Cat HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 714 of 1395

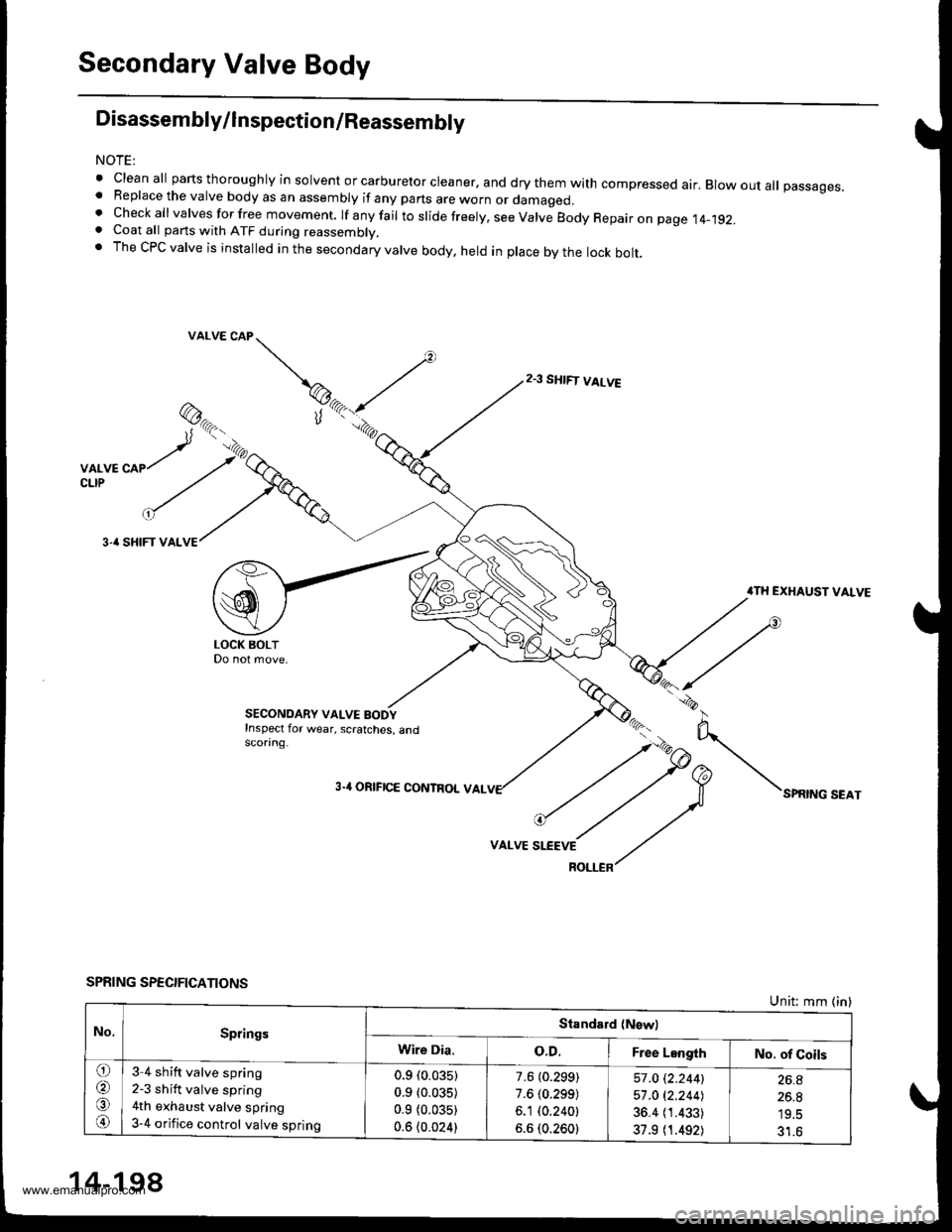

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

' clean all parts thoroughly in solvent or carburetor cleaner. and dry them with compressed air. Blow out aU passages,. Replace the valve body as an assembly if any parts are worn or damaged.t check all valves for free movement. rf anyfair to sride freery. see varve Body Repair on page 14-192.. Coat all parts with ATF during reassembly.. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

@,.-.t'tr.,

,rr'^'//u

"/ ./

3-' SHIFT VALVE

VALVE CAP

SPRING SPEC!FICATIONS

2.3 SHIFT VALVE

VALVE SLEEVE

ROLLER

ilTH EXHAUST VALVE

N"*,"o"*,

Unit: mm (in)

t*-1

SECONOARY VALVE BODYInspect for wear, scratches, andscorang.

3.4 ORIFICE CONTROL VAL

No.SpringsStandald {Nswl

Wire Dia.o.D.Free LengthNo. of Coils

o

@

o

@

3 4 shift valve spring

2-3 shift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.9 (0.035)

0.9 (0.035)

0.9 {0.035)

0.6 {0.024}

7.6 (0.299)

7.6 (0.299)

6.1 (0.240t

6.6 (0.2601

57 .O i.2.2441

57 .O 12.244J

36.4 (1.433)

37.9 (1.492)

