length HONDA CR-V 2000 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 82 of 1395

Charging System

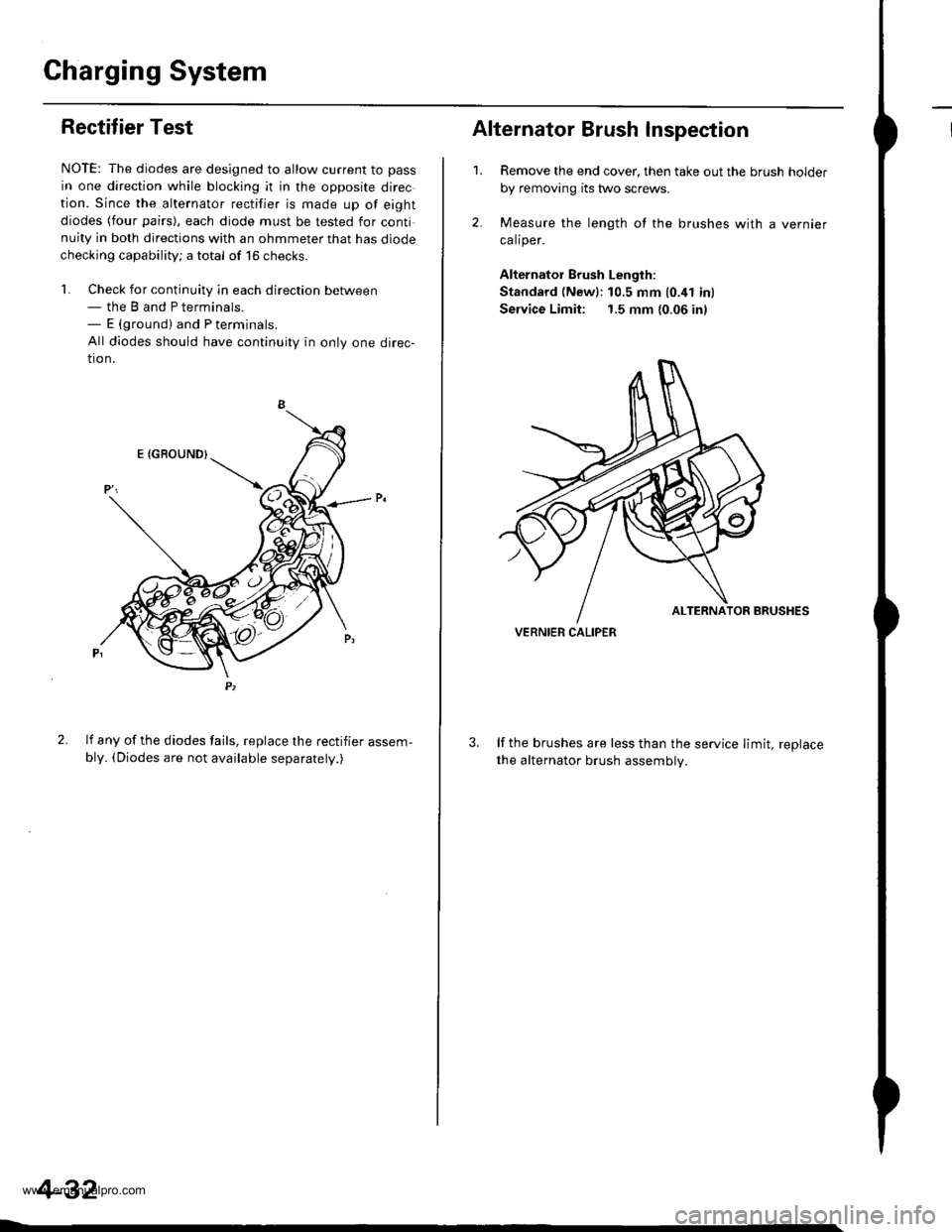

IRectifier Test

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc

tion. Since the alternator rectifier is made up of eight

diodes (four pairs), each diode must be tested for continuity in both directions with an ohmmeter that has diode

checking capability; a total of 16 checks.

'l. Check for continuity in each direction between- the B and P terminals.- E (ground) and P terminals.

All diodes should have continuity in only one direc-

tion.

2. lf any of the diodes fails, replace the rectifier assem-

bly. (Diodes are not available separatelv.)

4-32

1.

