Light HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 939 of 1395

6.

7.

8.

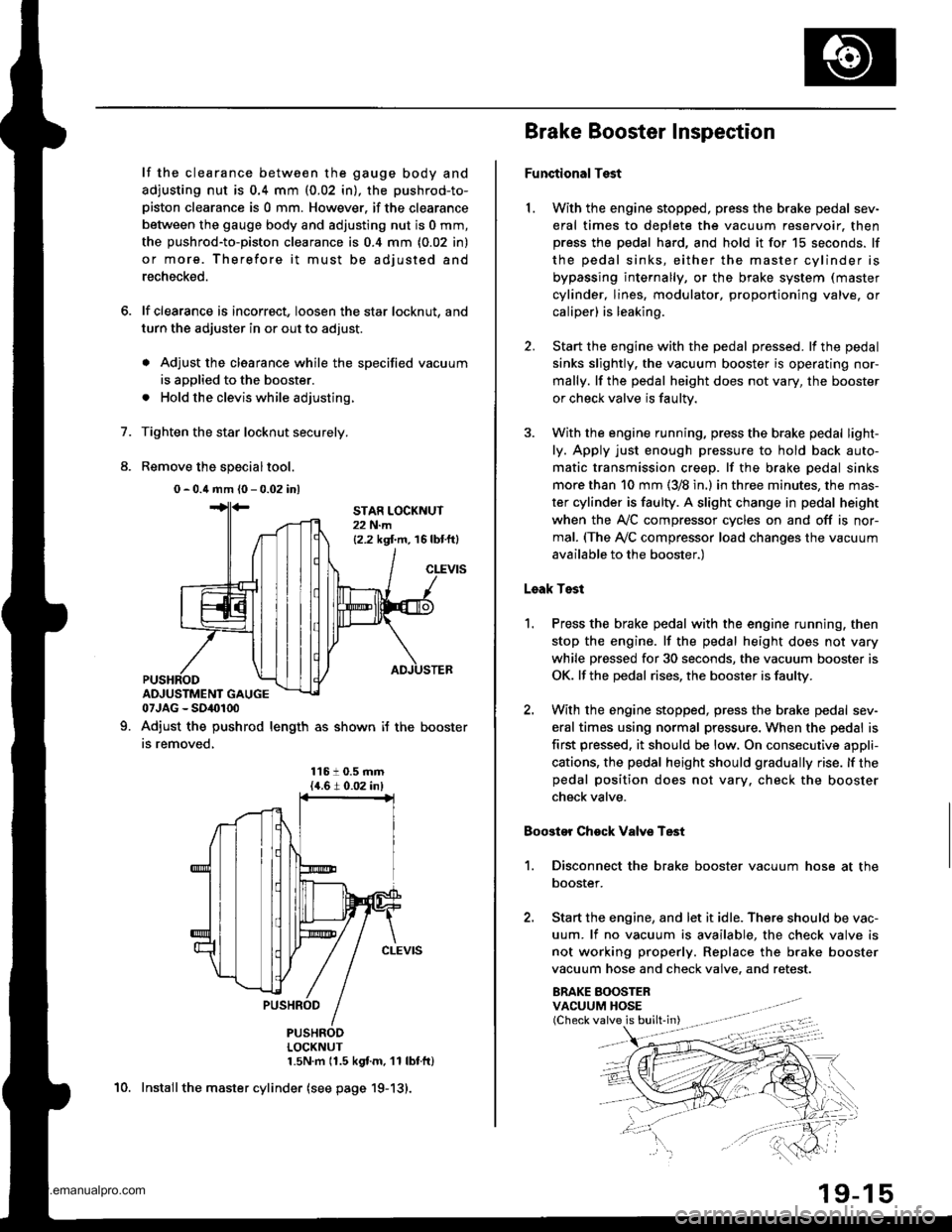

lf the clearance between the gauge body and

adjusting nut is 0.4 mm (0.02 in), the pushrod-to-

piston clearance is 0 mm. However. if the clearance

between the gauge body and adjusting nut is 0 mm,

the pushrod-to-piston clearance is 0.4 mm (0.02 in)

or more. Therefore it must be adjusted and

recheck€d.

lf clearance is incorrect, loosen the star locknut, and

turn the adjuster in or out to adjust.

. Adjust the clearance while the specified vacuum

is applied to the booster.

. Hold the clevis while adjusting.

Tighten the star locknut securely.

Remove the special tool.

0 - 0.4 mm (0 - 0.02 inl

Adjust the pushrod length as shown if the

is removed,

booster

11610.5 mm{4.6 t 0.02 inl

PUSHRODLOCKNUT1.5N.m 11.5 kgf.m. '11 lbtfl)

Install the master cylinder (see page 19-13).

9.

STAR LOCKNUT22 N.m12.2 kgt m. 16 lbtftl

10.

(Check valve is built-in)

Brake Booster Inspection

FunctionalTest

1. With the engine stopped, press the brake pedal sev-

eral times to deplete the vacuum reservoir. thenpress the pedal hard, and hold it for 15 seconds. lf

the pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines, modulator, proportioning valve. or

caliper) is leaking.

2. Start the engine with the pedal pressed. lf the pedal

sinks slightly. the vacuum booster is operating nor-

mally. lf the pedal height does not vary, the booster

or check valve is faultv.

3. With the engine running, press the brake pedal light-

ly. Apply just enough pressure to hold back auto-

matic transmission creep. lf the brake pedal sinks

more than 10 mm (3/8 in.) in three minutes, the mas-

ter cylinder is faulty. A slight change in pedal height

when the Ay'C compressor cycles on and off is nor-

mal. (The Ay'C compressor load changes the vacuum

available to the booster.)

Leak Test

1.Press the brake pedal with the engine running, then

stop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum booster is

OK. lf the pedal rises, the booster is faulty.

