Countershaft speed sensor HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 576 of 1395

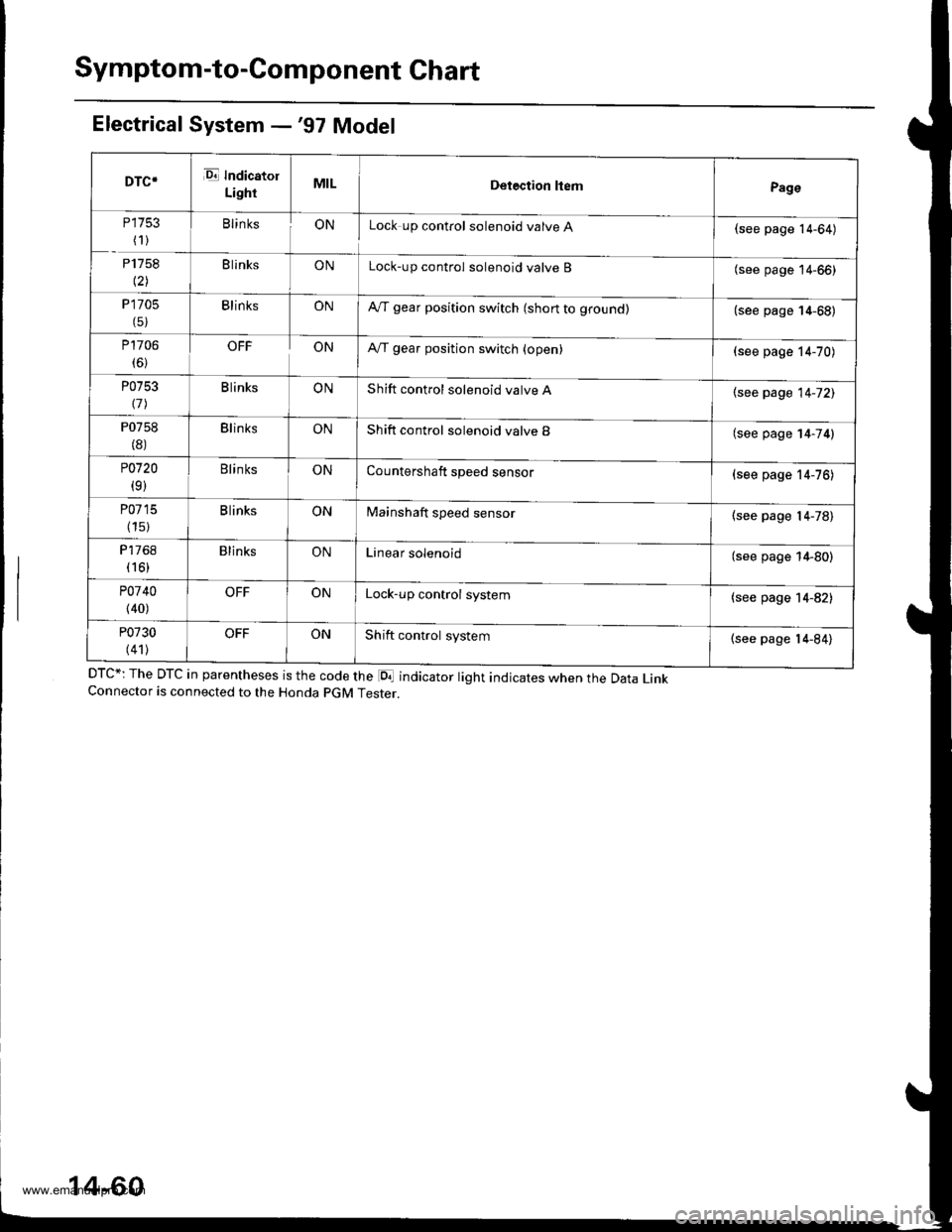

Symptom-to-Component Chart

Electrical System -'97 Model

DTC*: The DTc in parentheses is the code the loa indicator right indicates when the Data LinkConnector is connected to the Honda pGM Tester.

DTC*E Indicatol

LightMILDetection ltemPage

P 1753

(1)BlinksONLock up control solenoid valve A(see page 14-64)

P1758

\21

B linksONLock-up control solenoid valve B(see page 14-66)

P 1705

(5)BlinksONA,/T gear position switch (short to ground)(see page 14-68)

P1706

(6)OFFONA,/T gear position switch {open)(see page 14-70)

P0753

\11

B linksONShift control solenoid valve A(see page 14-72)

P0758

(8)BlinksONShift control solenoid valve B(see page 14-74)

P0720

(9)BlinksONCountershaft speed sensor{see page 14-76)

P0715

(15)B linksONMainshaft speed sensor(see page l4-78)

P17 68( 16)

BlinksONLinear solenoid(see page 14-80)

P0740

{40)

OFFONLock-up control system(see page 14-82)

P0730

(41)OFFONShift control system(see page 14-84)

