lock HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 858 of 1395

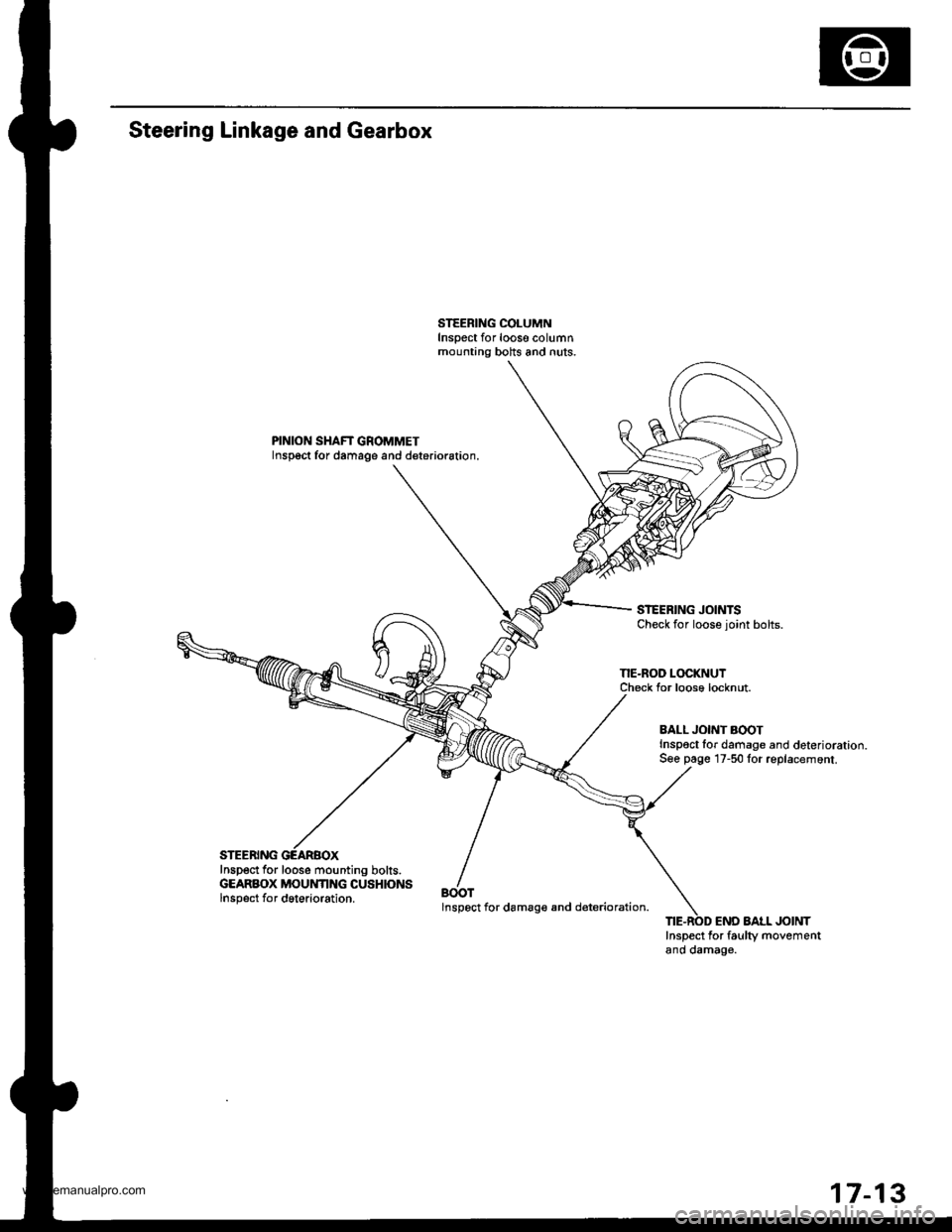

Steering Linkage and Gearbox

PINION SHAFT GROMMETInspoct for damage and deterioration.

STEERING JOINTSCheck for loose joint bolts.

NE-ROD LOCKNUTCheck Ior loose locknut.

Inspect for loose mounting bolts.GEARBOX MOUNTING CUSHIONSlnsp6ct for dgterioration.BOOTlnspect for damag€ and d€terioration.

BALL JONT AOOTInspoct lor damage and deterioration.S€e page 17-50 for replacemont.

END AAtL JOINTInspect for faulty movementano oamag€.