With the engine stopped, press the brake pedal sev-

eral times using normal pressure. When the pedal is

first pressed. it should be low, On consecutive appli-

cations, the pedal height should gradually rise. lf thepedal position does not vary. check the booster

check valve.

Boostor Chock Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Start the engine, and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve. and retest.

ERAKE BOOSTERVACUUM HOSE

www.emanualpro.com

Page 940 of 1395

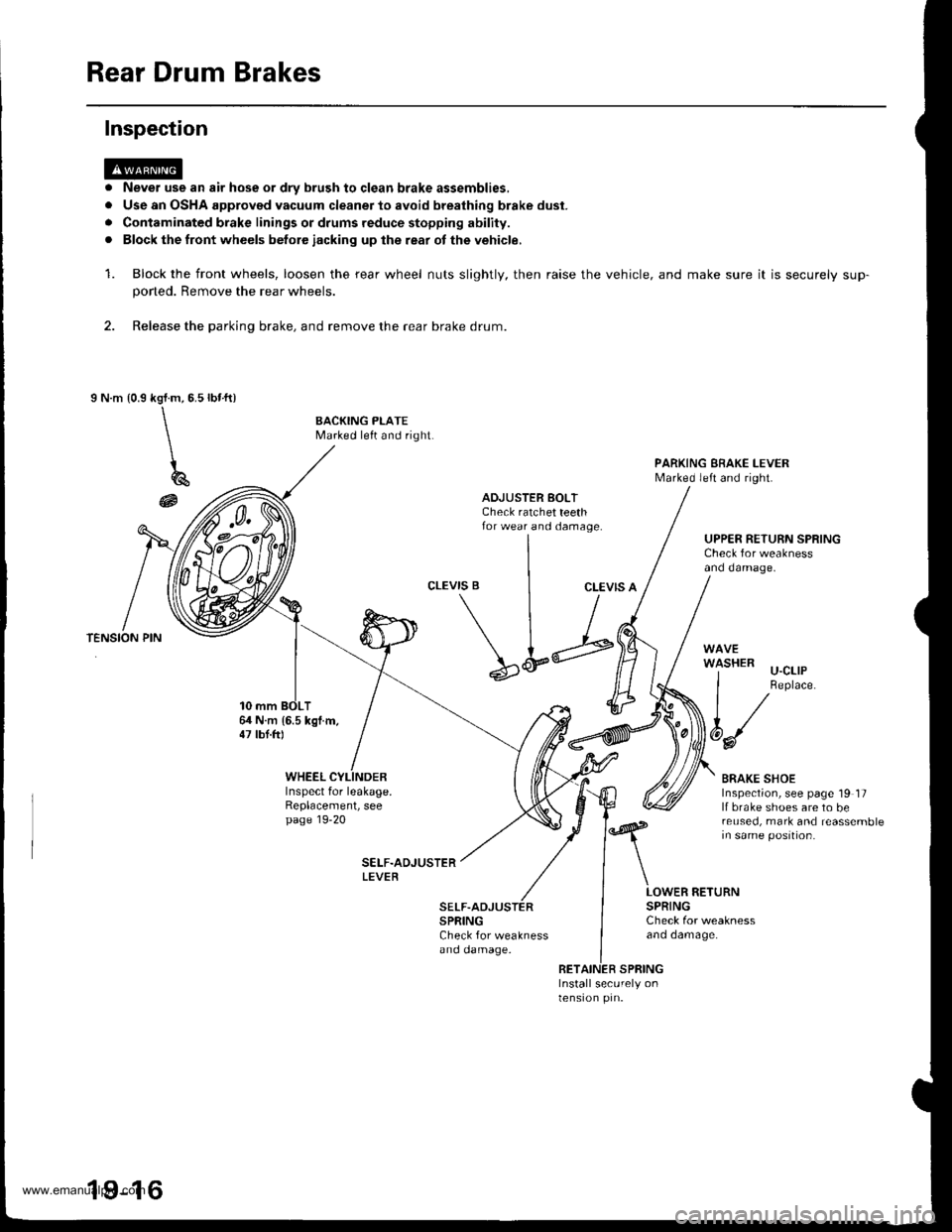

Rear Drum Brakes

Never use an air hose or dry brush to clgan brake assemblies,

Use an OSHA approved vacuum cleaner to avoid breathing brake dust.

Contaminated brake linings or drums reduce stopping ability.

Block the front wheels betore iacking up lhe rear ot the vehicle,

Block the front wheels, loosen the rear wheel nuts slightly, then raise the

poned. Remove the rear wheels.

2. Release the parking brake, and remove the rear brake drum.

I N.m {0.9rbr.ft)kgl.m,5.5

\\

\

196

@

Inspection

a

a

rl

a

1.vehicle, and make sure it is securely sup-

BACKING PLATEMarked left and right.

PARKING EBAKE I-EVERMarked left and right.

ADJUSTER BOLTCheck ratchet teethfor wear and damage.UPPER RETURN SPRINGCheck for weaknessand damage.

CLEVIS BCLEVIS A

64 N.m 16.5 kgl.m,47 lbt.ftl

\L;

SPRINGCheck for weaknessano oamage.

'l-'-' u-cllP

I Replace.

t/

6d/

BRAKE SHOEInspection, see page 19 17lf brake shoes are to bereused, mark and reassemblein same position.

WHEELInspect for leakage.Replacement, seepage 19-20

LOWER RETURNSPRINGCheck for weaknessano oamage.

RETAINER SPRINGInstall securely onlensron prn.

