Hose HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1160 of 1395

Gondenser

't.

Replacement

Recover the refrigerant with a recovery/recycling/

charging ststion (see page 22-59)

Remove the front grille (see section 20).

Remove the coolant reservoii, but do not discon-

nect the reservoir hose Jrom the coolant reservoir

and the radiator.

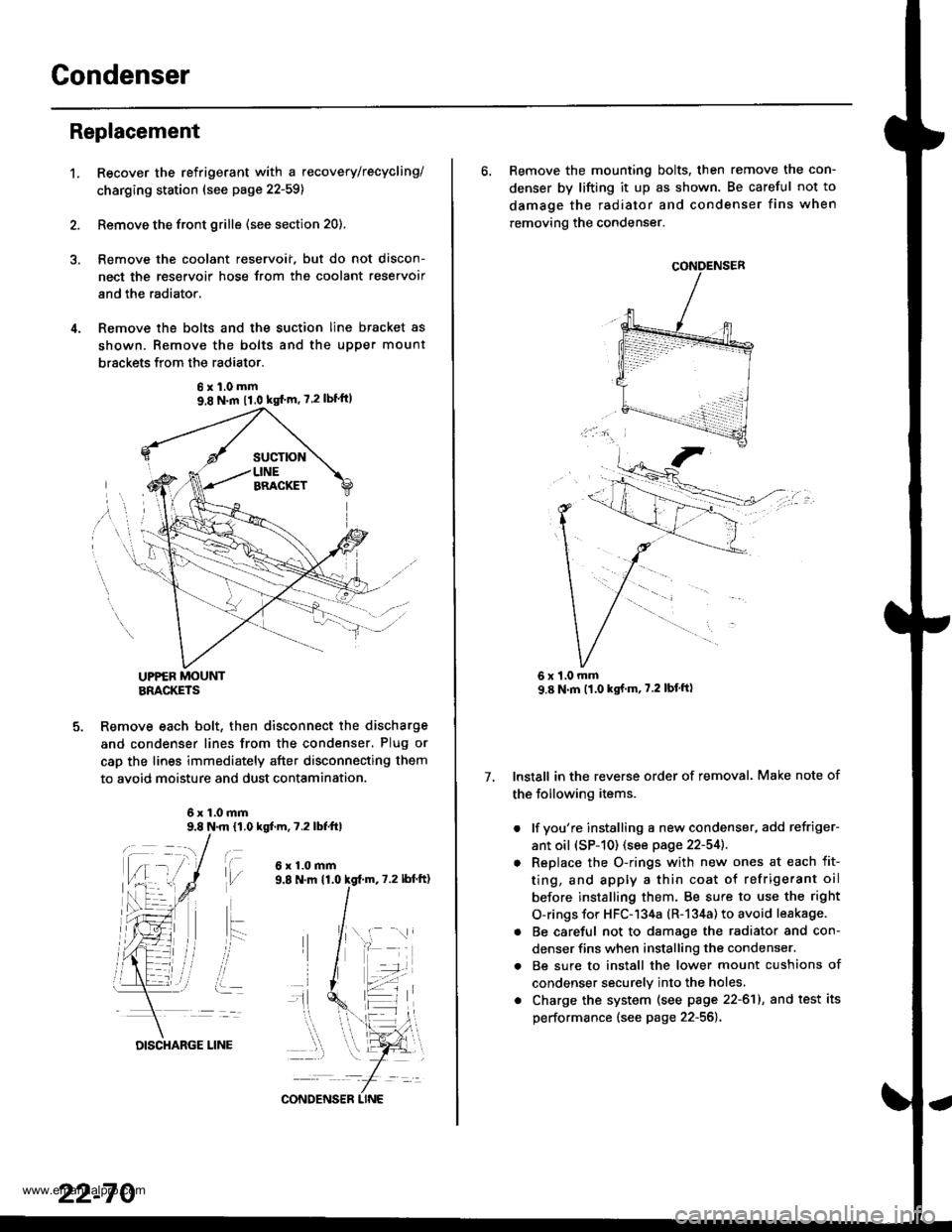

Remove the bolts and the suction line bracket as

shown. Remove the bolts and the upper mount

brsckets from the radiator.

UPPER MOUNTBRACKETS

Remove each bolt, then disconnect the discharge

and condenser lines from the condenser, Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contamination.

6x1.0mm9.8 N.m 11,0 kgf.m, 7.2 lbfttl

t\,l/

ait- -:

i..