26.A

26.8

19.5

31.6

14-198

www.emanualpro.com

Page 716 of 1395

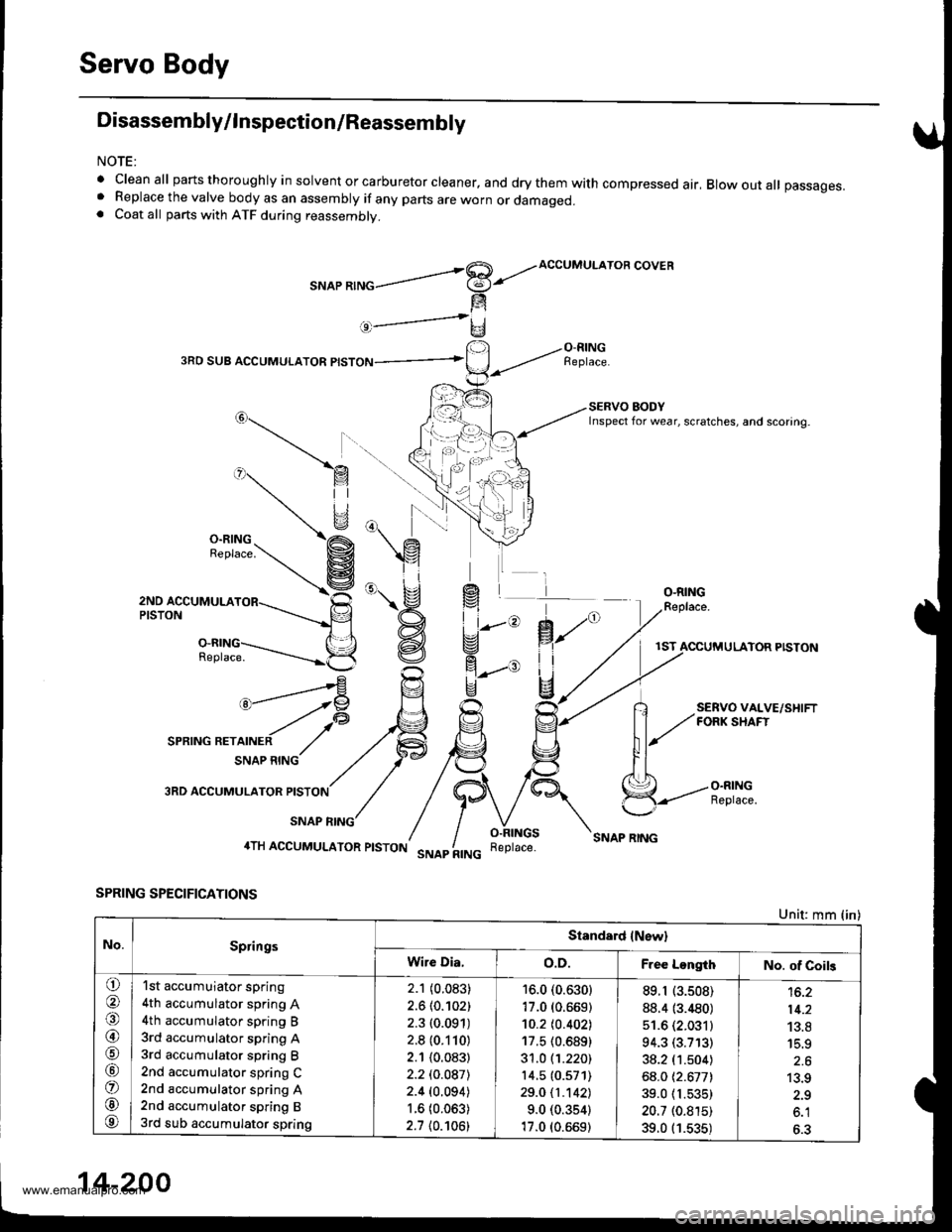

Servo Body

Disassembly/lnspection/Reassembly

NOTE:

' cleanall parts thoro ugh ly in solvent or ca rbu retor clea ner, a nd dry them with compressed air, Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damaged.. Coat all parts with ATF during reassembly.

ACCUMULATOR COVER

3RO SUB ACCUMULATOR

O-RINGFeplace.

SERVOFORK S

fi,

il

g

1ST ACCUMULATOR PISTON

Replace.

RVO VAL\IRK SHAFT

O.RING

VE/SHIFT

3RD ACCUMULATOR

SPRING SPECIFICATIONS

\_)

SNAP RING

SNAP RING

Unit: mm {in)

@"- -tP

-.t l@SPR|NG RETATNER ,/

No.SpringsStandard lNewl

Wire Dia,o.D.Free LongthNo. of Coil3

o

@J6

@.A

\o,

o

@

@

1st accumuiator spring

4th accumulator spring A

4th accumulator spring B

3rd accumulator spring A

3rd accumulator spring B

2nd accumulator spring C2nd accumulator spring A2nd accumulator spring B

3rd sub accumulator spring

2.1 (0.083)

2.6 {0.102)

2.3 (0.091)

2.8 (0.110)

2.1 (0.083)

2.2 (0.087l-

2.4 (0.094)

r.6 (0.063)

2.7 {0.106)

16.0 (0.6301

17.0 (0.669)'t0.2 t0.402]�

17.5 (0.689)

31.0 (1.220)

14.5 {0.571)

29.0 11.1421

9.0 (0.354)

17.0 (0.669)

89.r (3.508)

88.4 (3.480)

51.6 (2.031)

94.3 (3.713)

38.2 (1.504)

68.0 {2.677)

39.0 fi.535)

20.7 (0.815)

39.0 (1.535)