19-16

www.emanualpro.com

Page 948 of 1395

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 952 of 1395

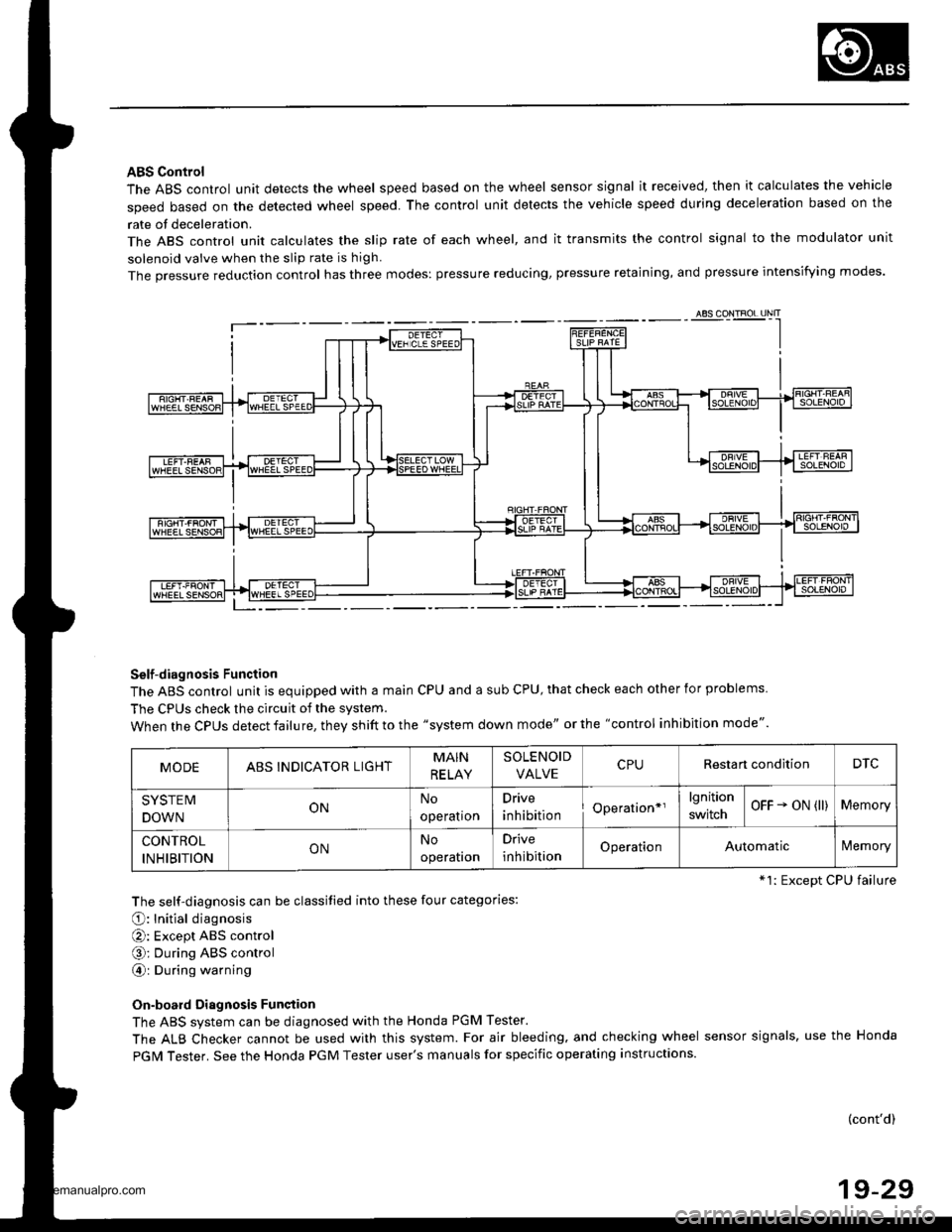

ABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high

The pressure reduction control has three modes: pressure reducing, pressure retaining, and pressure intensi{ying modes.

Self-diagnosis Function

The ABS control unit is equipped with a main cPU and a sub cPU, that check each other for problems.

The CPUs check the circuit of the system.

When the CPUS detect failure, they shift to the "system down mode" or the "control inhibition mode".

The self-diagnosis can be classitied into these four categories:

O: Initial diagnosis

O: Except ABS control

O; During ABS control

@: During warning

On-board Diagnosis Function

The ABS system can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding. and checking wheel sensor signals, use the Honda

PGIM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

(cont'd)

19-29

ABS CONTROL I-INIT

MODEABSINDICATOR LIGHTMAIN

RE LAY

SOLENOID

VALVERestan conditionDTC

SYSTEM

DOWNONNo

operatron

Drive

inhibitionOperation*rlgnition

switchOFF - oN (ll)Memory

CONTROL

INHIBITIONONNo

operaton

Drive

inhibitionOperationAutomaticlVemory

*1: Except CPU failure

www.emanualpro.com

Page 1005 of 1395

Doors

(cont'd)

