switch HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1380 of 1395

)

)

From page 24-82 iA)

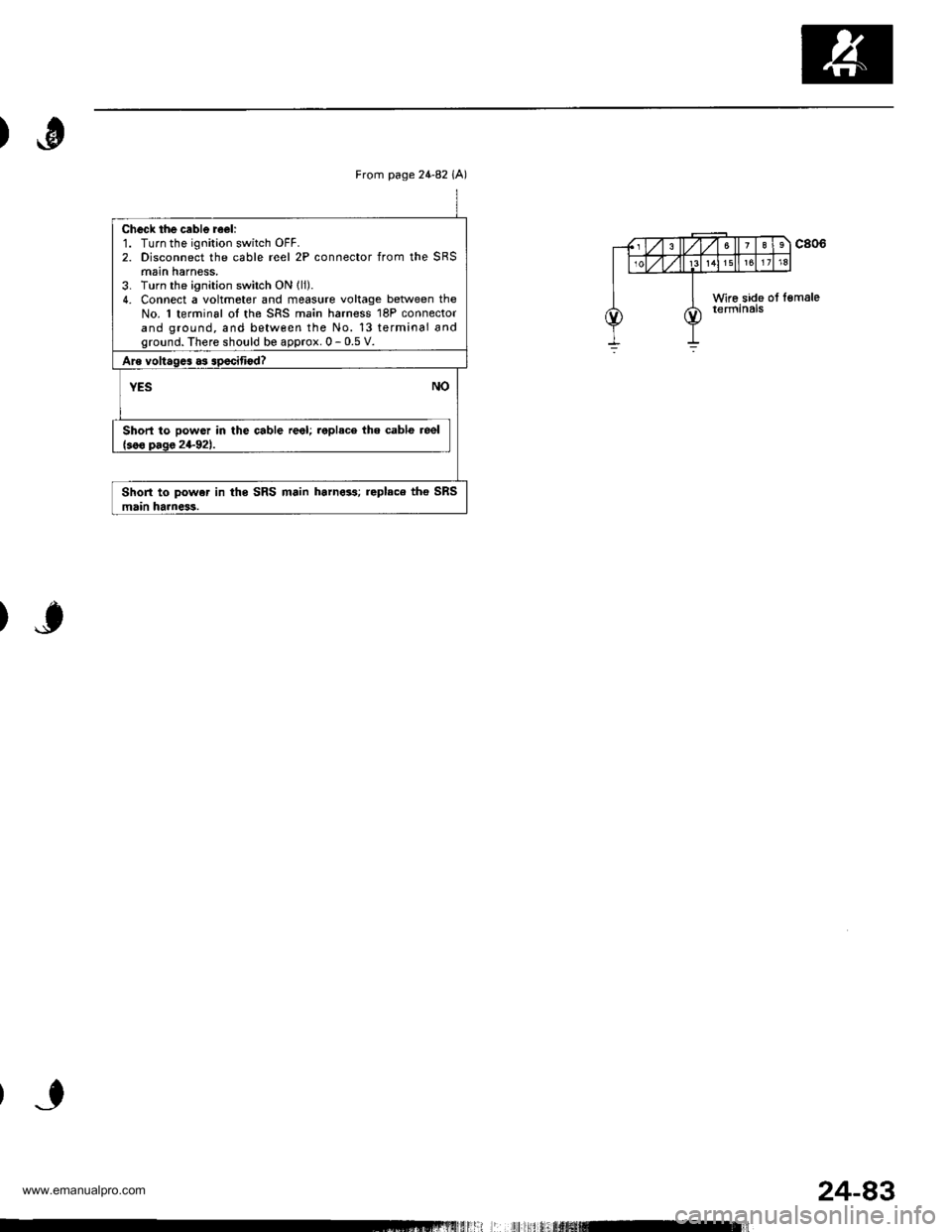

Check the cable reeli1. Turn the ignition switch OFF.2. Disconnect the cable reel 2P connector from the SRSmain harness,3. Turn the ignition switch ON lli).4. Connect a voltmeter and fieasute voltage beNveen theNo. 'l terminal oI the SRS main harness 18P connectorand ground, and between the No. 13 terminal andground. There should be approx. 0 - 0.5 V.

Are voltagcs as specifiod?

YESNO

Short to powor in the cable reel; replace the cable reel{soo oaqa 24-921.

Short to powe. in ths SRS main harn633; replaco tho SRSmain harness.

