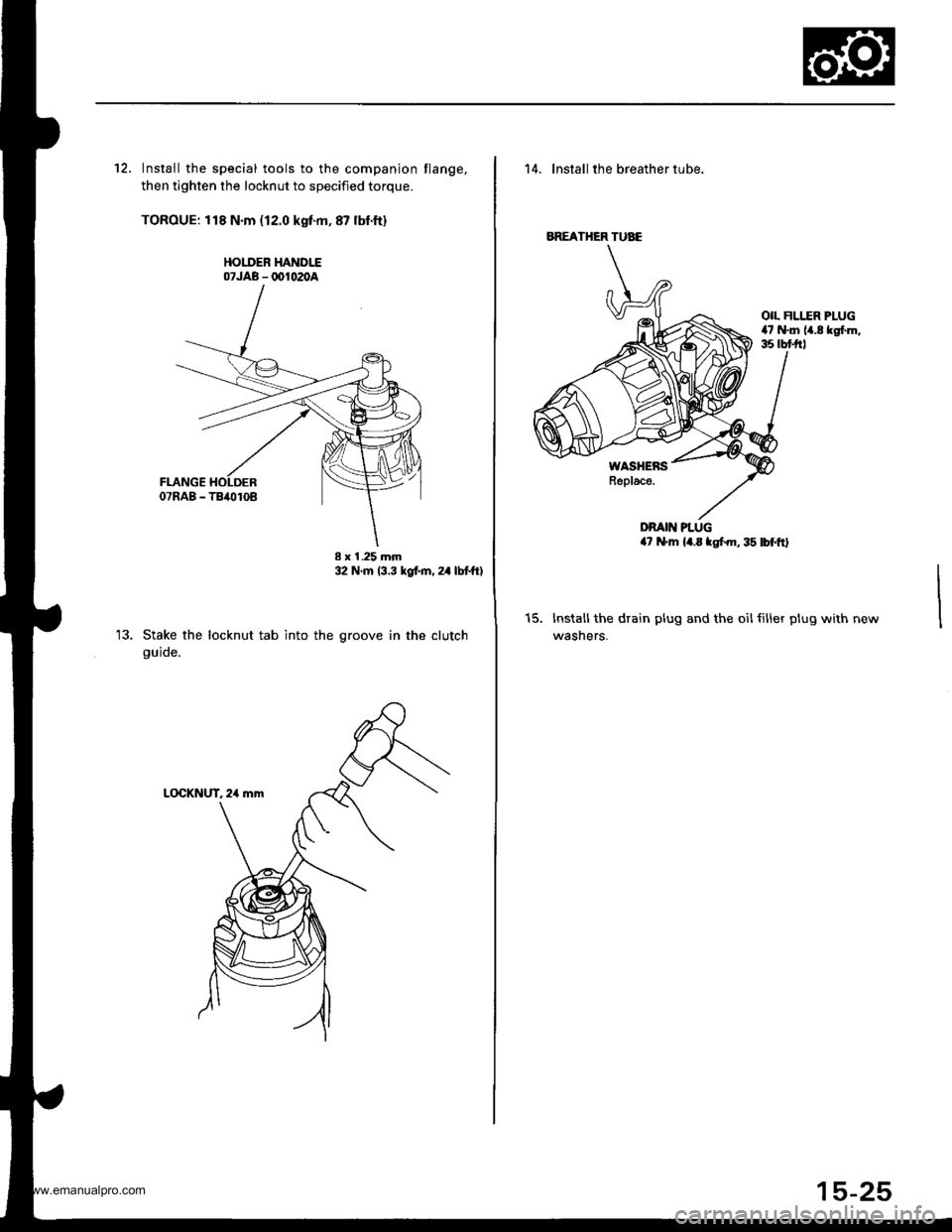

12. Install the special tools to the companion flange,

then tighten the locknut to specified torque.

TOROUE: 118 N.m (12.0 kgf-m,87 lbf'ft)

HOLDEB HANDLE07JAB - @1020A

Stake the locknut tab into the

guide.

I x I .25 mm32 N'm (3.3 kgt m, 24 lbtftl

groove in the clutch

14. lnstall the breather tube.

OIL FILI..ER PLUG47 N.m 14.8 kgf.m,35 tbt frl

WASHENSReplace.

DRAIN PLUG4? N'm l4.E tgf.m, 35 lbf'ftl

t5.Installthe drain plug and the oilfiller plug with

wasners.