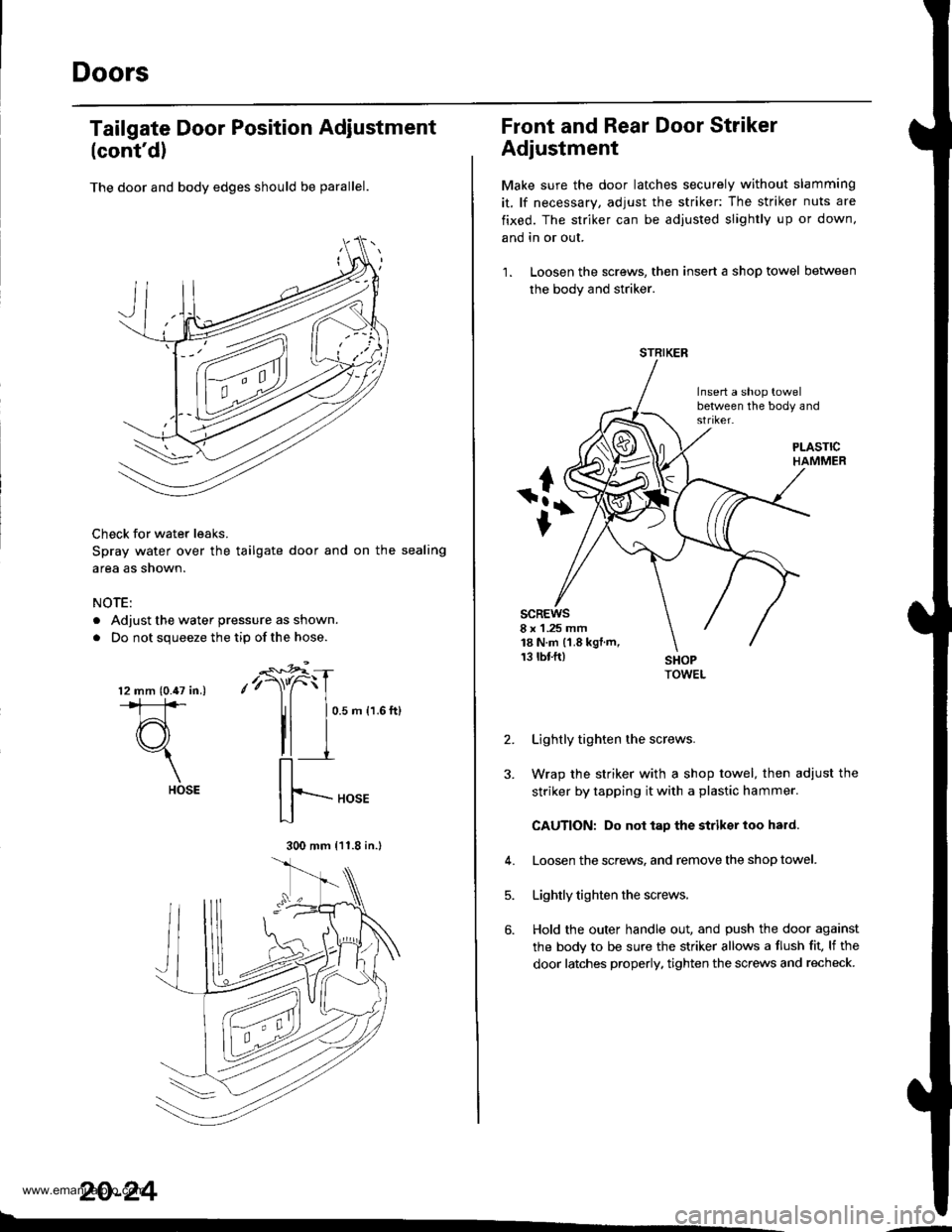

The door and body edges should be parallel.

Check for water leaks.

Spray water over the tailgate door and on the sealing

area as shown.

NOTE:

. Adjust the water pressure as shown.

. Do not squeeze the tip ofthe hose.

