Interlock HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 517 of 1395

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 523 of 1395

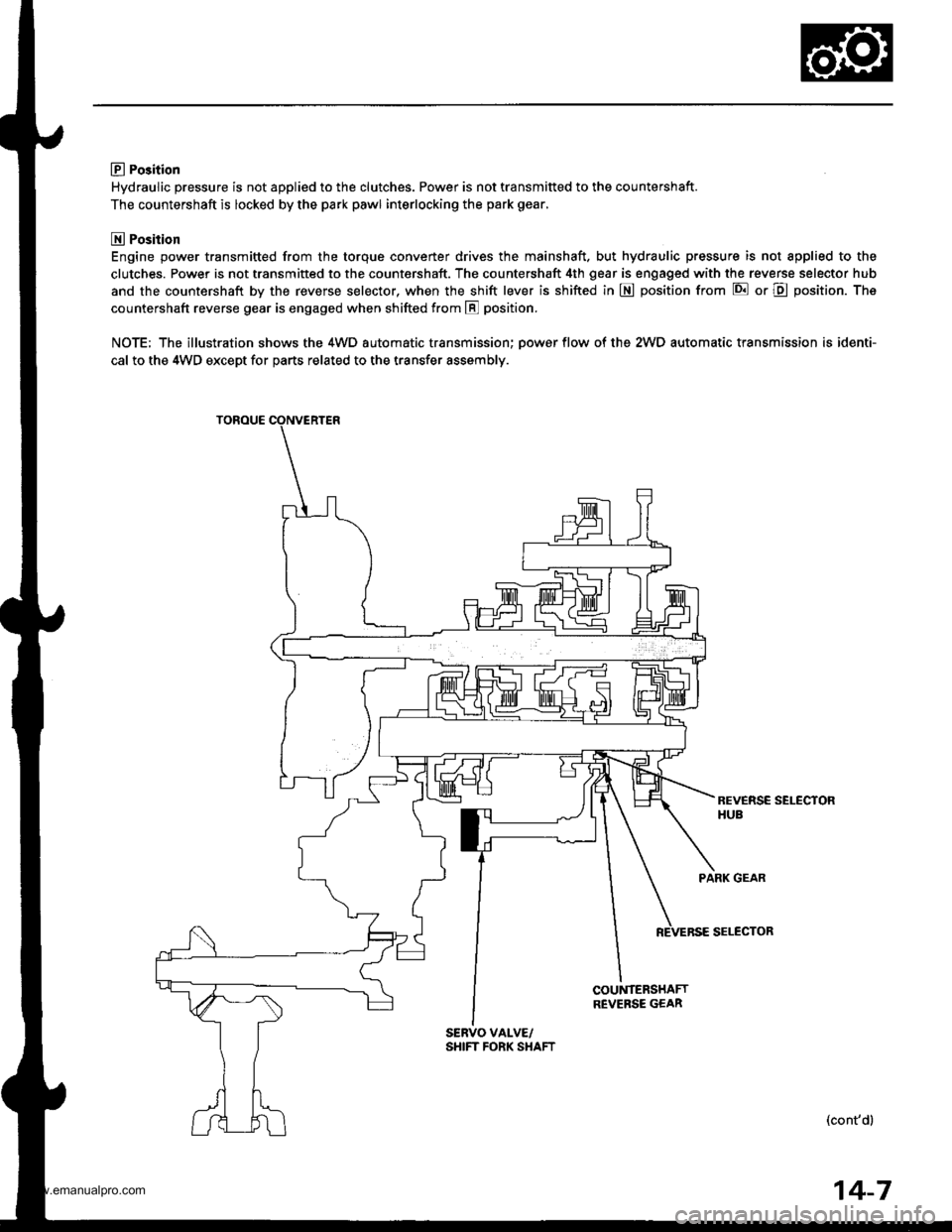

E Po3ition

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

The countershaft is locked by the park pawl interlocking the park gear,

E Position

Engine power transmitted from the torque converter drives the mainshaft. but hydraulic pressure is not applied to the

clutches. Power is not transmitted to the countershaft. The countershaft 4th gear is engaged with the reverse selector hub

and the countershaft by the reverse selector, when the shift lever is shifted in E position from E or E position. The

countershaft reverse gear is engaged when shifted from E position.

NOTE; The illustration shows the 4WD automatic transmission; oower flow of the 2WD automatic transmission is identi-

cal to the 4WD exceDt for oarts related to the transfer assemblv.

