Alternator HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 179 of 1395

1.

2.

3.

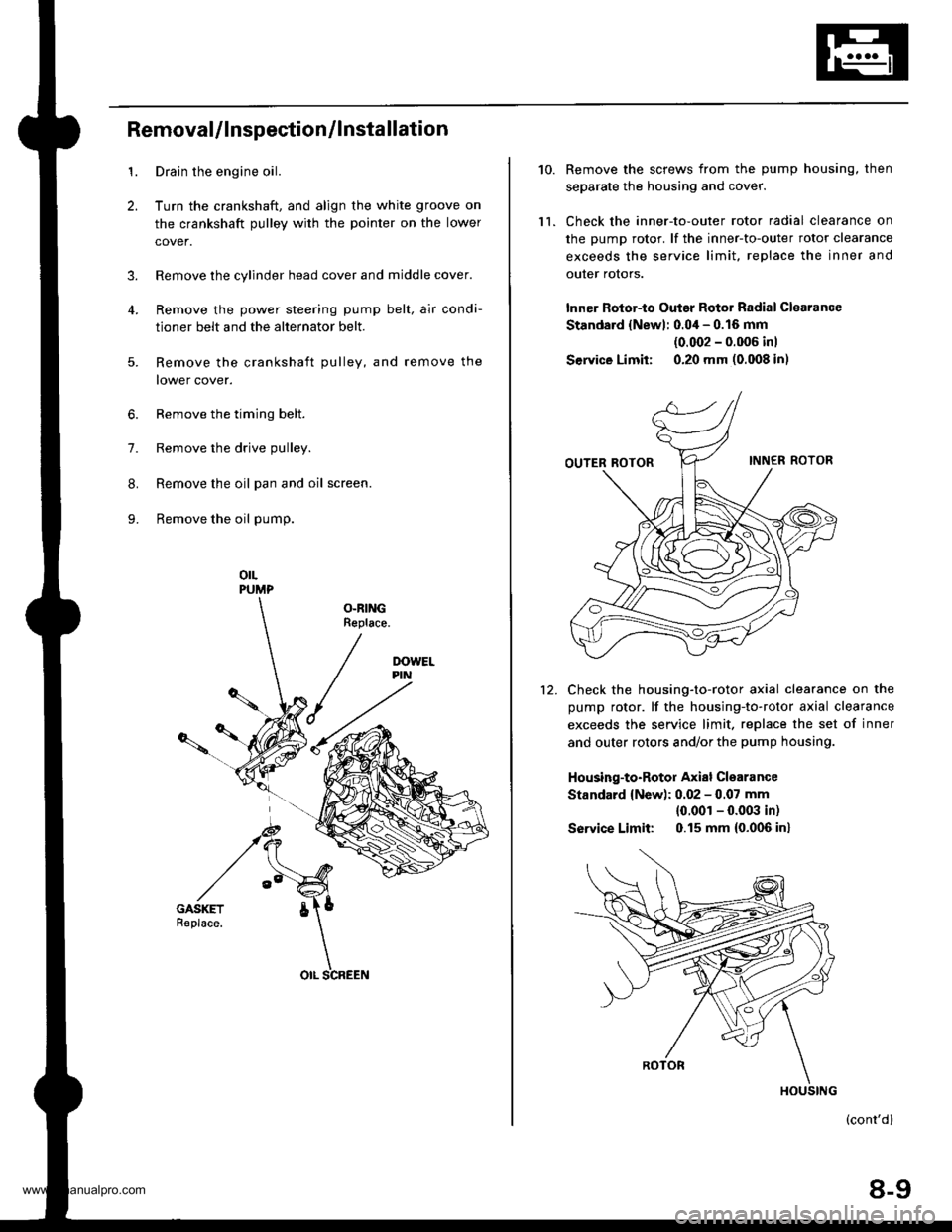

RemovaUlnspection/lnstallation

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 218 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

Electrical Connections -97 Model

f_ --- --- -t _l-1r -lla^^^ tirrnl

(.J

no 3wrcx (-]lrLt -o.:\-tlDl"ii

\

HT:

v

l-I

tl

I-6,

I

4

^li lGPlf----;;ltl

tl

T

FUEL lltlEcToes

oa 9I3

aEt30F

TDC3ErcON

ct HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

Electrical Connections -97 Model

f_ --- --- -t _l-1r -lla^^^ tirrnl

(.J

no 3wrcx (-]lrLt -o.:\-tlDl"ii

\

HT:

v

l-I

tl

I-6,

I

4

^li lGPlf----;;ltl

tl

T

FUEL lltlEcToes

oa 9I3

aEt30F

TDC3ErcON

ct](/img/13/5778/w960_5778-217.png)

Electrical Connections -'97 Model

f_ --- --- -t _l-1r -lla^^^ tirrnl

(.J

no 3wrcx (-]lrLt -'o.:\-'tlDl"ii

\

HT:

v

l-I

tl

I-6,

I

4

' ^li lGPlf----;;ltl

tl

T

FUEL ll'tlEcToes

oa 9I3

aEt30F

TDC3ErcON

ctPSErAOi

CKF3EN30F

TO EIIF-

*f

ctovEu

A' lGI

aztL@,

Xo.2|NJ2 3

ca tDcP[{J3 A2

cra Tltcl

||tL

Gt ct(iP?

er2 cxP{

cfl ct(Ftr

1

Dta ELtr

c|| v!]3TL T'

t ^cc ^r?to l/C CLUTCfl BELAYto i^Ol^toh F tl REI Y,@III'C|{AEi FA'I iEL Y

rtT

c. K.uirEuNxcoi||lEctoh

SERVICECl|ECK@ NEqroi

I ^ca 6

d__-lb

qr 3c3

ilaALTF CI'

rt: usAEII ATPI{PE

6uI)r^ l

t*frl

E

t'-

bI. ATPfi

B2a AtPtX

E' TPDI

Att lEFOgn3wltc

gi7 alP:l

I

I

ON

Ei. ATPID{ND tir

FUSES :(D BACK uP (RADro) (7.sr0.