17-13

www.emanualpro.com

Page 859 of 1395

Inspection and Adjustment

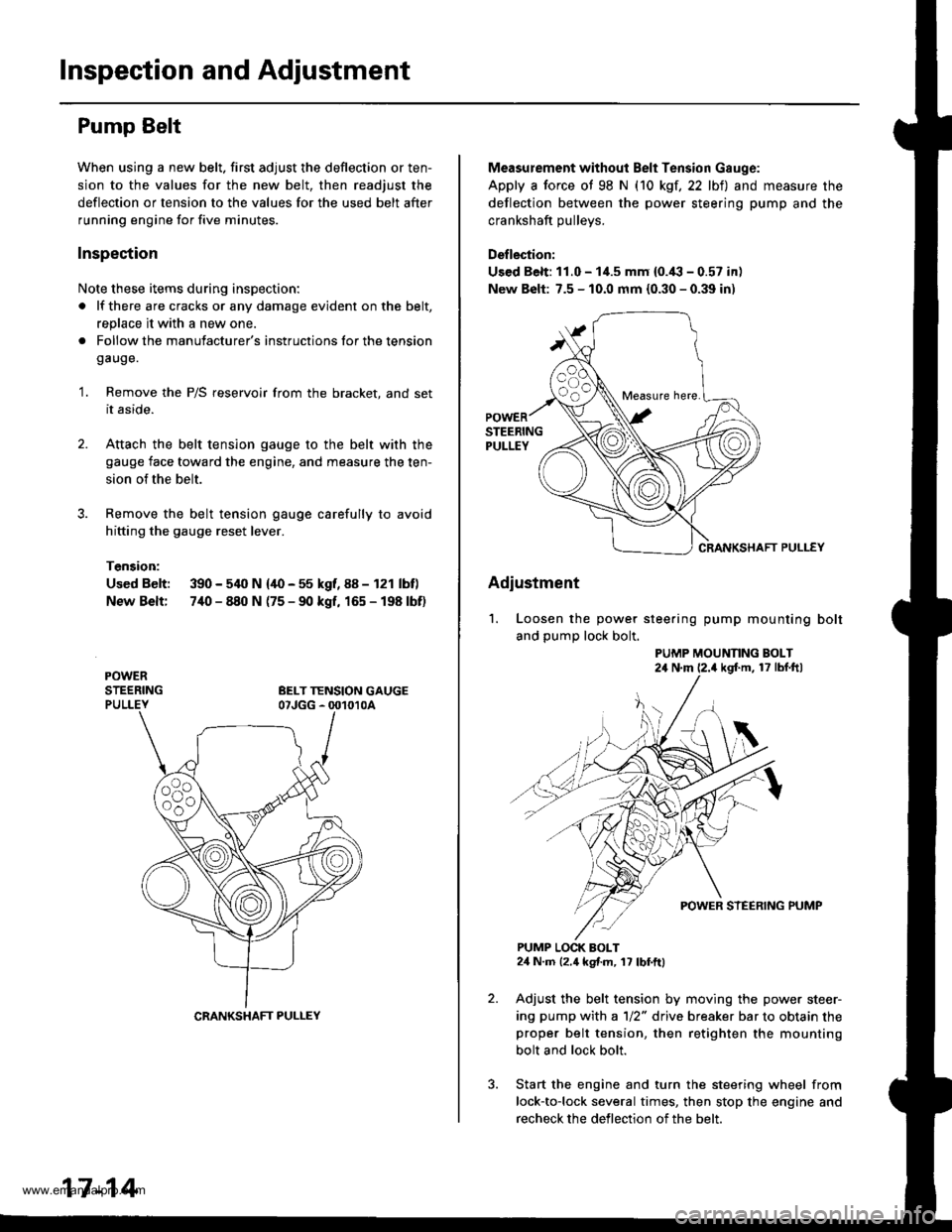

Pump Belt

When using a new belt. first adjust the deflection or ten-

sion to the values for the new belt, then readjust the

deflection or tension to the values for the used belt after

running engine for five minutes.

Inspection

Note these items during inspection:

a lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions lor the tension

gauge.

'1. Remove the P/S reservoir from the bracket, and set

it aside.

2. Attach the belt tension gauge to the belt with the

gauge face toward the engine, and measure the ten-

sion of the belt.

Remove the belt tension gauge carefully to avoid

hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N {40 - 55 kgf, 88 - 121 lbf)

New Belt: 7,[0 - 840 N (75 - 90 kgf, 165 - 198 lbf)

CRANKSHAFT PULLEY

17-14

Measurement without Belt Tension Gauge:

Apply a force ot 98 N (10 kgf,22 lbt) and measure the

deflection between the power steering pump and the

crankshaft oullevs.

Deflection:

Used Belt: 11.0 - 1i1.5 mm {0.'(l - 0.57 in)

New Belt: 7.5 - 10.0 mm {0.30 - 0.39 in)

CRANKSHAFT PULLEY

Adiustment

'1. Loosen the power steering pump mounting bolt

and pump lock bolt.

PUMP MOUNNNG BOLT24 N'm (2.4 kgf'm, 17 lbf ftl

PUMP LOCK BOLT24 N.m 12.4 kgf.m, 17 lbf.ftl

Adjust the belt tension by moving the power steer-

ing pump with a 1/2" drive breaker bar to obtain theproper belt tension, then retighten the mounting

bolt and lock bolt.

Start the engine and turn the steering wheel from

lock-to-lock several times, then stop the engine and

recheck the deflection of the belt.

Measure here.

www.emanualpro.com

Page 860 of 1395

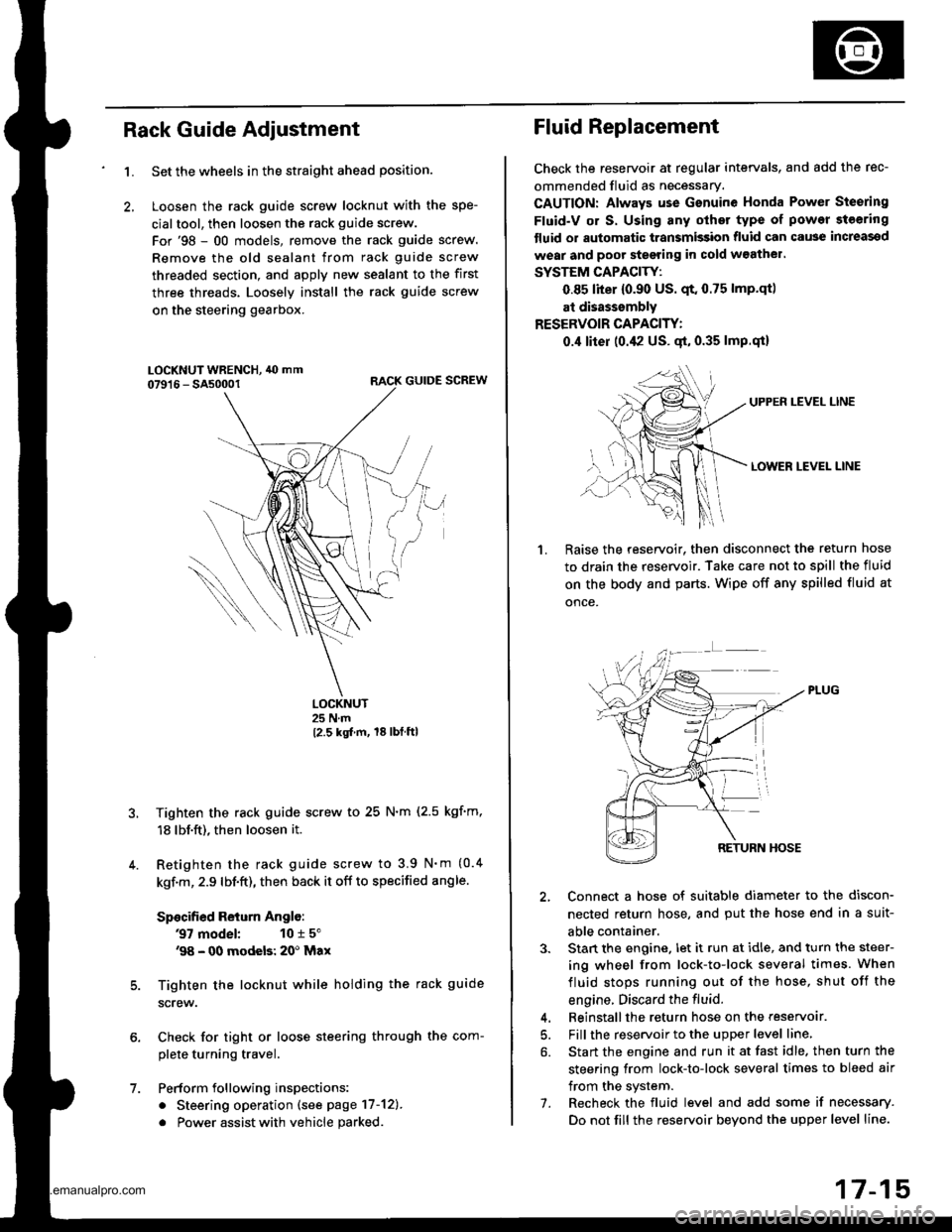

Rack Guide Adjustment

1.