14-60

www.emanualpro.com

Page 578 of 1395

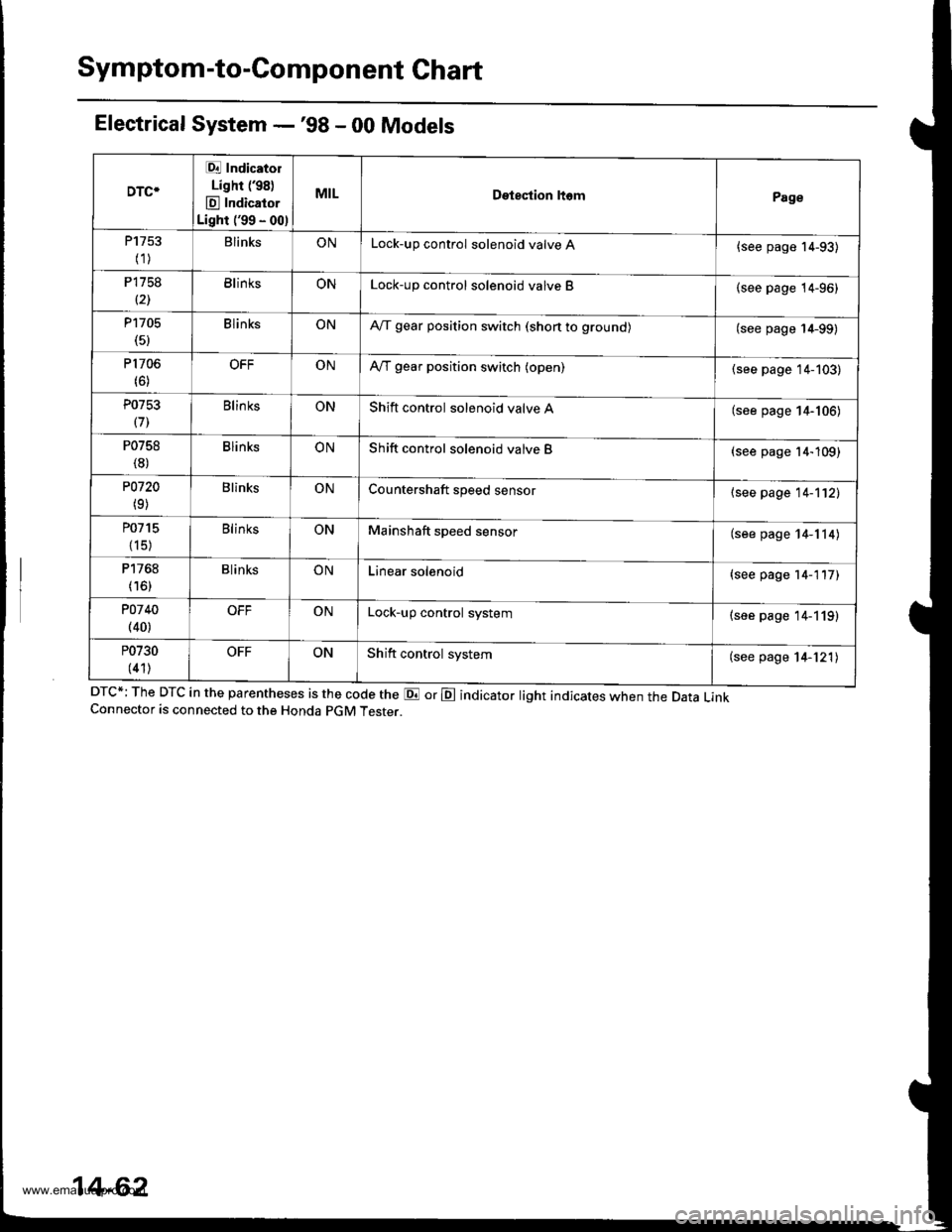

Symptom-to-Component Chart

Electrical System -'98 - 00 Models

DTC*; The DTC in the parentheses is the code the E or E indicator light indicates when the Data LinkConnector is connected to the Honda pGM Tester.

DTC*

Et Indicatol

Lighr (98)

E Indicator

Light ('99 - 00)

MILDetestion ltomPage

P1753

(1)BlinksONLock-up control solenoid valve A{see page 14-93)

P1758

(21BlinksONLock-up control solenoid valve B(see page 14-96)

P1705(5)BlinksONA,/T gear position switch (shon to grounol(see page 14-99)

P1706(6)OFFONA,/T gear position switch (open)(see page 14-103)

P0753

(71Blin ksONShift control solenoid valve A(see page 14-106)

P0758

(8)BlinksONShift control solenoid valve B(see page 14-109)

P0720

(9)BlinksONCountershaft speed sensor{see page 14-112)

P0715

{15)

BlinksONMainshaft speed sensor(see page 14-114)

P1768

(16)BlinksONLinear solenoid(see page 14-117)

POl 40(40)OFFONLock-up control system(see page 14-119)

P0730

(41)OFFONShift control system(see page 14-121)