@ "o^n ttot (tuo)'(D BATfERY (IOOA) *

o rcl (4oA)*

GAIXIEASSEIBLY

(DFt E/ flsA).@ No.13 FUEL PU P ('l5A)

O No. 2s METER (7.5A)(D NO. 'I5 ALTERNATOR SP SENSOB (7.5A) *

O No. 3i STABTER SIGNAL (7.5A)*: In lhc und?r.lrood tu$/rclay bor

(cont'd)

1 1-15

www.emanualpro.com

Page 269 of 1395

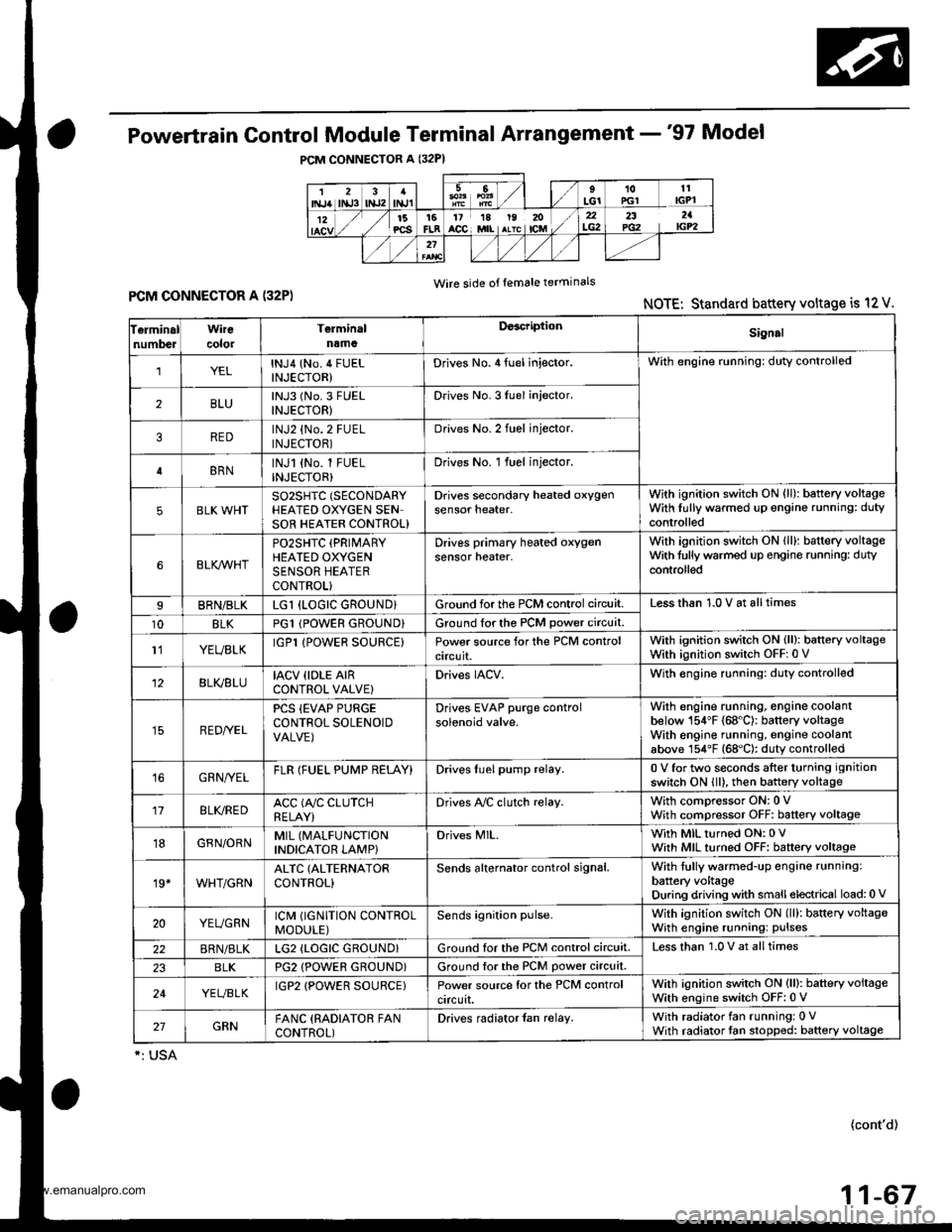

Powertrain Control Module Terminal Arrangement -'97 Model

FCM CONNECTOR A (32P)NOTE: Standard battery voltage is 12 V.

Wire side of lemale terminals

f€rminalnumlreJWirecolor

Telminalnama

DescriptionSignal

YELlNJ4 (No.4 FUELINJECTOR)Drives No. 4 {uel injector.With engine running: duty controlled

2BLUlNJ3 (No.3 FUELINJECTOR)Drives No. 3luel injector.

