shaft HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 631 of 1395

A {32P}

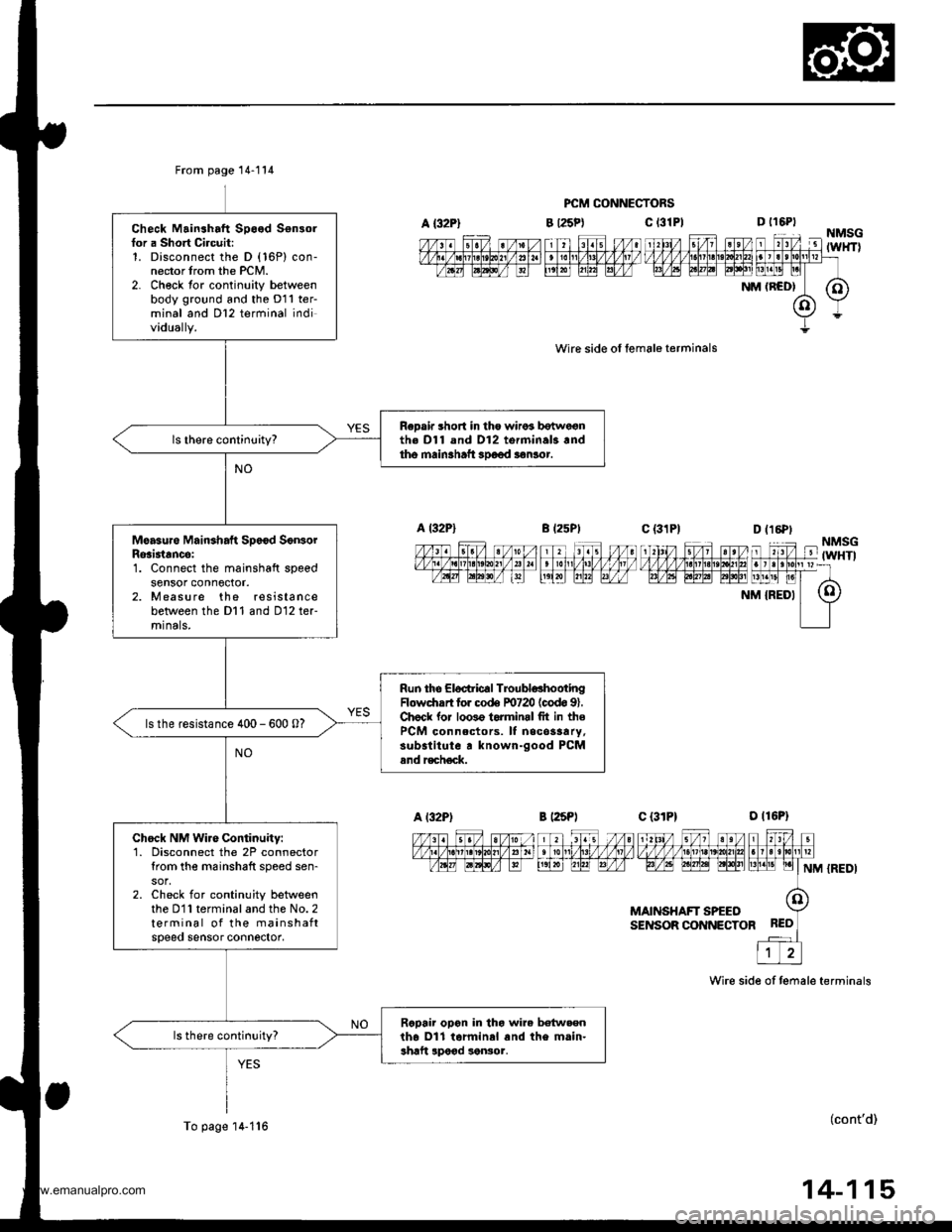

From page 14-114

Check Mainshaft Speed Sensorfor a Short Circuit:1. Disconnect the D (16P) con-nector trom the PCM.2- Ch€ck tor continuity betweenbody ground and the D11 ter-minal and Dl2 terminal individually.

ReDair short in tho wiros botwe€nth€ Dl1 and D12 torminal3.ndtho main3haft 3Doed aonlor.

Moasure Mainshaft Sp6€d SonsorRosi3tancei1. Connect the mainshaft speedsensor conn6ctor.2. Measure the resistancebetween the Dl1 and D12 ter-mrnals,

Run the Eloctric€l TroubldhootingFlowdrrrt for co& F0720 (codo 91.Chock lor loo3o torminrl fit in thePCM connectors. It necos3ary,substitute r known-good PCMand r€ch€ck.

ls the resistance 400 - 600 0?