14.2

13.8

15.9

2.6

13.9

2.9

o.l

6.3

14-200

www.emanualpro.com

Page 717 of 1395

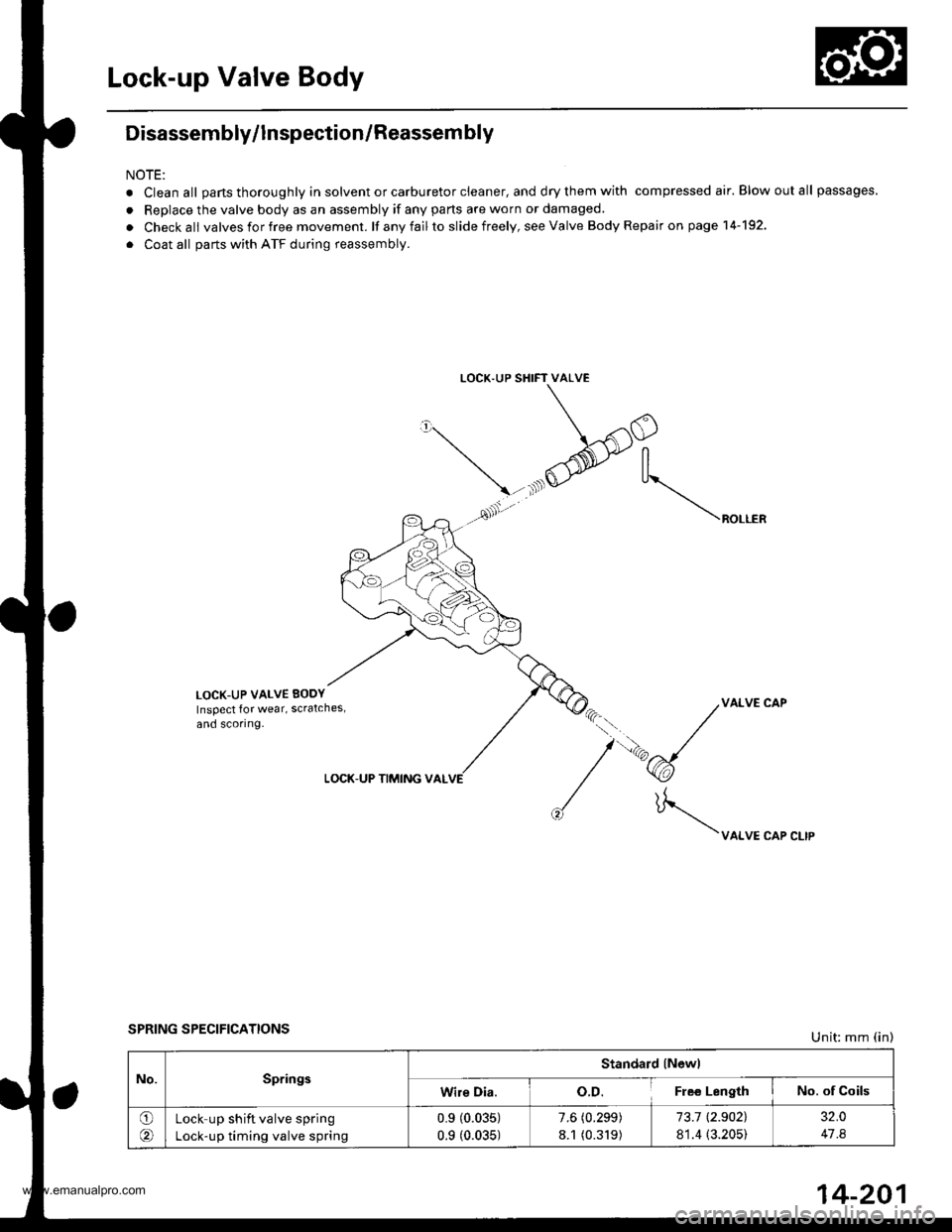

Lock-up Valve Body

Disassembly/lnspection/Reassem bly

NOTE:

. Clean all parts thoroughly in solvent or carburetor cleaner, and dry them with compressed air. Blow out all passages.

. Replace the valve body as an assembly if any parts are worn or damaged.

. Checkall valvesforfree movement. lf anyfailto slide freely, seeValve Body Repairon page 14-192.

. Coat all parts with ATF during reassembly.

LOCK.UP SHIFT VALVE

\/'

\-.xlO

@-tr

, ^ ,As'. \"o...*

LOCK-UP VALVE EODY

Inspect lor wear, scratches,

and scoring.

VALVE CAP

\uo.*"or".,,

LOCK-UP TIMING VAL

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard lNewl

Wire Dia.o.D.Fle€ LengthNo. of Coils

O(Lock up shift valve spring

Lock-up timing valve spring

0.9 (0.035)

0.9 (0.035)

7.6 (0.299)

8.1 (0.319)

73.1 t2.902),

81.4 (3.205)

32.0

47 .8

14-201

www.emanualpro.com

Page 718 of 1395

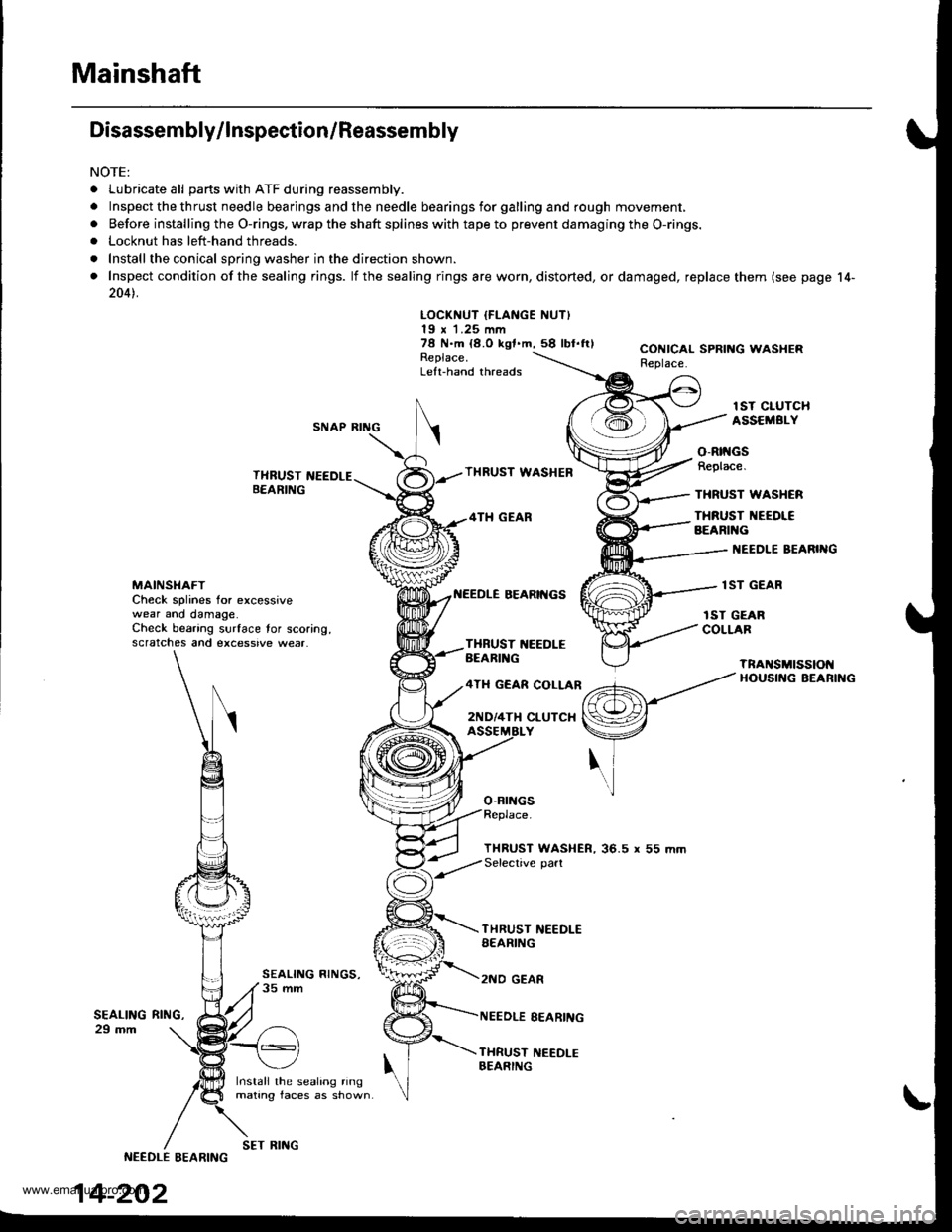

Mainshaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all parts with ATF during reassembly.