Lll l| i,ltufiffifil-]ll

24-83

www.emanualpro.com

Page 1381 of 1395

Troubleshooting

DTC 9-2 -'97 model

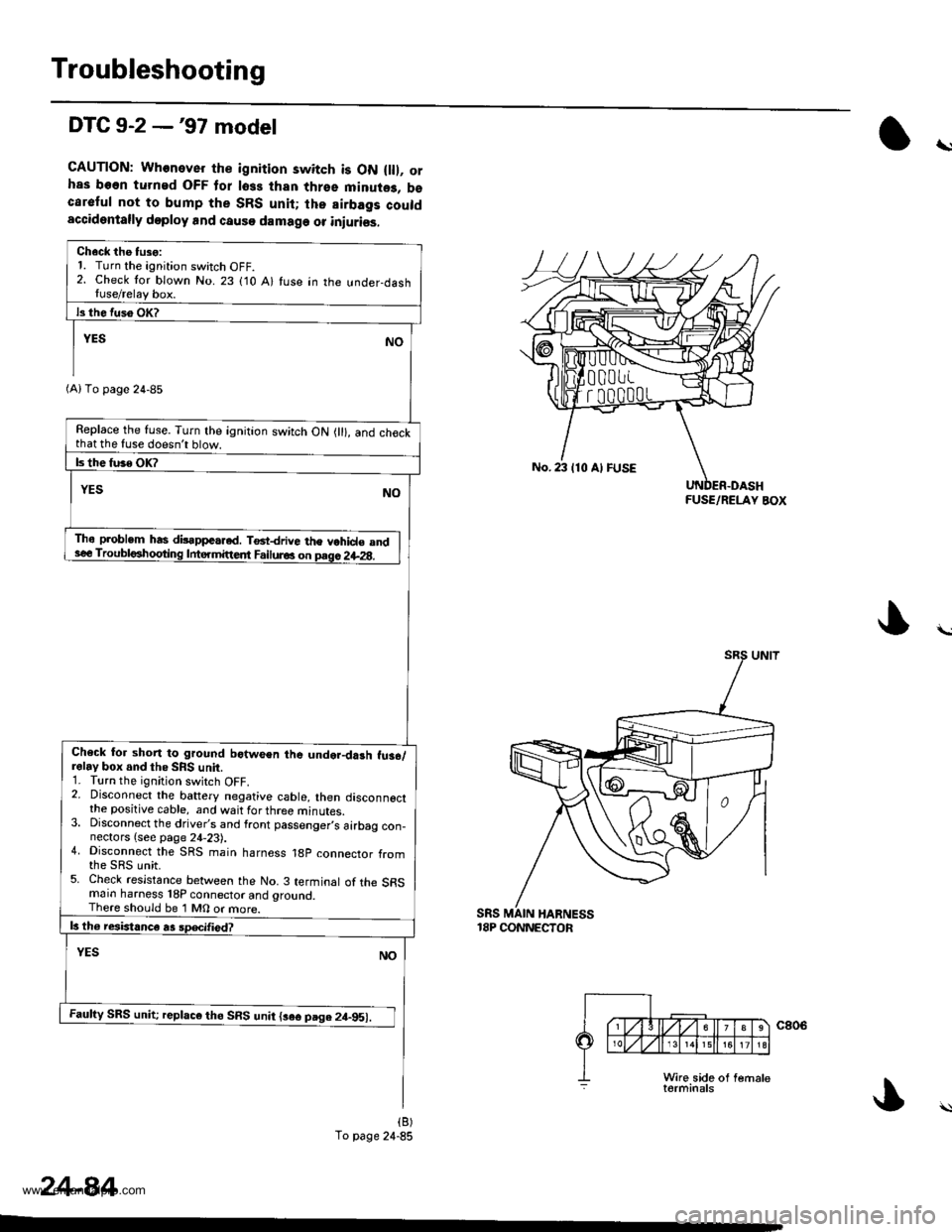

CAUTION: Whenever the ignition switch is ON flll, orhas been turned OFF tor loss than thrse minute3, bscareful not to bump the SRS unit; lhe airbags couldaccidentally doploy and causo damage or iniuriss.

\

Ch6ck the tuso:1. Turn the ignition switch OFF.2. Check tor blown No. 23 (10 A) fuse in the !nder-dashIuse/relay box.

Replace the fuse. Turn the ignition switch ON {ll}, and ch€ckthat the fuse doesnt blow.

Tho problem has dilappeared. T6t-drive the vohid€ andsee Troubl6hogting Intermittedt Failur6 on prgc 2il-2g.

Check for shon to ground botween the undor-darh fu36,/relay box and tho SRS unit.1. Turn the ignition switch OFF.2. Disconnect the battery negative cable, then disconnectthe positive cable, and wait for three minutes.3. Disconnect the driver's and front passenger,s airbag con-nectors {see page 24,23).4. Disconnect the SRS main harness 18p connector from

5. Check resistance between the No. 3 terminal of the SFSmain harness 18P connector and grouncl.There should be 1 M0 or more.

Faufty SRS unit; replaco th6 SRS unit {3e€ page 2t-951.