6.

7.

5.

4.

Set the wheels in the straight ahead position.

Loosen the rack guide screw locknut with the spe-

cialtool, then loosen the rack guide screw.

For'98 - 00 models, remove the rack guide screw.

Remove the old sealant from rack guide screw

threaded section, and apply new sealant to the first

three threads. Loosely install the rack guide screw

on the steering gearbox.

RACK GUIDE SCREW

LOCKNUT25 N.m

12.5 kgt m, 18lbtftl

Tighten the rack guide screw to 25 N.m (2.5 kgf'm,

18 lbf.ft), then loosen it.

Retighten the rack guide screw to 3.9 N'm (0.4

kgf.m, 2.9 lbf.ft), then back it off to specified angle.

Specified Return Anglo:

37 model: 10 r 5"'98 - 00 modeb: 20' Max

Tighten the locknut while holding the rack guide

screw.

Check for tight or loose steering through the com-

plete turning travel.

Perform following inspections:

. Steering operation (see page 17-12).

. Power assist with vehicle parked

Fluid Replacement

Check the reseryoir at regular intervals, and add the rec-

ommended fluid as necessary.

CAUTION: Always use Gsnuine Honda Power Steering

Fluid-V or S. Using any other type of power steering

tluid or automatic transmission fluid can cause increassd

wear and poor steering in cold w3athel.

SYSTEM CAPACITY:

0.85 liter {0.90 US. qt. 0.75 lmp.qtl

at disasssmbly

RESERVOIR CAPACITY:

0.,1 liter (0.42 US. gt, 0.35 lmp.qi)

UPPEN LEVEL LINE

LOWER LEVEL LINE

1.Raise the reservoir. then disconnect the return hose

to drain the reservoir. Take care not to spill the fluid

on the body and parts. Wipe off any spilled fluid at

once.

2, Connect a hose of suitable diameter to the discon-

nected return hose, and put the hose end in a suit-

able container.

3. Stan the engine. let it run at idle, and turn the steer-

ing wheel from lock-to-lock several times. When

fluid stops running out of the hose, shut off the

engine. Discard the fluid.

4. Beinstallthe return hose on the reservoar.

5. Fill the reservoir to the upper level line,

6. Start the engine and run it at fast idle. then turn the

steering from lock-to-lock several times to bleed air

from the system.

7. Recheck the fluid level and add some if necessary.

Do not fill the reservoir beyond the upper level line.

www.emanualpro.com

Page 861 of 1395

lnspection and Adjustment

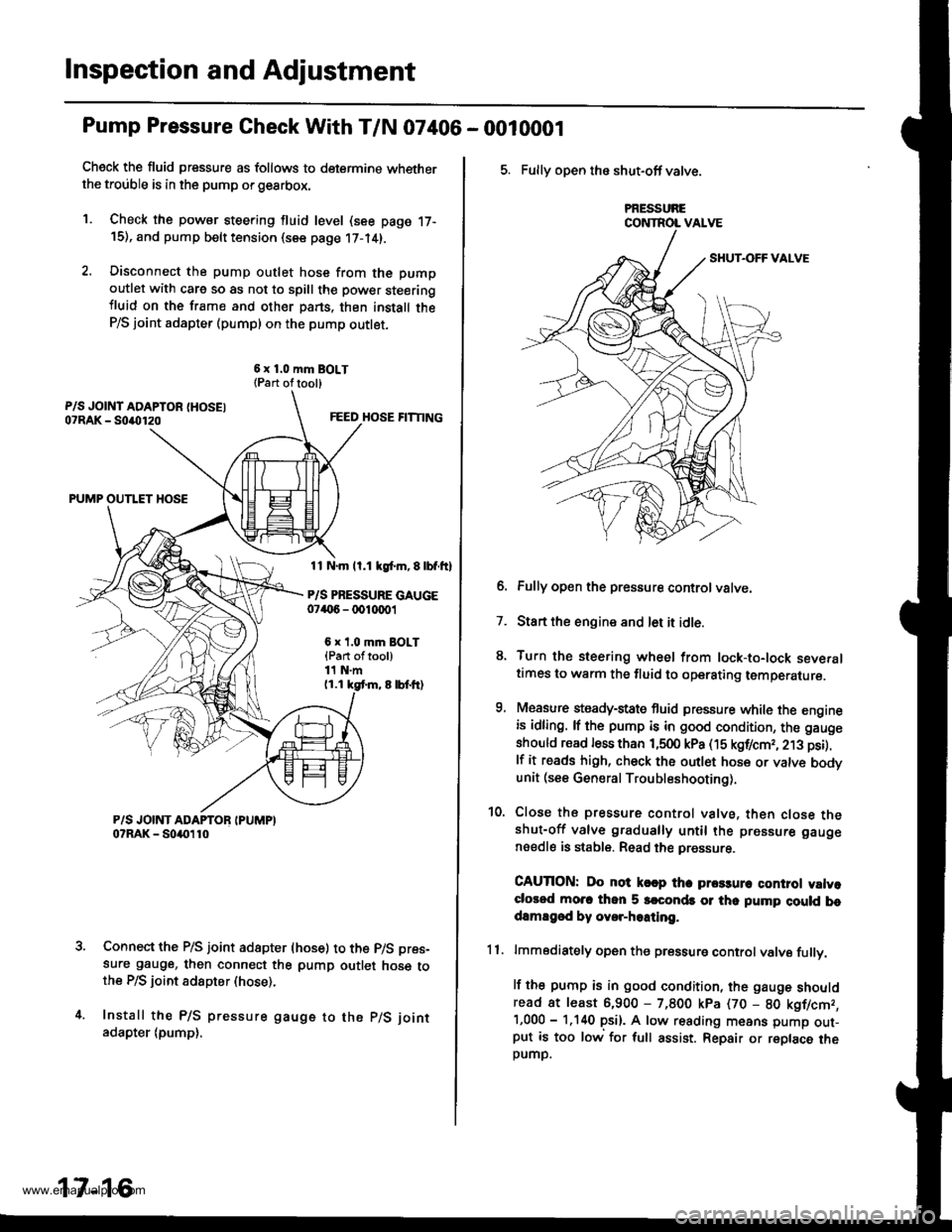

Pump Pressure Gheck With T/N 07406 - 0010001

Check the fluid pressure as follows to determine whetherthe trouble is in the pump orgearbox.