.Inspectthethrustneedlebearingsandtheneedlebearingsforgallingandroughmov\

ement,

. Before installing the O-rings. wrap the shaft splines with tape to prevent damaging the O-rings.. Locknut has left-hand threads.

. Install the conical spring washer in the direction shown.

. Inspect condition of the sealing rings. lf the sealing rings are worn, distorted, ordamaged, replace them (see page 14-

2041.

LOCKNUT IFLANGE NUT)19 x 1.25 mm78 N.m {8.O kgf.m,58 lbl.ftlReplace.Left-hand threads

CONICAL SPRING WASHERReplace.

lST CIUTCHASSEMBI.YSNAP RING

THRUST NEEDLEB€ARING

Install the sealing ringmating faces as shown

THRUST WASHEB

4TH GEAR

BEARII{GS

o-Brr{Gs

o-Rtt{GsReplace.

THRUST WASHCR

THRUST NEEOI€BEARIl{G

I{EEDLE BEARIIIG

lST GEARMAINSI{AFTCheck splines for excessivewear ano damage.Check bearing surface tor scoring,scratches and excessive wear.

rST GEARCOLLARTXBUST 1{EEDLEBEARIl{G

4TH GEAR COLLAR

2ND/4TH CLUTCX

TnANSMtSSIOt{HOUSII{G BEARII{G

THRUST WASHER, 36.5 r 55 mmSelective part

SEALING29 mm

THRUST NEEDLESEARING

2NO GEAR

NEEDLE EEARING

THRUST NEEDI-EBEARING

RltrlG,

NEEDLE EEARING

14-202

SET RING

www.emanualpro.com

Page 721 of 1395

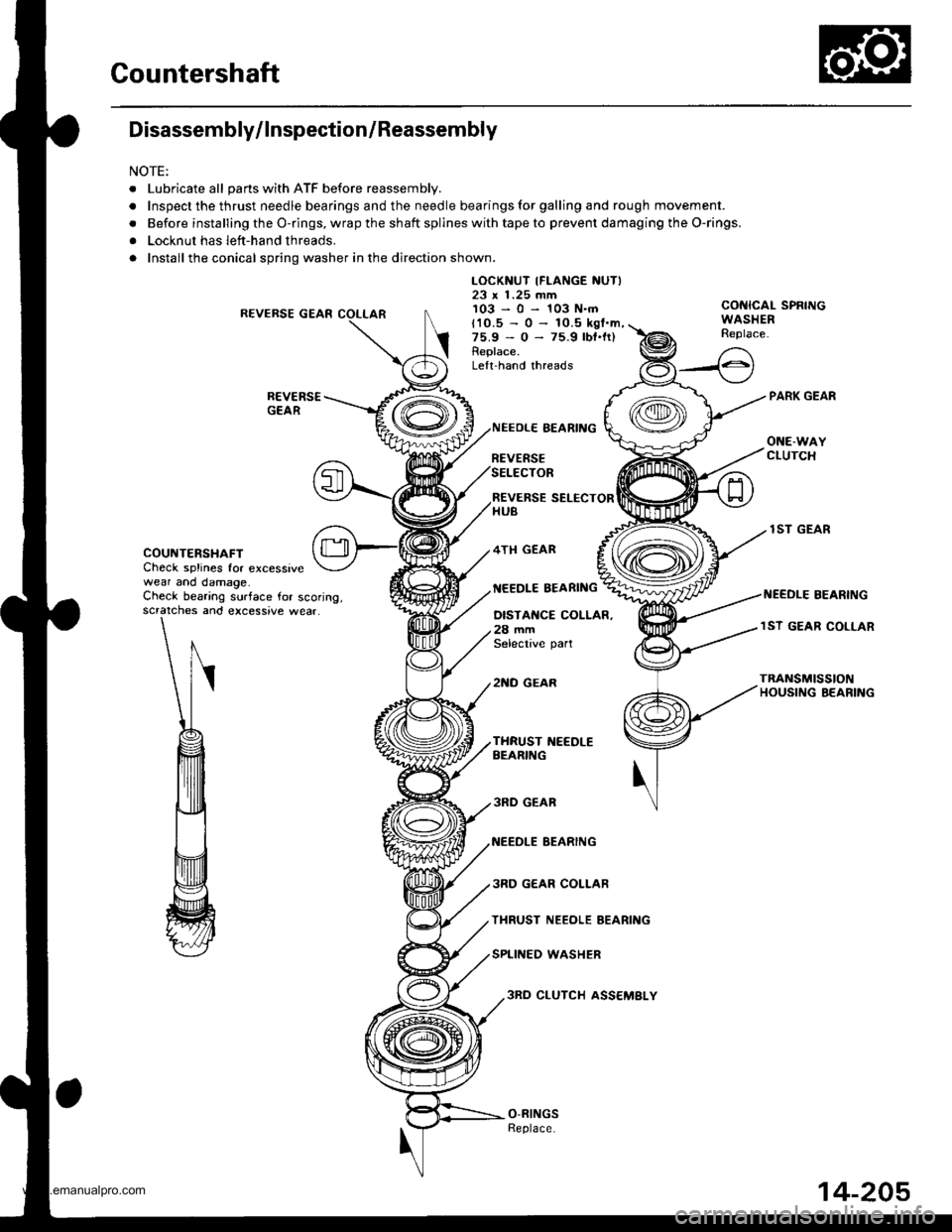

Countershaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all pans with ATF before reassembly.