BREATHER TUAE

www.emanualpro.com

Page 832 of 1395

Front Driveshafts

lnstallation

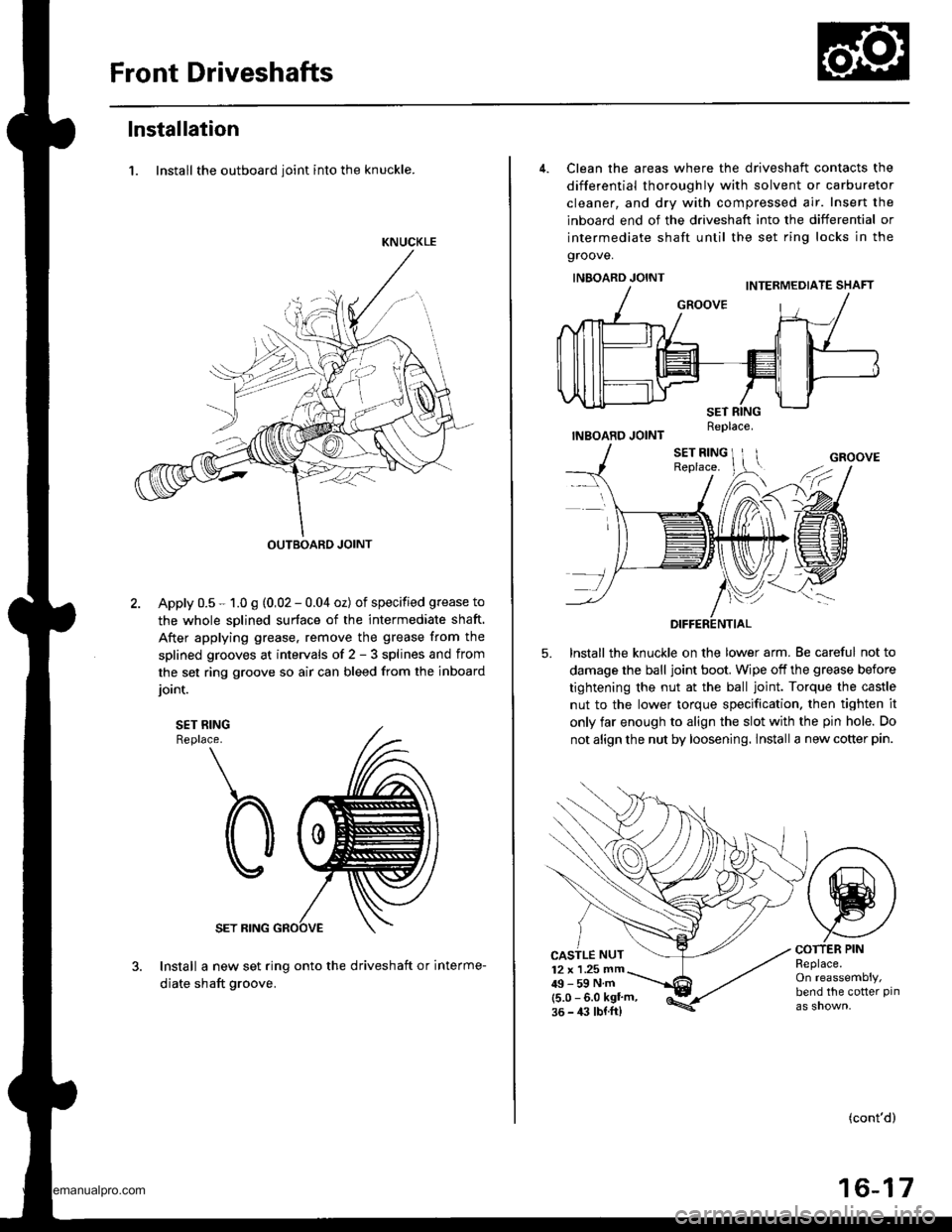

1. Install the outboard ioint into the knuckle.

KNUCKLE

OUTBOARD JOINT

Apply 0.5 - 1.0 g (0,02 - 0.04 oz) of specified grease to

the whole sDlined surface of the intermediate shaft.

After applying grease. remove the grease from the

splined grooves at intervals of 2 - 3 splines and from

the set ring groove so air can bleed from the inboard

ioint.

SET RINGReplace.

SET RING

Install a new set ring onto the driveshaft or interme-

diate shaft groove.

4. Clean the areas where the driveshaft contacts the

differential thoroughly with solvent or carburetor

cleaner, and dry with compressed air. Insert the

inboard end of the driveshaft into the differential or

intermediate shaft until the set ring locks in the

groove.

INBOARD JOINT

INBOARD JOINT

lnstall the knuckle on the lower arm. Be careful not to

damage the ball joint boot. Wipe off the grease before

tightening the nut at the ball joint. Torque the castle

nut to the lower torque specification. then tighten it

only far enough to align the slot with the pin hole. Do

not align the nut by loosening. lnstall a new cotter pin.

5.