Chock NM Wire Continuity:1. Disconnect the 2P connectortrom the m6inshaft speed sen-

2. Check for continuity betweenthe D11 terminal and the No. 2terminal of the mainshaftspeeo sensor connector,

Rcpair opon in tho wire betw.enth6 Dll tarminal and the main-shaft lpood sonsor.

To page'14-1'16

PCM CONNECTORS

c t3lPl

wire side ol female terminals

B l25Pt

D t16PtNMSG-'lTZ lit4'l Fl l'1til FTil ,'l unrv v v v v l.t1lLtLt?!/]|,1tut larrlrllllpr=rtavtq tptntat EElt [1!]t! pl

NM (RCD| (O)

(o)Y

Y=

c {31P1--_|--1\‰1,/ s/1 st/v,1zzfififinffiiFrF/l,6t FFF| LrLrEllNM {REDI

MAINSHAFT SPEEOSENSOR CONNECTOR

Wire side of temale terminals

(cont'd)

14-115

www.emanualpro.com

Page 632 of 1395

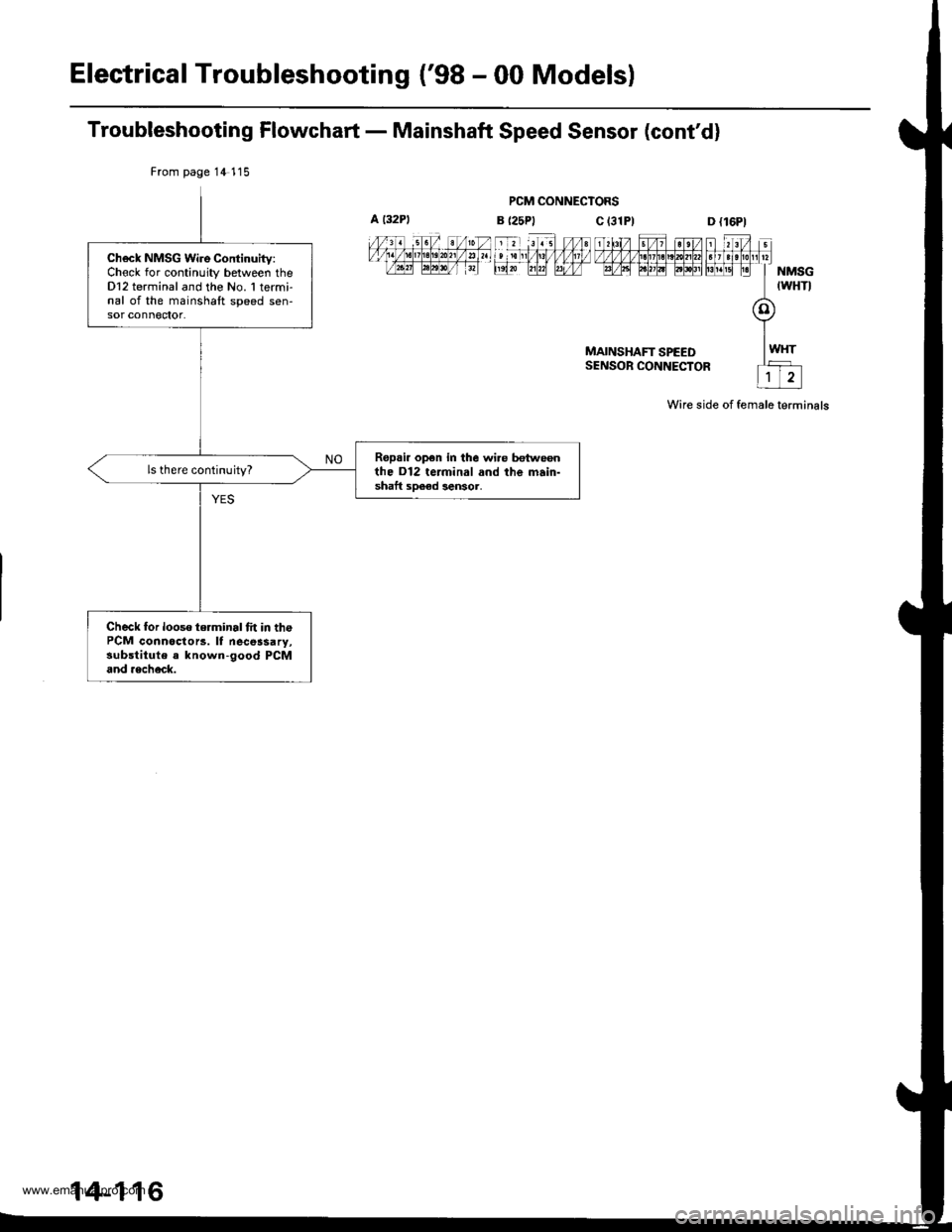

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Mainshaft Speed Sensor (cont'd)

PCM CONNECTORS

MAINSHAFT SPEEDSENSOR CONNECTOR

Wire side of female terminals

From page 14 115

Ch6ck NMSG Wire Continuitv:Chock for continuity between theDl2 terminal and the No. 1 termi-nal of the mainshaft speed sen-sor conn€ctot.