1. Check the powsr steering fluid level (see page 17-15), and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the pow€r steeringiluid on the frame and other pans. thon install theP/S joint adapter (pumpl on the pump outlet.

6 x 1.0 mm BOLT{Part oftool)

FEED HOSE FITTING

PUMP OUTLET HOSE

11 N.m ll.1 kgl.m, E lbf.ftl

P/S PRESSURE GAUGE07('6 - 0010001

6 x t.0 mm BOLT{Part oftool)11 N.m(1.1 kgt m, 8 lbf.tr)

Connect the P/S joint adapter (hose) to the p/S pres-

sure gauge, then connect the pump outlet hose tothe P/S ioint adspter (hose).

Install the P/S pressure gauge to the p/S joint

adapter (pump),

17-16

5. Fully open the shut-off valve.

PRESSURECONTROL VALVE

6. Fully open the pressure controlvatve.

7. Start the engine and let it idle.

8. Turn the steering wheel from lock-to-lock severaltimes to warm the fluid to operating temperature.

9, Measure steady-state fluid pressure while the engineis idling. lf the pump is in good condition, the gauge

should read less than 1,500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet hose or valve bodvunit (see General Troubleshooting).

10. Close the pressure control valve, then close theshut-off valve gradually until the pressure gauge

nsedle is stable. Read the pressure.

CAUTION: Do not k€ap tha prca3un control valvoclorod mo.c thon 5 srconds or thc pump cluld bodamEgod by ovor-hoating.

11. lmmodiately open the pressure controlvalve fullv.

lf the pump is in good condition, the gauge shouldread at least 6,900 - 7,800 kpa (70 - 80 kgflcmr,'1,000 - 1.140 psi). A low reading means pump out-put is too low for full assist. Repair or replace theDUMD.

www.emanualpro.com

Page 862 of 1395

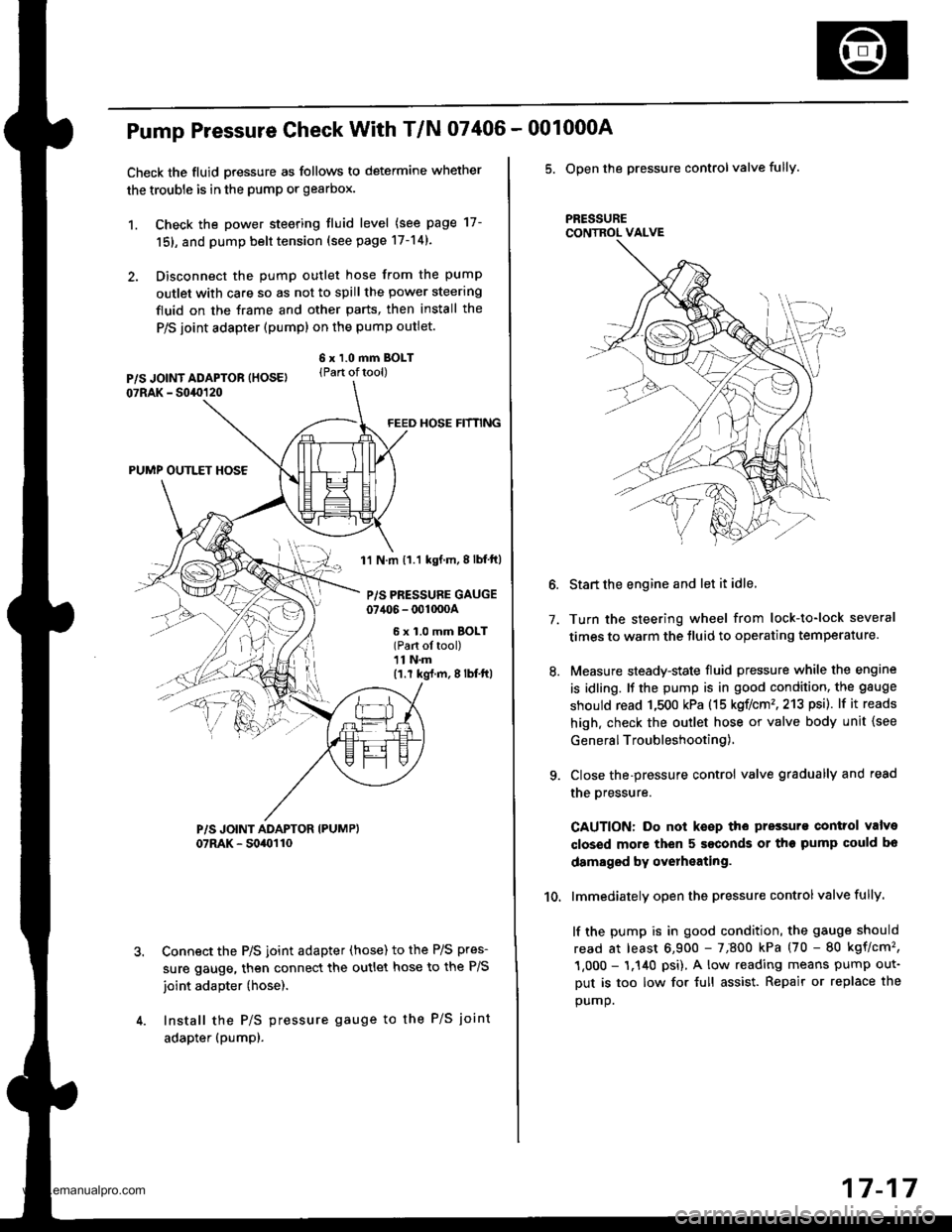

Pump Pressure Check With T/N 07406 -

Check the fluid pressure as follows to determine whether

the trouble is in the pump or gearbox.

1. Check the power steering tluid level (see page 17-

151, and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the power steering

fluid on the frame and other parts, then install the

P/S joint adapter (pump) on the pump outlet.