.Inspectthethrustneedlebearingsandtheneedlebearingsforgallingandroughmov\

ement.

. Before installing the O-rings, wrap the shaft spllnes with tape to prevent damaging the O-rings.

. Locknut has left-hand threads.

. Install the conical spring washer in the direction shown.

R€VERSE GEAR

LOCKNUT IFLANGE NUTI23 x 1.25 mm103-0-103N.mCONICAL SPRINGWASHERReplace.t10.5 - 0 -

75.9 - 0 -

Replace.

10.5 kgl.m,75.9 lbt.lr)

Lelt.hand threads

COUNTERSHAFTCheck splines for excessivewear and damage.

REVERSE SELECTORHUB

4TH GEAR

NEEDLE EEARING

NEEOLE BEARING

REVERSESELECTOR

OISTANCE COLLAR.28 mmSelective part

2NO GEAR

lST GEAR

I{EEDLE BEARINGCheck bearing surface for scoring,scratches and excessive wear.lST GEAR COLLAR

TRANSn SSTONHOUSI G BEARING

3RD GEAR

NEEDLE BEARING

3RD GEAR COLLAR

THRUST NEEOLE BEARING

SPLINED WASHER

3RO CLUTCH ASS€MBLY

14-205

www.emanualpro.com

Page 722 of 1395

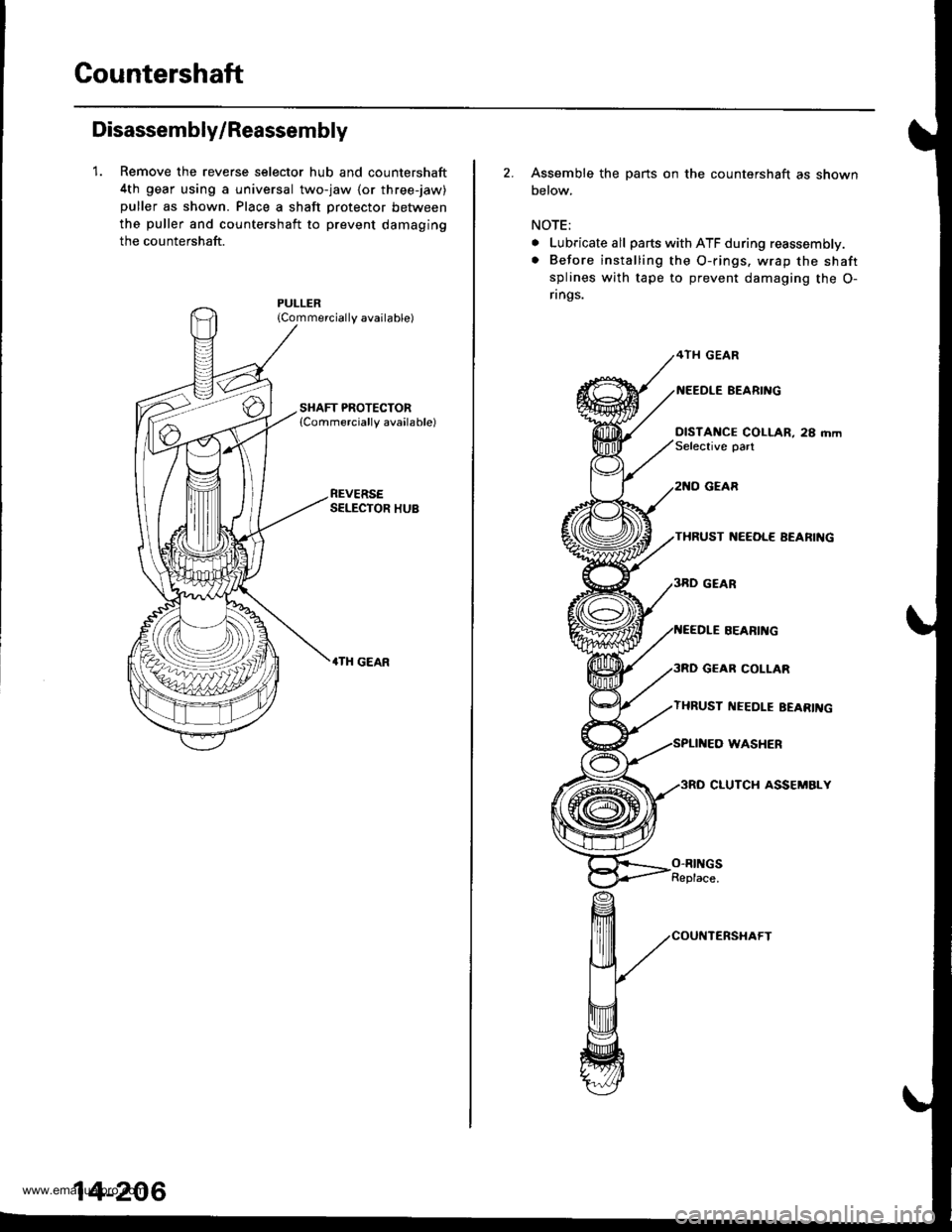

Gountershaft

Disassembly/Reassembly

1. Remove the reverse selector hub and countershaft

4th gear using a universal two-jaw lor three-jaw)

puller as shown. Place a shaft protector between

the puller and countershaft to prevent damaging

the countershaft.

{Commercially available)

REVERSESELECTOR HUB

.TH GEAR

14-206

2. Assemble the parts on the countershaft as shown

below.

NOTE;

. Lubricate all parts with ATF during reassembly.

. Before installing the O-rings. wrap the shaft

splines with tape to prevent damaging the O-

rings.