14-62

www.emanualpro.com

Page 592 of 1395

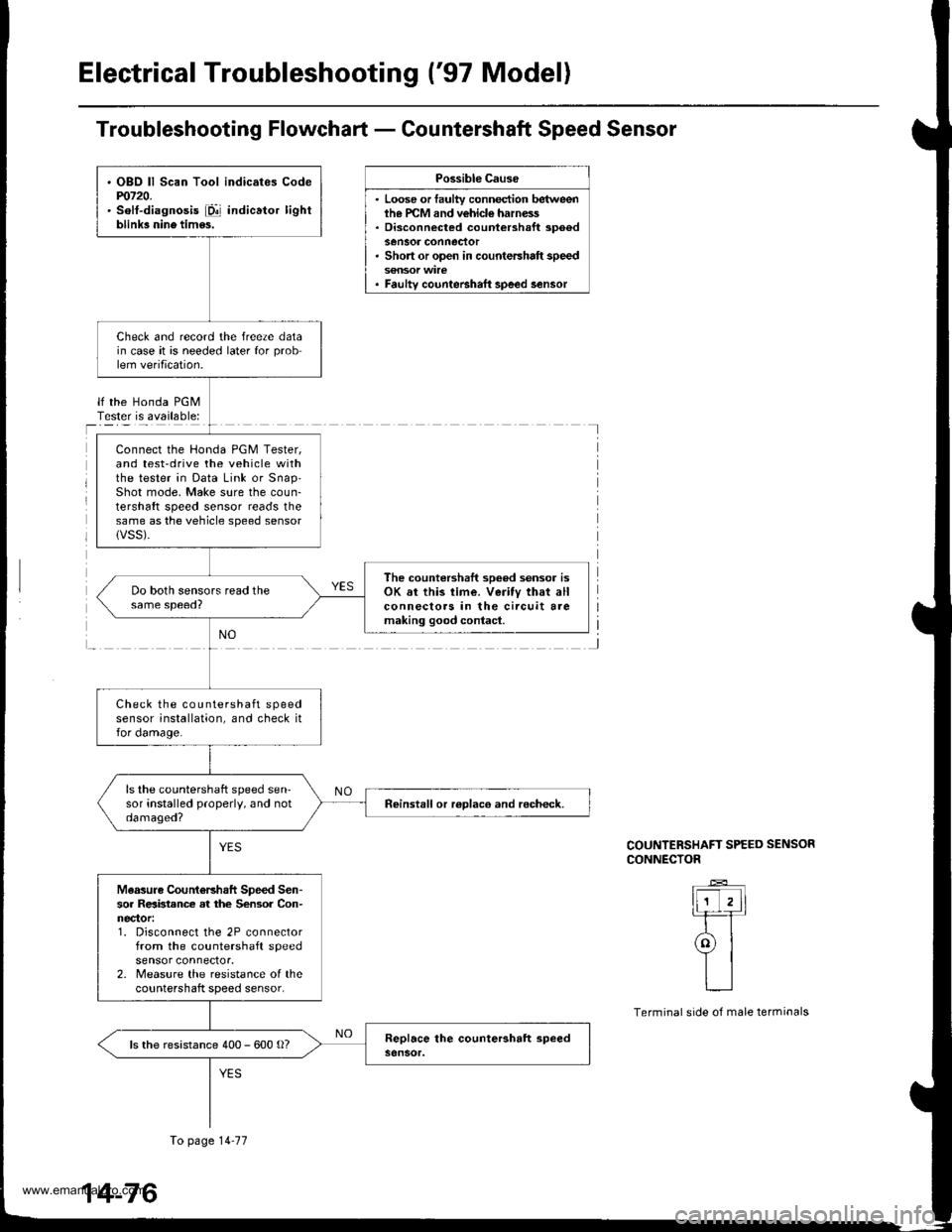

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Countershaft Speed Sensor

Possible Cause

. Loose or faulty connection betweenih€ PCM and vehicle harness. Disconnected countershaft spoedsensor conneclor. Short or open in countershaft speed

. Faulty counteBhaft speed lensor

lf the Honda PGMTester is available:I

J

COUNTERSHAFT SPEED SENSOR

CONNECTOR

ll-'T,ll-rT

ral

YIL__l

Terminal side of male terminals

. OBO ll Scan Tool indicates Codem720.' solt-diagnosis iD!' indicator lightblink3 nine tim6s.

Check and record the freeze datain case it is needed later for problem verification.

Connect the Honda PGM Tester,and test-drive the vehicle withthe tester in Data Link or snap'Shot mode, Make sure the coun-tershaft speed sensor reads thesame as the vehicle speed sensorlVSS).