6 x 1.0 mm BOLT(Part oftool)

FEED HOSE HfNNG

PUMP OUTLET HOSE

1'l N.m 11.1 kgf.m,8lbf ft)

P/S PRESSURE GAUGE07406 - 001000A

6 x 1.0 mm BOLT(Part ol tool)11 N.m(1.r kg{.m,8lbf'ft|

Connect the P/S joint adapter (hose) to the P/S pres-

sure gauge, then connect the outlet hose to the P/S

joint adapter (hose).

Install the P/S pressure gauge to the P/S joint

adapter (pumpl.

001000A

5. Open the pressure controlvalve fully.

PRESSURECONTROL VALVE

7.

10.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the tluid to operating temperature.

Measure steady-state fluid pressure while the engine

is idling. It the pump is in good condition, the gauge

should read 1,500 kPa (15 koflcm'�,213 psi). lf it reads

high. check the outlet hose or valve body unit {see

General Troubleshooting),

Close the-pressure control valve gradually and read

the oressure.

CAUTION: Do not keep the pressurs control valve

closed more then 5 seconds or the pump could bo

damaged by overheating.

lmmediately open the pressure controlvalve fully.

lf the pump is in good condition, the gauge should

read at least 6,900 - 7;800 kPa (70 - 80 kgflcm'�,

1,000 - 1.140 psi), A low reading means pump out-

Dut is too low for {ull assist. Repair or replace the

oumo.

17-17

www.emanualpro.com

Page 864 of 1395

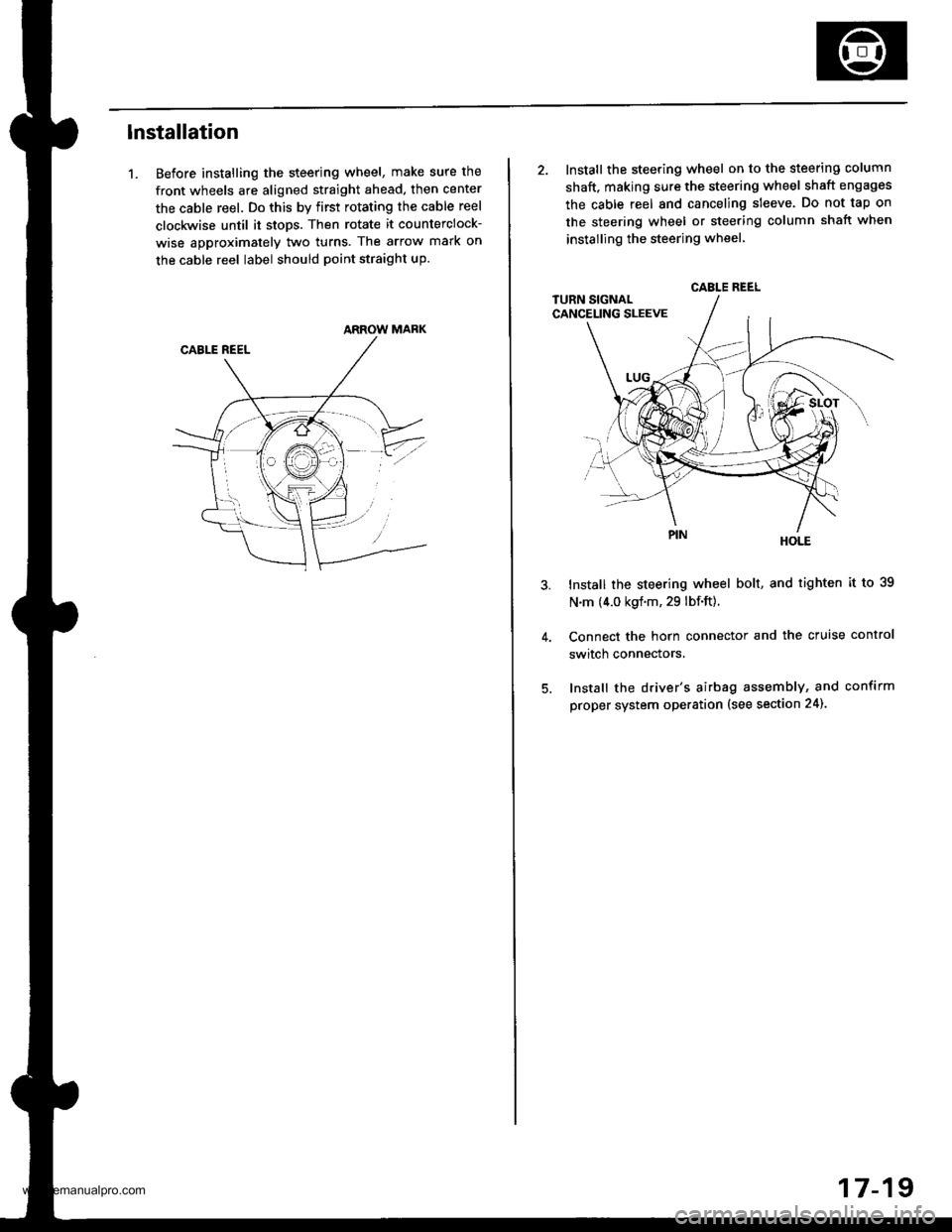

lnstallation

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel. Do this by first rotating the cable reel

clockwise until it stops. Then rotate it counterclock-

wise approximately two turns. The arrow mark on

the cable reel label should point straight up.

ARROW MARK

2. Install the steering wheel on to the steering column

shaft, making sure the steering wheel shaft engages

the cable reel and canceling sleeve. Do not tap on

the steering wheel or steering column shatt when

instailing the steering wheel

HOLE

Install the steering wheel bolt, and tighten it to 39

N.m (4.0 kgf.m, 29 lbf.ft).

Connect the horn connector and the cruise control

switch connectors,

Install the driver's airbag assembly, and confirm

proper system operation (see section 24).