PARK GEAR

SELECTOR

(cont'd)

COUNTERSHAFTREVEBSE GEAR

14-7

www.emanualpro.com

Page 531 of 1395

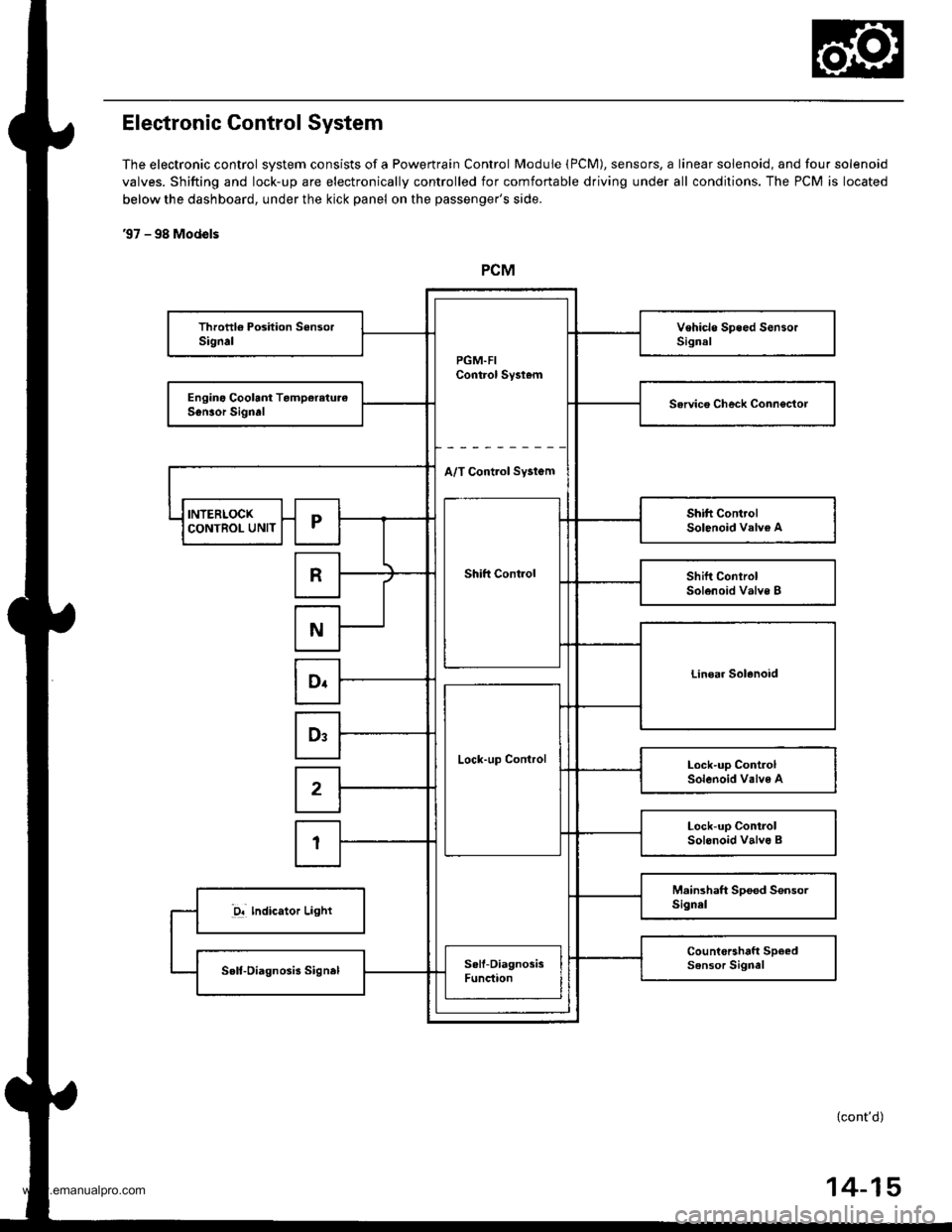

Electronic Control System

The electronic control svstem consists of a Powertrain Control Module (PCM), sensors, a linear solenoid, and four solenoid

valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions. The PCM is located

below the dashboard, under the kick panel on the passenger's side.

'97 - 98 Mod€ls

PGM.FIControl Sy3t6m

Throttl€ Poshion SensorSignalVehicle Sp.ed SensorSignal

Engino Coolant TamperetureService Check connectorSonsor Signrl

A/T Control Sy3tem

INTERLOCK

Shift Cont.ol

Shift ControlSolenoid valve ACONTROL UNITr

RShift ControlSolenoid Valve B

N

Linear SolenoidDr

Lock-up Control

Ds

Lock-up ControlSolenoid Valve A2

Lock-up ConirolSol6noid valvo B1

M.inshaft Spoed SensorSignel-D! Indicator Light

Count€rahaft Speedsensor SignelSelt-Oiagnosb signel

I

Sell-DiagnosisFunction

l-

{cont'd)