CASTLE NUT12 x 1 .25 mm49-59Nm(5.0 - 6.0 kgl'm,36 - 4:l lbl.ft)

COTTER PINReplace.On reassembly,bend the cotter pin

(cont'd)

16-17

Replace.

www.emanualpro.com

Page 836 of 1395

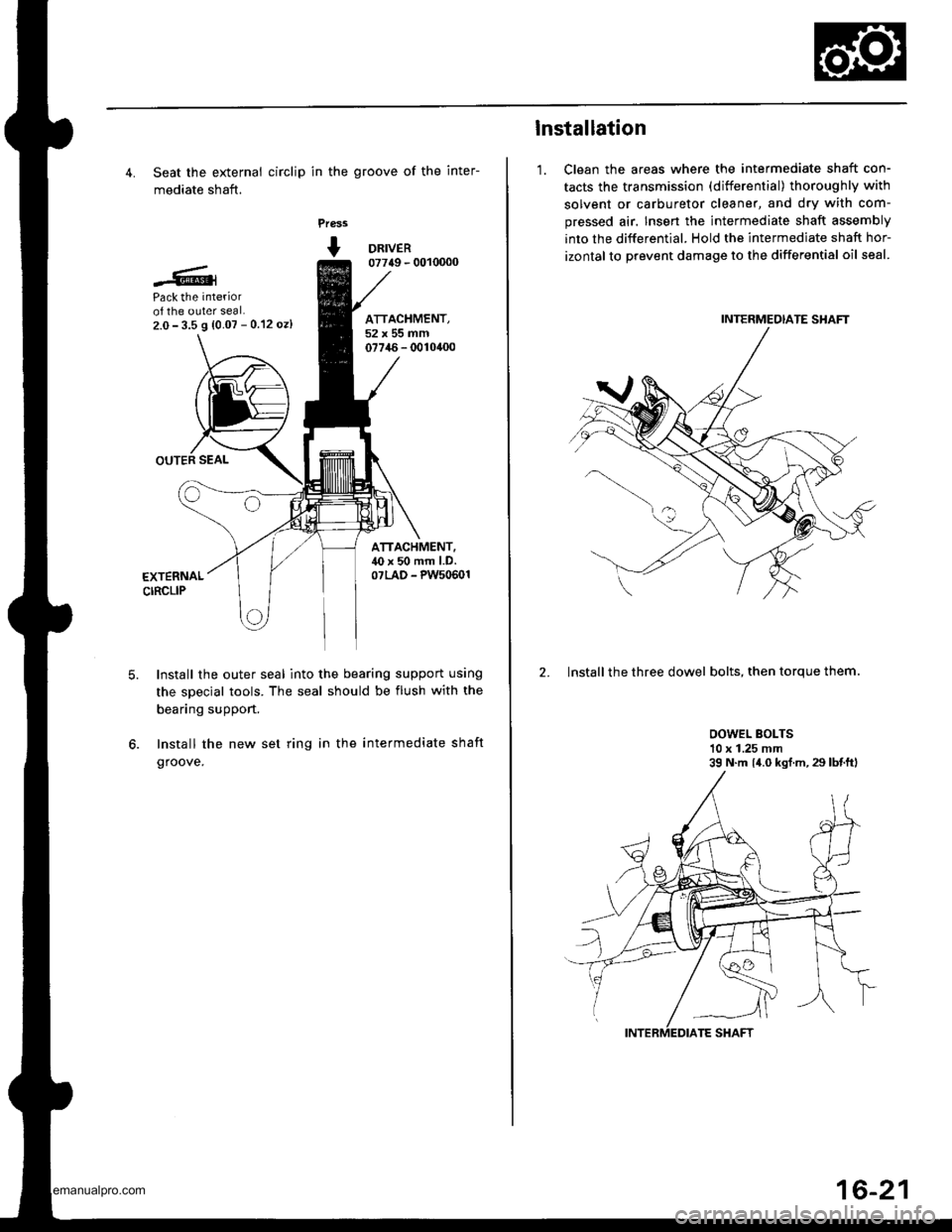

4. Seat the external circlip in the groove of the inter-

mediate shaft.

Press

+ DRNER07749 - 0010000

Pack the interiorof the outer seal.2.0- 3.5 9 {0.07 - 0.12 oz)

OUTER SEAL

ATTACHMENT,52x55mm07746- 0010400

ATTACHMENT.40 x 50 mm l.D.07LAD - PW50601EXTERNALCIRCLIP

6.

Install the outer seal into the bearing support using

the special tools. The seal should be flush with the

bearing support.

Install the new set ring in the intermediate shaft

groove.

lnstallation

1. Clean the areas where the intermediate shaft con-

tacts the transmission (differential) thoroughly with

solvent or carburetor cleaner, and dry with com-

pressed air. Insen the intermediate shaft assembly

into the differential. Hold the intermediate shaft hor-

izontal to prevent damage to the differential oil seal.