(A) To page 24-85

To page 24-85

No. 23 110 Al FUSE

FUSE/RELAY BOX

sRs18P CONNECTOR

24-84

www.emanualpro.com

Page 1382 of 1395

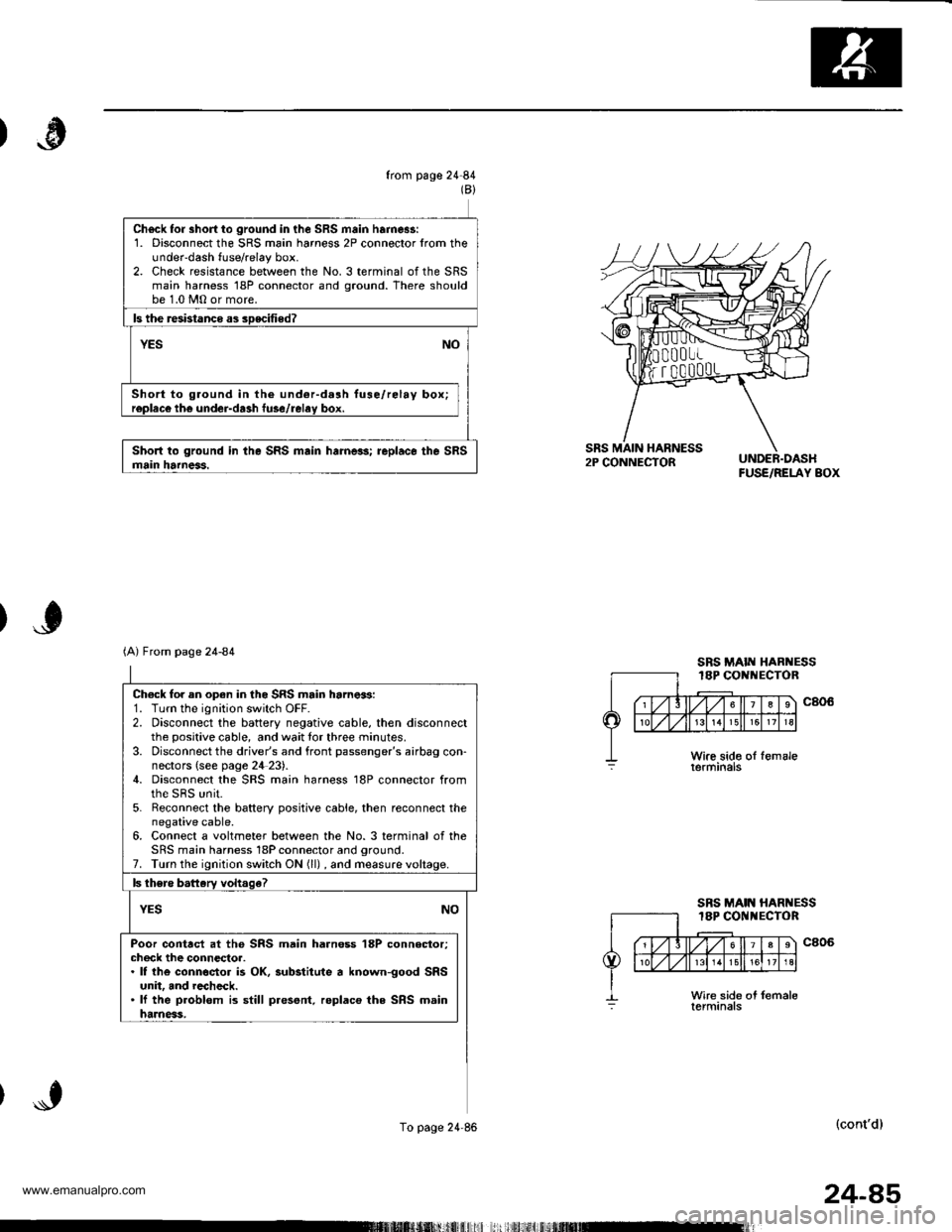

from page 24'84(B)

Ch6ck fo. short io ground in the SRS main harnes!:1. Disconnect the SRS main harness 2P connector lrom theunder-dash fuse/relay box.2. Check resistance between the No. 3 terminal of the SRSmain harness 18P connector and ground. There shouldbe 1.0 MO or more.

ls the resbtanco as soecitied?

YESNO

Short to ground in the undor-dalh fuse/relay box;r€placo th€ under-da3h fuse/relav box.