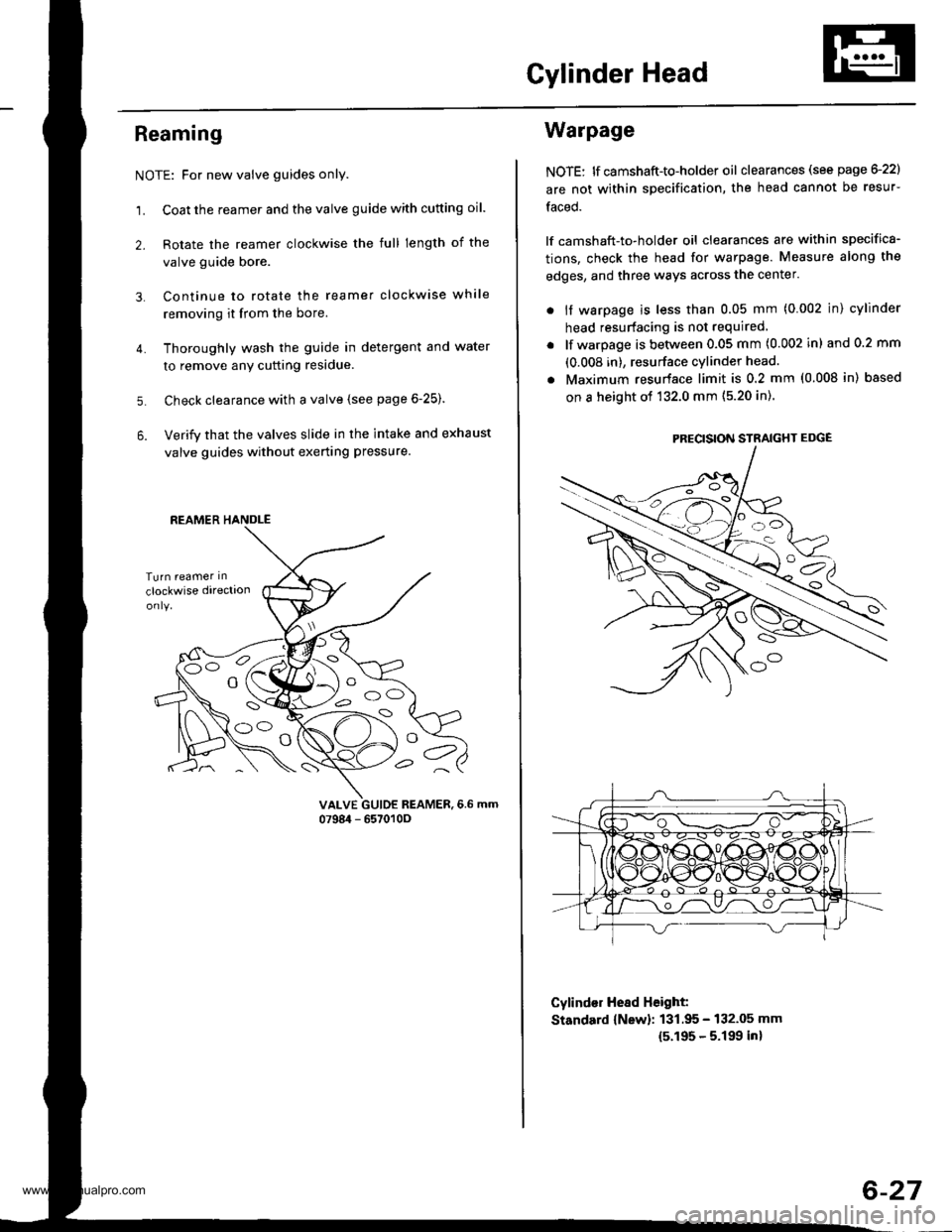

Alternator Brush Inspection

2.

Remove the end cover, then take out the brush holder

by removing its two screws.

Measure the length of the brushes with a vernier

calrper.

Alternator Brush Length:

Standard (Newl:10.5 mm 10.41 inl

Service Limit: 1.5 mm {0.06 in)

lf the brushes are less than the service limit, replace

the alternator brush assemblv.

VERNIER CALIPER

www.emanualpro.com

Page 140 of 1395

Cylinder Head

Reaming

NOTE: For new valve guides only.

1. Coat the reamer and the valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the

valve guide bore.

Continue to rotate the reamer clockwise while

removing it from the bore.

Thoroughly wash the guide in detergent and water

to remove anY cutting residue.

Check clearance with a valve (see page 6-25).

Verify that the valves slide in the intake and exhaust

valve guides without exerting pressure.

3.

4.

5.

6.

vALvE GUIDE REAMER,6.6 mm0798i1 - 657010O

REAMER HANDLE

e

Warpage

NOTE: lf camshaft-to-holder oil clearances (see page G22)

are not within specification, the head cannot be resur-

faced.

lf camshaft-to-holder oil clearances are within specifica-

tions, check the head for warpage. Measure along the

edges, and three ways across the center.

. if warpage is less than 0.05 mm (0.002 in) cylinder

head resurfacing is not required

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in), resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Cylind€r Hesd Height:

Standard {New}: 131.95 - 132.05 mm

15.195 - 5.199 inl

PRECISION STRAIGHT EDGE

6-27

www.emanualpro.com

Page 160 of 1395

Piston PinsConnecting Rods

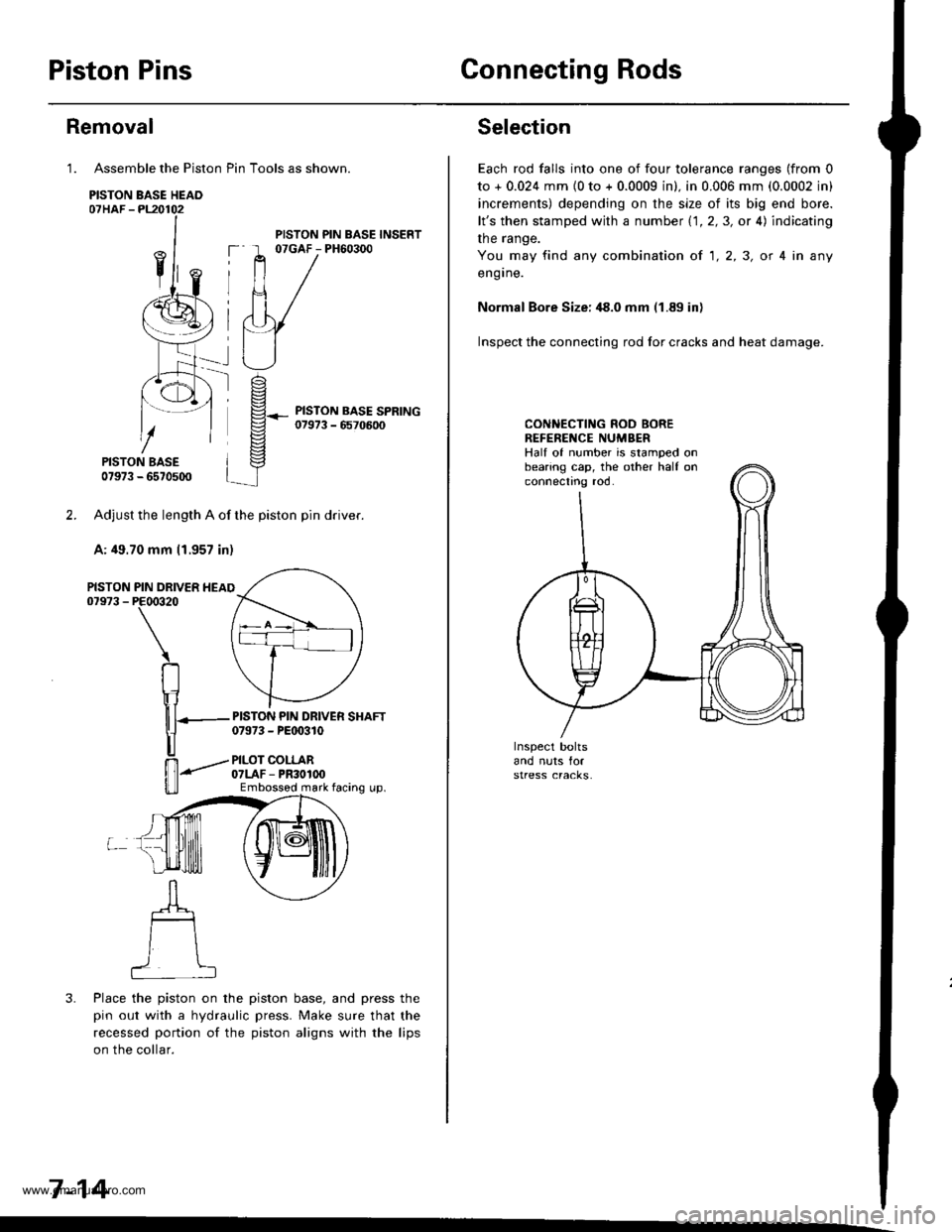

Assemble the Piston Pin Tools as shown.

PISTON BASE HEAO07HAF -PL20102

PISTON BASE07973 - 6570500

Adjust the length A of the piston pin dflver.

A: 49.70 mm 11.957 in)

PIN DRIVER HEAIPE00320

\

RIr1

nT---

u

ffi-"""-

u_ll

3. Place the piston on the piston base, and press the

pin out with a hydraulic press. Make sure that the

recessed portion of the piston aligns with the lips

on the collar.

7-14

Removal

1.

PISTON07973 -

PISTON PIN BASE INSERT07GAF - PH60300

PISTON PIN DRIVER SHAFT07973 - PEt 0310

PILOT COLLAR07LAF - PR30100Embossod mark facing up.

Selection

Each rod falls into one of four tolerance ranges (from 0

to + 0.024 mm {0 to + 0.0009 in). in 0.006 mm (0.0002 in)

increments) depending on the size of its big end bore.

lt's then stamped with a number 1.1.2,3, or 4) indicating

the range.

You may find any combination ot 1,2,3, or 4 in any

engrne.

Normal Bore Size: ,18.0 mm (1.89 in)

Inspect the connecting rod for cracks and heat damage.

CONNECTING ROD BOREREFENENCE NUMBERHalf of number is stamped onbearing cap, the other half onconnectno roo.

www.emanualpro.com

Page 161 of 1395

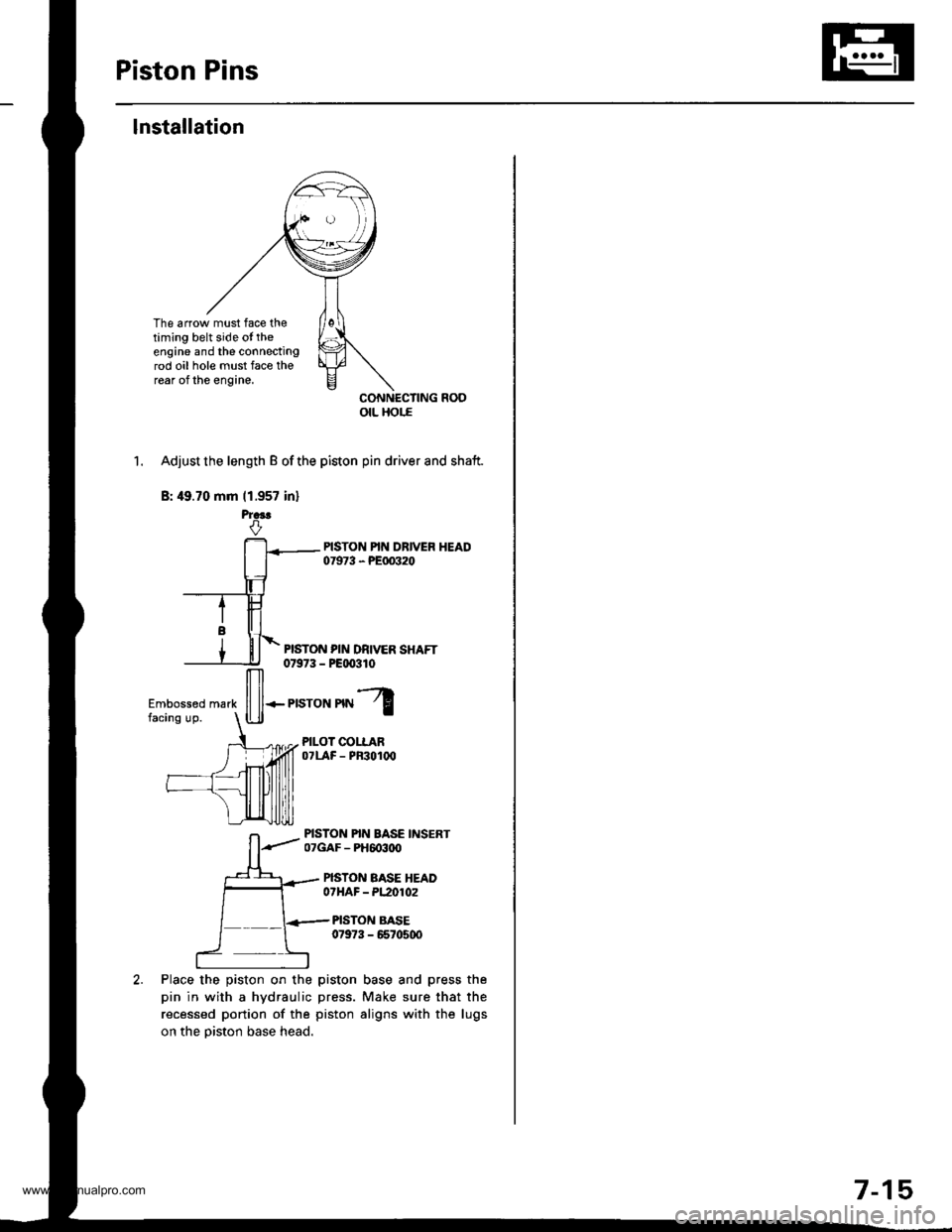

Piston Pins

lnstallation

The arrow must face thetiming belt side ot theengine and the connectingrod oil hole must face therear of the engine.