Ropai. op€n in the wi.e hn eonthe D12 terminal and the main-shaft sDeed lensor,

ls there continuity?

Check for looso terminal fit in thePCM connoctorc. lf necessary,substitute a known-good PCMand aech6ck.

14-116

www.emanualpro.com

Page 654 of 1395

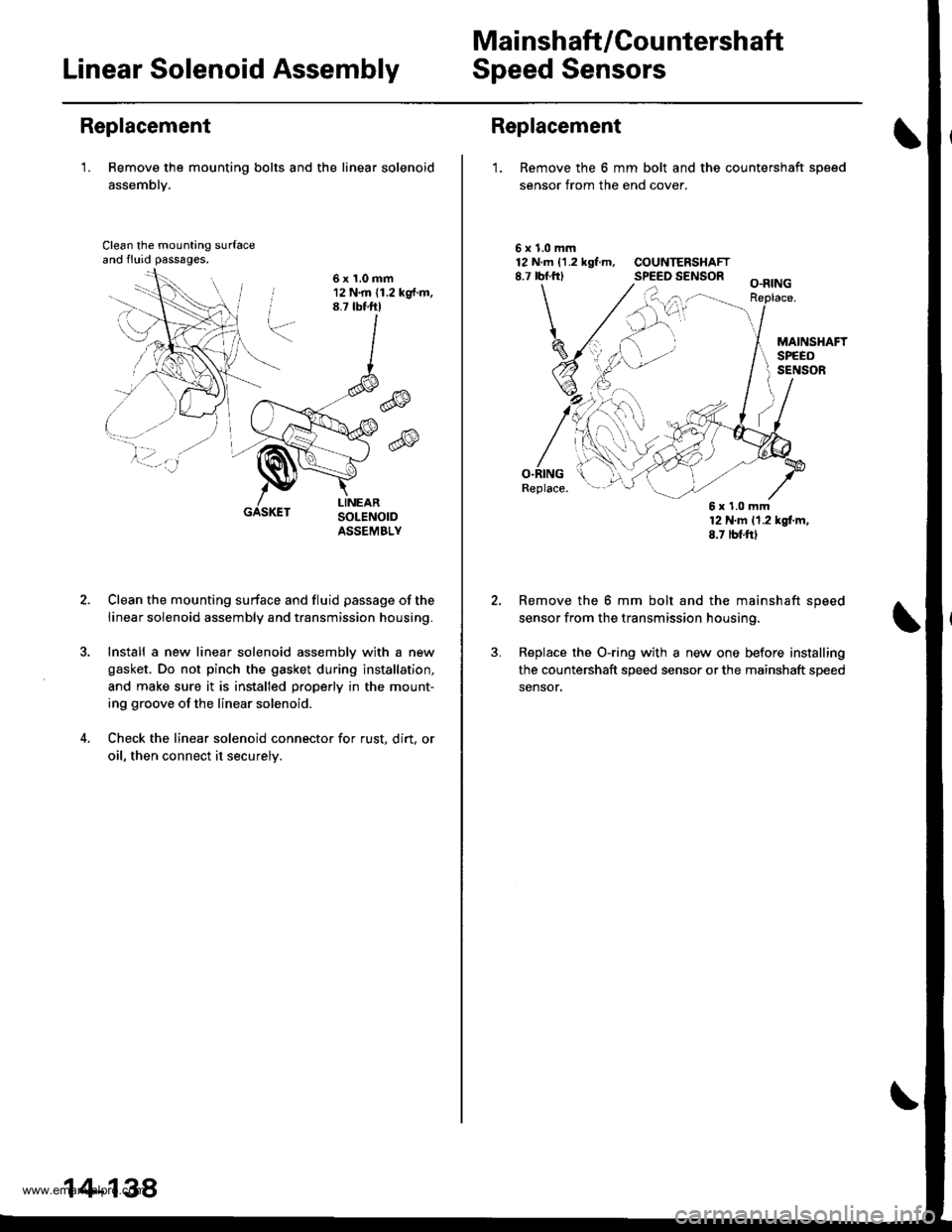

Mai nshaft /Cou ntershaft

Linear Solenoid AssemblySpeed Sensors

Replacement

'1. Remove the mounting bolts and the linear solenoid

assemblY.

Clean the mounting surfaceand fluid passages.

6x1.0mm12 N.m (1.2 kg{.m.8.7 tbtftl

@

@

GASKET

Clean the mounting surface and fluid passage of the

linear solenoid assembly and transmission housing.