14-15

www.emanualpro.com

Page 532 of 1395

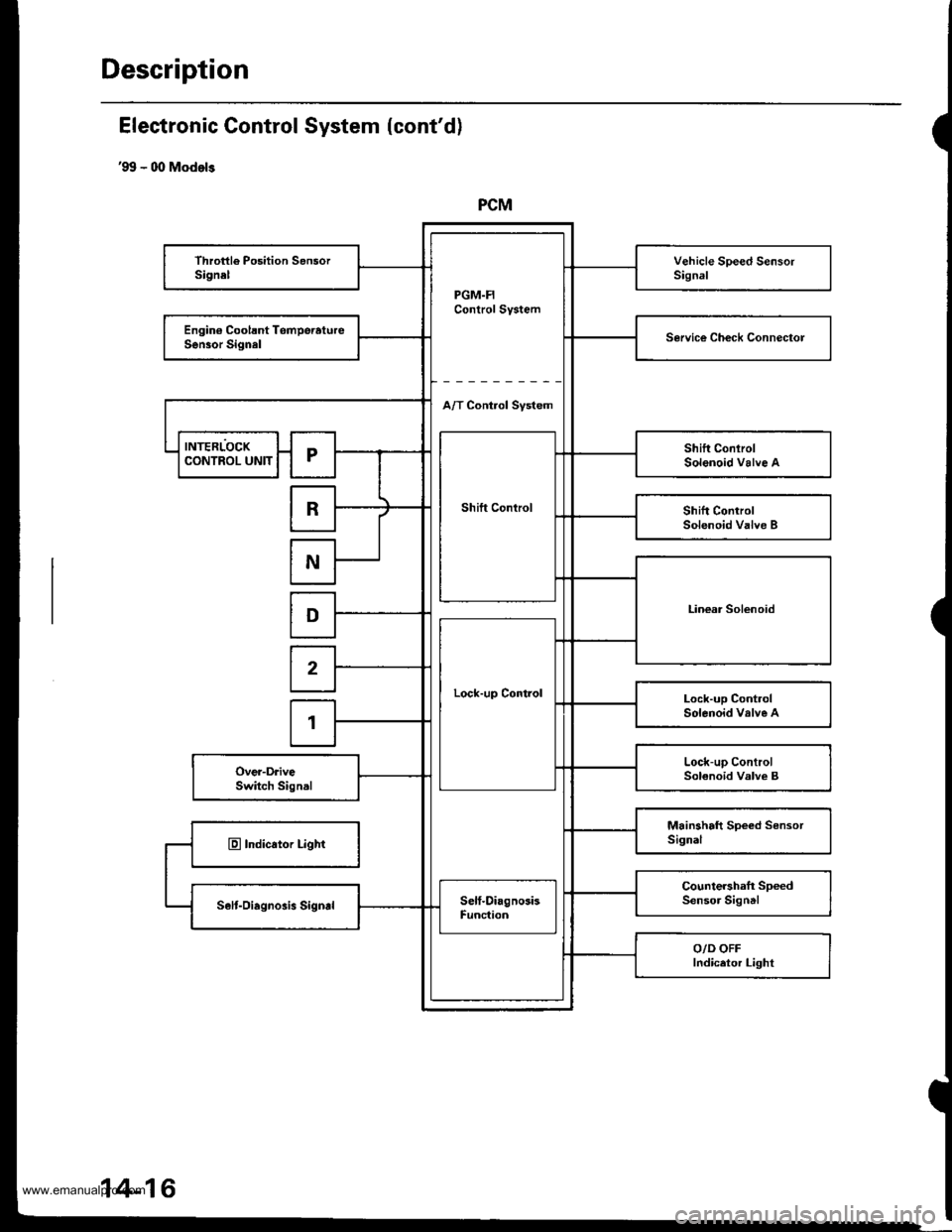

Description

PCM

PGM.FIControl System

Throttle Position SensorSignelVehicle Speed SensorSignal

Engin€ Coolsnt TomperatureSen30r SignalService Ch€ck Connectol

A/T Control Svstem

INTERLOCK

Shift Control

Shift ConlrolSolenoid Valve ACONTROL UNITr

RShift ControlSolenoid Valve B

N

Linear SolenoidD

Lock-up Control

2

Lock-up ControlSolenoid valve A1

Lock-up ControlSolenoid Valve BOver-DriveSwitch Signal

Mainshaft Speed SensorSignalE Indicator Light

Countershaft SpeedSensor SigntlSelt-Oiagnosis SigndSelf-DiagnosisFunc{ion

O/D OFFIndicetor Light

Electronic Gontrol System (cont'd)