6x1.0mm

6xl.0mm9,8 N.m 11.0 kgf'm' 7.2lbf'ft)

22-70

DISCHARGE LINE

CONDENS€R LINE

6. Remove the mounting bolts, then remove the con-

denser by lifting it up as shown. Be careful not to

damage the radiator and condenser fins when

removing the condenser.

Install in the reverse order of removal. Make note of

the following items.

. lf you're installing a new condenser, add refriger-

ant oil (sP-10) (see page 22-54]..

o Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Be careful not to damage the radiator and con-

denser fins when installing the condenser.

. Be sure to install the lower mount cushions of

condenser securely into the holes,

. Charge the system (see page 22-61), and test its

performance (see page 22-56).

7.

1,0 mm

www.emanualpro.com

Page 1164 of 1395

Troubleshooting

Tips and Precautions (cont'dl

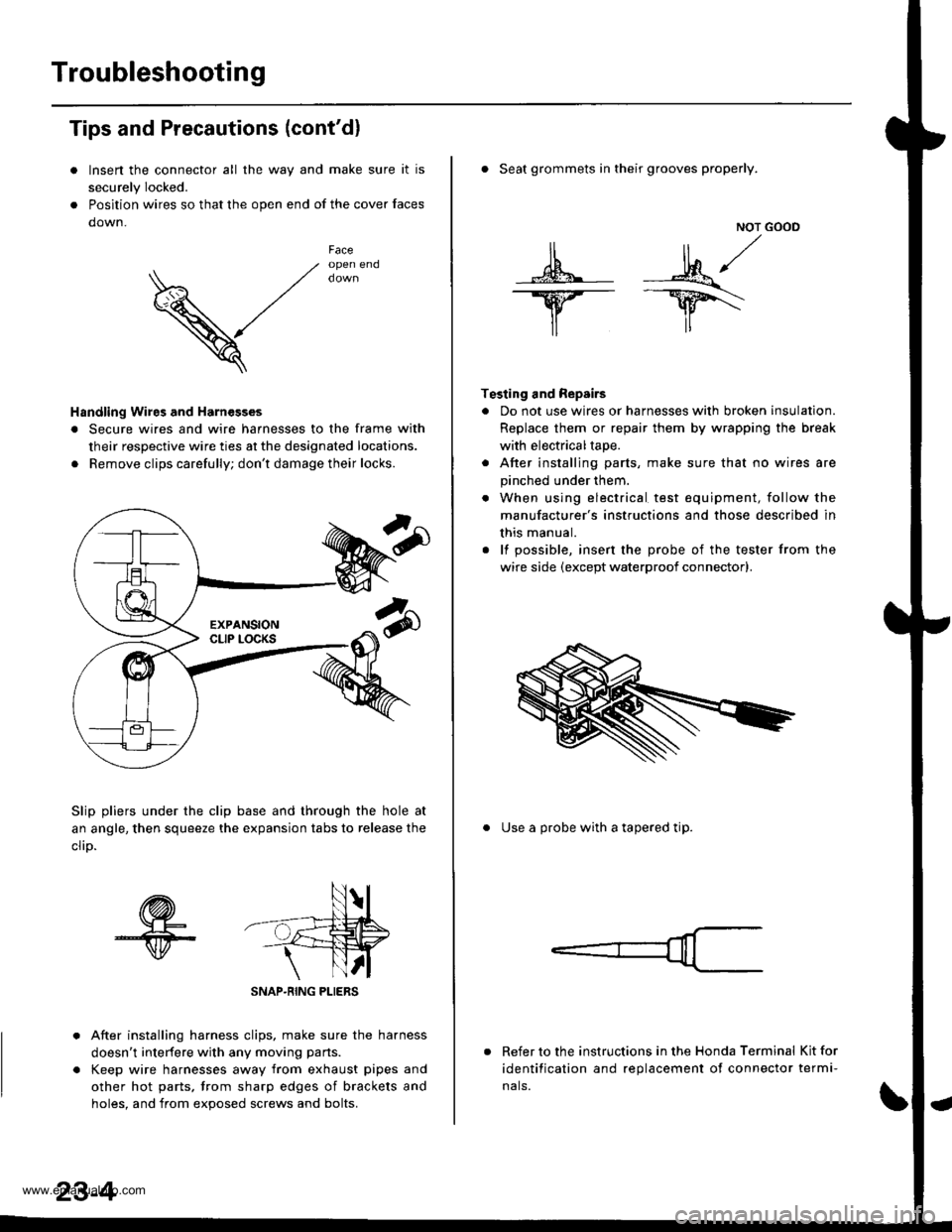

Insen the connector all the way and make sure it is

securely Iocked.