CABLE REEL

17-19

www.emanualpro.com

Page 867 of 1395

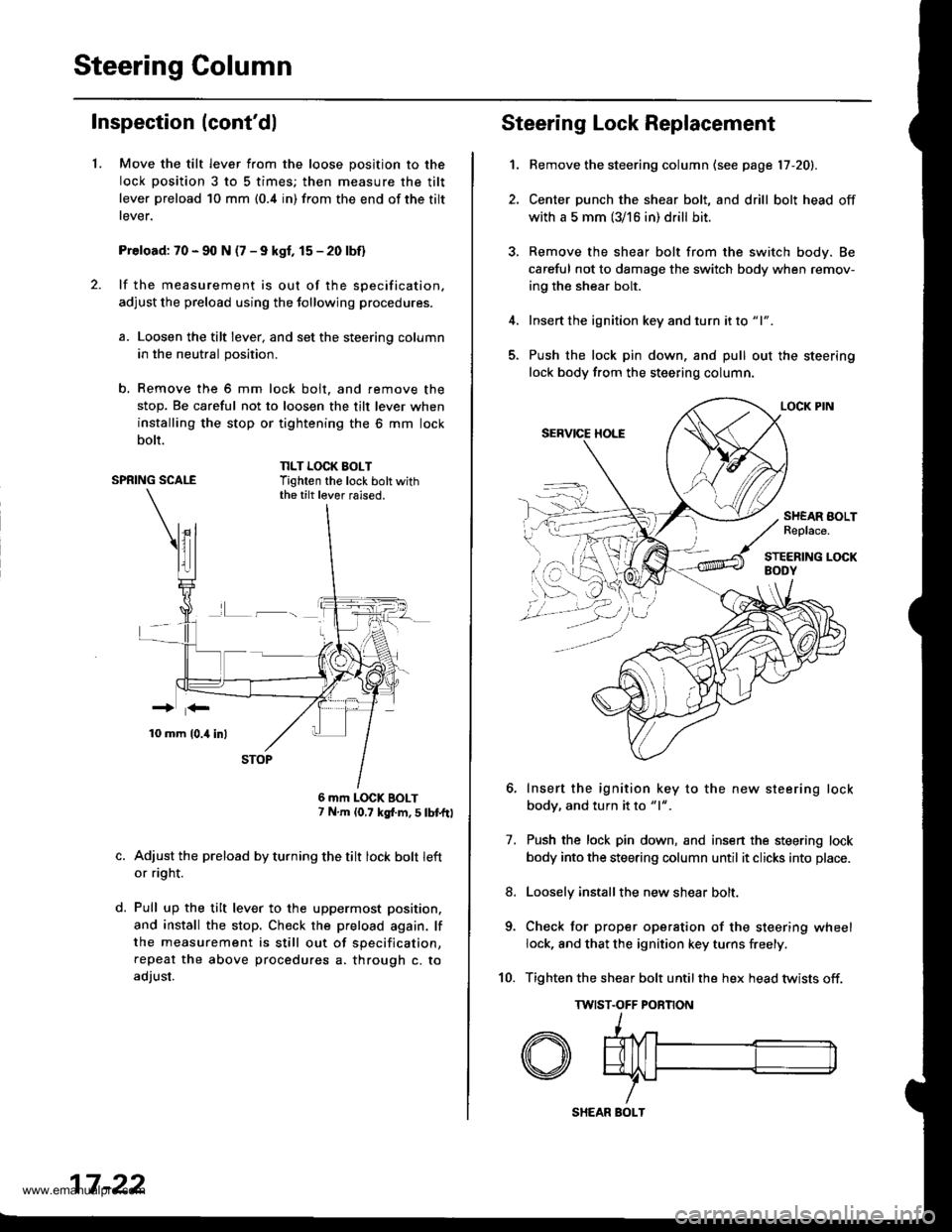

Steering Column

Inspection (cont'dl

1.Move the tilt lever from the loose position to the

lock position 3 to 5 times; then measure the tilt

lever preload 10 mm (0.4 in) from the end of the tilt

rever.

Preload: 70 - 90 N (7 - 9 kgf, 15 - 20 lbf)

lf the measurement is out of the specification.

adjust the preload using the tollowing procedures.

a. Loosen the tilt lever, and set the steering column

in the neutral position.

b, Remove the 6 mm lock bolt. and remove the

stop. Be careful not to loosen the tilt lever when

installing the stop or tightening the 6 mm lock

bolt.

SPRING SCALENLT LOCK BOLTTighten the lock bolt withthe tilt lever raised.

L-_

d.

6 mm LOCK BOLT7 N.m (0,7 kgf.m, S tbtftl

Adjust the preload by turning the tilt lock bolt left

or ri9ht.

Pull up the tilt lever to the uppermost position.

and install the stop. Check the preload again. lf

the measurement is still out of specification,

repeat the above procedures a. through c. to

adjust.

17 -22

SHEAR BOLT

Steering Lock Replacement

1.

7.

Bemove the steering column (see page 17 -20).

Center punch the shear bolt, and drill bolt head off

with a 5 mm (3/16 in) drill bit.

Remove the shear bolt from the switch body. Be

careful not to damage the switch body when remov-

ing the shear bolt.

Insert the ignition key and turn it to "1".

Push the lock pin down, and pull out the steering

lock body from the steering column.

Insert the ignition key to the new steering lock

body, and turn it to "1".

Push the lock pin down, and insen the steering lock

body into the steering column until it clicks into place.

Loosely installthe new shear bolt.

Check tor proper operation of the steering wheel

lock, and that the ignition key turns freely.

Tighten the shear bolt untilthe hex head twists off.

TWIST.OFF PORNON

8.

10.

SHEAR BOLTReplace.