'99 - 00 Models

14-16

www.emanualpro.com

Page 570 of 1395

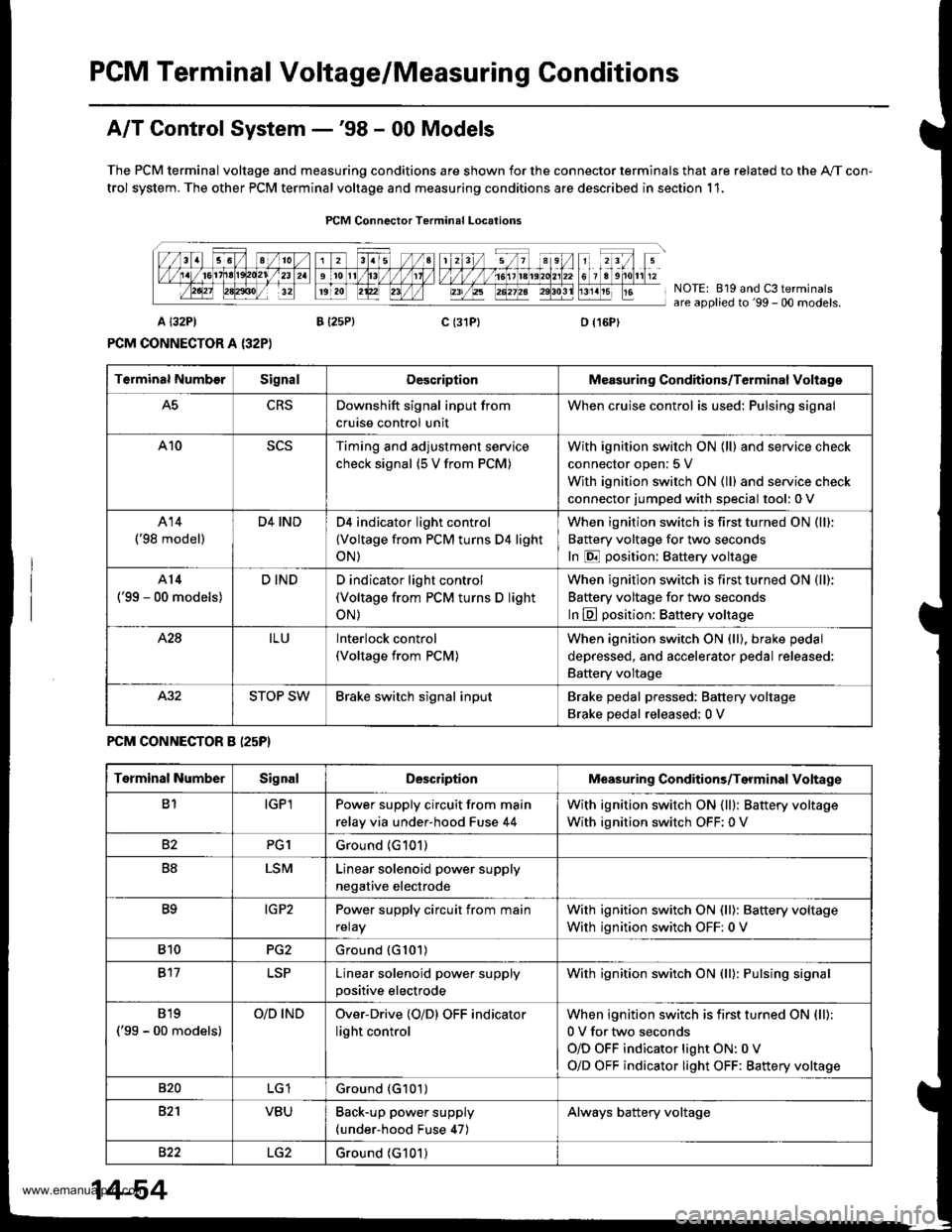

PCM Terminal Voltage/Measuring Conditions

A/T Control System -'98 - 00 Models

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A"/T con-

trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

FCM Connector Terminal Localions

NOTE: 819 and C3 terminalsare applied to'99 - 00 models.

o (16Pt

T6rminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

A5CRSDownshift signal input from

cruise control unit

When cruise control is used; Pulsing signal

A10scsTiming and adjustment service

check signal (5 V from PCM)

With ignition switch ON (ll) and service check

connector open:5 V

With ignition switch ON (ll) and service check

connector jumped with special tool: 0 V

A14('98 model)

D4 INDD4 indicator light control

{Voltage from PCM turns D4 light

oN)

When ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltage

A14

('99 - 00 models)

D INDD indicator light control(Voltage from PCM turns D light

oN)

When ignition switch is first turned ON (ll):

Baftery voltage for two seconds

ln E position: Battery voltage

428ILUInterlock control(Voltage from PCM)

When ignition switch ON {ll), brake pedal

depressed, and accelerator pedal released:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal pressed; Battery voltage

Brake pedal released: 0 V

FCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

B1IGPlPower supply circuit from main

relay via under-hood Fuse 44

With ignition switch ON {ll): Battery voltage

With ignition switch OFF: 0 V

82PG1Ground (G101)

B8LSMLinear solenoid power supply

negative electrode

IG P2Power supply circuit from main

relay

With ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2Ground (G101)

B17Linear solenoid power supply

positive electrode

With ignition switch ON (ll): Pulsing signal

819

('99 - 00 models)

O/D INDOver-Drive (O/D) OFF indicator

light control

When ignition switch is first turned ON (ll):

0 V for two seconds

O/D OFF indicator light ON:0 V

O/D OFF indicator light OFF: Battery voltage

s20Ground (G101)

B�21VBUBack-up power supply(under-hood Fuse 47)

Always battery voltage

B�22LG2Ground (G101)