CONNECTING ROOotL Hor.E

1. Adjust the length B of the piston pin driver and shaft.

B: 49.70 mm (1.957 in)

PISTON PIN DRIVER SHAFT0t973 - P€qxtlo

Place the piston on the

pin in with a hydraulic

recessed portion of the

on the piston base head.

ffi*r,"ron'nl

PILOT COLLAROTLAF - PF3O1(x'

PISTON PIN BASE INSERT07GAF - PH6o3ttO

PISTON BASE HEADOTHAF - PL2O102

PISTON BASE07973 - 6670500

piston base and press the

press. Make sure that the

piston aligns with the lugs

7-15

www.emanualpro.com

Page 713 of 1395

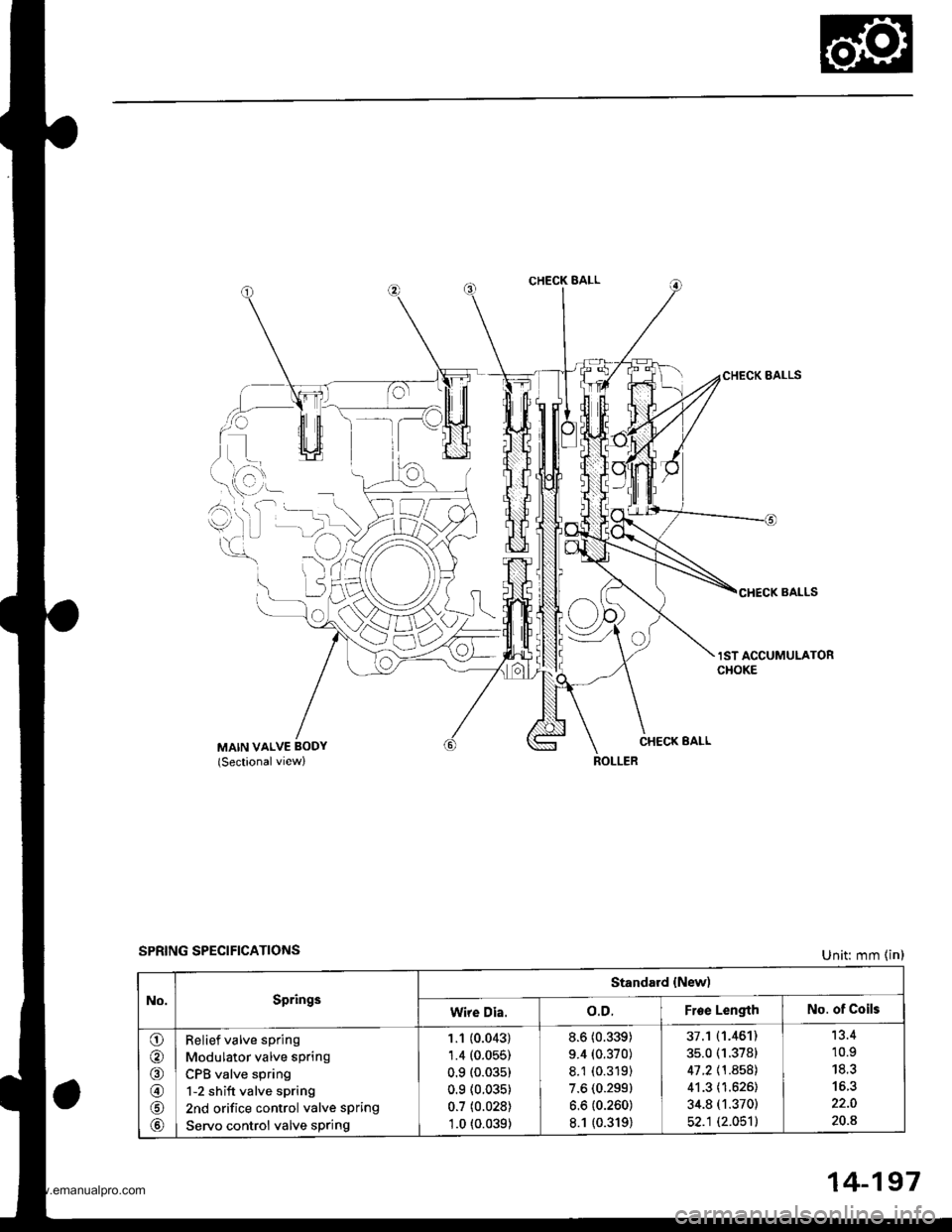

CHECK BALL

i)L)

lo

CHECK BALLS

lST ACCUMULATORCHOKE

CHECK EALLMAIN VALVE BODY(Sectionalview)

SPRING SPECIFICATIONSUnit: mm (in)

No.Springs

Standard {New)

Wire Dia.o.D.Froe LengthNo. of Coils

o

@

@

@

Relief valve spring

Modulator valve spring

CPB valve spring

1-2 shift valve spring

2nd orifice control valve spring

Servo control valve sPring

1.1 (0.043)

1.4 (0.055)

0.9 (0.03s)

0.9 (0.035)

0.7 (0.028)

1.0 t0.039)

8.6 (0.339)

9.4 (0.370)

8.1 (0.319)

7.6 (0.299)

6.6 (0.260)

8.1 {0.319)

37.1 (1.461)

35.0 (1.3781

41 .2 \1 .8581

41.3 (1.626)

34.8 (1.370)

52.1 (2.051)