Short to ground in the SRS main harneas; replaco the SRSmain harneas.FUSE/RELAY BOX

Ch€ck for an open in the SRS main harnes:1. Turn the ignition switch OFF.2. Disconnect the battery negative cable, then disconnectthe positive cable, and wait tor three minutes.3. Disconnect the driver's and front passenger's airbag con-nectors {see page 2il 23).4. Disconnect the SRS main harness 18P connector fromthe sRs unit.5. Reconnect the baftery positive cabie, then reconnect thenegative cable.6. Connect a voltmeter between the No. 3 terminal of theSRS main harness 18P connector and oround.7. Turn the ignition switch ON (ll) , and measure

Poor contrct at the SRS main harn€ss 18P connector;check the connectoa.. lf the connsctor is OK, substitute a known-good SRSunit, and rccheck.. lf the problom is still present. replaco the SRS mainharness,

(A) From page 24-84

To page 24'86

SRS MAIN HARNESS18P CONI{ECTOR

SBS MAIN HARNESS18P COI{l{ECTOR

(cont'd)

24-85

www.emanualpro.com

Page 1383 of 1395

Troubleshooting

DTC 9-2 -'97 model lcont'dl

UNDER.OASHFUSE/RELAY BOX

SRS MAII{ HARI{ESS2P CONNECTOR

24-86

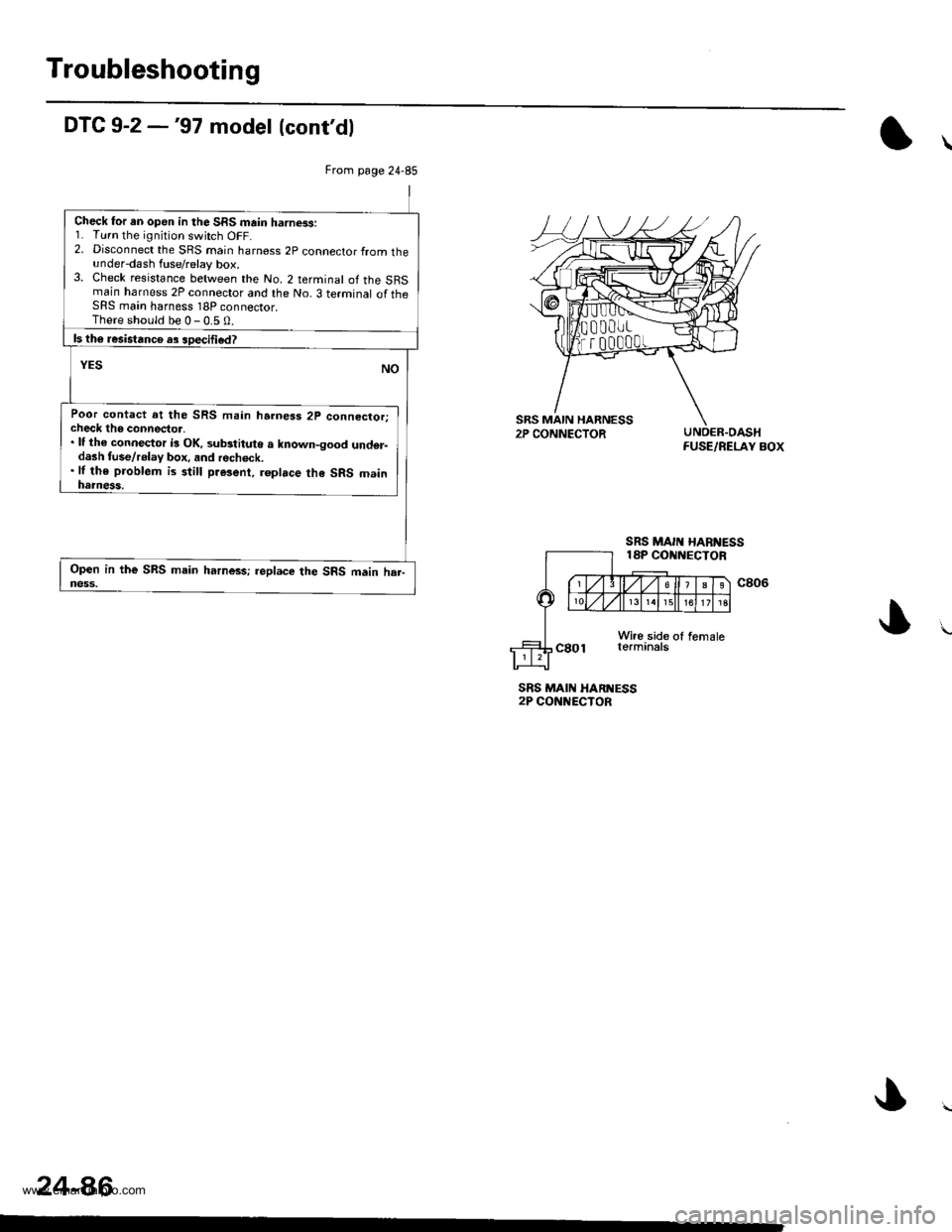

From page 24-85

Check for an open in the SRS main harness:1. Turn the ignition switch OFF.2. Disconnect the SRS main harness 2p connector from theunder-dash fuse/relay box.3. Check resistance between the No. 2 terminal of the SRSmain harness 2P connector and the No. 3 terminal of theSRS main harness 18P connector.There should be 0-0.5 0.

ls th6 resistance as soecified?