The countershaft sooed sensor isOK sr this time. Veritv that allconnecloas in the circuit aremaking good contacl.

Check the countershaft speedsensor installation, and check itfor damage.

ls the countershaft speed sen-sor installed properly, and notdamaged?neinstall or roDlaco and recheck.

Measuro CountoBhaft Speed Sen-sor Relbtance at the Sensor Con-nector:1. Disconnect the 2P connectorfrom the countershaft speedsensor connector.2. Measure the resistance of thecountershaft speed sensor.

ls the resistance 400 - 600 o?

To page 14-77

14-76

www.emanualpro.com

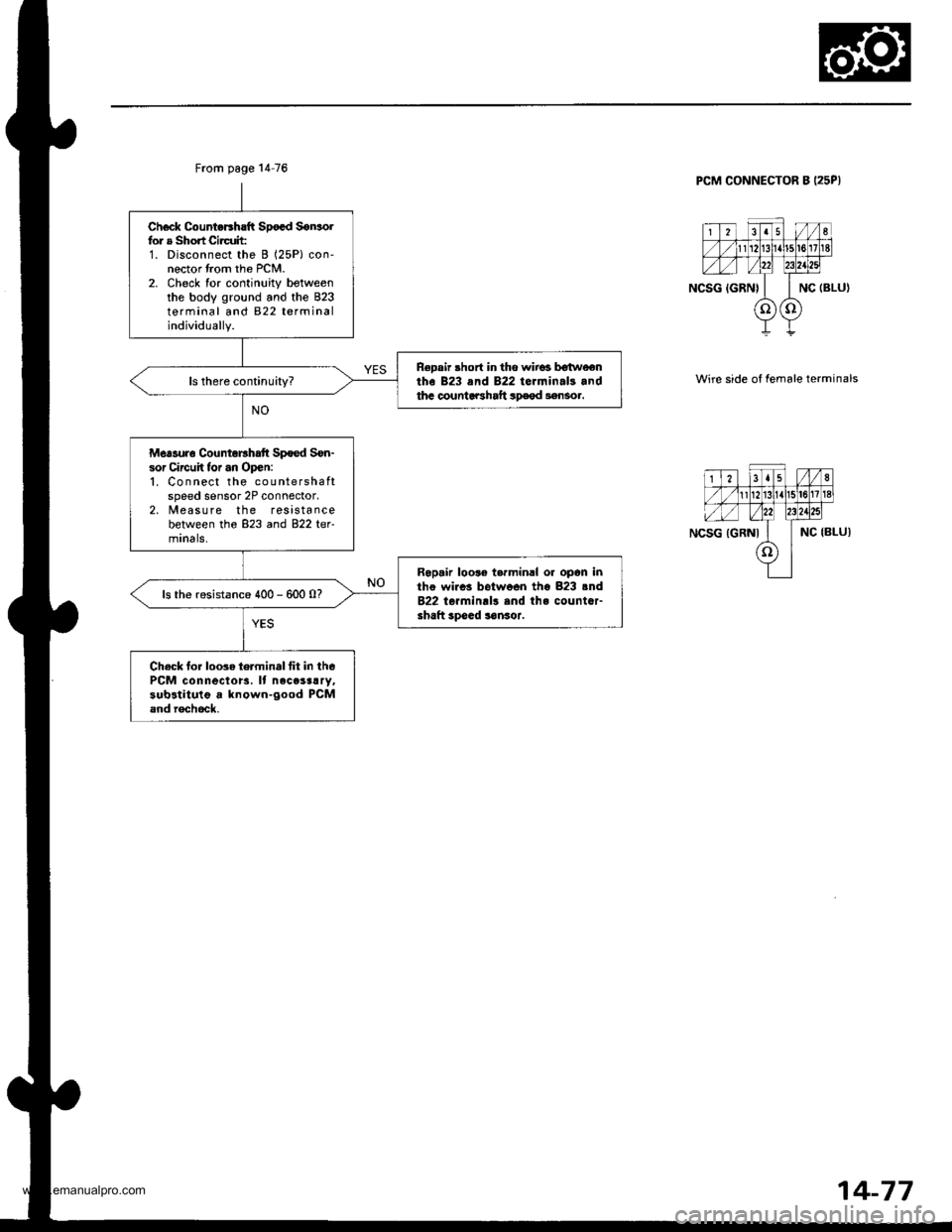

Page 593 of 1395

Ch€ck CounteGh!ft Spocd Sonsoifor a Short Cirruit:1. Disconnect the B 125P) con'nector lrom the PCM.2. Check for continuity botweenthe body ground and the B23terminal and 822 term ina Iindividually.

Repair short in tho wirgs b€twoentho 823 ,nd 822 te.minals andthc countaBhaft sp€€d senso..