Tailgate Door Position Adiustment

-€*4

,'r)"C

II

0.5 m {1.6 ft}

20-24

l2 mm (0.47 in.).*1:]*

d3"1

HOSE

300 mm {11.8 in.l

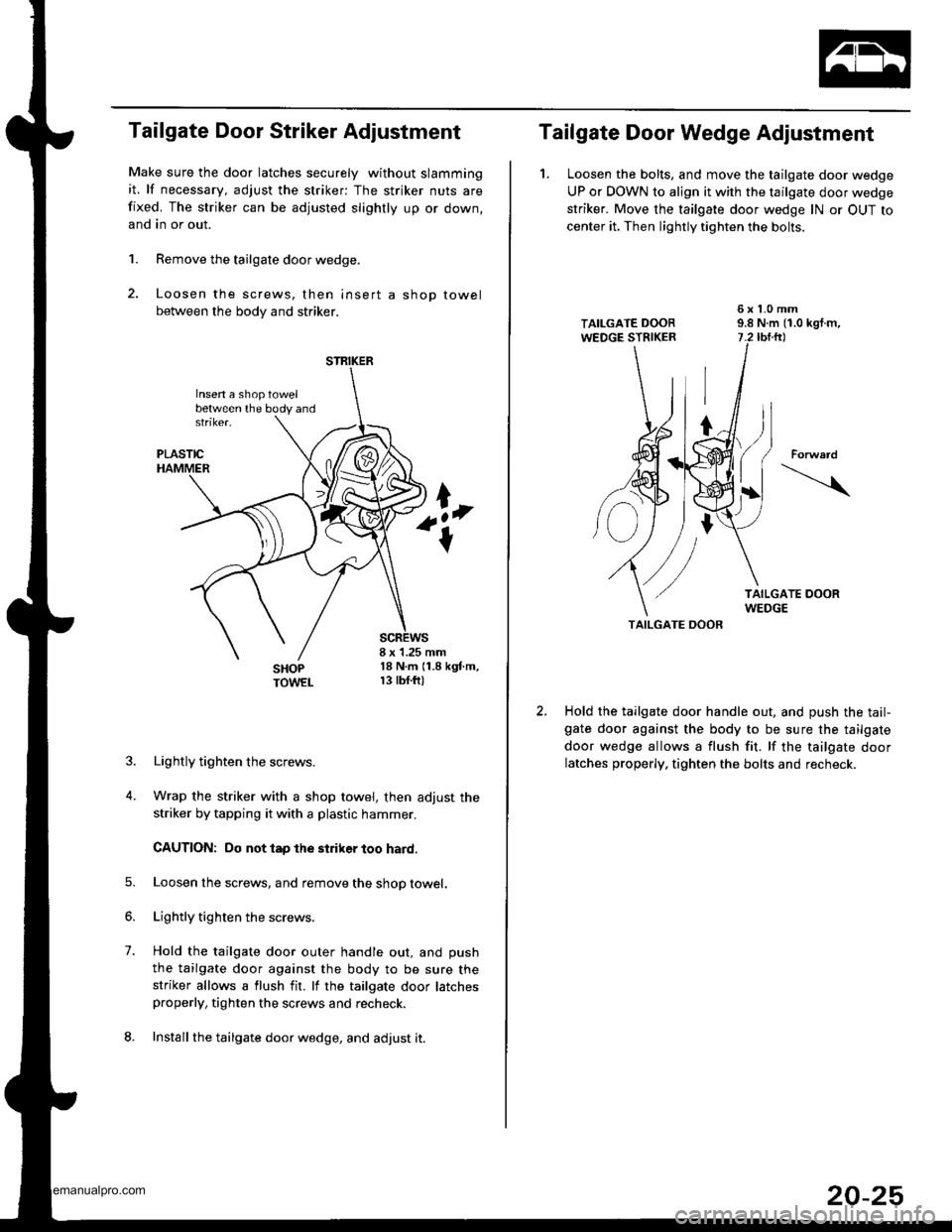

Front and Rear Door Striker

Adjustment

Make sure the door latches securely without slamming

it, lf necessary, adjust the striker: The striker nuts are

fixed. The striker can be adjusted slightly up or down,

and in or out.

1. Loosen the screws, then insert a shop towel between

the body and striker.

Insert a shop towelbetween the body and

scREws8 x 1 .25 mm18 N.m (1.8 kgt.m,13 rbf.ft)

2.

J.

Lightly tighten the screws.

Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striksr loo hard.

Loosen the screws. and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door against

the body to be sure the striker allows a flush fit, lf the

door latches properly. tighten the screws and recheck.

4.

5.

6.

STRIKER

www.emanualpro.com

Page 1006 of 1395

Tailgate Door Striker Adjustment

Make sure the door latches securely without slamming

it. lf necessary, adjust the striker: The striker nuts are

fixed. The striker can be adjusted slightly up or down,

and in or out.

1. Remove the tailgate door wedge.

2. Loosen the screws, then insert a shop towel

between the body and striker.

8 x 1.25 mm18 N.m (1.8 kgf.m,r 3 tbf.ft)

1.

4.

Lightly tighten the screws.

Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striker too hard.

Loosen lhe screws, and remove the shop towel.

Lightly tighten the screws.

Hold the tailgate door outer handle out, and push

the tailgate door against the body to be sure thestriker allows a flush fit. lf the tailgate door latchesproperly, tighten the screws and recheck.

Install the tailgate door wedge, and adjust it.

STRIKER

Insen a shoptowelbetween the body and

Tailgate Door Wedge Adjustment

1. Loosen the bolts, and move the tailgate door wedge

UP or DOWN to align it with the tailgate door wedge

striker. Move the tailgate door wedge lN or OUT to

center it. Then lightly tighten the bolts.

TAILGATE OOOR

Hold the tailgate door handle out, and push the tail-gate door against the body to be sure the tailgate

door wedge allows a flush fit. lf the tailgate door

latches properly, tighten the bolts and recheck.