Position wires so that the open end of the cover faces

down.

V

Faceopen end

Handling Wires and Harnesges

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations.

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrD.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts, trom sharp edges of brackets and

holes. and from exoos€d screws and bolts.

NOT GOOD

A -M/

lr lr*

T€sting and Repairs

. Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrapping the break

with electricaltape.

. After installing parts, make sure that no wires are

pinched under them.

. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nals.

www.emanualpro.com

Page 1280 of 1395

Wipers/Washers

1.

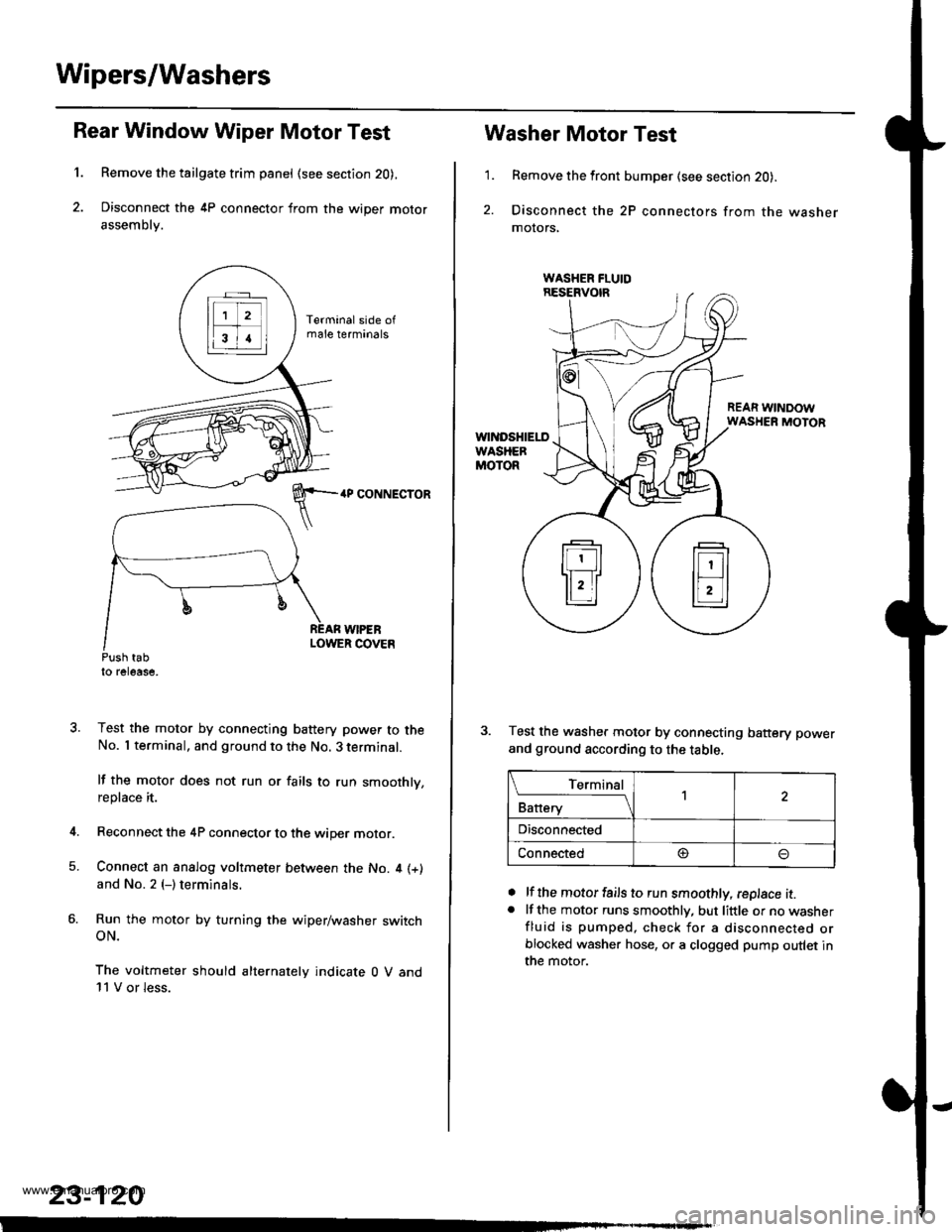

Rear Window Wiper Motor Test

Remove the tailgate trim panel (see section 20),

Disconnect the 4P connector from the wiper motor

assembly.