YESNO

Poor contact at the SRS main harness 2p connector;check tho connector,. lf the connector i3 OK, substituto a known-good und€r-dash fuse/relay box, and recheck.. lf the problem is still present, roplace the SRS mainnatness,

Open in the SRS main harn$s;.eplace the SRS main har-ness.

www.emanualpro.com

Page 1385 of 1395

Driver's Airbag

Replacement lcont'd)

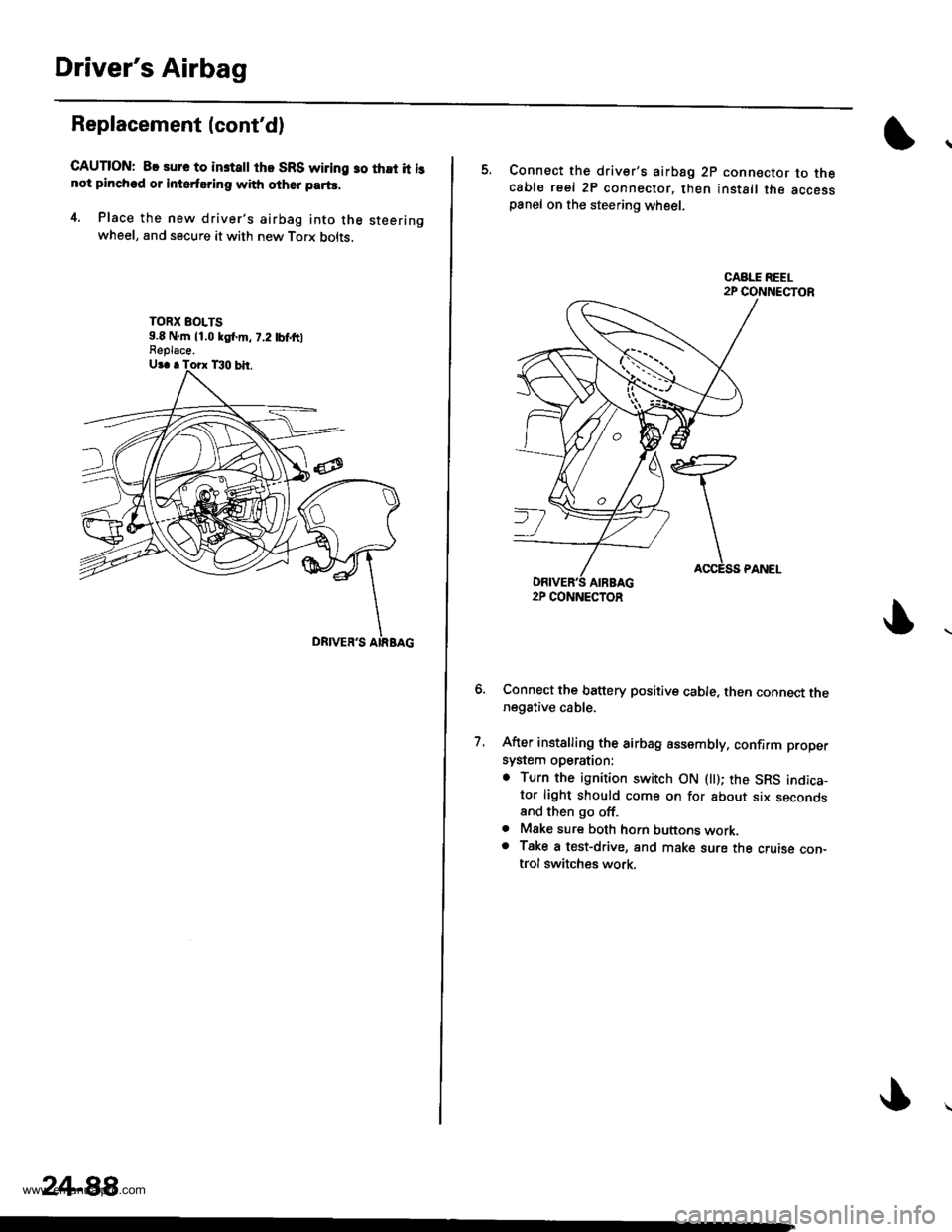

CAUTION: 8. sure to instattthe SRS wiring so that it isnot plnched or inlerfsring with other parts.

4. Place the new driver's airbag into the steeringwheel, and secure it with new Torx bolts.

TORX EOLTS9.8 N,m 11.0 kgl.m, 7.2 tbf,ftlFeplace.

24-88,

5. Connect the driver's airbsg 2p connector to thecable reel 2P connector, then install the accesspanel on the steering wheel.

Connect the battery positive cable. then connect thenegative cable.

After installing the airbag assembly, confirm proper

system operation:

. Turn the ignition switch ON llt); the SRS indica-tor light should come on for about six secondsand then go off.. Mske sure both horn buttons work.o Take a test-drive, and make sure the cruise con-trol switches work.

7.