Forward

20-25

www.emanualpro.com

Page 1011 of 1395

Glass

Windshield Replacement

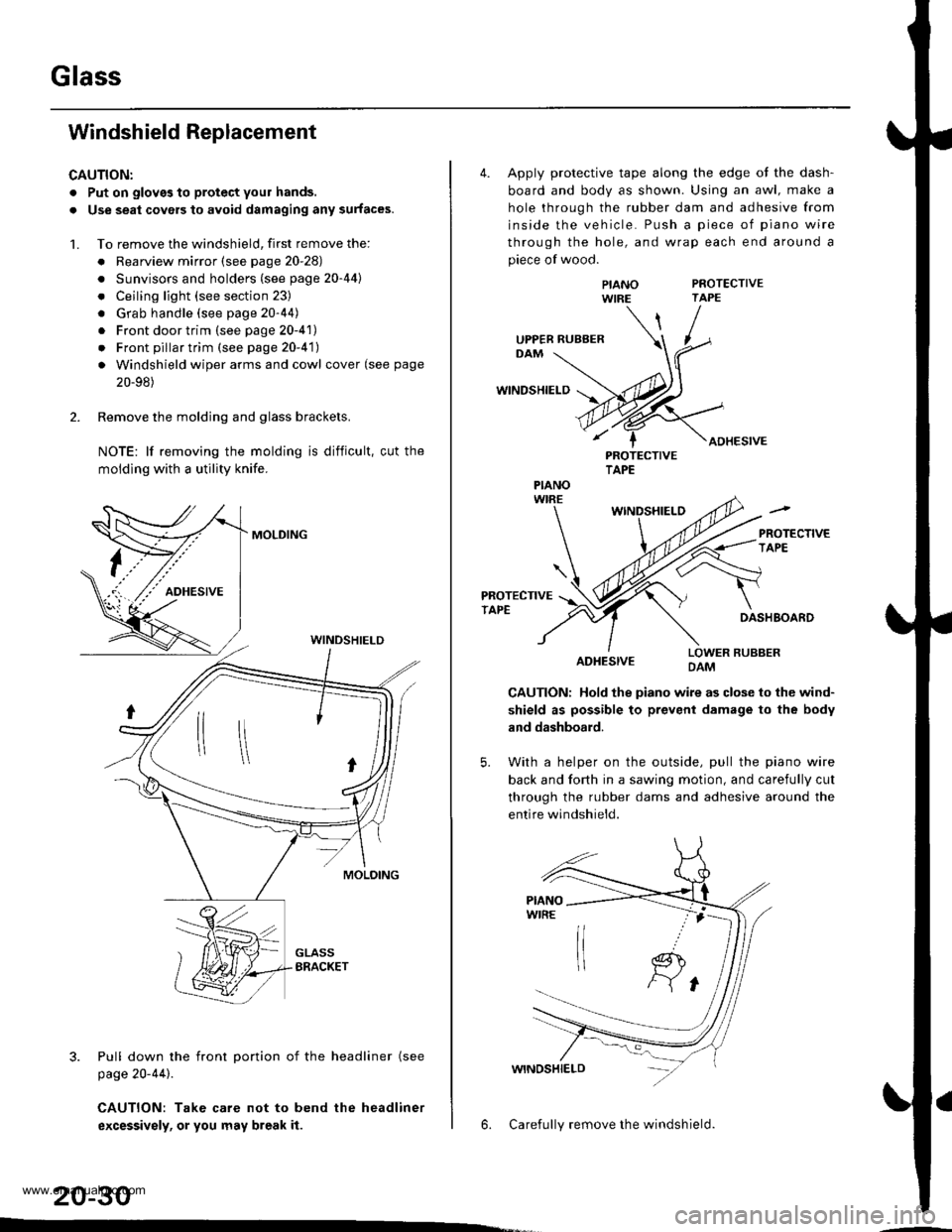

CAUTION:

. Put on gloves to protect your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the windshield, first remove the:

. Rearview mirror (see page 20-28)

. Sunvisors and holders (see page 20-44l'

. Ceiling light (see section 23)

. Grab handle (see page 20-44)

. Front door trim (see page 20-41)

. Front pillar trim (see page 20-41)

. Windshield wiper arms and cowl cover (see page

20-98)

2. Remove the molding and glass brackets.

NOTE: lf removing the molding is difficult, cut the

moldlng with a utility knife.

MOLDING

3. Pull down the front Dortion of the headliner (see

page 20-44).

CAUTION: Take care not to bend the headliner

excessivsly, or you may break it.

WINDSHIELD

20-30

4. Apply protective tape along the edge ot the dash-

board and body as shown. Using an awl, make a

hole through the rubber dam and adhesive from

inside the vehicle. Push a piece of piano wire

through the hole, and wrap each end around a

piece of wood.

PROTECTIVETAPE

WINDSHIELD

ADHESIVE

PIANOWIRE

PROTECTIVETAPE

WINDSHIELO

PROTECTIVETAPEDASHBOARD

ADHESIVELOWER RUBBERDAM

CAUTION: Hold the piano wire as close to the wind-

shield as possible to prevent damage to the body

and dashboard.

5. With a helper on the outside, pull the piano wire

back and fo(h in a sawing motion, and carefully cut

through the rubber dams and adhesive around the

entire windshield.