4P CONNECTOR

WIPEBLOWER COVEnPush tabto release,

Test the motor by connecting battery power to theNo. I terminal, and ground to the No. 3 terminal.

lf the motor does not run or fails to run smoothly,replace it.

Reconnect the 4P connector to the wiper motor.

Connect an analog voltmeter between the No. 4 (+)

and No. 2 (-) terminals.

Run the motor by turning the wiper/washer switchoN.

The voltmeter should alternately indicate 0 V and11 V or less.

4.

5.

23-120

1.

Washer Motor Test

Remove the front bumper (see section 20).

Disconnect the 2P connectors from the washermolors,

REAR WINDOWWASHER MOTOR

Test the washer motor by connecting battery power

and ground according to the table.

lf the motor fails to run smoothly, replace it.lf the motor runs smoothly, but little or no washerfluid is pumped, check for a disconnected orblocked washer hose, or a clogged pump outlet inthe motor.

a

a

L_Iq'.r91

Battery

,l

Disconnected

Connected@

www.emanualpro.com

Page 1291 of 1395

Transmitter Programming

Storing transmitter codes:

The codes of up to three transmitters can be read into

the kevless receiver unit memory (lf a fourth code is

stored. the code which was inDUt first will be erased.)

NOTE: lt is important to maintain the time limits

between the steps.

1.

11.

Turn the ignition switch ON (ll).

Within 1 to 4 sec., push the transmitter lock or unlock

button with the transmitter aimed at the vehicle.

Within 1 to 4 sec., turn the ignition switch OFF.

Within 1 to 4 sec., turn the ignition switch ON (ll).

Within 1 to 4 sec.. push the transmitter lock or

unlock button with the transmitter aimed at the

vehicle.

Within 1 to 4 sec., turn the ignition switch OFF.

Within 4 sec., turn the ignition switch ON {ll).

Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the

vehicle.

Within 1 to 4 sec., turn the ignition switch OFF,

Within 4 sec., turn the ignition switch ON (ll).

Within 1 to 4 sec., push the transmitter lock of

unlock button with the transmitter aimed at the

vehicle.

Confirm you can hear the sound of the door lock

aduators.

Within 8 sec., aim the transmitters (up to three)

whose codes you want to store at the receiver, and

press the transmitter lock or unlock buttons.

Confirm that you can hear the sound of the door

lock actuators after each transmitter code is stored.

Turn the ignition switch OFF, and pull out the key.

Confirm proper operation with the new code{sl.

-

o.

1.

9.

10.

12.

13.

14.

-

15.