2P CONNECTOR

www.emanualpro.com

Page 1387 of 1395

Front Passenger's Airbag

Replacement (cont'd)

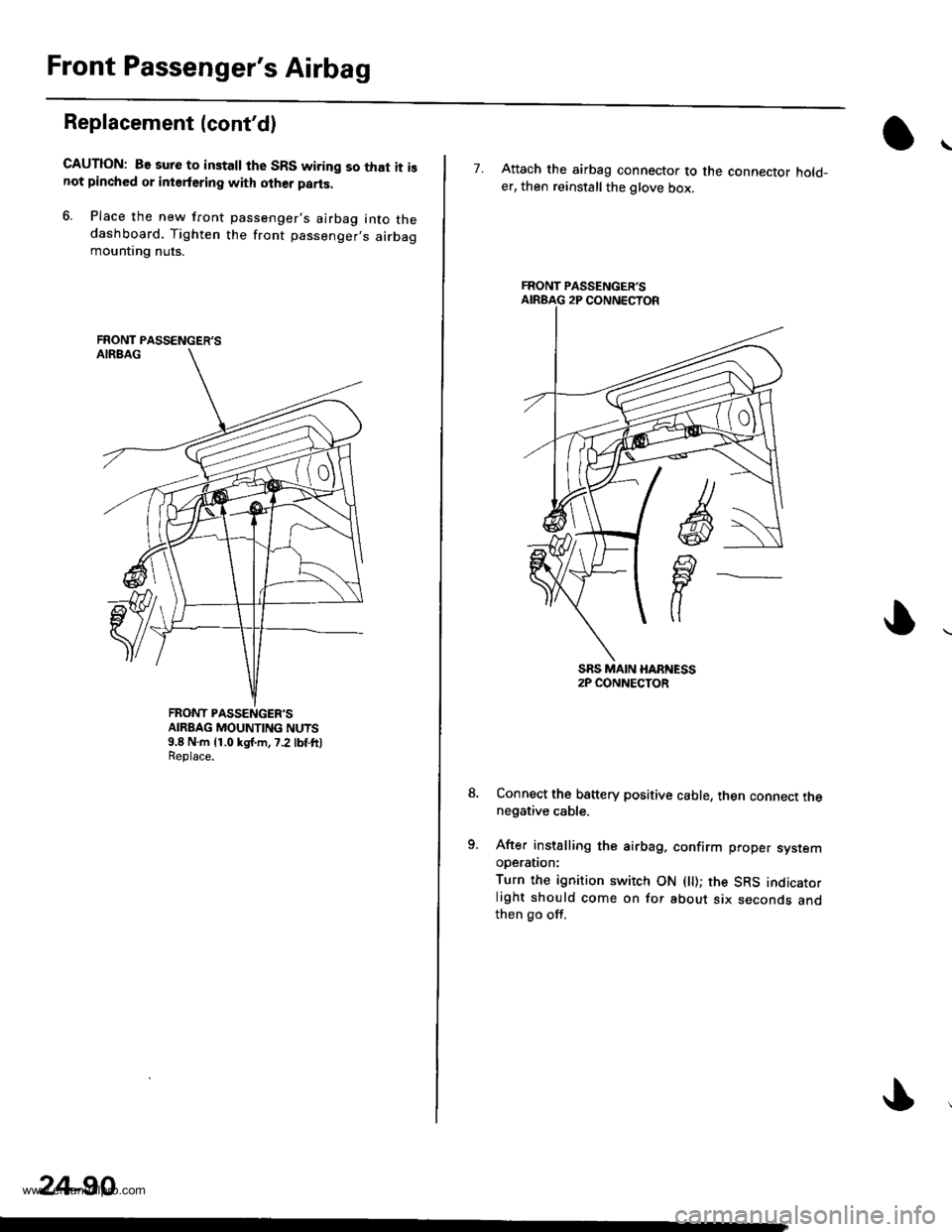

GAUTION: Be sure to installthe SRS wiring so that it isnot pinched or interfering with olher parts.

6. Place the new front passenger's airbag into thedashboard. Tighten the front passenger,s airbagmountrng nuts.

FRONT PASSENGER'SAIRBAG MOUNTING NUTS9.8 N.m {1.0 kgJ.m,7.2 lbf ft)Replace.

FRONT PASSENGER'S

24-90

7. Attach the airbag connector to the connector hold_er, then reinstall the glove box.

Connect the b8ttery positive cable, then connect thenegative cable.

After installing the airbag. confirm proper sysremooerauon:

Turn the ignition switch ON ( ); the SRS indicatorlight should come on for about six seconds andthen go off.