4TH GEAR

BEARI'{G

DISTANCE COLLAR, 28 mmSelective oart

GEAR

THRUST ]{EEOL€ AEARIIIG

GEAR COLLAR

THRUST I{EEDLE EEARII{G

WASHER

3RO CLUTCH ASSEMBLY

SEARII{G

O-RINGSReplace.

www.emanualpro.com

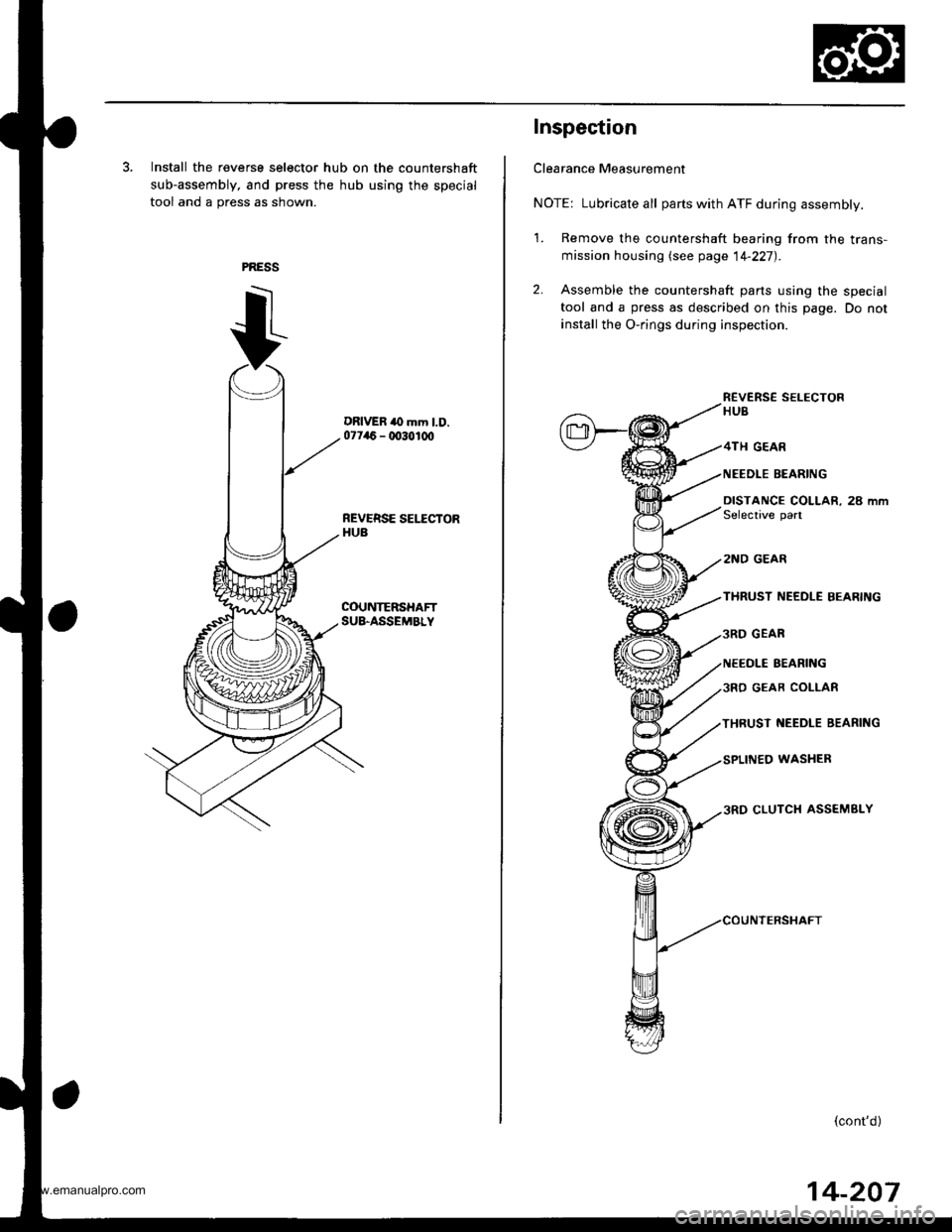

Page 723 of 1395

3. Install the reverse selector hub on the countershaft

sub-assembly, and press the hub using the special

tool and a press as shown.

DRIVER to mm l.D.07746 - 0030100

REVERSE SEI.ICTORHUB

COUNTERSHAFTSU&ASSEMBLY

Inspection

Clearance Measurement

NOTE: Lubricate all parts with ATF during assembly.

1. Remove the countershaft bearing from the trans-

mission housing lsee page 14-227).

2. Assemble the countershaft parts using the special

tool and a press as described on this page. Do not

install the O-rings during inspection.

R€VERS€ SELECTORHUB

GEAR

NEEDLE BEARING

DISTANCE COLLAR, 28 mmSelective part

2NO GEAR

THRUST NEEDLE BEARING

GEAR

NEEOLE BEARING

GEAR COLIAR

THRUST NEEDLE BEARING

WASHER

CLUTCH ASSEMBLY

(cont'd)