Install a new linear solenoid assemblv with a new

gasket. Do not pinch the gasket during installation,

and make sure it is installed properly in the mount-

ing groove of the linear solenoid.

Check the linear solenoid connector for rust. dirt, or

oil, then connect it securelv.

14-138

Replacement

1. Remove the 6 mm bolt and the countershaft sDeed

sensor from the end cover.

\

5x1.0mm12 N.m 11.2 kgf.m, COUNTERSHAFT8.7 rbf.frl SPEED SENSOR

O.RINGReplace.

12 N'm 11.2 kgl.m,8.7 tbf.ftl

Remove the 6 mm bolt and the mainshaft speed

sensor from the transmission housing.

Replace the O-ring with a new one before installing

the countershaft speed sensor or the mainshaft speed

sensor,

6x1.0mm

www.emanualpro.com

Page 657 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the AyT gear position switch cover and har-

ness clamp on the end cover.

Connect the HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the AyT gear position switch cover and har-

ness clamp on the end cover.

Connect the](/img/13/5778/w960_5778-656.png)

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the Ay'T gear position switch cover and har-

ness clamp on the end cover.

Connect the A,/T gear position switch connector.

then install it on the connector bracket.

Turn the ignition switch ON (ll). Move the shift lever

through all gears, and check the AfI gesr position

switch synchronization with the A/T gear position

indicator.

9.

10.

11.

A/TGEARPOSMON A/T GEAR POSITIONINDICATOR INDICATOR'99 - 00 MODELS '�97 - 98 MOOELS

12, Start the engine. Move the shift lever through all

gears. and verify the following:

. The shift lever cannot be moved to E] position

from E position unless the shift lever is pulled.

. The engine will not start in any position other

than E or E.. The back-up lights come on when the shift lever

is in El position.