14-54

www.emanualpro.com

Page 577 of 1395

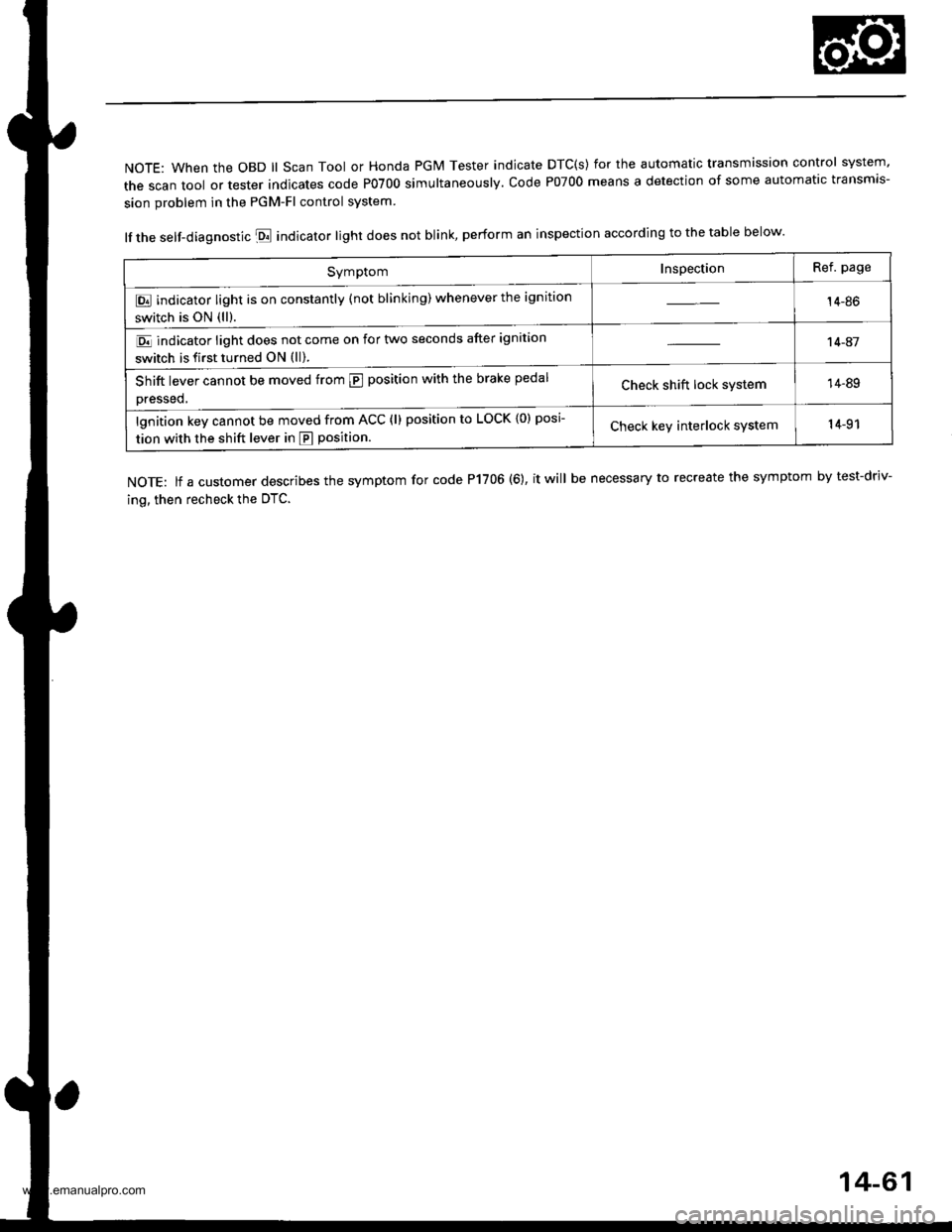

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(s) for the automatic transmission control system'

the scan tool or tester indicates code P0700 simultaneously. code P07oo means a detection of some automatic transmis-

sion problem in the PGM-Fl control system

lf the self-diagnostic E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P1706 (6), it will be necessary to recreate the symptom by test-driv-

ing, then recheck the OTC.

SymptomInspectionRef. page

E indicator light is on constantly (not blinking) whenever the ignition

switch is ON (ll).14-86

E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).