Mersuro Countorrhrtt Spoed Son-sor qrcuit tor an Open:'1. Connect the countershaftspeed sensor 2P connector,2, Measure the resistancebetween the 823 and 822 termrnals.

Rapair loor€ t.rminll or opon intho wircs betwoon tho 823 .nd822 terminrl! .nd th. countaFshaft specd san3or.

ls the resistance 400 - 600 0?

Check for loo3e terminsl fit in thePCM connecto13. It necess!ry,sub3titulg s known-good PCMand rochock.

PCM CONNECTOR B I25PI

Wire side of lemale terminals

14-77

www.emanualpro.com

Page 628 of 1395

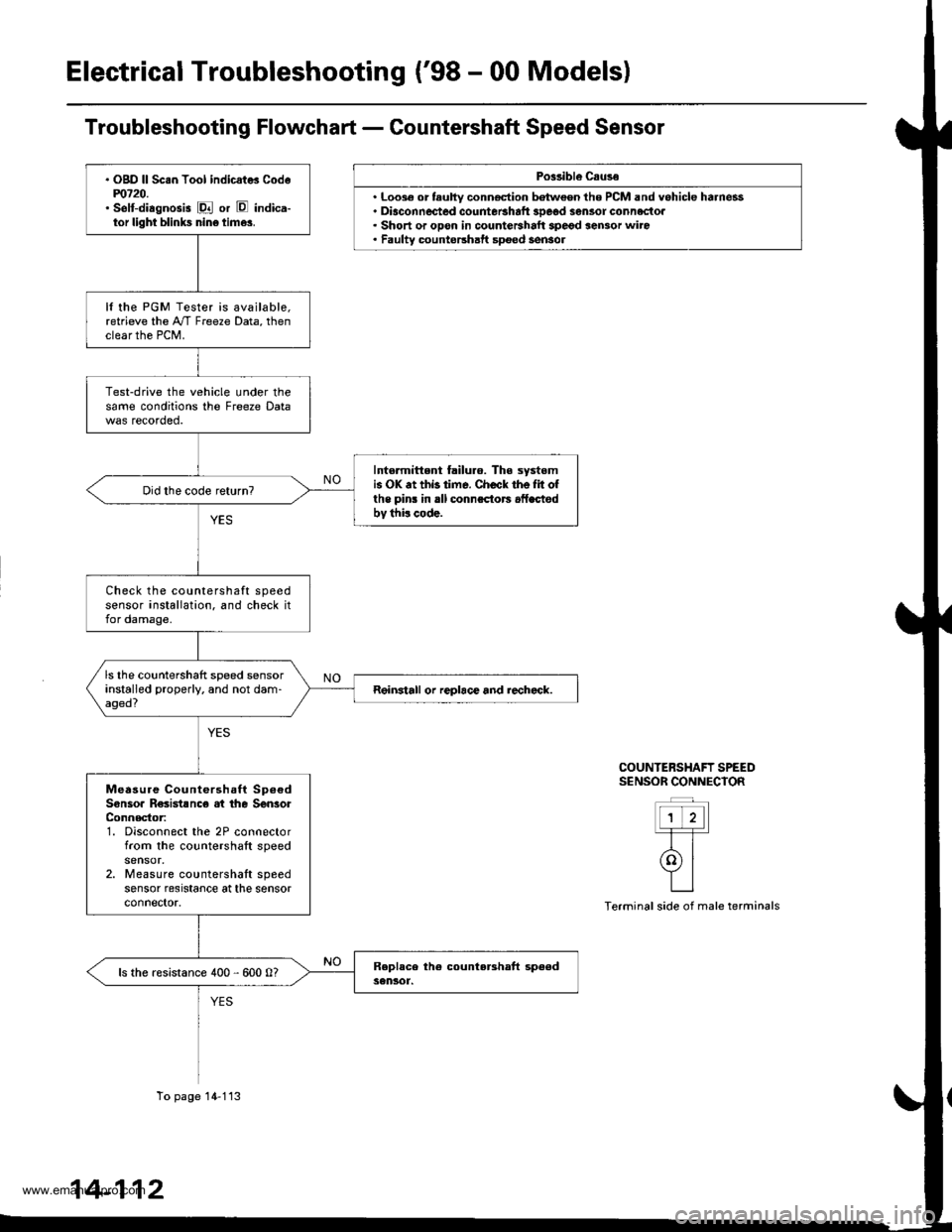

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

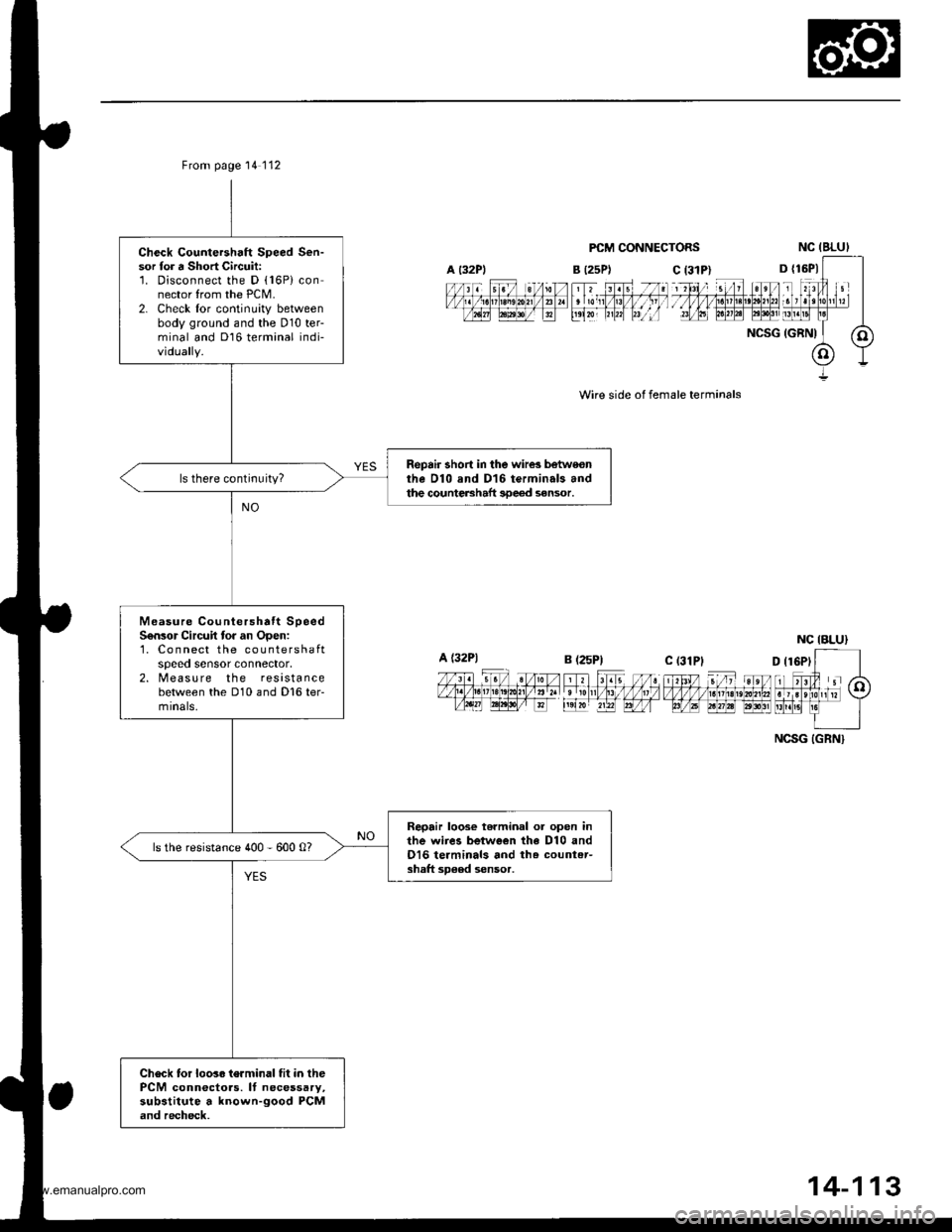

Page 629 of 1395

Check Countershaft Speed Sen-sor for a Short Circuit:'1. Disconnect the D (16P) connector from the PCM.2. Check lor continuity betweenbody ground and the D10 ter-minal and Dl6 terminal indi-vidually.

Repair short in the wire3 botweonthe Dl0 and D16 terminals andthe countershaft 3De€d sensor.

Measure Countershatt SpeedS6n3or Circuit to. an Open:1, Co n nect the countershaftspeeo sensor connector,2. Measu re the resistancebetween the D10 and D16 ter-mrnals,

Repair loose terminal or open inthe wiies between the D10 andO16 terminals and th. countet-shaft sD€ed sensor.

ls the resistance 400 - 600 0?

Check tor loos. terminal fit in thePCM conn€ctoas. It necessary,substitute a known-good PCMand recheck.

From page 14'112

A t32PlB (25P1

a l32PlB (25P1

PCM CONNECTORS

Wire side ol female terminals

NC IBLUI

D {16P1

NCSG IGRNI

c l31P)