6. Carefully remove the windshield.

UPPER RUBBER

PIANO

www.emanualpro.com

Page 1013 of 1395

Glass

Windshield Replacement (cont'dl

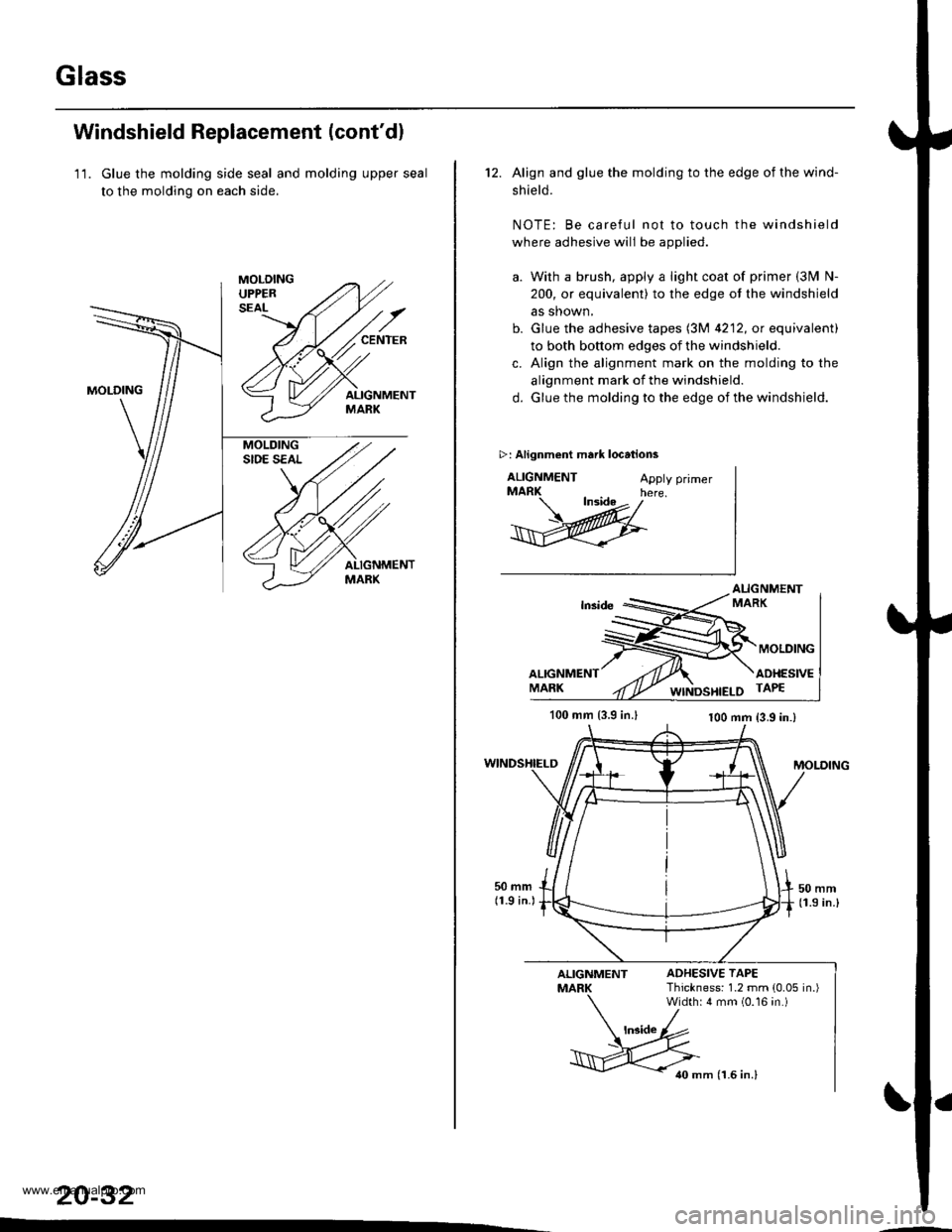

11. Glue the molding side seal and molding upper seal

to the molding on each side.

20-32

12. Align and glue the molding to the edge of the wind-

shield.

NOTE: Be careful not to touch the windshield

where adhesive will be applied.

a. With a brush, apply a light coat of primer (3lvl N-

200, or equivalent) to the edge ot the windshield

as shown,

b. Glue the adhesive tapes l3M 4212, or equivalent)

to both bottom edges of the windshield.

c. Align the alignment mark on the molding to the

alignment mark of the windshield.

d. Glue the molding to the edge of the windshield.

>: Alignment mark locations

ALIGNMENTApply primerMARK here. ln3ide , /

@

100 mm {3.9 in.l100 mm {3.9 in.}

ADHESIVE TAPEThic*ness: 1.2 mm (0.05 in.)Widthr 4 mm (0.16 in.)

r0 mm (1.6 in.l

www.emanualpro.com

Page 1014 of 1395

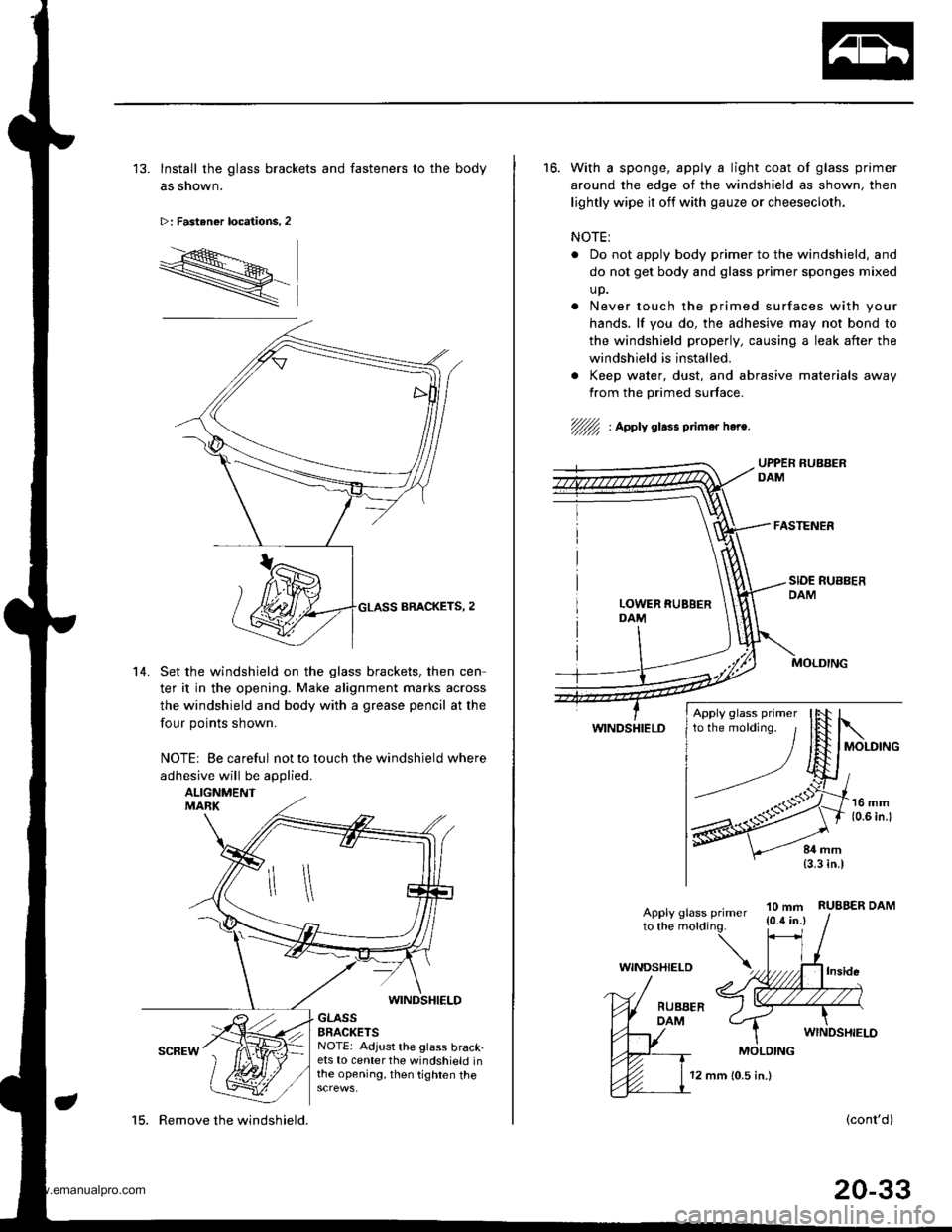

'13. Install the glass brackets and fasteners to the body

as shown.

>: Fastener locations, 2

R-

14. Set the windshield on the glass brackets. then cen

ter it in the opening. Make alignment marks across

the windshield and body with a grease pencil at the

four points shown.