'13.4

10.9

20.8

14-197

www.emanualpro.com

Page 714 of 1395

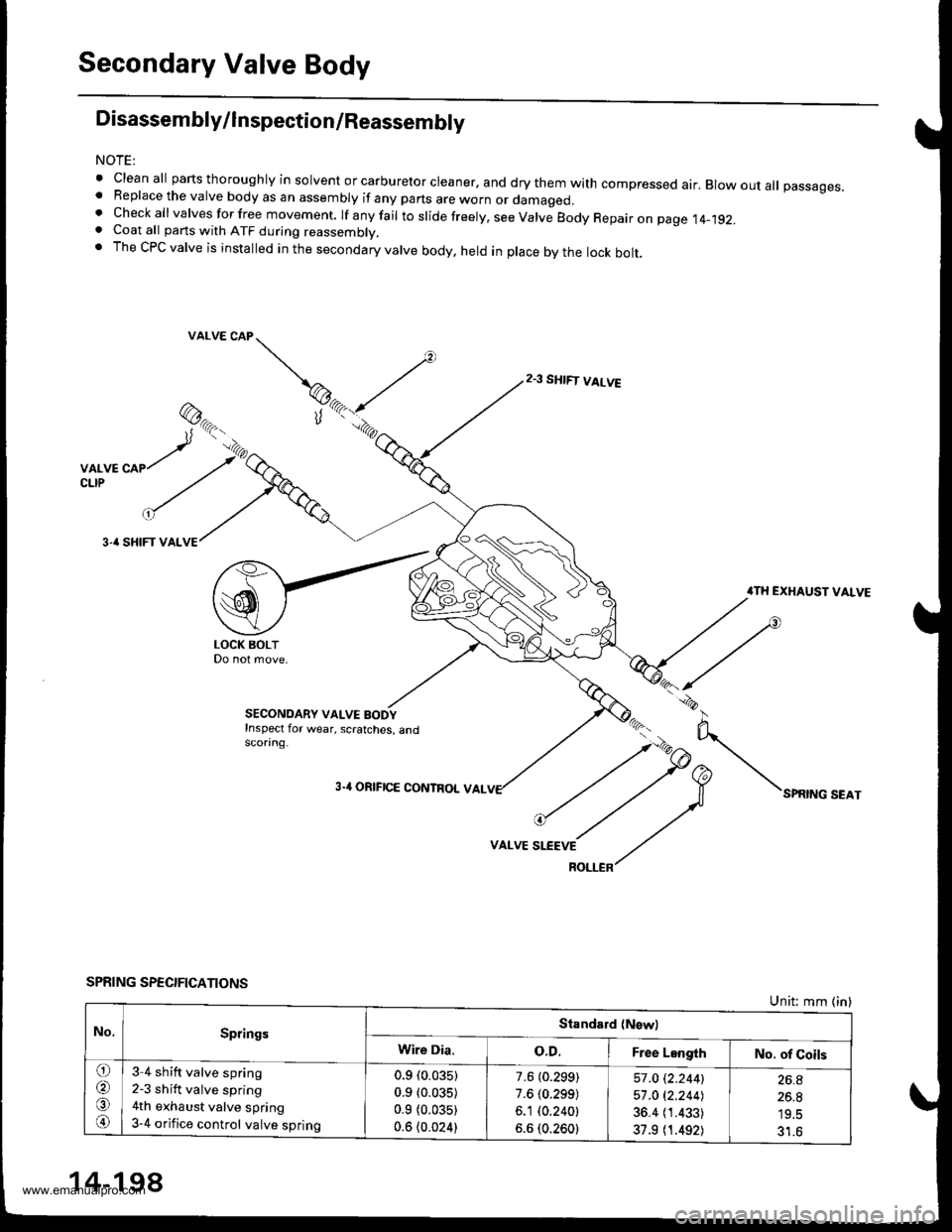

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

' clean all parts thoroughly in solvent or carburetor cleaner. and dry them with compressed air. Blow out aU passages,. Replace the valve body as an assembly if any parts are worn or damaged.t check all valves for free movement. rf anyfair to sride freery. see varve Body Repair on page 14-192.. Coat all parts with ATF during reassembly.. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

@,.-.t'tr.,

,rr'^'//u

"/ ./

3-' SHIFT VALVE

VALVE CAP

SPRING SPEC!FICATIONS

2.3 SHIFT VALVE

VALVE SLEEVE

ROLLER

ilTH EXHAUST VALVE

N"*,"o"*,

Unit: mm (in)

t*-1

SECONOARY VALVE BODYInspect for wear, scratches, andscorang.

3.4 ORIFICE CONTROL VAL

No.SpringsStandald {Nswl

Wire Dia.o.D.Free LengthNo. of Coils

o

@

o

@

3 4 shift valve spring

2-3 shift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.9 (0.035)

0.9 (0.035)

0.9 {0.035)

0.6 {0.024}

7.6 (0.299)

7.6 (0.299)

6.1 (0.240t

6.6 (0.2601

57 .O i.2.2441

57 .O 12.244J

36.4 (1.433)

37.9 (1.492)