ial, tu]g

c (31PI

NCSG IGRN}

14-113

www.emanualpro.com

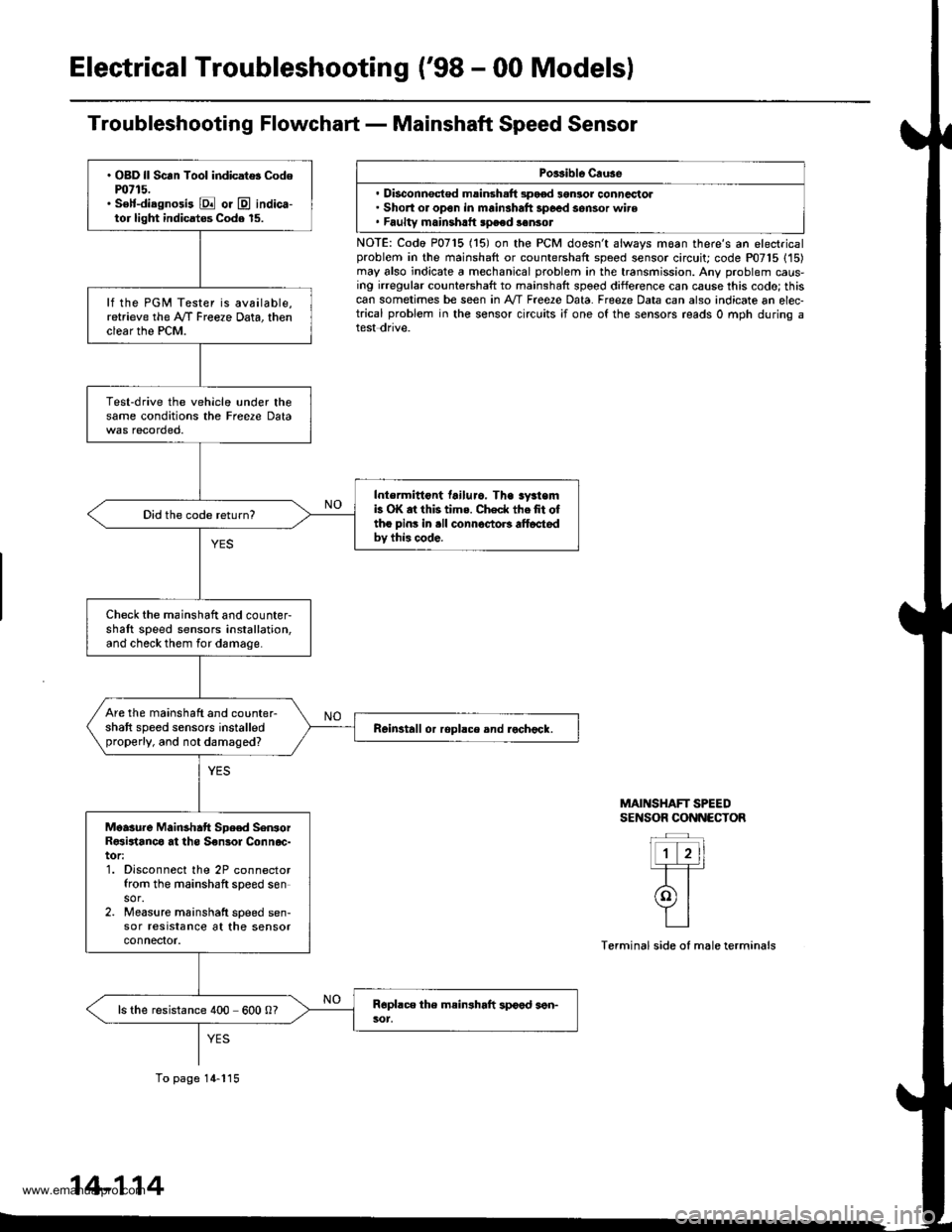

Page 630 of 1395

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

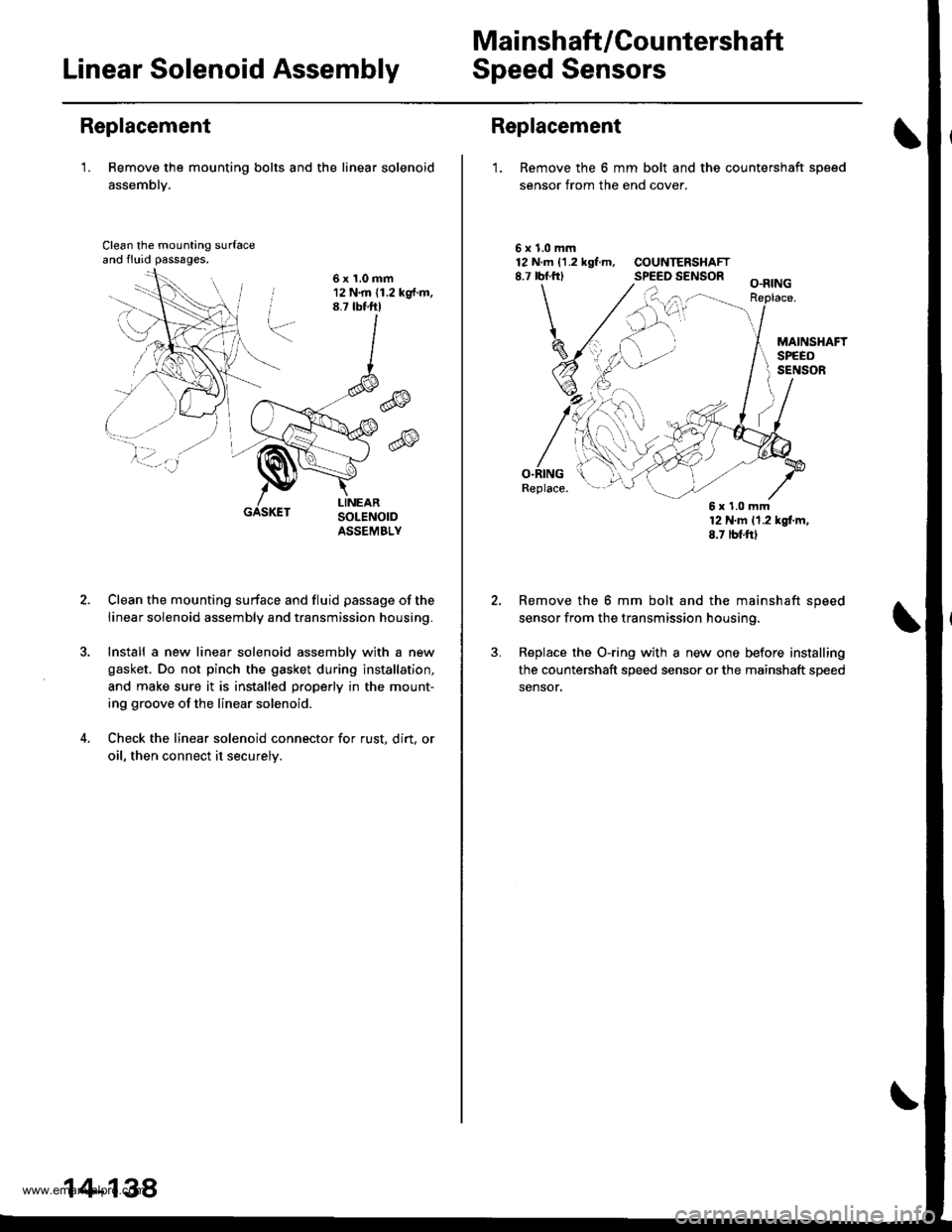

Page 654 of 1395

Mai nshaft /Cou ntershaft

Linear Solenoid AssemblySpeed Sensors

Replacement

'1. Remove the mounting bolts and the linear solenoid

assemblY.

Clean the mounting surfaceand fluid passages.

6x1.0mm12 N.m (1.2 kg{.m.8.7 tbtftl

@

@

GASKET

Clean the mounting surface and fluid passage of the

linear solenoid assembly and transmission housing.

Install a new linear solenoid assemblv with a new

gasket. Do not pinch the gasket during installation,

and make sure it is installed properly in the mount-

ing groove of the linear solenoid.

Check the linear solenoid connector for rust. dirt, or

oil, then connect it securelv.

14-138

Replacement

1. Remove the 6 mm bolt and the countershaft sDeed

sensor from the end cover.

\

5x1.0mm12 N.m 11.2 kgf.m, COUNTERSHAFT8.7 rbf.frl SPEED SENSOR

O.RINGReplace.

12 N'm 11.2 kgl.m,8.7 tbf.ftl

Remove the 6 mm bolt and the mainshaft speed

sensor from the transmission housing.