14-141

www.emanualpro.com

Page 670 of 1395

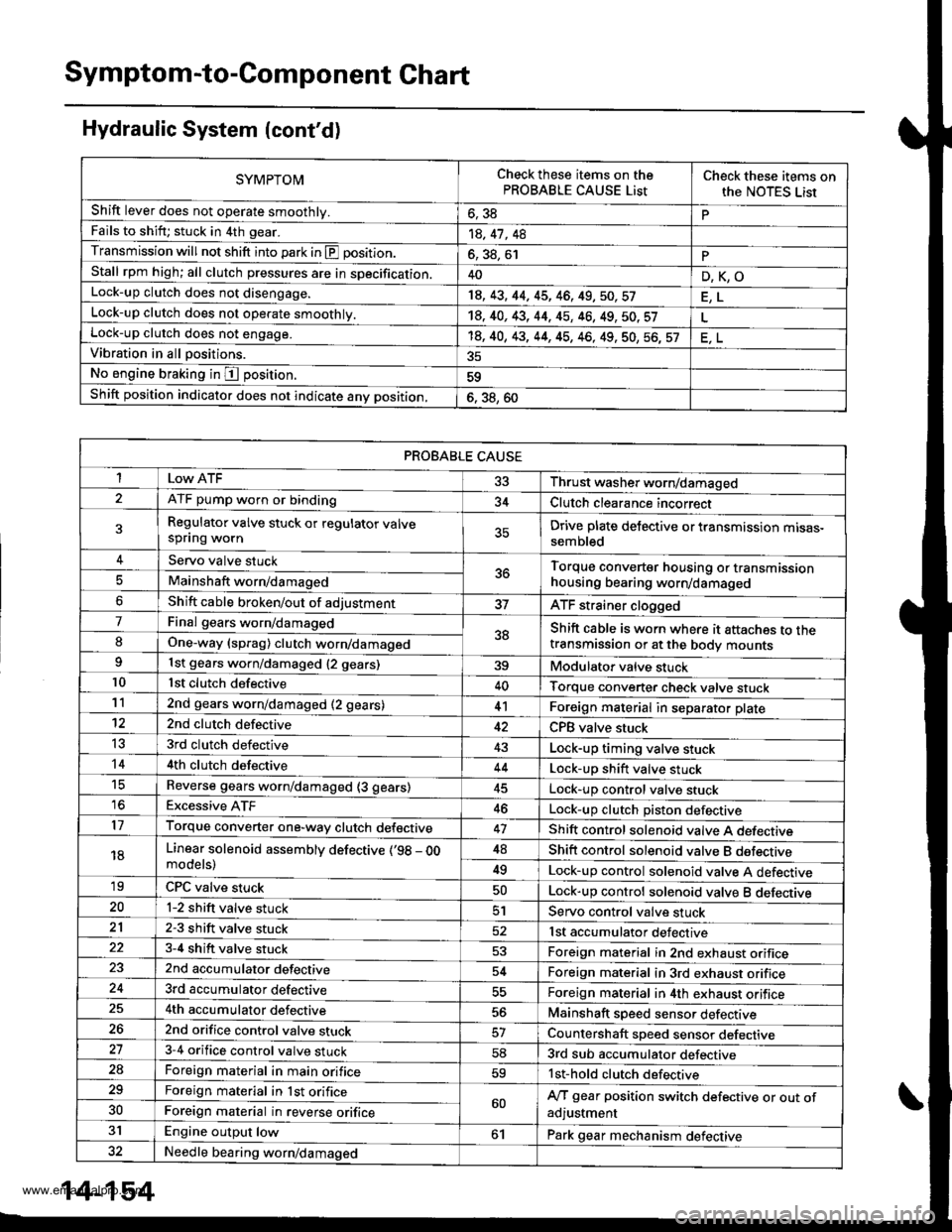

Symptom-to-Component Chart

Hydraulic System (cont'd)

SYMPTOMCheck these items on thePROBABLE CAUSE ListCheck these items onthe NOTES Lisr

Shift lever does not operate smoothly.o, JdPFails to shift; stuck in 4th gear.14, 41 , 48

Transmission will not shift into park in E position.6, 38, 61PStall rpm high; all clutch pressures are in specification.40D,K,OLock-up clutch does not disengage.18, 43, 44, 45, 46, 49,50,57

Lock-up clutch does not operate smoothly.14, 40, 43, 44, 45, 46, 49, 50. 57Lock-up clutch does not engage.'t8, 40, 43, 44, 45, 46, 49, 50, 56, 57Vibration in all positions.

No engine braking in I position.59

Shift position indicator does not indicate anv position,6. 38, 60

PROBABLE CAUSE

I 33 Thrust washer worn/damaged

ATF pump worn or binding34Clutch clearance incorrect

Regulator valve stuck or regulator valvespflng wornDrive plate delective or transmission mtsas-sembled

Servo valve stuck5ttTorque converter housing or transmissionhousing bearing worn/damagedMainshaft worn/damaged

Shift cable broken/out of adjustmentATF strainer clogged

7Final gears worn/damaged38Shift cable is worn where it attaches to thetransmission or at the body mountsIOne-way (sprag) clutch worn/damaged

1st gears worn/damaged {2 gears)39Modulator valve stuck10lst clutch defective40Torque converter check valve stuck112nd gears worn/damaged (2 gears)41Foreign material in separator plate't22nd clutch defectiveCPB valve stuck

t53rd clutch defective43Lock-up timing valve stuck144th clutch defective44Lock-up shift valve stucktcReverse gears worn/damaged (3 gears)Lock-up control valve stuck16Excessive ATF46Lock-up clutch Diston defective17Torque converter one-way clutch defective47Shift control solenoid valve A defecttve

18Linear solenoid assemblv defective (,98 - OOmodels)48Shift control solenoid valve B dsfectrve

49Lock-up control solenoid valve A defective'19CPC valve stuckLock-up control solenoid valve B deleqtve20l-2 shift valve stuck51Servo control valve stuck212-3 shift valve stuck52lst accumulator defective3-4 shift valve stuck53Foreign material in 2nd exhaust orifice2nd accumulator defective54Foreign material in 3rd exhaust orifice3rd accumulator defectiveForeign material in 4th exhaust orifice4th accumulator defective56Mainshaft speed sensor defective262nd orifice control valve stuckCountershaft speed sensor defective273-4 orifice control valve stuck583rd sub accumulator defective2aForeign material in main orifice59lst-hold clutch defective29Foreign material in lst orifice60A/T gear position switch defective or out ofadjustment30Foreign material in reverse orifice

31Engine output low61Park gear mechanism defective32Needle bearing worn/damaged

14-154

www.emanualpro.com

Page 671 of 1395

The following symptom can be caused

by improper repair or assemblYCheck these items

. lmproper clutch clearance

. lmproper gear clearance

One-way (sprag) clutch installed upside down

Park lever installed upside down

Shift fork bolt not installed

Vehicle creeps in N position.

Vehicle does not move in E, [D.lj, or E

position.

Transmission locks up in E position.

Excessive drag in transmission.ATF pump binding and seizure

Use proper tools when replacing the ATF pump gears, and be careful

to damage the ATF pump when torque down the main valve body.

Check that the shift fork bolt is installed on the shift fork shaft

not

Excessive vibration, rpm related.Torque converter not fully seated in ATF pump

Reverse selector hub installed upside downNoise only with wheels moving.