23-131

www.emanualpro.com

Page 1394 of 1395

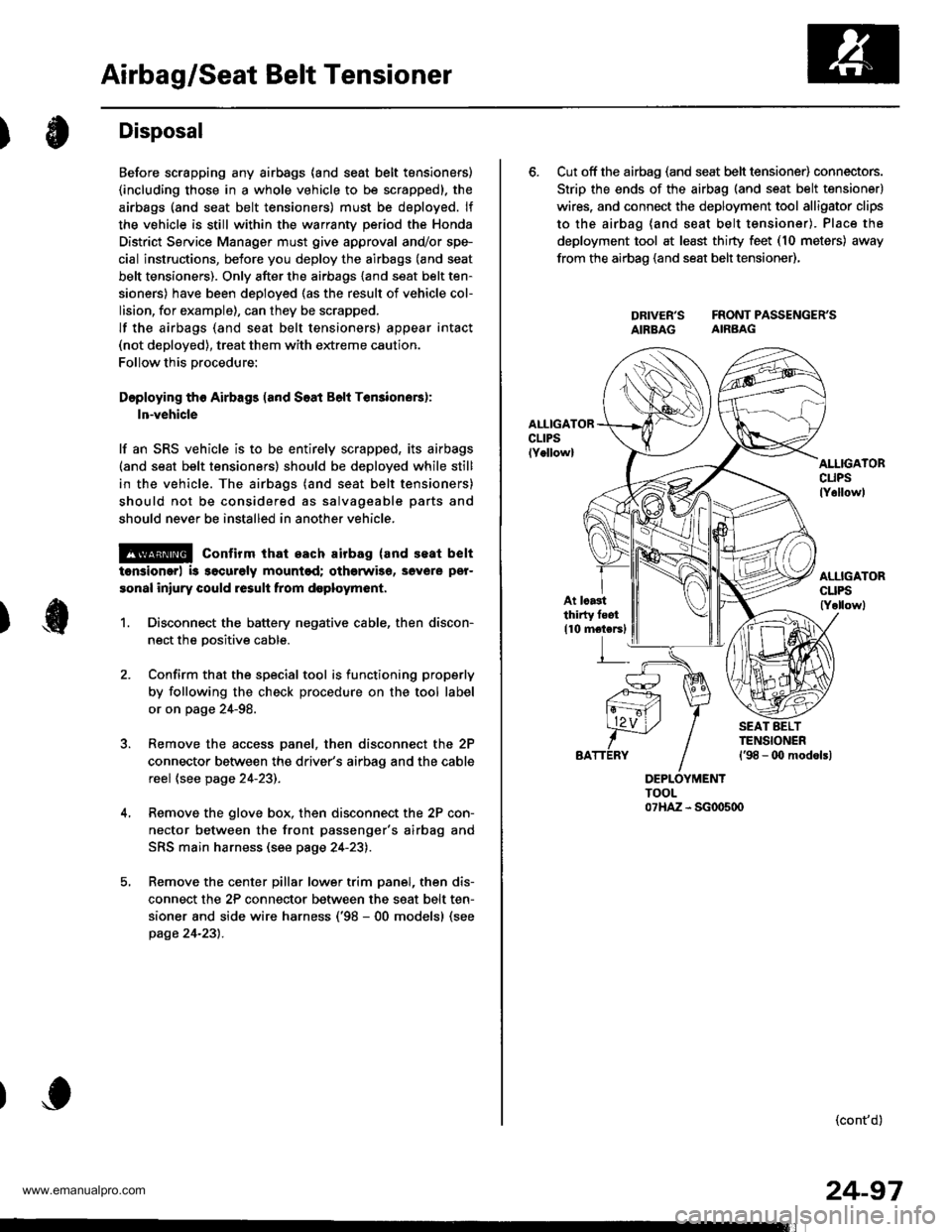

Airbag/Seat Belt Tensioner

)Disposal

)

Before scrapping any airbags {and seat belt tansioners)

(including those in a whole vehicle to be scrappedl. the

airbags (and seat belt tensioners) must be deployed. lf

the vehicle is still within the warrantv oeriod the Honda

District Service Manager must give approval and/or spe-

cial instructions, before you deploy the airbags (and seat

belt tensioners). Only after the airbags {and seat belt ten-

sioners) have been deployed (as the result of vehicle col-

lision, for example), can they be scrapped.

lf the airbags (and seat belt tensioners) appear intact

(not deployed), treat them with extreme caution.

Follow this procedure:

Doploying tho Airbags (and Soat B6li Ten3ione6):

ln-vehicle

lf an SRS vehicle is to be entirely scrapped, its airbags(and seat belt tensioners) should be deployed while still

in the vehicle. The airbags (and seat belt tensioners)

should not be considered as salvageable parts and

should never be installed in another vehicle.

@ confirm that each airbag {and seat belt

tonsiongr) i3 ggcurely mountod; othgrwise, severe per-

sonal iniury could result from d6ploym6nt,

1. Disconnect the battery negative cable, then discon-

nect the oositive cable.

Confirm that the special tool is functioning properly

by following the check procedure on the tool label

or on page 24-98.

Remove the access panel, then disconnect the 2P

connector between the driver's airbag and the cable

reel (see page 24-23).

Remove the glove box, then disconnect the 2P con-

nector between the front passenger's airbag and

SRS main harness (see page 24-23).

Remove the center pillar lower trim panel, then dis-

connect the 2P connector between the seat belt ten-

sioner and side wire harness ('98 - 00 models) (see

page 24-231.

6. Cut off the airbag (and seat belt tensioner) connectors.

Strip the ends of the airbag (and seat belt tensioner)

wires. and connect the deployment tool alligator clips

to the airbag (and seat belt tensioner). Place the

deployment tool at least thirty feet (10 meters) away

from the airbao (and seat belt tensioner),

DRIVER'S FRONTPASSENGER'SAIBBAG AIRBAG

AI.IIGATORcuPslY6llowl

At lcastthirty feot

110 motersl

(cont'd)

24-97

www.emanualpro.com