www.emanualpro.com

Page 869 of 1395

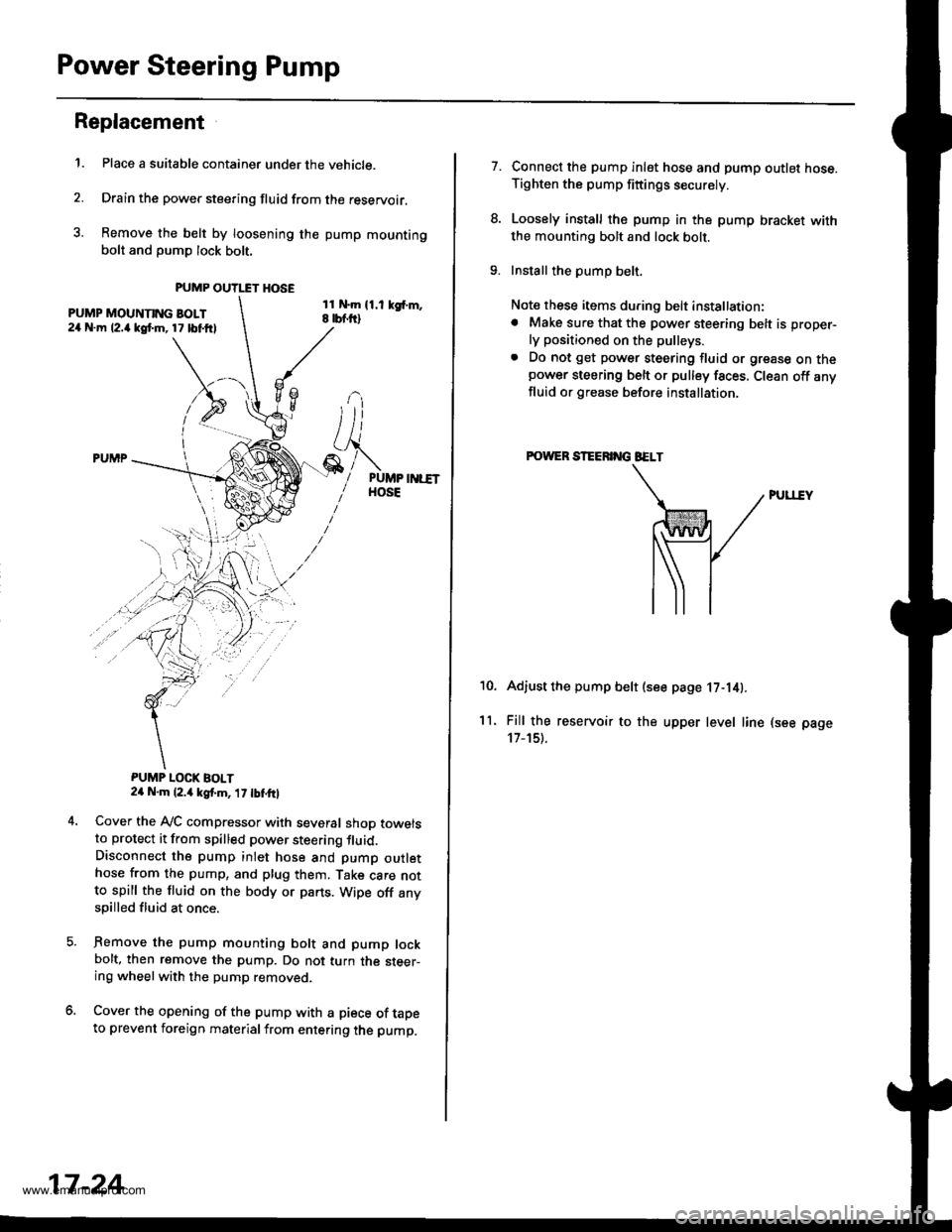

Power Steering Pump

Replacement

1.Place a suitable container under the vehicle.

Drain the power steering fluid from the reservoir.

Remove the belt by loosening the pump mountingbolt and pump lock bolt.

PUMP MOUNNNG BOI.T24 N.m 12.4 kgt m, 17 lbl.ftl

PUMP LOCK BOLT24 N.m (2.4 kg{.m, 1, tbfttl

Cover the IVC compressor with several shop towelsto protect it from spilled power steering fluid.Disconnect the pump inlet hose and pump outlethose from the pump, and plug them. Take care notto spill the lluid on the body or parts. Wipe off anyspilled fluid at once.

Remove the pump mounting bolt and pump lockbolt, then remove the pump. Do not turn the steer-ing wheelwith the pump removed.

Cover the opening of the pump with a piece of tapeto prevent foreign materialfrom entering the pump.

PUMP OU'I.TT HOSE

11 N.m (1.1 kgf.m,E rbf.ti)

17-24

7.Connect the pump inlet hose and pump outlet hose.Tighten the pump fittings securely.

Loosely install the pump in the pump bracket withthe mounting bolt and lock bolt.

Install the pump belt.

Note these items du.ing belt instsllation:. Make sure that the power steering belt is proper-

ly positioned on the pulleys.

. Do not get power steering fluid or grease on thepower steering belt or pulley faces, Clean off anyfluid or grease before installation

FOWER STEER G EELT

PUTrlY

Adiust the pump belt (see page 17-141.

Fill the reservoir to the upper level line (see page't7 -151..

10.

'l l.