Mainshaft oil seal po9s out.Mainshaft oil seal improperly installed

lnstallthe mainshaft oil seal tlush with the torque converter housing lf

the mainshaft oil seal is installed into the torque converter housing until

it bottoms. it will block the fluid return passage and result in damage

Various shifting problems.. Springs improperly installed

. Valves improperly installed

Harsh upshift.Check valve balls not installed

(cont'd)

4-155

www.emanualpro.com

Page 672 of 1395

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 680 of 1395

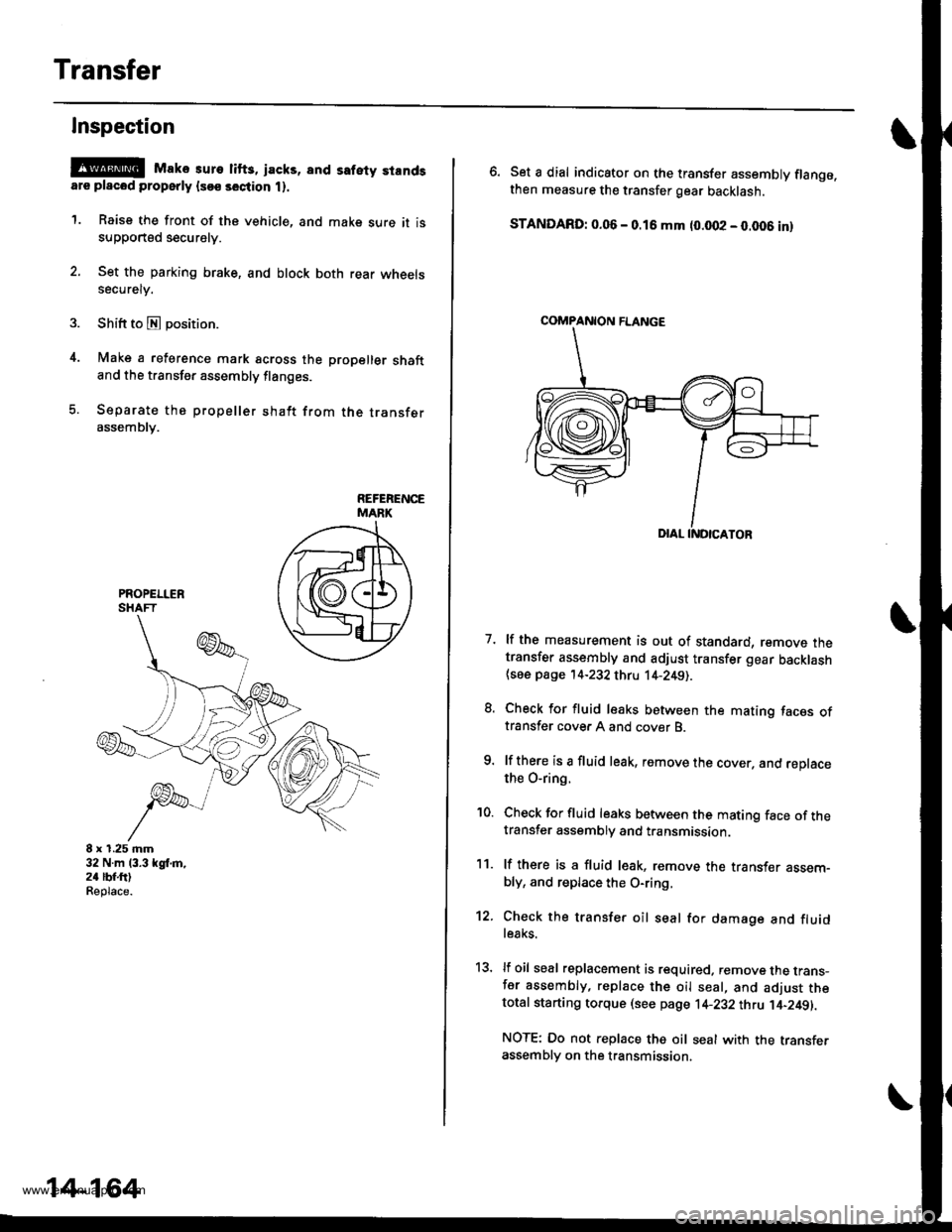

Transfer

4.

Inspection

@E Mako suro lifts, jacks, and safety standsare placod properly lsoe section t).

1. Raise the front of the vehicle, and make sure it issupported securely.

2. Set the parking brake, and block both rear wheelssecurely.

Shift to E position.

Make a reference mark across the propeller shaftand the transfer assembly flanges.

Separate the propeller shaft from the transferassembly.

8 x 1.25 mm32 N.m 13.3 kgl,m,24 lbf.ftlReplace.

14-164

\

6. Set a dial indicator on the transfer assembly flange.then measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm (0.002 - 0.006 inl

7. lf the measurement is out of standard, remove thetransfer assembly and adjust transfer gear backlash{see page '14-232 thru 14-2491.

8. Check for fluid leaks between the mating faces oftransfer cover A and cover B.

9. lf there is a fluid leak, remove the cover, and reDlacethe O-ring.

'10. Check for fluid leaks between the mating face of thetransfer assembly and transmission.