14-207

www.emanualpro.com

Page 726 of 1395

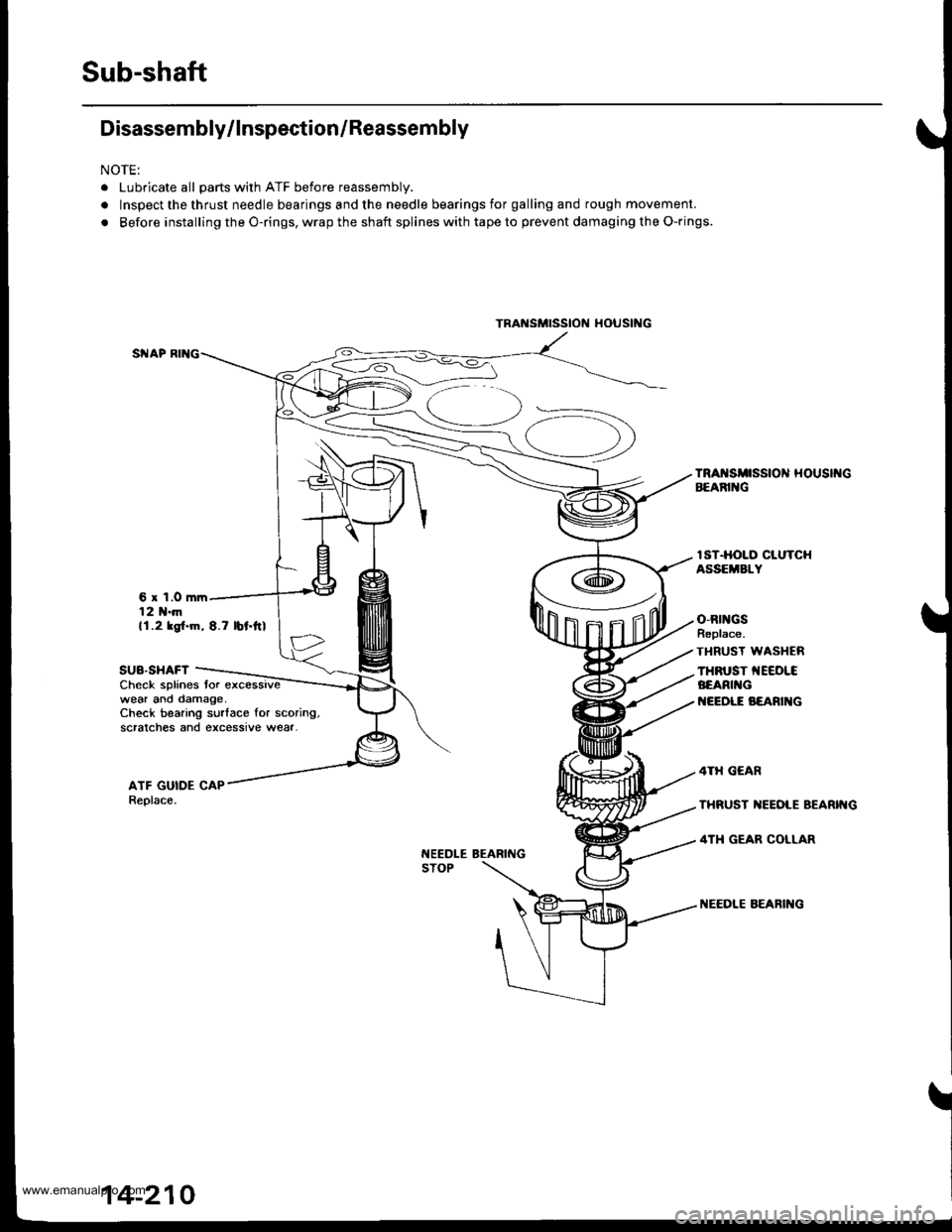

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all parts with ATF before reassembly.

. Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

. Before installing the O-rings, wrap the shaft splines with tape to prevent damaging the O-rings.

6 x 1.0 mrr12 1{.mll.2 ksl.m, 8.7 lbt.ftl

SUB.SHAFTCheck splines tor excessivewear ano damage,Check bearing surlace for scoring,scralches and excessive wear-

t{EEDLE BEARINGSTOP

IST.HOLO CLUTCHASSEMBLY

o,Rtl{GSReplace.

TI{RUST WASI{ER

THFUST TEEOLCBEARI G

I{EEDLE B€ARI G

TRAi{SMTSStON tl()UStNG

14-210

www.emanualpro.com

Page 728 of 1395

Sub-shaft Bearings

Replacement

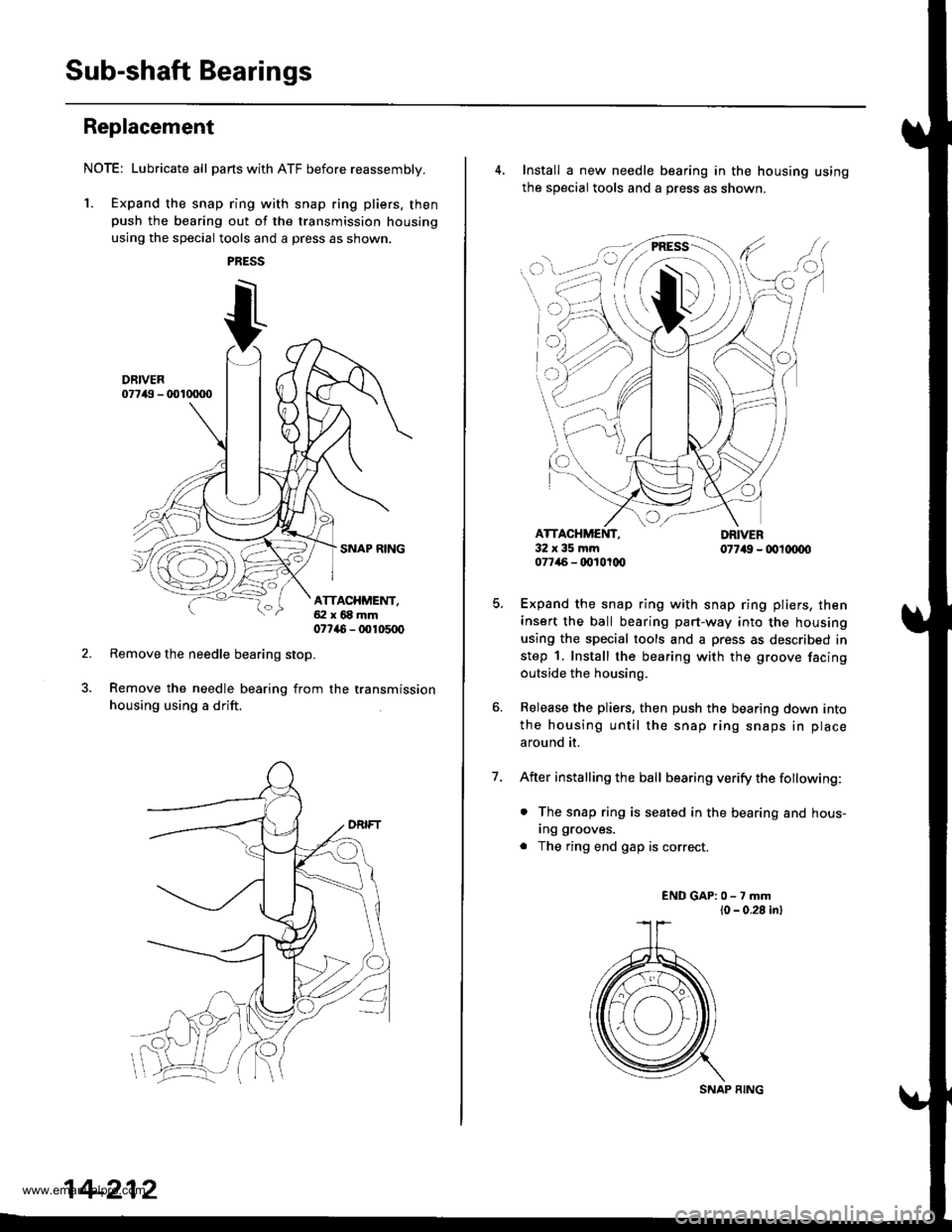

NOTE: Lubricate all parts with ATF before reassembly.