REDlNJ2 {No.2 FUELINJECTOR)Drives No.2 tuel injector.

BRNlNJl (No. l FUELINJECTOR)Drives No. 1 fuel injector.

5BLK WHTSO2SHIC (SECONDARY

HEATED OXYGEN SENSOR HEATER CONTROL)

D ves secondary heated oxygensensor heater.With ignition switch ON {ll): battery voltageWith fully warmed up engino running: dutycontrolled

6BLKAr'YHT

PO2SHTC (PRIMARY

HEATED OXYGENSENSOR HEATERCONTROL}

Drives primary heated oxygensensor heater,With ignition switch ON lll): battery voltagewith fully warmed up engine running: dutycontroll6d

I8RN/BLKLGl (LOGIC GROUND}Ground forthe PCM control circuit.Less than 1.0 V at all times

10BLKPG1 lPOWER GROUND}Ground for the PCM power circuit.

l1YEUELKIGPl lPOWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltageWith ignition switch OFF: 0 V

12BLI(BLUIACV {IDLE AIRCONTROL VALVE}Drives IACV.With €ngine running: duty controlled

REDryEL

PCS (EVAP PURGECONTFOL SOLENOIDVALVE)

Drives EVAP purge controlsolenoid valve.

With engine running, engine coolantbelow 154'F (68"C): battery voltageWith engine running, engine coolantabove 154"F (68"C): duty controlled

16GRN/VELFLR (FUEL PUMP RELAY)Drives Iuel pump relay.0 V for two seconds after turning ignition

switch ON lll), then battery voltage

118LI(REDACC (A,/C CLUTCHRELAY}Drives Ay'C clutch relay.With comoressor ON: 0 VWith compressor OFF: baftery voltage

18GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP}Drives MlL.With MIL turned ON: 0 VWith MIL turned OFF: baftery voltage

19*WHT/GRNALTC (ALTERNATOR

CONTROL}Sends alternator control signal.With tully warmed-up engine running:

battery voltageDuring driving with smallelectrical load:0 '

20YEUGRNICM (IGNITION CONTROLMODULE)Sends ignition pulse.With ignition switch ON (ll): baftery voltageWith engine running: pulses

22BRN/BLKLG2 (LOGIC GROUND}Ground tor the PCM control circuit.Less than 1.0 V at alltimes

23BLKPG2 {POWER GROUND}Ground lor the PCM power circuit.

24YEUBLKIGP2 {POWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltage

With engine switch OFF: 0 V

27GRNFANC (RADIATOR FANCONTROL)Drives radiator {an relay.With radiator fan running: 0 VWith radiator fan stopped: baftery voltage

*: USA

{cont'd)