www.emanualpro.com

Page 878 of 1395

REAR MOUNT

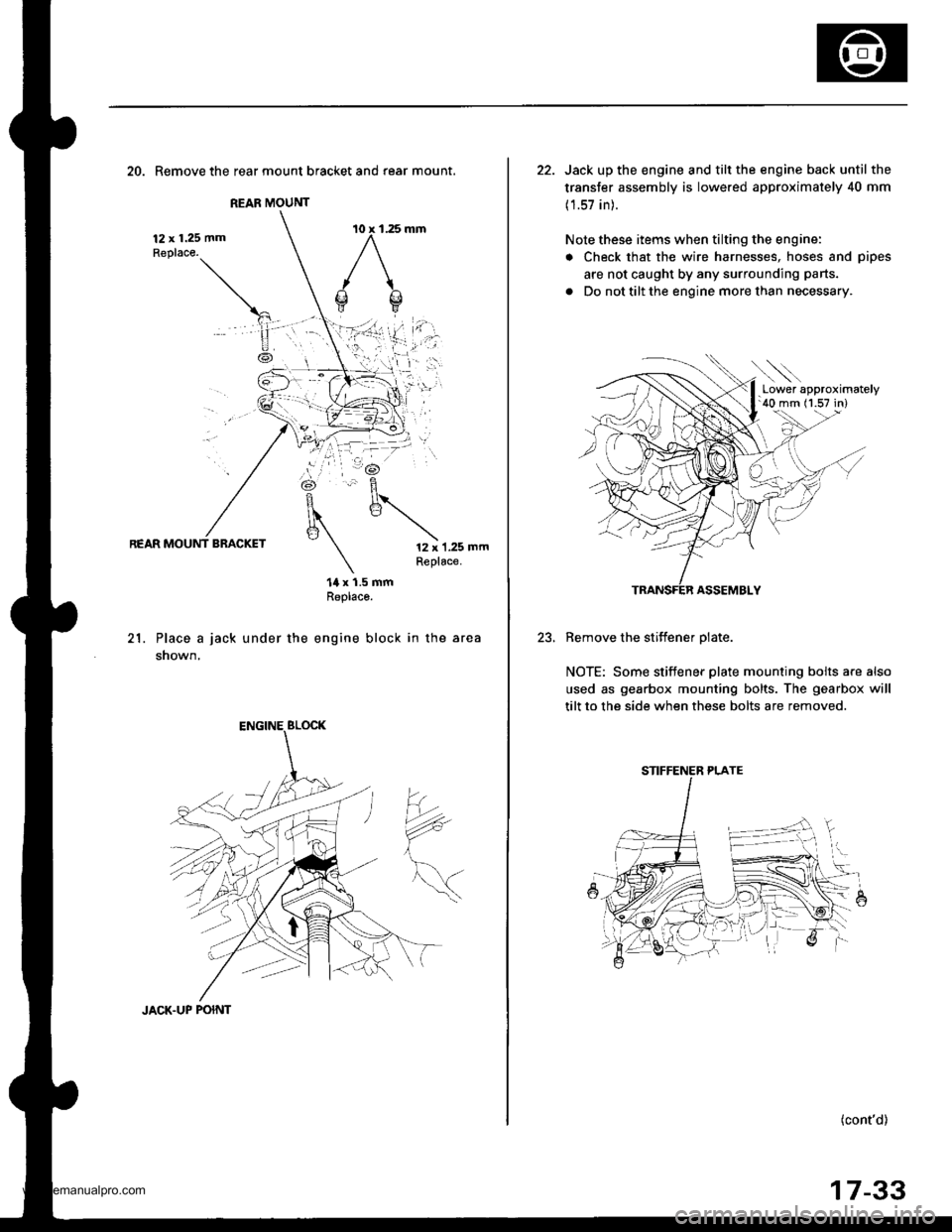

20. Remove the rear mount bracket and rear mount.

12 x 1.25 mmReplace.

REAR MOUNT BRACKET12 x 1.25 mmReplace.

21.

14 x 1.5 mmReplaco.

Place a jack under the engine block in the area

shown,

?*

JACK.UP POINT

17-33

22. Jack up the engine and tilt the engine back until the

transfer assembly is lowered approximately 40 mm

(1.57 in).

Note these items when tilting the engine:

. Check that the wire harnesses, hoses and pipes

are not caught by any surrounding parts.

. Do not tilt the engine more than necessary.

ASSEMBLY

Remove the stiffener olate.

NOTE: Some stiffener plate mounting bolts a.e also

used as gearbox mounting bolts. The gearbox will

tilt to the side when these bolts are removed.

(cont'd)

.Lower approximately'40 mm (1.57 in)

STIFFENER PLATE

www.emanualpro.com

Page 880 of 1395

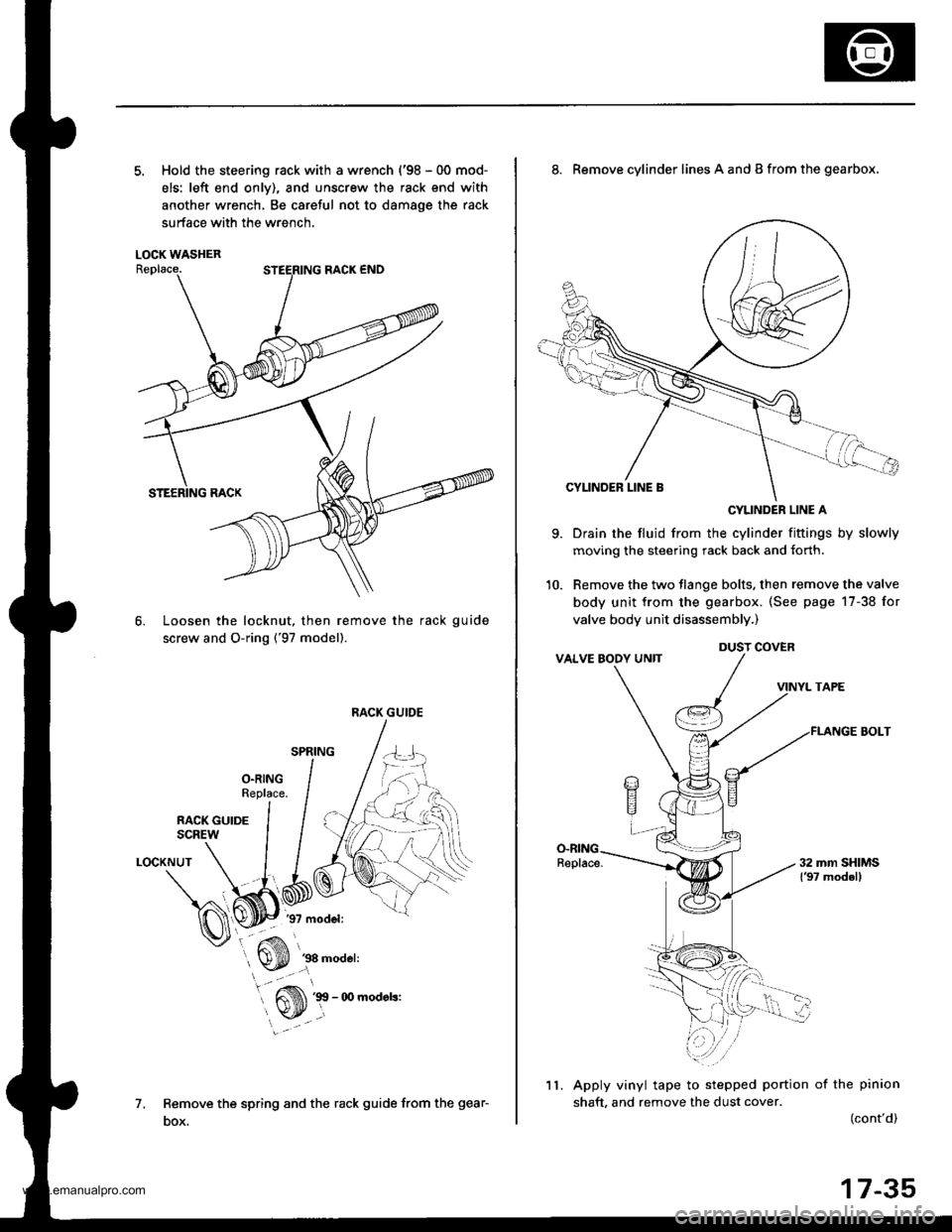

5. Hold the steering rack with a wrench {'98 - 00 mod-

els: left end onlv), and unscrew the rack end with

another wrench, Be careful not to damage the rack

surface with the wrench,

LOCK WASHER

Loosen the locknut, then remove the rack guide

screw and O-ring ('97 model).

6.

1.

LOCKNUT

Remove the spring and the rack guide from the gear-

DOX.

RACK GUIDE

9.

8. Remove cylinder lines A and B from the gearbox,

CYLINDER LINE A

Drain the fluid from the cylinder fittings by slowly

moving the steering rack back and {orth.

Remove the two tlange bolts, then remove the valve

body unit from the gearbox. (See page 17-38 for

valve body unit disassembly.)

VINYL TAPE

FLANGE BOLT

Apply vinyl tape to stepped portion of the pinion

shaft, and remove the dust cover.(cont'd)

DUST COVER

11.

17-35

www.emanualpro.com