1. Expand the snap ring with snap ring pliers. thenpush the bearing out of the transmission housing

using the special tools and a press as shown.

Remove the needle bearing stop.

Remove the needle bearing from the transmission

housing using a drift.

ATTACHMENT,ai:l x 68 mm07746 - 00105q)

14-212

SNAP RING

4. Install a new needle bearing in the housing using

the sOecial tools and a oress as shown.

7.

cI

32x35mm077/46 - qt10t(x,

Expand the snap ring with snap ring pliers, then

insert the ball bearing part-way into the housing

using the special tools and a press as described in

step 1. Install the bearing with the groove facing

outside the housing.

Release the pliers, then push the bearing down into

the housing until the snap ring snaps in place

around it.

After installing the ball bearing verify the fottowing:

. The snap ring is seated in the bearing and hous-

Ing grooves.

. The ring end gap is correct.

ENDGAP:0-7mml0 - 0.28 inl

www.emanualpro.com

Page 734 of 1395

Glutch

Reassembly

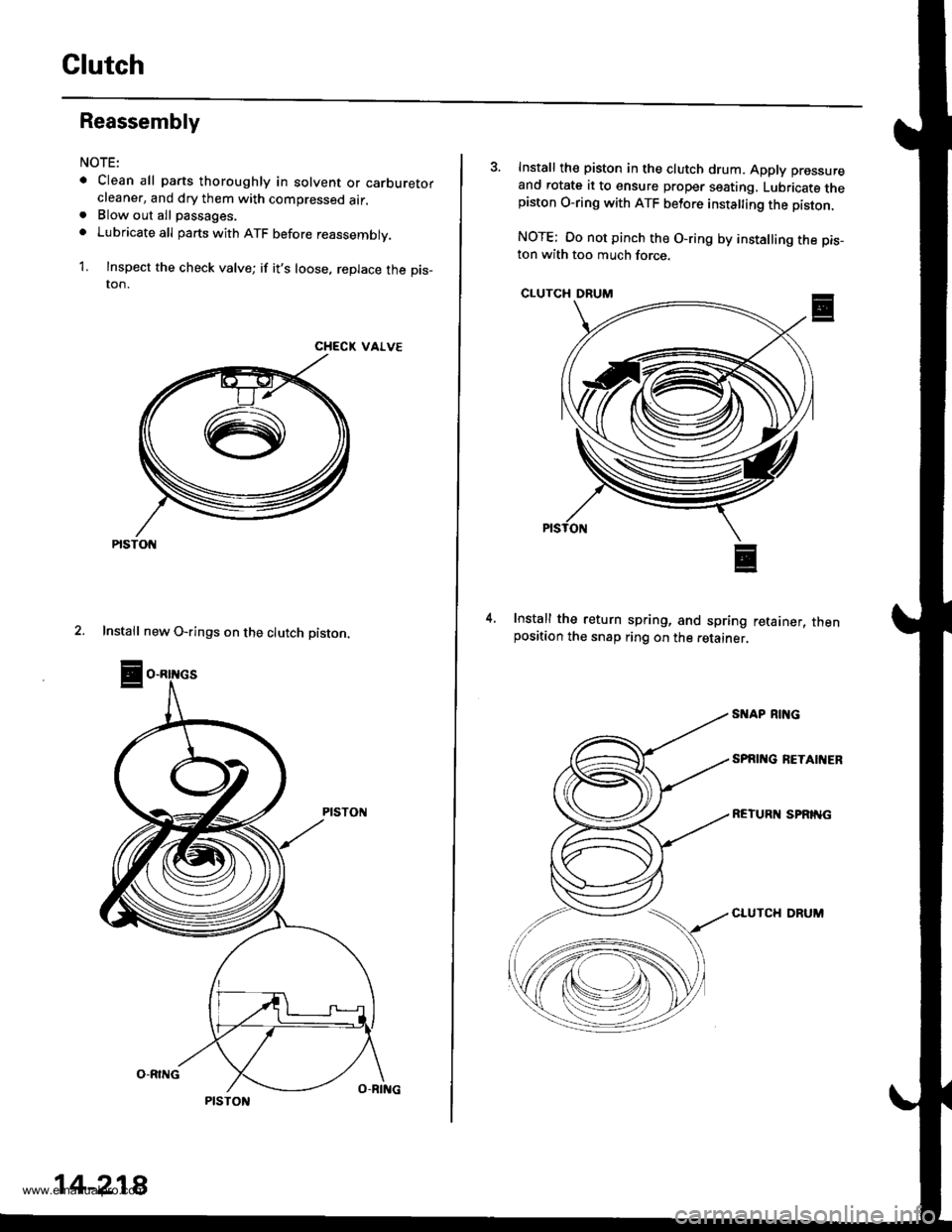

NOTE:

. Clean all parts thoroughly in solvent or carburetorcleaner, and dry them with compressed air.. Blow out all passages.

o Lubricate all parts with ATF before reassembly.

1. Inspect the check valve; if it's loose, replace the pis_ton.

CHECK VALVE

2. Install new O-rings on the clutch piston.

PtsTot{

14-218

3. Install th€ piston in the clutch drum. Apply pressure

and rotate it to ensure proper seating, Lubricate thepiston O-ring with ATF betore insta ing the piston.

NOTE: Oo not pinch the O-ring by installing the pis_ton with too much force.

CLUTCH DRUM

Install the return spring, and spring retainer, thenposition the snap ring on the retainer.

4.

SI{AP RING

SPAI'{G RETAIIIER

REIURN SPRING

CLUTCH DRUM

www.emanualpro.com