11-67

www.emanualpro.com

Page 271 of 1395

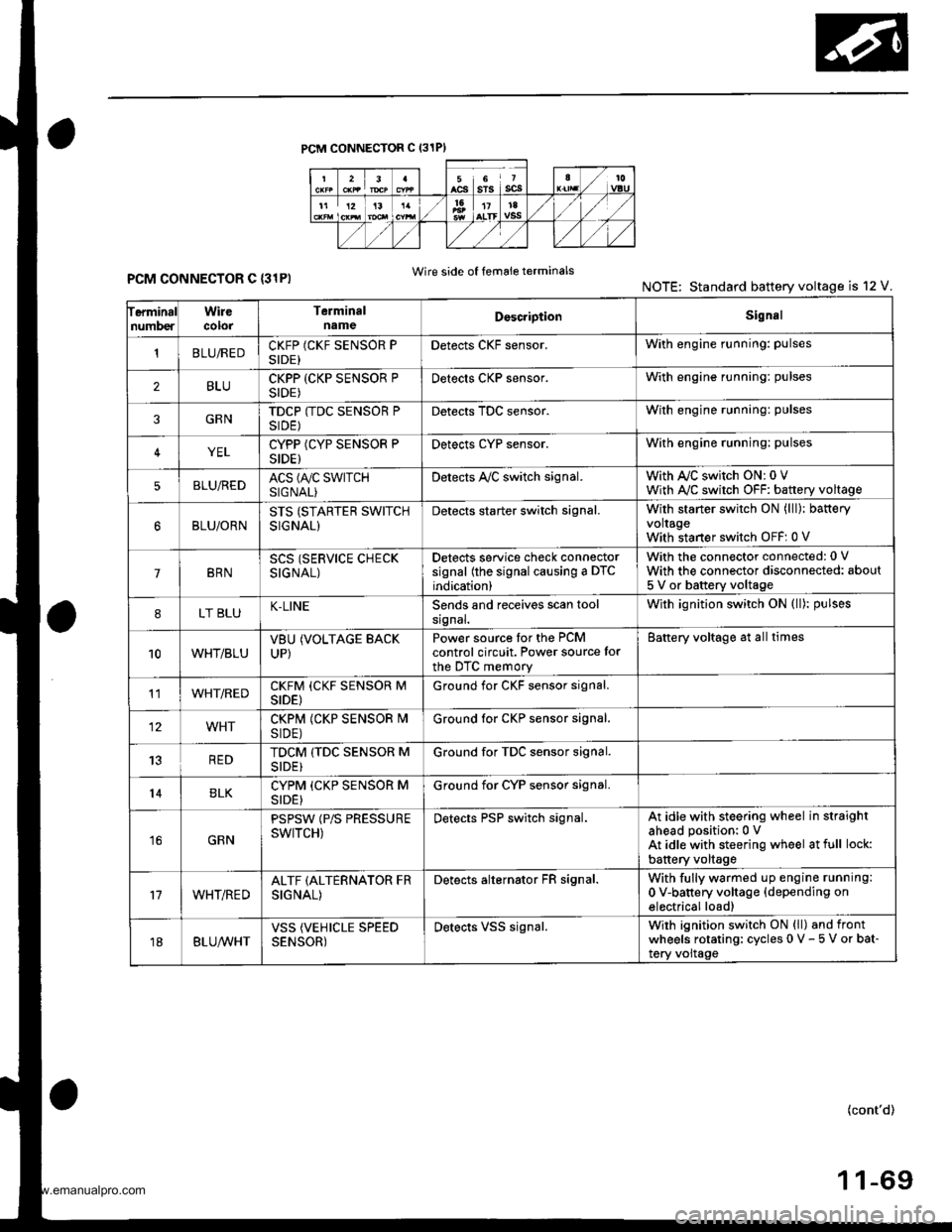

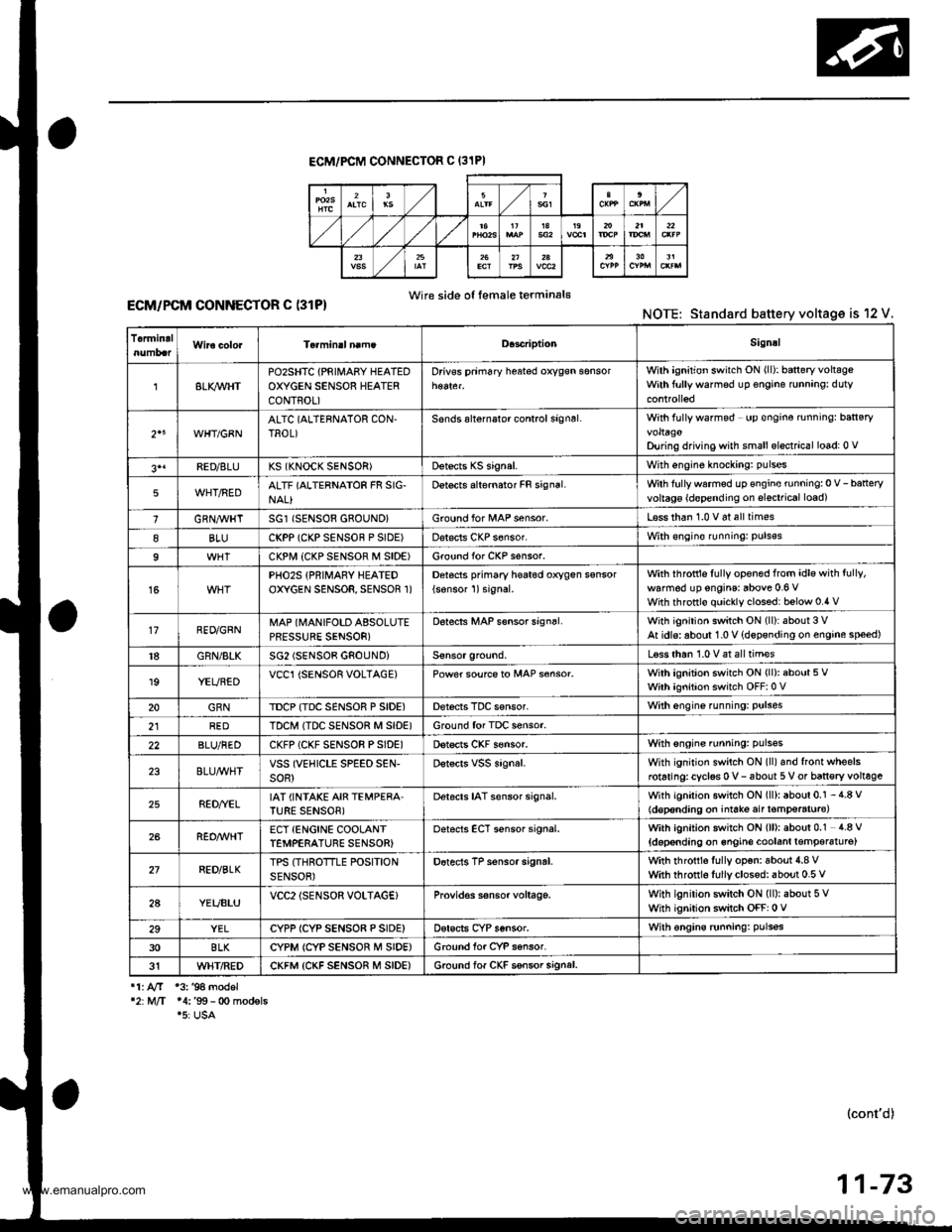

PCM CONNECTOR C (31PI

ferminalnumberWirecolorTerminalnameDoscriptionSignal

'tBLUiREDCKFP (CKF SENSOR PSIDE)Detects CKF sensor.With engine running: pulses

2BLUCKPP (CKP SENSOR PSIDE)Detects CKP sensor.With engine running: pulses

3GRNTDCP (TDC SENSOR PSIDE)Detects TDC sensor.With engine running: pulses

4YELCYPP (CYP SENSOR PSIDE)Detects cYP sensor.With engine running: pulses

5BLU,frEDACS (A/C SWTTCHSIGNAL)Detects A,/C switch signal.With AJC switch ON: 0 VWith A,/C switch OFF: battery voltage

BLU/ORNSTS (STARTER SWITCHSIGNAL)

Detects starter switch signal.With starter switch ON (lll): bafteryvoltageWith staner switch OFF: 0 V

7BRNSCS (SERVICE CHECKSIGNAL)

Detects service check connectorsignal (the signal causing a DTCindication)

With the connector connected: 0 V

With the connector disconnected: about

5 V or battery voltage

8LT BLUK-LINESends and receives scan toolsrgnal.With ignition switch ON (ll): pulses

10WHT/BLUVBUUP)

(VOLTAGE BACKPower source tor the PCMcontrol circuit. Power source for

the DTC memory

Battery voltage at all times

11WHT/REDCKFM (CKF SENSOR MSIDE)Ground for CKF sensor signal.