NOTE| Be careful not to touch the windshield where

adhesive will be applied.

ALIGNMENTMABK

WINDSHIELD

GLASSBRACKETSNOTE: Adjust the glass brack-ets to center the windshield inthe opening, then tighten the

15. Remove the windshield.

12 mm 10.5 in.)

16. With a sponge, apply a light coat of glass primer

around the edge of the windshield as shown, then

lightly wipe it off with gauze or cheesecloth.

NOTE:

Do not apply body primer to the windshield, and

do not get body and glass primer sponges mixed

up.

Never touch the primed surfaces with your

hands. lf you do, the adhesive may not bond to

the windshield properly, causing a leak after the

windshield is installed.

. Keep water, dust, and abrasive materials away

from the primed surface.

//fu : Apply glass ptimar hea.

WINDSHIELD

10 mm{0.4 in.}RUBBER DAMApply glass primerto the molding.

(cont'd)

20-33

Apply glass primer

WINDSHIELD

MOLDING

www.emanualpro.com

Page 1015 of 1395

Glass

Windshield Replacement (cont'dl

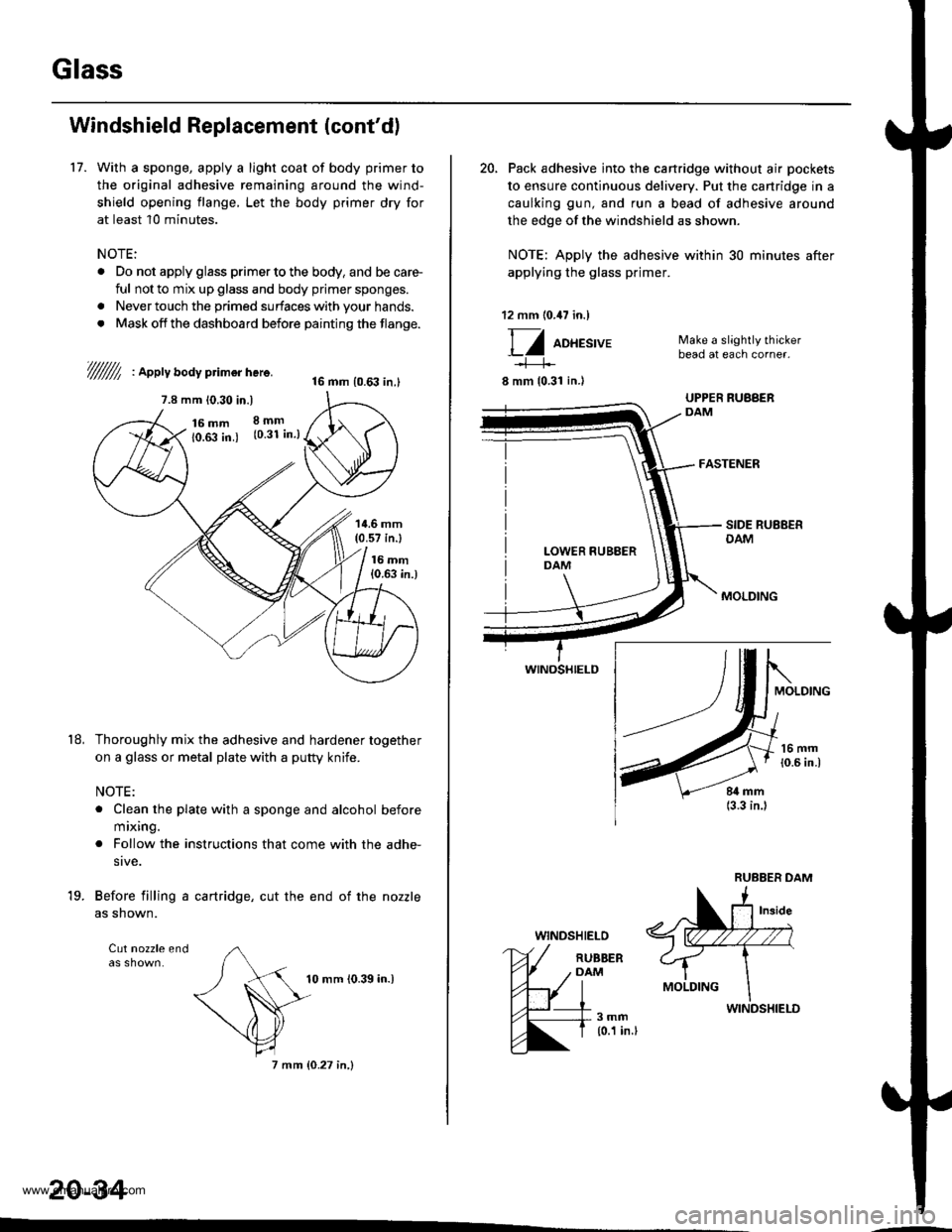

17. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange, Let the body primer dry for

at least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be care-

ful not to mix up glass and body prjmer sponges.

. Never touch the primed surfaces with your hands.

. Mask off the dashboard before painting the flange.

///////l , apptv aoav primor here.16 mm {0.63 in.l

7.8 mm 10.30 in.)

16 mm10.fi in.)

8mm(0.31 in.)

't8,

14.6 mm(0.57 in.l

16 mm{0.63 in.)

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

sive.

Before filling a cartridge, cut the end of the nozzle

as shown.

Cut nozzle end

'19.

10 mm {0.39 in.)

7 mm {0.27 in,}

20-34

20, Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

Ff oo*tt'u'

8 mm {0.31 in.l

WINOSHIELD

WINDSHIELO

Make a slightly thickerbead at each corner.

FASTENER

RUBBERDAM

3mm{0.1 in.l

www.emanualpro.com