26.A

26.8

19.5

31.6

14-198

www.emanualpro.com

Page 715 of 1395

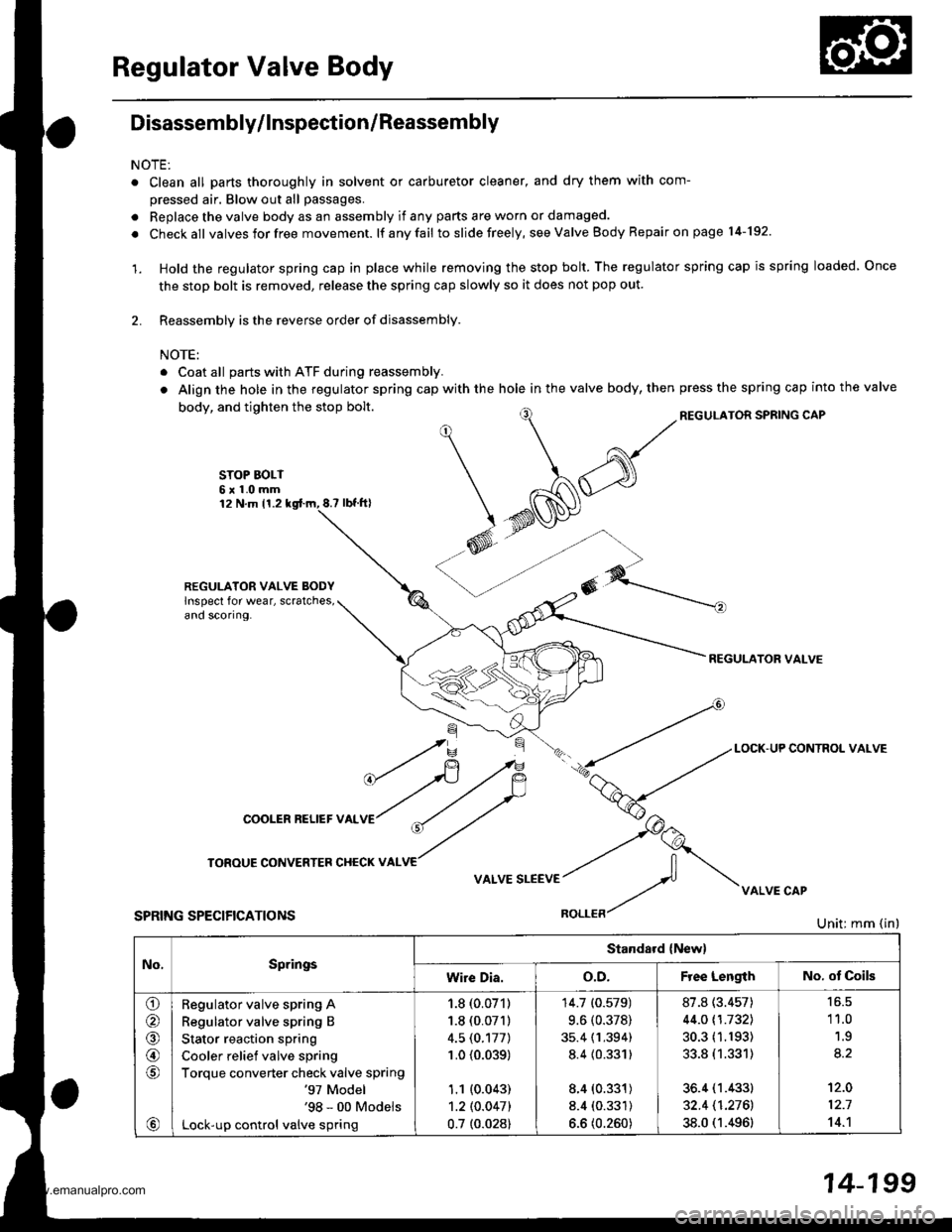

Regulator Valve Body

Disassembly/lnspection/Reassembly

NOTE:

o Clean all parts thoroughly in solvent or carburetor cleaner, and dry them with com-

pressed air. Blow out all passages.

. Replace the valve body as an assembly if any parts are worn or damaged.

. Checkall valvesforfree movement. lf anyfail toslidefreely, see Valve Body Repair on page l4-192.

'1. Hold the regulator spring cap in place while removing the stop bolt. The regulator spring cap is spring loaded Once

the stop bolt is removed, release the spring cap slowly so it does not pop out.

2. Reassembly is the reverse order of disassembly.

NOTE:

. Coat all parts with ATF during reassembly.

. Align the hole in the regulator spring cap with the hole in the valve body, thenpress the spring cap into the valve

REGULATOR SPSING CAPbody, and tighten the stop bolt.

STOP BOLT6x1.0mm12 N.m 11.28.? tbt.fil

REGULATOR VALVE BODYlnspect for wear, scratches,ano scoflng.

REGULATOR VALVE

No,SpringsStandard {New}

wire Dia.o.D.F ee LengthNo. ot Coils

o

@

@,6

a,

Regulator valve spring A

Regulator valve spring B

Stator reaction spring

Cooler relief valve spring

Torque converter check valve spring'97 Model'98 - 00 Models

Lock-up control valve spring

1.8 (0.071)

1.8 (0.071)

4.5 (0.177)

1.0 {0.039)

1.1 (0.043)

1.2lO.O47l

0.7 t0.028)

14.7 (0.579)

9.6 (0.378)

35.4 (1.394)

8.4 {0.331)

8.4 (0.331)

8.4 (0.331)

6.6 (0.260)

87.8 (3.457)

44.0 t1.7321

30.3 (1.193)

33.8 (1.331)

36.4 (1.433)

32.4 11.2761

38.0 (1.496)