FRONT PASSENGER'S

www.emanualpro.com

Page 1389 of 1395

Gable Reel

Replacement (cont'dl

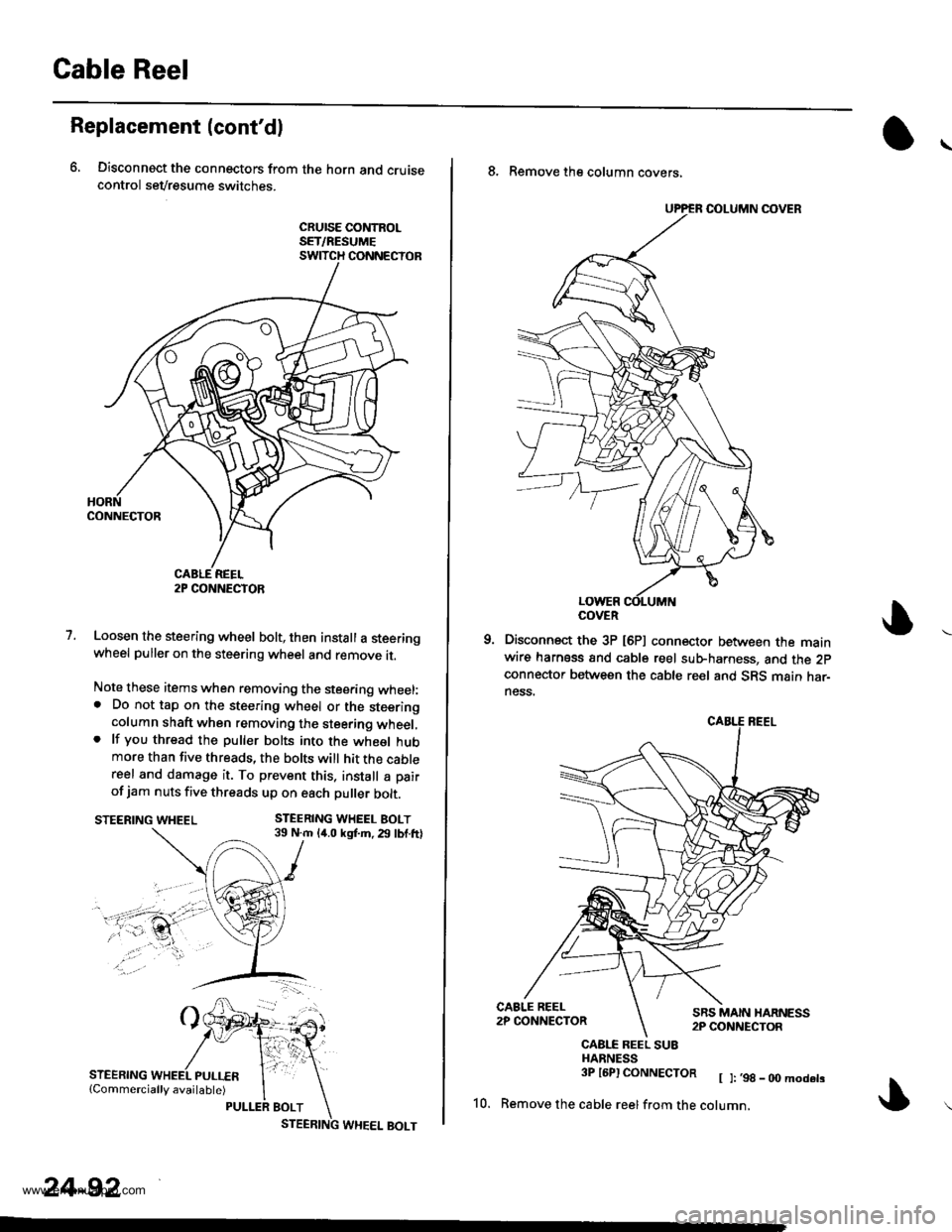

6, Disconnect the connectors from the horn and cruisecontrol sevresume switches.

cRursE coNtRoLSET/RESUMESWITCH CONNECTOR

1.Loosen the steering wheel bolt, then install a steeringwheel puller on the steering wheel and remove it.

Note these items when removing the stee.ing wheel:. Do not tap on the steering wheel or the steeringcolumn shaft when removing the steering wheel,. lf you thread the puller bolts into the wheel hubmore than five threads, the bolts will hit the cablereel and damage it. To prevent this. install a pair

of jam nuts five threads up on each puller bolt.

STEERING WHEEL BOLT39 N.m 14.0 kgf.m. 29 lbf.ftlSTEERING WHEEL

STEERING

2P CONNECTOR

24-92

8. Remove the column covers,

Disconnect the 3P [6P] connector between the mainwire harness and cable reel sub-harness, and the 2pconnector between the cable reel and SRS main har-ness.

CAALE REEL SU8HARNESS3P l6Pl CONNECTOR [ ]:,98_00modets

10. Remove the cable reelfrom the cotumn,

COVER

www.emanualpro.com

Page 1391 of 1395

Cable Reel

16.

Replacement (cont'dl

11.