12WHTCKPM (CKP SENSOR I\4SIDE)Ground lor CKP sensor signal.

13REDTDCM (TDC SENSOR MSIDE}Ground for TDC sensor signal.

14BLKCYPM (CKP SENSOR MSIDE}Ground for CYP sensor signal.

16GRN

PSPSW (P/S PRESSUREswtTcH)Detects PSP switch signal.At idle with steering wheel in straightahead position:0 VAt idle with steering wheel at full lock:

battery voltage

17WHT/REDALTF (ALTERNATOR FRSIGNAL)

Detects alternator FR signal.With fully warmed up engine running:

0 V-battery voltage {depending onelectrical load)

18BLUA/VHTVSS (VEHICLE SPEEDSENSOR)Detects VSS signal.Wirh ignition switch ON (ll) and frontwheels rotating: cycles 0 V - 5 V or bat-tery voltage

Wire side of femaie terminalsPCM CONNECTOR C {31PINOTE: Standard battery voltage is 12 V.

(cont'd)

www.emanualpro.com

Page 275 of 1395

ECM/PCM CONNECTOF C (31PI

Wire side o{ female terminal€ECM/PCM CONNECTOR C (31P)NOTE: Standard battery voltage is 12 V.

TermidalD.3criptionSignal

8LI(WHTPOzSHTC {PRIII4ABY HEATEDOXYGEN SENSOR HEATERCONTROL)

Drivss prim6ry h$ted oxygsn sensorWilh ignition switch ON (ll): baneryvoltsgeWith ftrllywarmsd up €ngine runnang: duty

2"WHT/GBNALTC (ALTERNATOR CON,TROL)Sonds alternalor control signsl.With fully wafmod up €ngine rnningr ban€ryvoltagoDu ng driving with small elsctrical lo6d: 0 v

3'1FED/8LUKS (KNOCK SENSOR)Dstects KS signal.With engine knockang: pulses

5WHT/REDALTF (ALTERNATOR FR SIG-NAL}Detects alternator FR signal.Wth fullywarmed up €ngine running:0 V-batteryvoltag€ {d€pending on slsctrical load)

1GRN,4trHTSG1 (SENSOR 680UND}Ground for l/tAP sensor.L€ss than 1.0 v 6t all times

8BLUCKPP (CKP SENSOF P SIDE)Dat€cls CKP s6nsor.With €ngin€ runningr puls€s

9CKPI.,I| {CKP SENSOF M SIDE)Ground for CKP s€nsor.

15PHO2S {PRIMARY HEATEDOXYGEN SENSOR, SENSOR 1)Detocts pfimary he6t6d oxygen ssnsor

{sonsor 1)signal.with ihfottls fully opened from idle with fully,

walm6d up engins: above 0.6 VWith throttlo quickly clossd: below 0.4 v

17RED/GRNMAP (MANIFOLD ABSOLUTEPRESSURE SENSOR)

D6tects MAP s€nsor sign6l.With ignition switch ON (ll):about 3 VAt idls: aboul 1.0 V {dspsnding on engine speed)

18GRN/BLKSG2 (SENSOB GNOUNDiLsss than 1.0 V at all tim€s

19YEUBEDVCCl {SENSOR VOLTAGE)Power soufce to MAP s€nsor.With ignition switch ON (ll): about 5 VWith ignition switch OFF:0 V

20GRNTDCP {TDC SENSOR P SIDE)Derecis TDC sensor.With engine funning: Pulses

2lREDTDCM ITDC SENSOR M SID€)Ground for TDC sensor.

22BLU/REDCKFP (CKF SENSOR PSIDE)Dstscts CKF s€nsor.With sngins running: pulsss

23BLU/WHTVSS (VEHICLE SPEED SEN-soR)Dstscrs vss signal.With ignition switch ON (ll)and front wheelsrotaringrcyclss 0 v- 6bout 5 V or ban€ry voltage

25RED//ELIAT (INTAKE AIR TEMPERA'TURE SENSOB)Detacts IAT sensor signal.With igniiion switch ON (ll): about 0.1 - 4.8 V(d€p€nding on iniate air t€mp€raturc)

26REO/WHTECT {ENCINE COOLANTTEMPERATURE SENSOR)oetscts ECT sensor signal.With ignition switch ON (ll): about 0.1 4.8 V

{doponding on 6ngin€ coolanl lemper6tu16)

27RED/BLKTPS (THROTTLE POSITIONSENSOR)Dotects TP sensor signrl.with rhrottls fully op€n: aboui 4.8 vwith throtrl6 fullyclosed: about 0.5 v

2AYEUBLUVCC2lSENSOR VOLTAG€}Provid€s s€nsor voltage.With ignilion switch ON (ll): about 5 VWhh ignition switch OFF: 0 V

29YELCYPP ICYP SENSO8 P SIDE)Dsrscts CYP sensor.With €ngins runningr pulsss

30BLKCYPM (CYP SENSOR M SIDE)Ground for CYP sansor.