Replace the O-ring with a new one before installing

the countershaft speed sensor or the mainshaft speed

sensor,

6x1.0mm

www.emanualpro.com

Page 670 of 1395

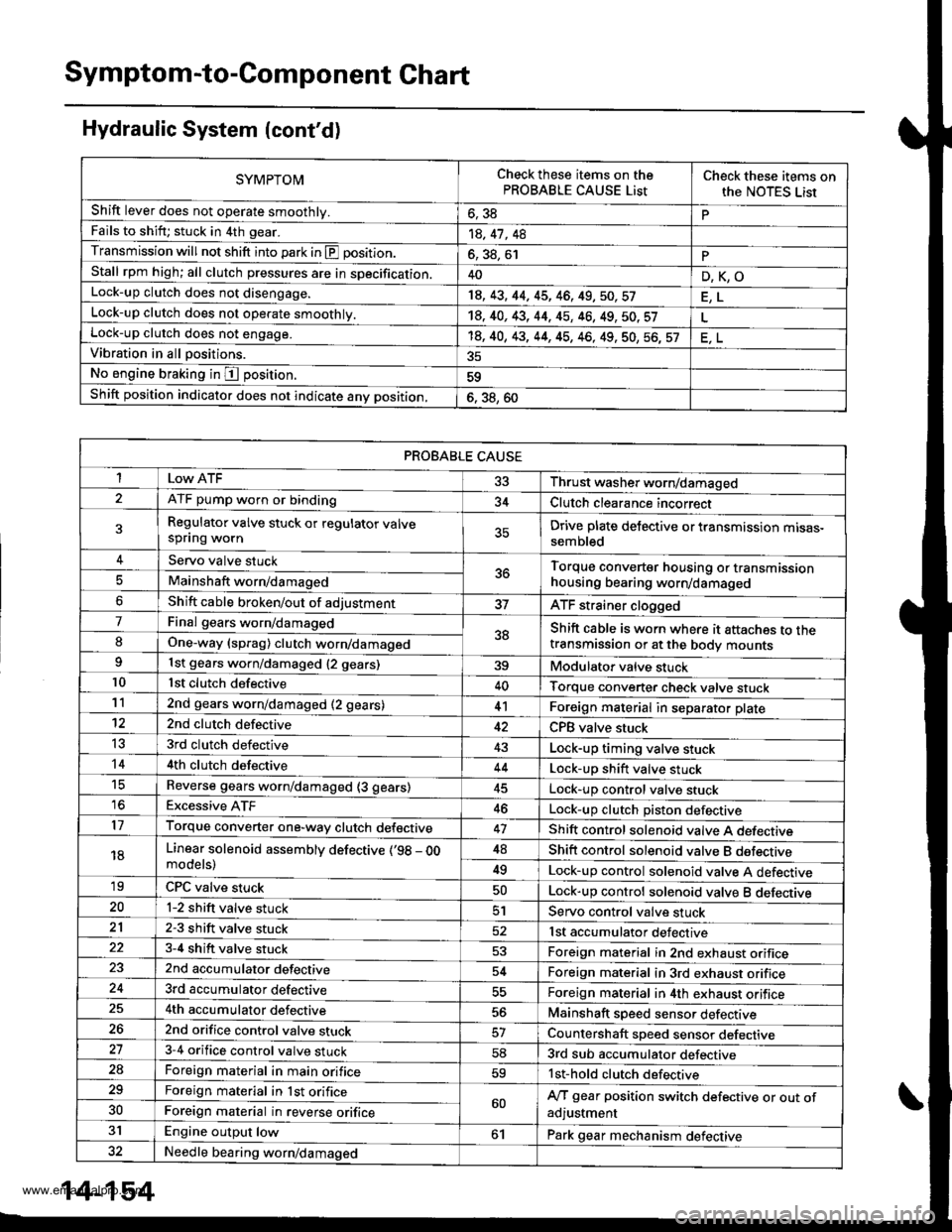

Symptom-to-Component Chart

Hydraulic System (cont'd)

SYMPTOMCheck these items on thePROBABLE CAUSE ListCheck these items onthe NOTES Lisr

Shift lever does not operate smoothly.o, JdPFails to shift; stuck in 4th gear.14, 41 , 48

Transmission will not shift into park in E position.6, 38, 61PStall rpm high; all clutch pressures are in specification.40D,K,OLock-up clutch does not disengage.18, 43, 44, 45, 46, 49,50,57

Lock-up clutch does not operate smoothly.14, 40, 43, 44, 45, 46, 49, 50. 57Lock-up clutch does not engage.'t8, 40, 43, 44, 45, 46, 49, 50, 56, 57Vibration in all positions.

No engine braking in I position.59

Shift position indicator does not indicate anv position,6. 38, 60

PROBABLE CAUSE

I 33 Thrust washer worn/damaged

ATF pump worn or binding34Clutch clearance incorrect

Regulator valve stuck or regulator valvespflng wornDrive plate delective or transmission mtsas-sembled

Servo valve stuck5ttTorque converter housing or transmissionhousing bearing worn/damagedMainshaft worn/damaged

Shift cable broken/out of adjustmentATF strainer clogged

7Final gears worn/damaged38Shift cable is worn where it attaches to thetransmission or at the body mountsIOne-way (sprag) clutch worn/damaged

1st gears worn/damaged {2 gears)39Modulator valve stuck10lst clutch defective40Torque converter check valve stuck112nd gears worn/damaged (2 gears)41Foreign material in separator plate't22nd clutch defectiveCPB valve stuck

t53rd clutch defective43Lock-up timing valve stuck144th clutch defective44Lock-up shift valve stucktcReverse gears worn/damaged (3 gears)Lock-up control valve stuck16Excessive ATF46Lock-up clutch Diston defective17Torque converter one-way clutch defective47Shift control solenoid valve A defecttve

18Linear solenoid assemblv defective (,98 - OOmodels)48Shift control solenoid valve B dsfectrve

49Lock-up control solenoid valve A defective'19CPC valve stuckLock-up control solenoid valve B deleqtve20l-2 shift valve stuck51Servo control valve stuck212-3 shift valve stuck52lst accumulator defective3-4 shift valve stuck53Foreign material in 2nd exhaust orifice2nd accumulator defective54Foreign material in 3rd exhaust orifice3rd accumulator defectiveForeign material in 4th exhaust orifice4th accumulator defective56Mainshaft speed sensor defective262nd orifice control valve stuckCountershaft speed sensor defective273-4 orifice control valve stuck583rd sub accumulator defective2aForeign material in main orifice59lst-hold clutch defective29Foreign material in lst orifice60A/T gear position switch defective or out ofadjustment30Foreign material in reverse orifice