't 4-41

Shift lever cannot be moved from @ position with the brake pedal

Dressed,Check shift lock system14-89

lgnition key cannot be moved from ACC (l) position to LOCK {0) posi

tion with the shift lever in E position.Check keY interlock system14-91

14-61

www.emanualpro.com

Page 579 of 1395

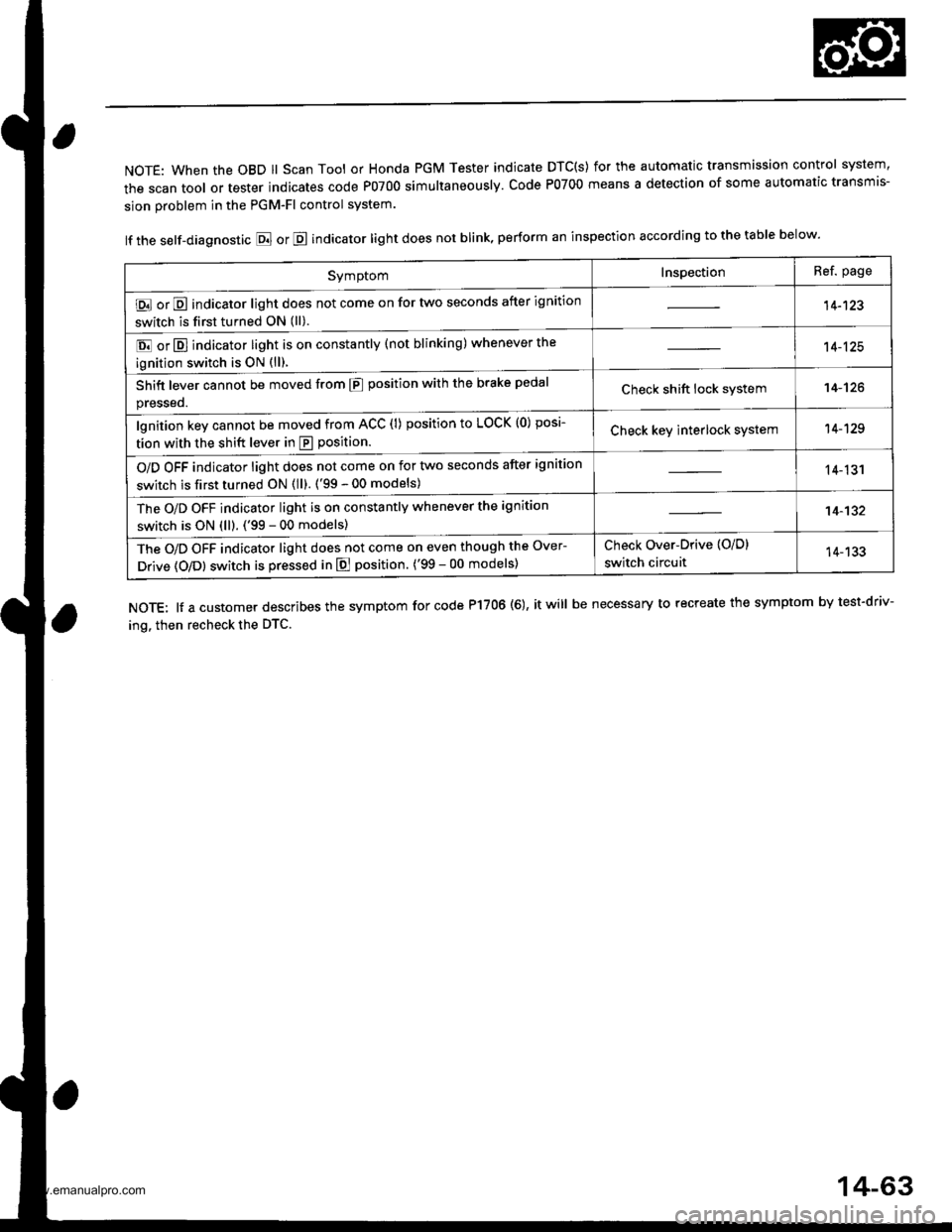

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(S) for the automatic transmission control system,

the scan tool or tester indicates code P0700 simultaneously. Code P0700 means a detection of some automatic transmis-

sion problem in the PGM-Fl control system.

lf the self-diagnostic E or E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P17OO (6), it will be necessary to recreate the symptom by test-driv-

ing. then recheck the DTC.

SymptomInspectionRef. page

E or E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).14-123

E or E] indicator light is on constantly (not blinking) whenever the

ignition switch is oN {ll).

14-125

Shift lever cannot be moved from E position with the brake pedal

presseo.Check shift lock system14-'t26

lgnition key cannot be moved from ACC (l) position to LOCK (0) posi-

tion with the shift lever in E position.Check key interlock system14-129

O/D OFF indicator light does not come on for two seconds after ignition

switch is first turned ON (ll). ('99 - 00 models)14-131

The O/D OFF indicator light is on constantly whenever the ignition

switch is ON (ll). ('99 - 00 models)14-132

The O/D OFF indicator light does not come on even though the Over-

Drive (O/Dl switch is pressed in E position. ('99 - 00 models)