31WHT/REDCKFM {CKF SENSOR M SIDE)6.ound lof CKF ssnsor signal.

11. AfT 13. '94 model'2:M/T 14:'99- 0o modsls.5: USA

(cont'd)

11-73

www.emanualpro.com

Page 282 of 1395

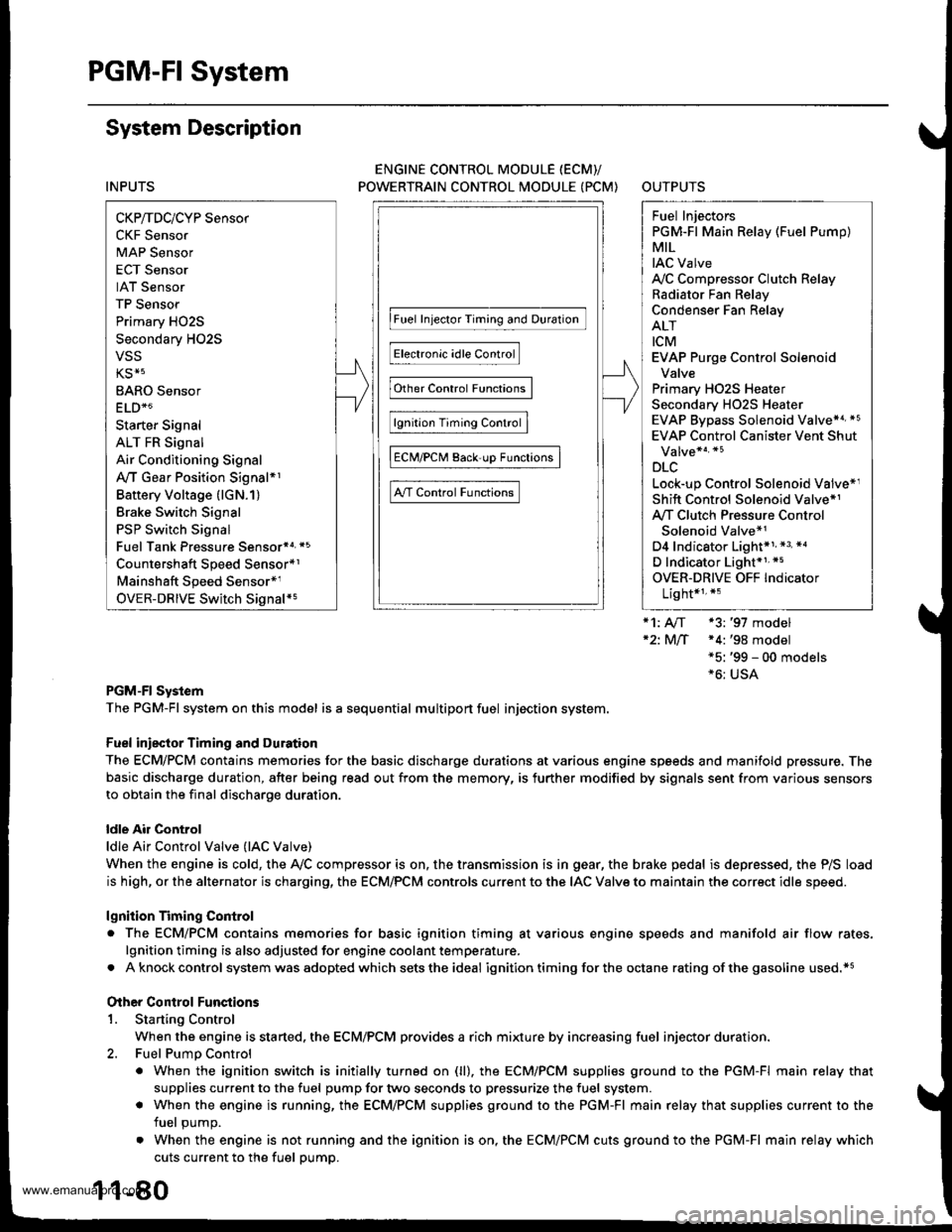

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 325 of 1395

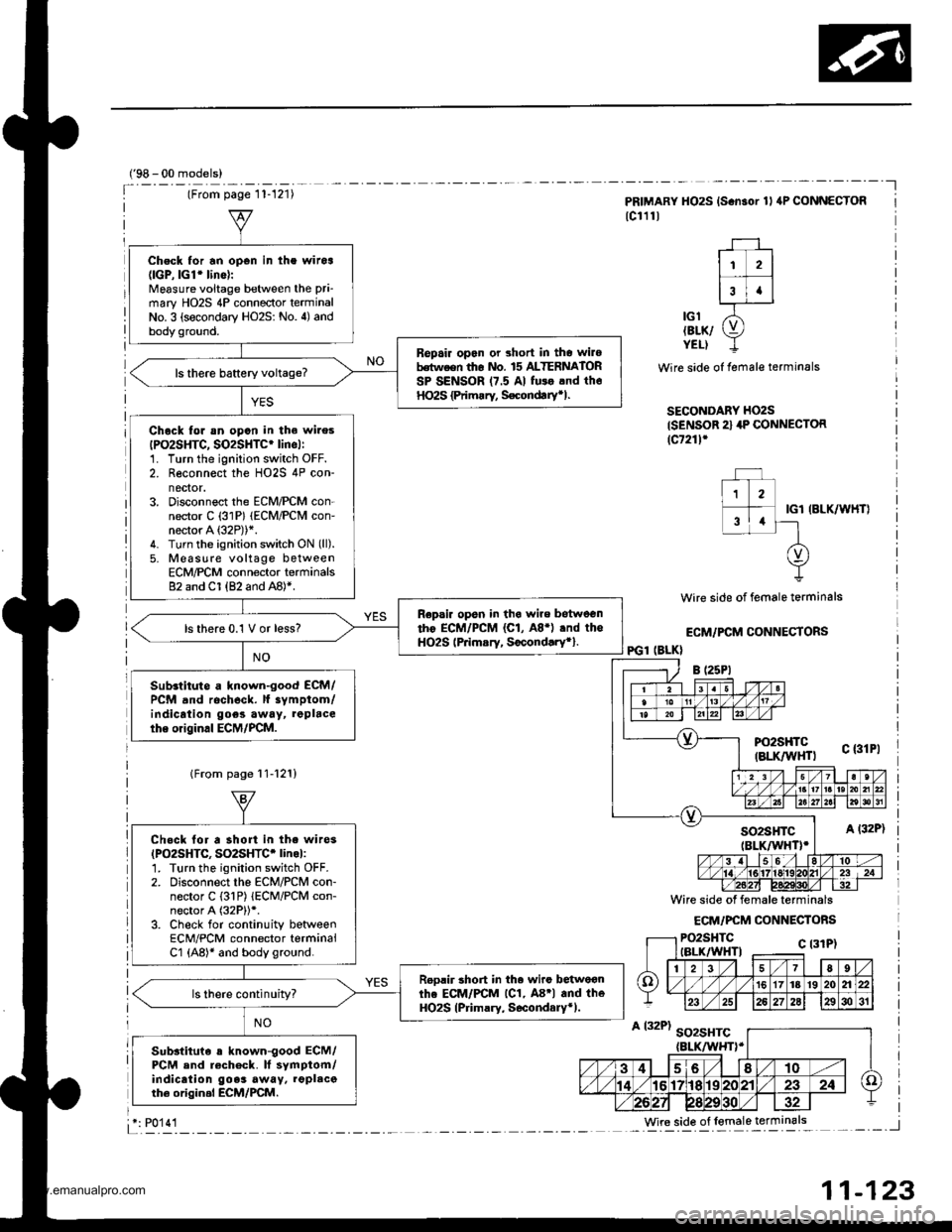

Check for an open in the witoa(lGP,lGl'lino):

Mgasure voitage between the pri-

mary HO2S 4P connector terminalNo. 3 (secondary HO2S: No. 4) andbody ground.

Bepair opan or short in tho wilobdtween th6 nlo. 15 ALTERNATORSP SENSOR 17.5 Al fu$ .nd th6HO2S {Primrry, S€condtrytl.

Chock lor sn opon in the wires

IPO2SHTC, SO2SHTC' lincl:1. Turn the ignition switch OFF.2. Reconnect the HO2S 4P con-nector.3. Disconnect the ECM/PCM con-nector C (31P) (ECM/PCM con-neaor A (32P))*.

4. Turn the ignition switch ON (ll).

5. Moasure voltage betweenECM/PCM connector terminals82 and Cl (82 and A8)*.