31Engine output low61Park gear mechanism defective32Needle bearing worn/damaged

14-154

www.emanualpro.com

Page 691 of 1395

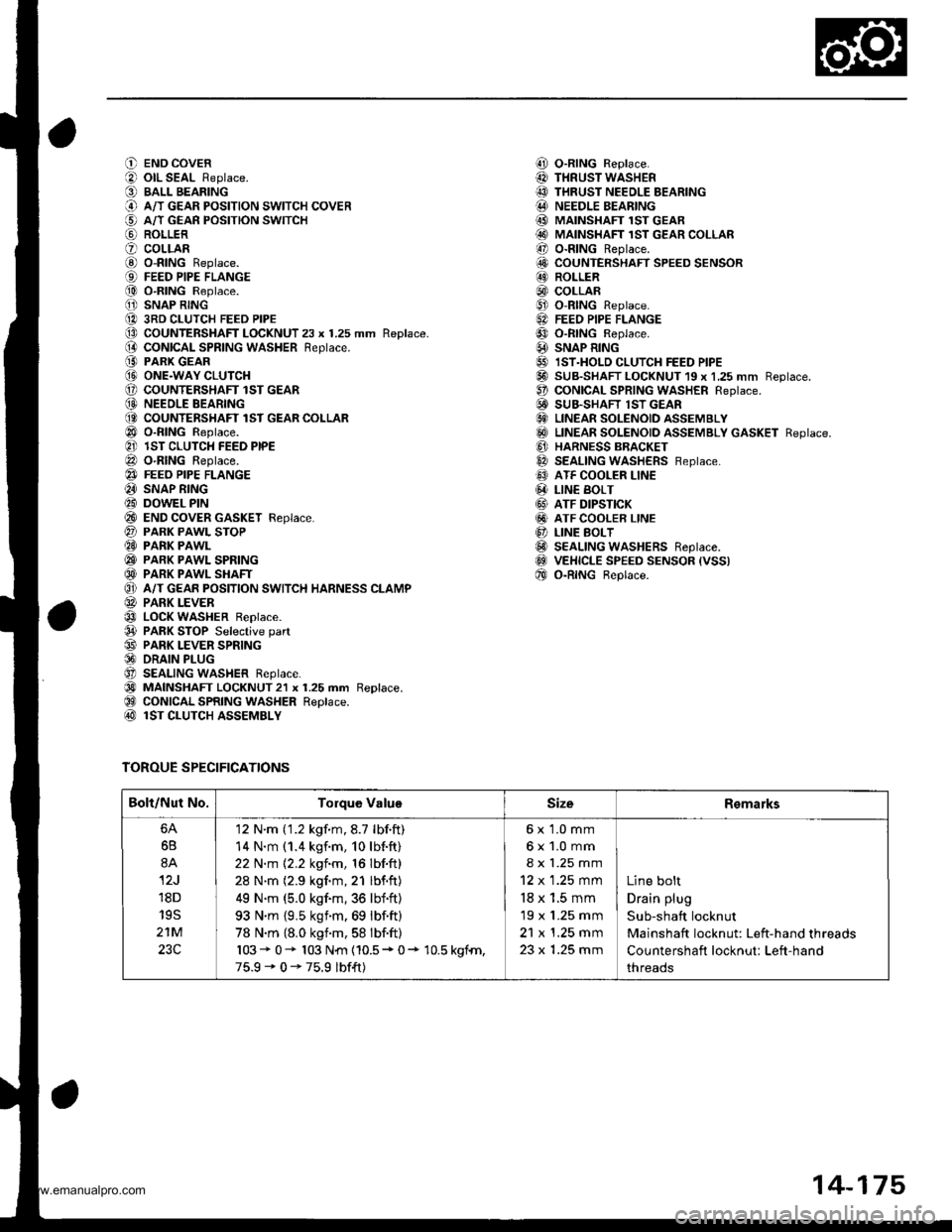

O END COVER

O olL SEAL Replace.

O BALL BEARING

@ A/T GEAR PoSITIoN swITcH coVER

€) A/T GEAn PosrloN swrrcH

@ ROLLER

O coLLARG) o-RING Replace.{9) FEED PIPE FLANGE

@ O-RING Replace.

O SNAP RING

@ 3RD CLUTCH FEED PIPE(D CoUNTERSHAFT LOCKNUT 23 x 1.25 mm Replace.(} coNtcAL SPR|NG WASHER Reptace.

@ PARK GEAR@ ONE.WAY CLUTCH(, COUNTENSHAFT lST GEAR(D NEEOLE BEARING(O COUNTERSHAFT lST GEAR COLLAR

@ o-RING Reptace.

@ lST CLUTCH FEED PIPE

@ O-RING Reptace.

@} FEEO PIPE FLANGE

@ SNAP RING

@ DOWEL PIN

@ END coVER GASKET Feplace.

@ PARK PAWL SToP@ PARK PAWL

@ PARK PAWL SPRING

@ PARK PAWL SHAFT

O} A/T GEAR POSITION SWITCH HARNESS CLAMP

@ PARK LEVER

@ LOCK WASHER Replace.

@ PARK STOP Selective part

@ PARK LEVER SPRING@ DRAIN PLUG

O SEALING WASHER Reptace.

@) MAINSHAFT LOCKNUT2l x 1.25 mm Replace.@ CONICAL SPRING WASHER Replace.@ lST CLUTCH ASSEMBLY

TOROUE SPECIFICATIONS

i!, O-RING Replace.

@ THRUST WASHER

@ THRUST NEEDLE BEARING@ NEEDLE BEARING

@ MAINSHAFI 1ST GEAR@ MAINSHAFT 1sT GEAR coLLAR

@ o-RING Replace.

6!, COUNTERSHAFT SPEED SENSOR@ ROLLER

@) COLLAR@ o-RtNG Replace.

6A FEEo PIPE FLANGE

@ o-RtNG Reptace.

@ SNAP R|NG

@ IST.HOLD cLUTcH FEED PIPE@ SUB-SHAFT LOCKNUT 19 x 1,25 mm Reptace.O coNtCAL SPR|NG WASHER Reptace.E! SUB.SHAFT lST GEAR€} LINEAR SOLENOID ASSEMBLY

@ LTNEAR soLENotD aSSEMBLy GASKET Reptace.

@ HARNESS BBACKET

@ SEALING WASHERS Feptace.

@ ATF COOLER LINE

@ LIN€ BoLT

@ ATF DIPSTICK

@ ATF COOLER LINE

@ LINE BoLT@ SEALING WASHERS Reptace.@ VEHICLE SPEED sENsoR (vss)

@ o-RtNG Beptace.

Bolt/Nut No.Torque ValuoSizeRemarks

6B

8A

12J

18D

19S

21M

23C

'12 N'm ('1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10lb{.ft}

22 N.m 12.2 kgf.m, 16 lbf.ft)

28 N'm (2.9 kgf.m,21 lbf.ft)

49 N.m (5.0 kgf.m,36 lbf'ft)

93 N'm {9,5 ksim.69 lbf.ft)

78 N.m {8.0 kgnm,58 lbf.ft)

103* 0- 103 N{n {10.5* 0+ 10.5 kgfn,

75.9-0-75.9 lbf{t)

6x 1.0 mm

6x1.0mm

8 x 1.25 mm

12 x 1.25 mm

18 x 1.5 mm

19 x 1.25 mm

21 x 1.25 mm

23 x 1.25 mm

Line bolt

Drain plug

Sub-shaft locknut

Mainshaft locknut: Left-hand threads

Countershaft locknut: Left-hand

threads

14-175

www.emanualpro.com