'11.0

1.9

't2.0

12.7

14.'l

14-199

www.emanualpro.com

Page 717 of 1395

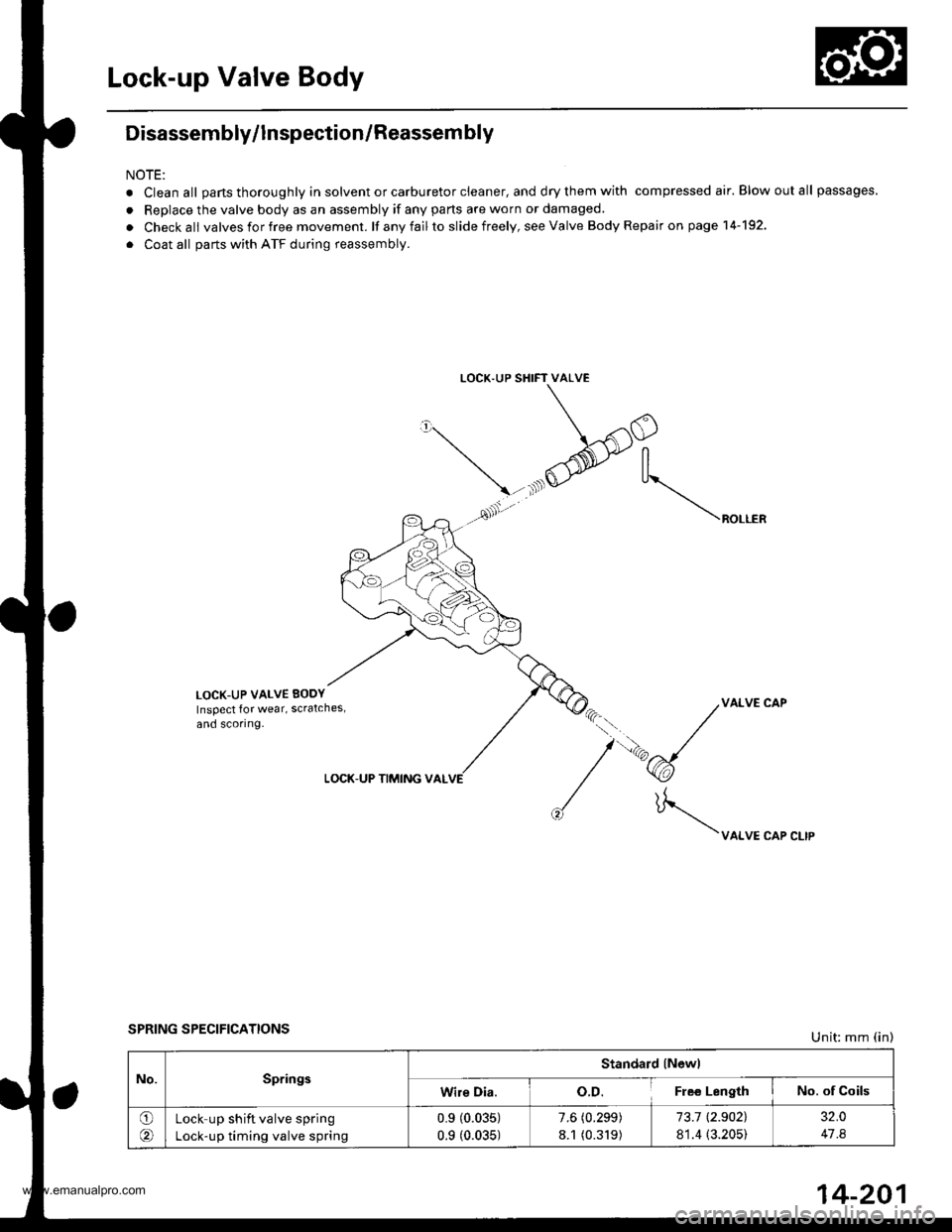

Lock-up Valve Body

Disassembly/lnspection/Reassem bly

NOTE:

. Clean all parts thoroughly in solvent or carburetor cleaner, and dry them with compressed air. Blow out all passages.

. Replace the valve body as an assembly if any parts are worn or damaged.

. Checkall valvesforfree movement. lf anyfailto slide freely, seeValve Body Repairon page 14-192.

. Coat all parts with ATF during reassembly.

LOCK.UP SHIFT VALVE

\/'

\-.xlO

@-tr

, ^ ,As'. \"o...*

LOCK-UP VALVE EODY

Inspect lor wear, scratches,

and scoring.

VALVE CAP

\uo.*"or".,,

LOCK-UP TIMING VAL

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard lNewl

Wire Dia.o.D.Fle€ LengthNo. of Coils

O(Lock up shift valve spring

Lock-up timing valve spring

0.9 (0.035)

0.9 (0.035)

7.6 (0.299)

8.1 (0.319)

73.1 t2.902),

81.4 (3.205)

32.0

47 .8

14-201

www.emanualpro.com

Page 825 of 1395

Front Driveshafts

Reassembly {cont'd)

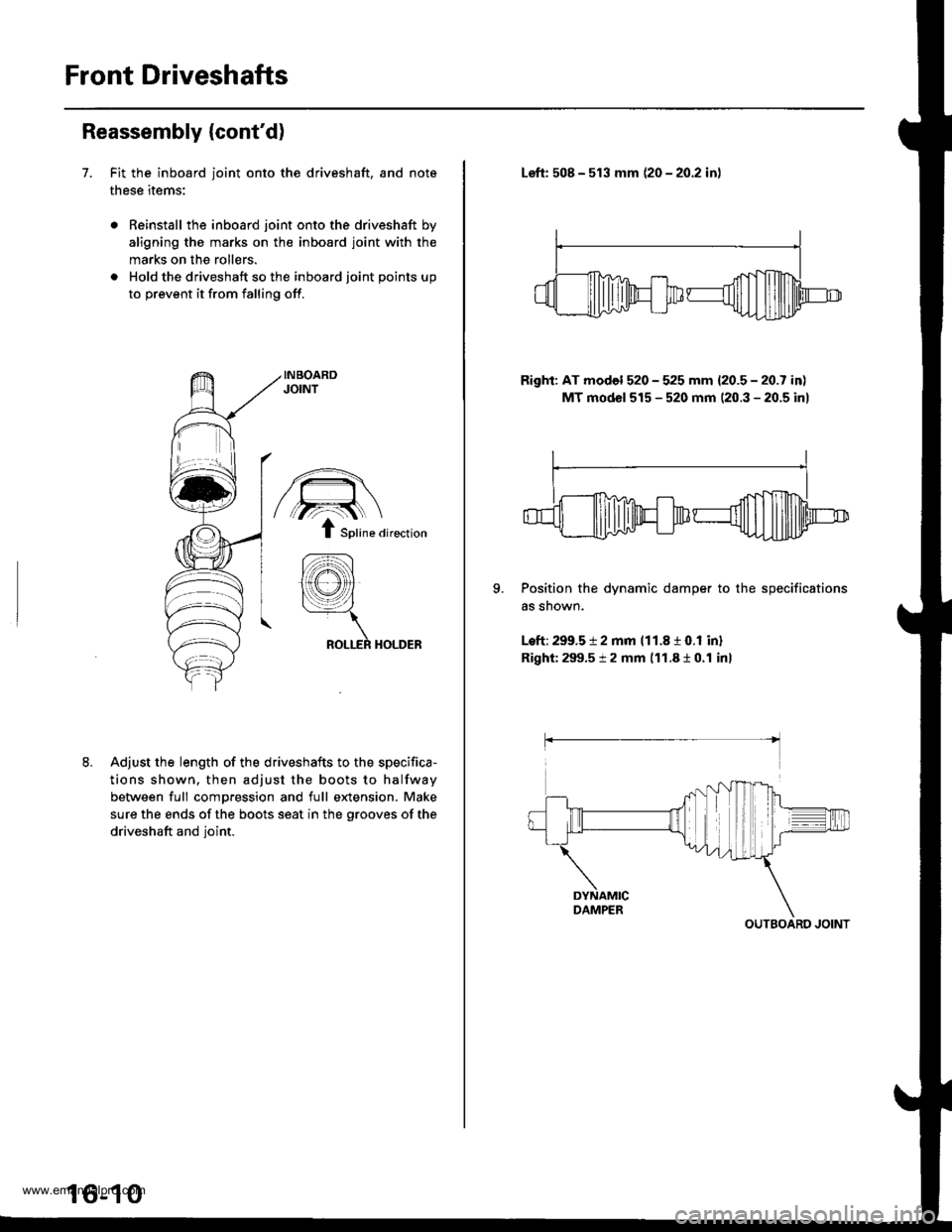

7. Fit the inboard joint onto the driveshaft, and note

these items:

Reinstall the inboard joint onto the driveshaft by

aligning ths marks on the inboard joint with the

marks on the rollers.