Repsir opsn in tha wire betweentho ECM/PCM (C1, A8.) .nd theHO2S lPrimsry, Socond.ry*}.ls there 0.1 V or less?

Sub.titute a known-good ECM/PCM and rocheck. lf iymptom/indicrtion goes away, repbcethe original ECM/PCM.

('98 - 00 models)

Wire side of female terminals

ECM/FCM CONNECTORS

IGl IBLK/WHT}

PRIMARY HO2S {S.n3or 1l aP CONNECTOR

lc111l

11 2l

r--T -l3t.lL-.IJ------J

lcl /5'tErK/ g,YELI I

Wire side of female terminals

SECONDARY HO2S

{SENSOR 2} 4P CONNECTOR(c7211'

PGl (BLK}

lFrom page 11-12'!)

Chock lor a short in the wi.es(PO2SHTC, SO2SHTC' linol:1. Turn the ignition switch OFF.2. Disconnect the EcM/PcM con-nector C {31P) lECM/PCM con-nector A (32P))*.

3. Check for continuity betweenECM/PCM connector terminalCl (A8)* and body ground.

Roolir 3hort in th. wiro betwoonthe ECM/PCM lC1, A8'l and theHO2S (Primary, S6condary*).ls there continuity?

Sub3tituie s known-good ECM/PCM and rech6ck. It symptom/indicaiion goes away. lgplacoth6 origin.l ECM/PCM.