11. lf there is a fluid l€ak, remove the transf€r assem-bly, and replace the O-ring,

12. Check the transfer oil seal for damage and fluidle8ks.

13, lf oil seal replacement is required. remove the trans-fer assembly, replace the oil seal, and adjust thetotal starting torque (see page 1+232 thtu ]'4-249||.

NOTE: Do not replace the oil seal with the transferassembly on the transmission.

COMPANION FLANGE

www.emanualpro.com

Page 682 of 1395

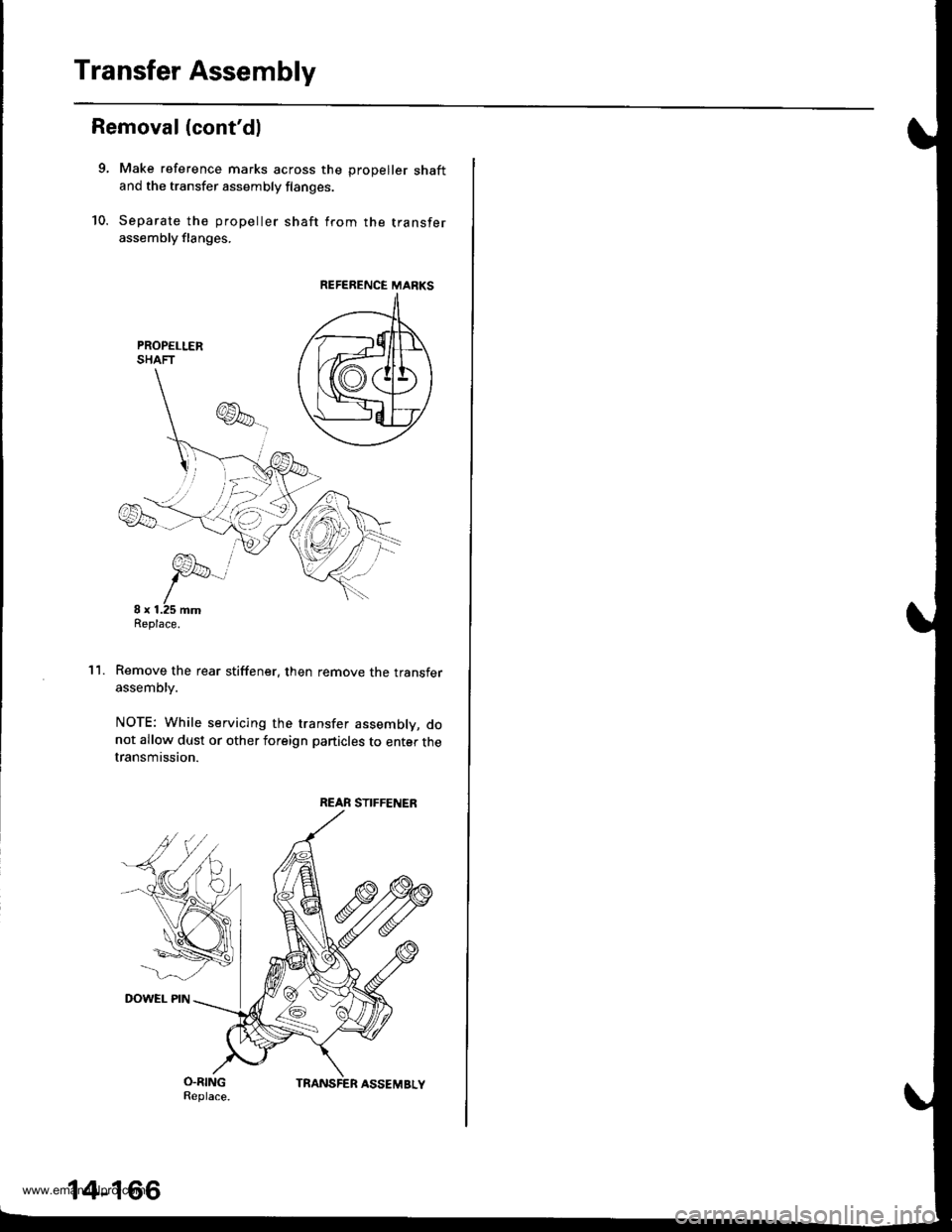

Transfer Assembly

Removal (cont'dl

9, Make reference marks across the prooeller shaftand the transfer assembly flanges.

10. Separate the propeller shaft from the transferassembly flanges.

PROPELLERSHAFT

Remove the rear stiffener. then remove the transferassembly.

NOTE: While servicing the transfer assembly, donot allow dust or other foreign particles to enter thetransmission.

'l l.