Hold the driveshaft so the inboard joint points up

to prevent it from falling off.

Adjust the length of the driveshafts to the specifica-

tions shown. then adjust the boots to halfway

between full compression and full e)dension. Make

sure the ends of the boots seat in the grooves of the

driveshaft and Ioint.

/€\

/,?:..�{ \

t Sptine airection

lffi

tYl:\

ROLLER HOLDER

16-10

Left: 508 - 513 mm 120 - 2O.2 inl

Right: AT model 520 - 525 mm {20.5 - 20.7 in)

MT mod6l 515 - 520 mm (20.3 - 20.5 inl

II

-flm+dm@

9. Position the dynamic damper to the specifications

as snown.

Left: 299.5 t 2 mm 111.8 r O.l inl

Right: 299.5 t 2 mm 111.810.1 inl

OUTBOARO JOINT

www.emanualpro.com

Page 840 of 1395

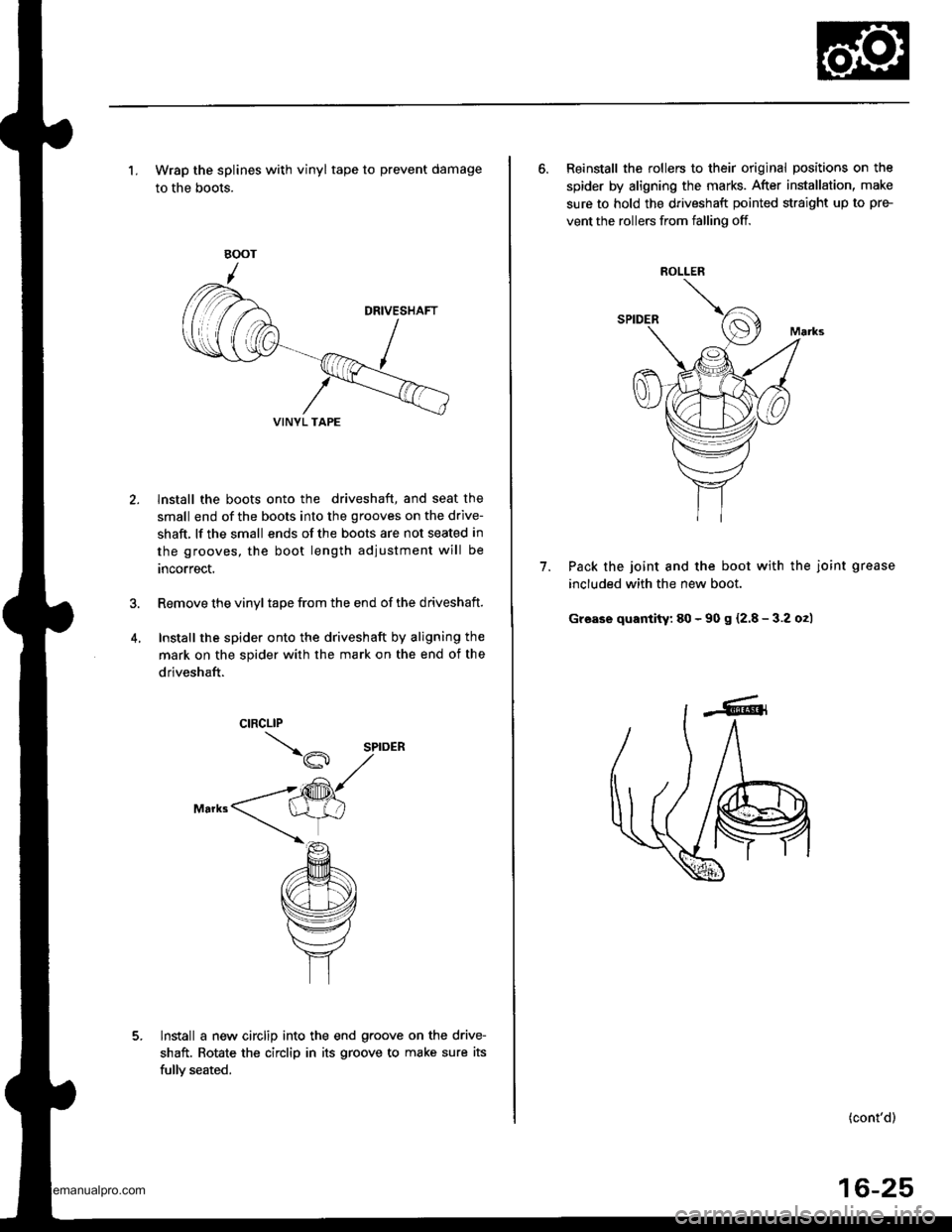

'1. Wrap the splines with vinyl tape to prevent damage

to the boots.

lnstall the boots onto the driveshaft, and seat the

small end of the boots into the grooves on the drive-

shaft, lf the small ends of the boots are not seated in

the grooves, the boot length adiustment will be

rncorrect.

Remove the vinyl tape from the end of the driveshaft.

Install the spider onto the driveshaft by aligning the

mark on the spider with the mark on the end of the

driveshaft.

lnstall a new circlip into the end g.oove on the drive-

shaft. Rotate the circlip in its groove to make sure its

fullv seated.

VINYL TAPE

6. Reinstall the rollers to their original positions on the

spider by aligning the marks. After installation, make

sure to hold the driveshaft pointed straight up to pre-

vent the rollers from falling off.

Pack the joint and the boot with the joint grease

included with the new boot.

Grease quantity: 80 - 90 s {2.8 - 3.2 o2)

7.

ROLLER

(cont'd)

16-25

www.emanualpro.com