Wire side of lemale terminals: P0'14'l

11-123

www.emanualpro.com

Page 342 of 1395

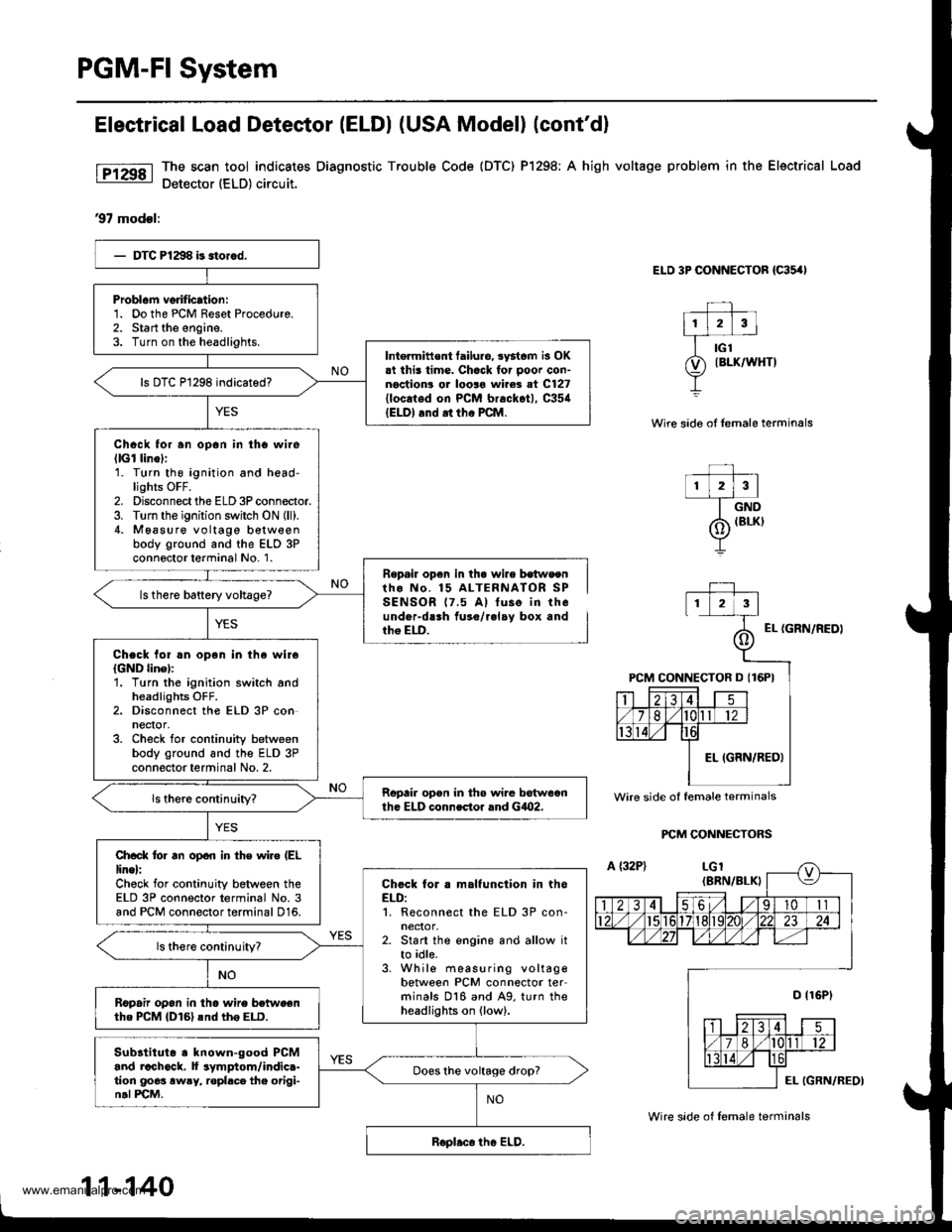

PGM-FI System

Electrical Load Detestor (ELDI (USA Model) (cont'dl

The scan tool indicates Diagnostic Trouble Code {DTC) Pl298; A high voltage problem in the Electrical Load

Detector (ELD) circuit.

97 modsl:

ELD 3P CONNECTOR {C35,'I

Wire sido oI lemale terminals

r lzlrl--T_ow

/6 IBLKI

Y

Repail op€n in th. wire b€tws€ntho No. 15 ALTERNATOR SPSENSOR 17.5 A) tuse in theunder-dlrh fuso/r.lay box andth6 ELD.EL {GRN/NEDI

PCM CONNECTORS

Problam verification:1. Do the PCM Reset Procedure.2. Start the engine.3. Turn on the headlights.Intermittent tailuro, systcm is OK.t this time. Chack for ooor con-noction! or looro wire3 at C127{locaied on PCM brackot), C35{{ELDI and .t tho PCM.

Chack for an opan in tho wilellGl linol:1. Turn thg ignition and head-lights OFF.2. Disconnect the ELD 3P connector.3. Turn the ignition switch ON {ll).4. M6asure voltage b€tw€enbody ground and the ELD 3Pconnoctor terminal No. 1.

Chock lol !n open in the wireIGND linel:'1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P conneqor,3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2.

Ropair opon in th6 wi.e betweonth. ELD connector rnd GiO2,

Ch.ck lo. an open in th€ wiro (EL

line):Check for continuity between theELD 3P connector terminal No. 3and PCM connector terminal 016.

Chock for . malfunction in theELD:1. Reconnect the ELD 3P con-neclor,2. Start the engine and allow itto idle.3. While measuring voltagebetween PCM connector terminals 016 and A9. turn theheadlights on (low).

ls there continuityT

R6pafu op6n in tho wire betweenthe PCM {D161snd th6 ELD.

Subltituto . known-good PCMand rachock, f symptom/indic.-tion goes awry, ropl.ce the origi-n.l PCM.

Does the voltage drop?

Wire side of lemale terminals

11-140

Wire side of lemale terminals

www.emanualpro.com