2. Install the three dowel bolts, then torque them.

OOWEL BOLTS10 x 1.25 mm39 N.m {4.0 kgf.m, 29 lbtftl

INTERMEOIATE SHAFT

16-21

www.emanualpro.com

Page 843 of 1395

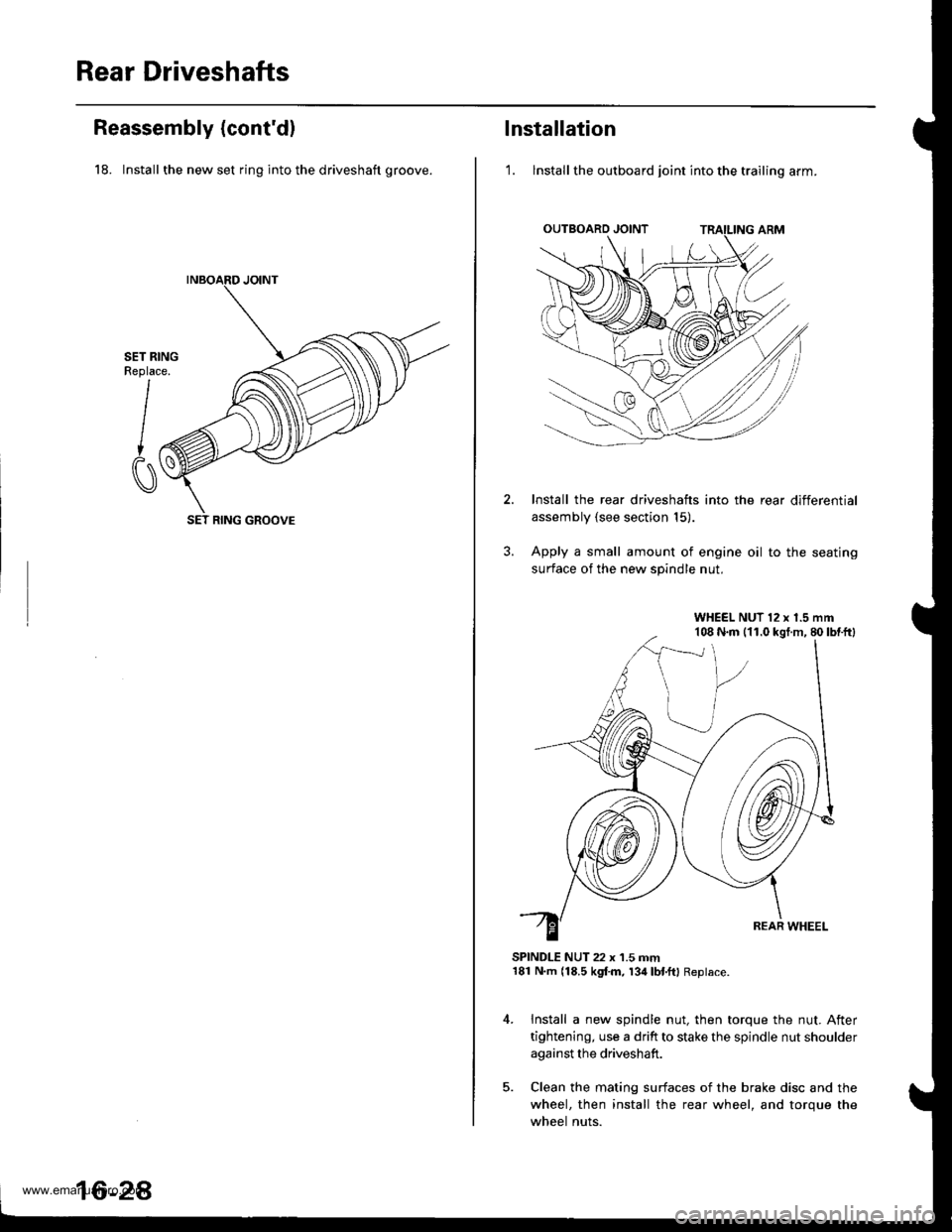

Rear Driveshafts

Reassembly (cont'd)

18. Install the new set ring into the driveshaft groove.

SET RINGReplace.

I

CI

SET RING GROOVE

16-2A

lnstallation

'1. lnstall the outboard joint into the trailing arm.

Install the rear driveshafts into the rear differential

assembly (see section 15).

Apply a small amount of engine oil to the seating

surface of the new spindle nut.

SPINDLE NUT 22 x 1.5 mm181 N.m (18.5 kgf.m, 134lbl.ftl Replace.

Install a new spindle nut, then torque the nut. After

tightening, use a drift to stake the spindle nut shoulder

against the driveshaft.

Clean the mating surfaces of the brake disc and the

wheel, then install the rear wheel, and torque the

wheel nuts.

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgt.m, 80lbtftl

www.emanualpro.com