Check Over-Drive {O/D}

switch circuit14-133

14-63

www.emanualpro.com

Page 605 of 1395

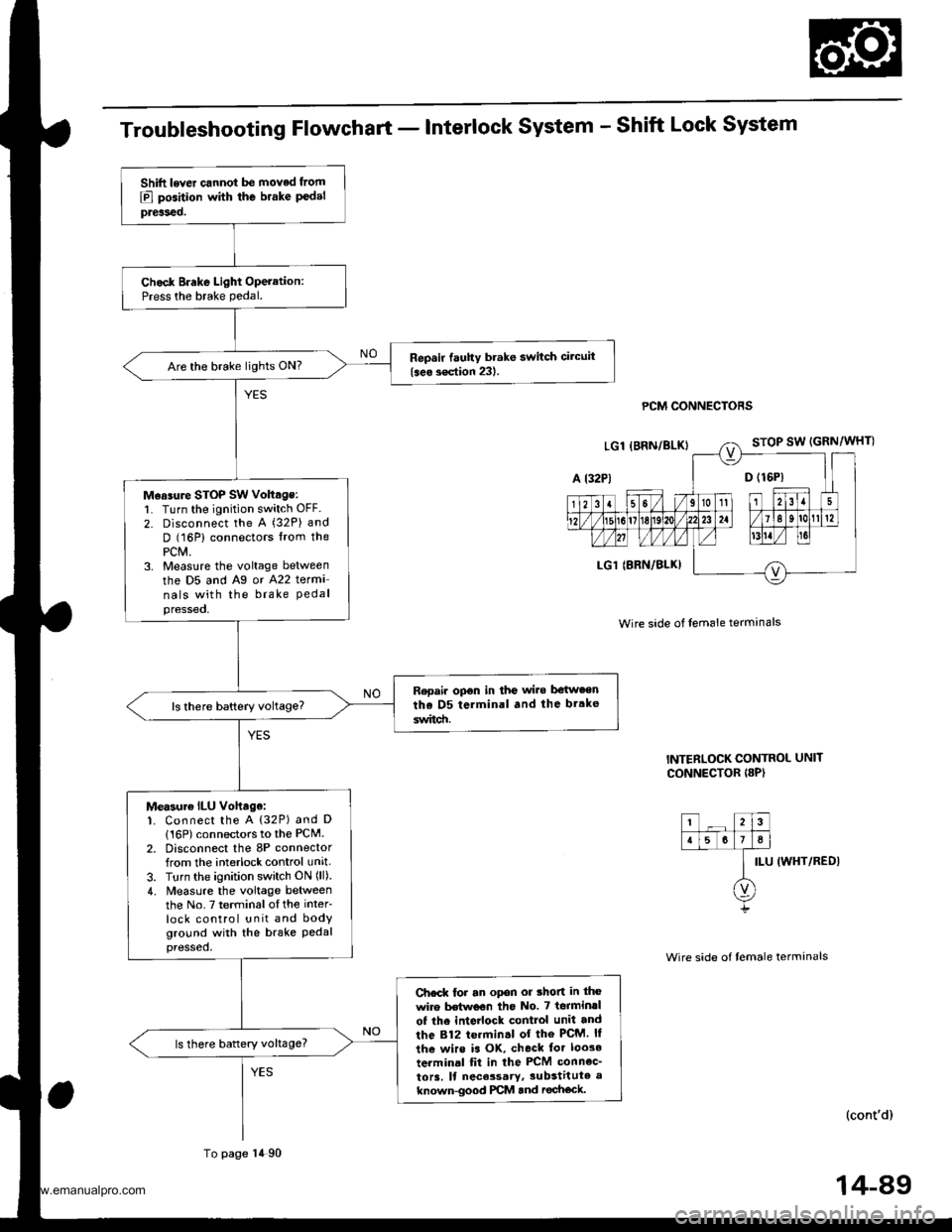

Troubleshooting Flowchart - Interlock System - Shift Lock System

PCM CONNECTORS

Wire side of lem6le termanals

INTERLOCK CONTROL UNIT

CONNECTOR I8P)

ILU IWHT/REDI

(cont'd)

Shift lever cannot be moved from

E] position with the brake P€delpreiseo.

Chock Brake Light Operation:Press the brake pedal.

Repsir fauhy brake switch circuit

{seo s€ction 231.Are the brake lights ON?

M€asure STOP SW voltage:l� Turn the ignition switch OFF.

2. Disconnect the A (32P) and

D (16P) connectors lrom thePCM.3. Measlre the voltage between

the D5 and Ag or A22 terma

nals with the brake Pedalpressed,

Repair opon in the wi.e be{w.enthe D5 terminal and the br.ke

switd!.

Measur€ ILU vohage:1. Connect the A {32P) and D

116P) connectors to the PCM.2. Disconnect the 8P connectorfrom the interlock control unit

3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe No.7 terminalofthe inter

lock control unit and bodyground with the brake Pedalpressed,

Ch€ck for an opon or thon in the

wire Mwoon tho No. 7 terminrl

of the inte ock control unit and

the 812 termin.l of the PcM. ll

the wirs is OK, check tor loo3e

terminal fit in the PCM connec_

to13. ll nece3sary,3ubstitute a

known-good PCM and rechock.

ls there battery voltage?