REFERENCE MANKS

REAR STIFFENER

14-166

www.emanualpro.com

Page 683 of 1395

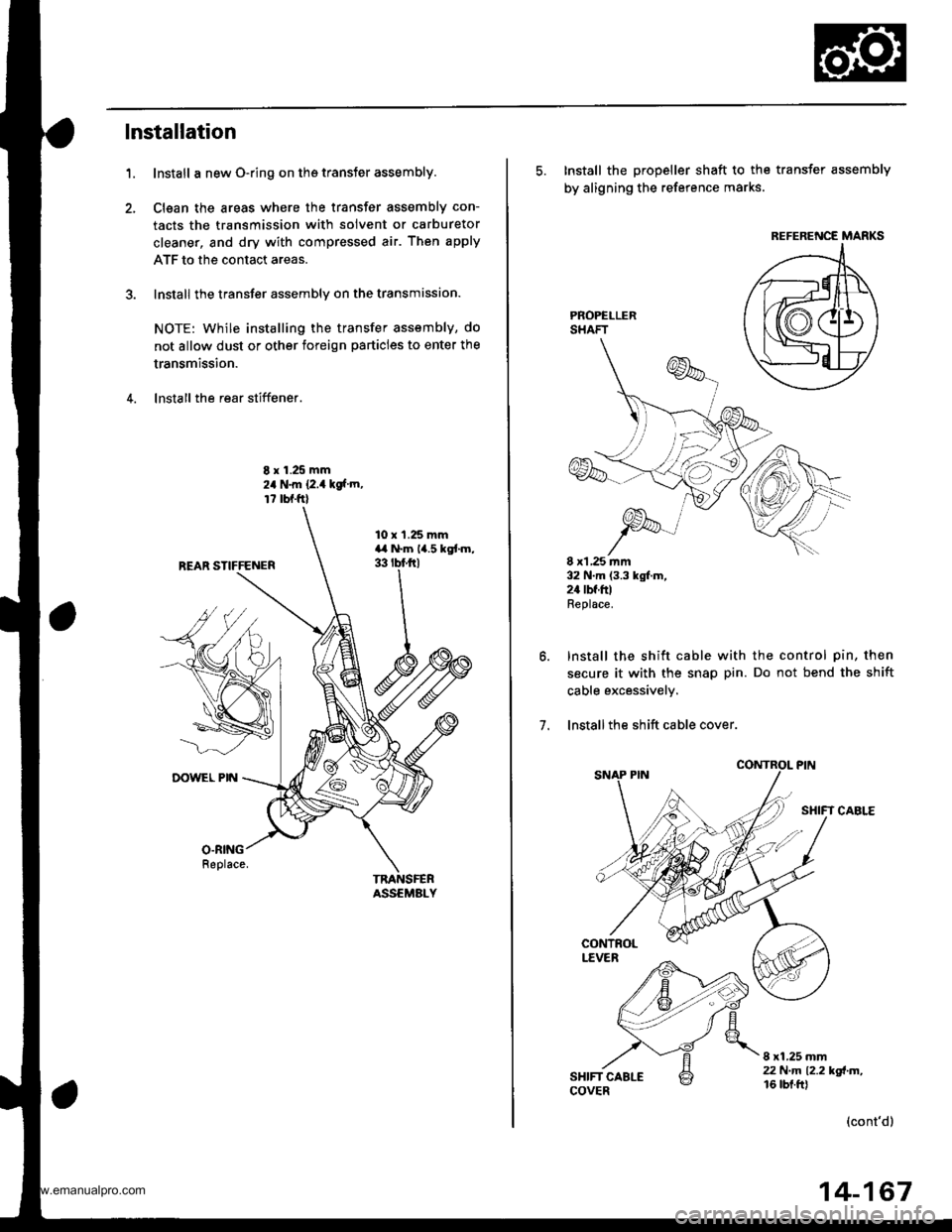

lnstallation

Install a new O-ring on ths transfer assembly.

Clsan the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, and dry with compressed air. Then apply

ATF to the contact areas.

Install the transter assembly on the transmission.

NOTE: while installing the transfer assembly, do

not allow dust or other foreign particles to enter the

transmission.

lnstall the rear stiffener.

1.

8 r 1.25 mm24 N.m {2.4 kgf m,

r7 bl.ftl

TNANSFERASSEMALY

10 x'l.25 mmara N.m 14.5 kgtm,33 tbf trl

O.RING

5. Install the propeller shaft to the transfer assembly

by aligning the reference marks

PROPELLERSHAFT

8 xl,25 ]nm32 N.m (3.3 kgl.m,2a tbf.ftlReplace.

Install the shift cable with the control pin, then

secure it with the snap pin. Do not bend the shift

cable excessively.

lnstallthe shift cable cover.

SHIFT CABLE

7.

8 xl.25 mm22 N.m 12.2 kd-m,16 tbt.ftl

(cont'd)

REFERENCE MARKS

14-167

www.emanualpro.com