To page 14 90

14-89

www.emanualpro.com

Page 606 of 1395

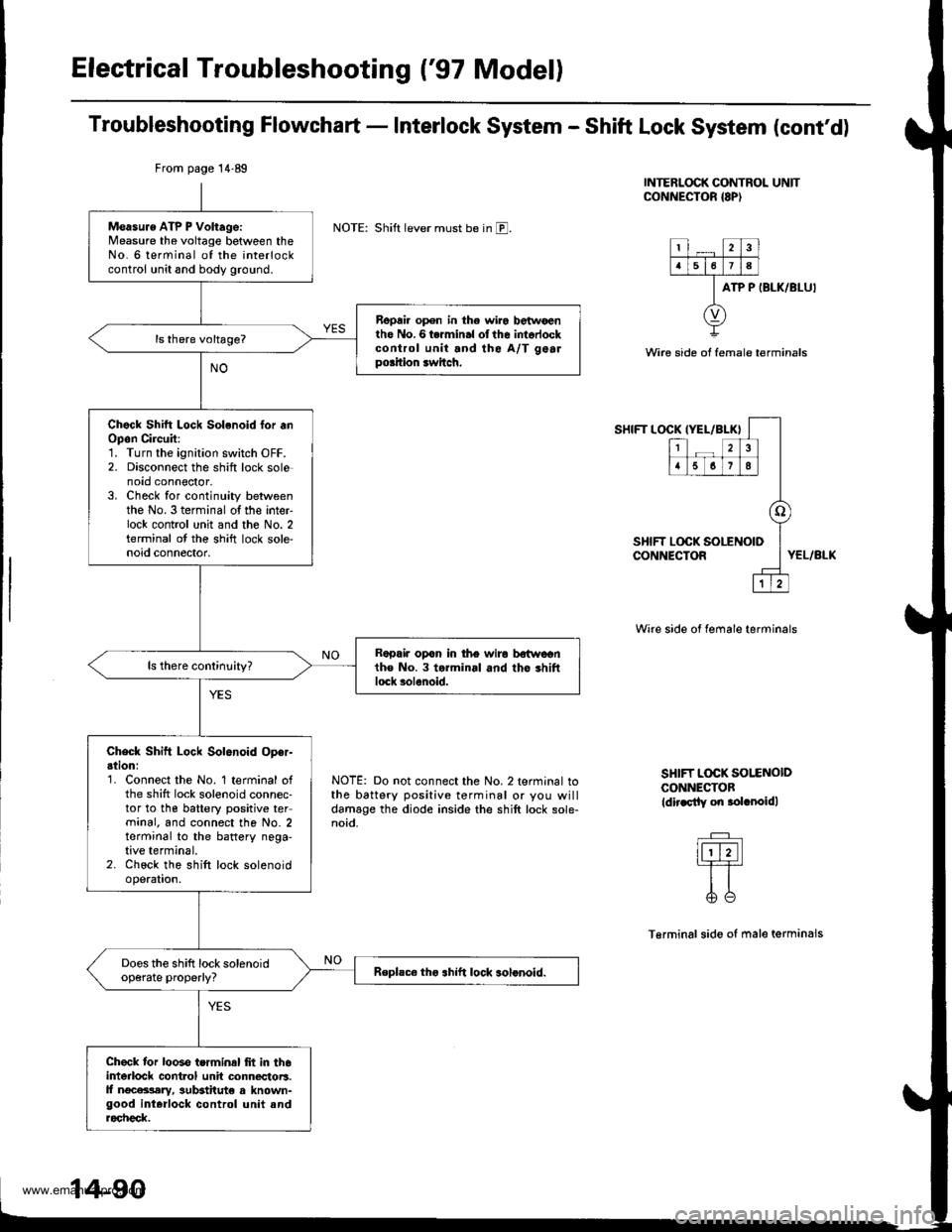

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Interlock System - Shift Lock System (cont'd)

INTERLOCK CONTROL UNITCONNECTOR {8P)

NOTE: Shift lever must be in E.

ATP P IBLK/BLU'

Wire side ot female terminals

SHIFT LOCKIYEL/BLK}

12

5678

o

LOCK SOLENOID

1

SHIFT LOCK !CONNECTORYEL/BLK

NOTE: Do not connect the No. 2 terminal tothe battery positive terminal or you willdamage the diode inside the shift lock sole-noid.

Wire side of female terminals

SHIFT L@K SOI.ENOIDCONNECTOBldir.sily on .olrnoidl

Terminalsido of male terminals

From page 14.89

Measu.e ATP P Voltage:Measure the voltage between theNo. 6 terminal of the interlockcontrol unit and body ground.

Repai. open in the wir6 betwoentho No.6 termin.l olthe intorlockcontrol unit and the A/T gealpo.ition rwitch.

Chock Shitt Lock Solenoid lor .nOpon Circuit:1. Turn the ignition switch OFF.2. Disconnect the shift lock solenoto connoctor.3. Check for continuity betweenthe No. 3 terminal of the inter-lock contrcl unit and the No. 2terminal ot the shift lock sole-noid connector.

Rapair opon in the wiro bstwcentho No. 3 torminal and tho shiftlock solenoid.

Check Shift Lock Solenoid Oper-ation:'1. Connect the No. 1 terminal ofthe shift lock solenoid connec-tor to the battery positive terminal. and connect the No. 2terminal to the battery nega-tive terminal.2. Chock the shift lock solenoidoperation.

Does the shift lock solenoidop€rate properly?Replsc€ tho .hift lock solonoid.

Check tor looso terminal frt in th6interlock cont.ol unit connectoB.ll ngcara,lary, sutEtitut€ a known-good interlock control unit androcheck.

www.emanualpro.com

Page 607 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont](/img/13/5778/w960_5778-606.png)

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont'd)

lgnition key cannot be moved

Irom ACC (l) pGition to LOCK (0)

position while Pushing the igni-

tion kev with the shift lever in lllposifio;, and the shift lever but-

ton rcleased.

Check Key Interlock Solenoid

Op€ration:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-

tor to the battery Positive ter

minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole

noid operation A clicking

so!nd sho!ld be heard.

Faulty koy interlock solenoid.

Replace the ignition key cylinder/

steedng lock as36mbly

Does the key interlock

solenoid operate properly?

Check Key Interlock Switch OPer'

adon:1. Connect the No. 5 terminal of

the ignition switch connector

to the battery Positive termi

nal, and connect the No 3 ter

minal to the baftery negative

termrnal,2. Turn the ignition switch to

ACC (l), then push rt.

3. Check the key interlock sole'

noid operation. A clicking

sound should be heard whilepushing the ignition key.

Faulty key inte.lock switch

Replaco the ignition key cylindor/

stoering lock a3r.mblY.

Does the key interlocksolenoid operate ProPerlY?

To page 14 92

14-91

www.emanualpro.com