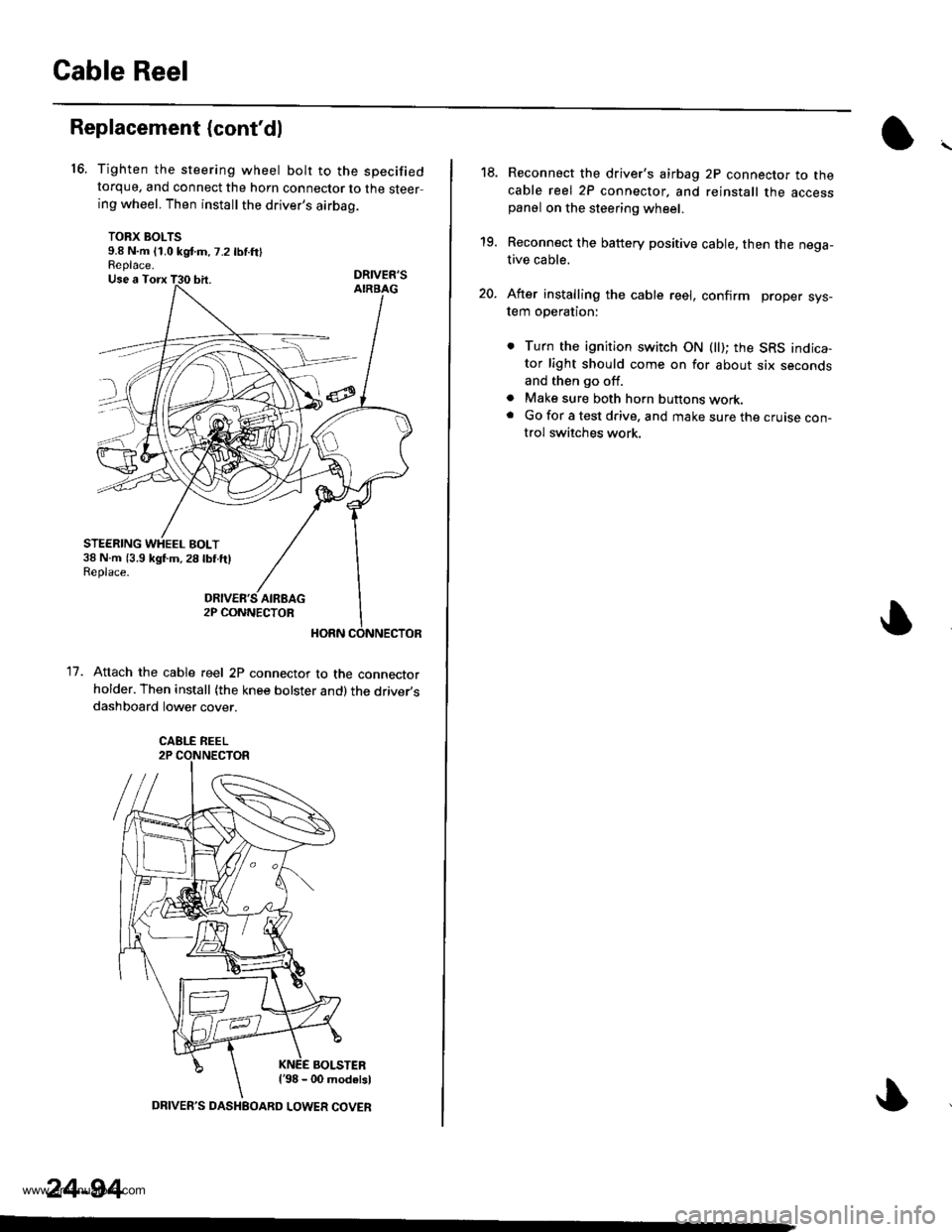

Tighten the steering wheel bolt to the specifiedtorque, and connect the horn connector to the steering wheel. Then install the driver's airbag.

TORX BOLTS9.8 N.m (1.0 kgd.m,7.2 lbnftlReplace.DRIVER'S

Attach the cable reel 2P connector to the connectorholder. Then install (the knee bolster and)the driver,sdashboard lower cover.

BOLSTERl'98 - 00 modalsl

STEERING WHEEL BOLT38 N.m (3.9 kgl.m,28lbf.ftlReplace.

CABLE REEL

24-94

DRIVER'S DASHEOARD LOWER COVER

19.

20.

Reconnect the driver's airbag 2P connector to thecable reel 2P connector, and reinstall the accesspanel on the steering wheel.

Reconnect the battery positive cable, then the nega-tive cable.

After installing the cable reel, confirm proper sys-tem operation:

. Turn the ignition switch ON (ll); the SRS indica-tor light should come on for about six secondsand then go off.

a Make sure both horn buttons work.. Go for a test drive. and make sure the cruise con-trol switches work.

www.emanualpro.com

Page 1393 of 1395

SRS Unit

Replacement (cont'dl

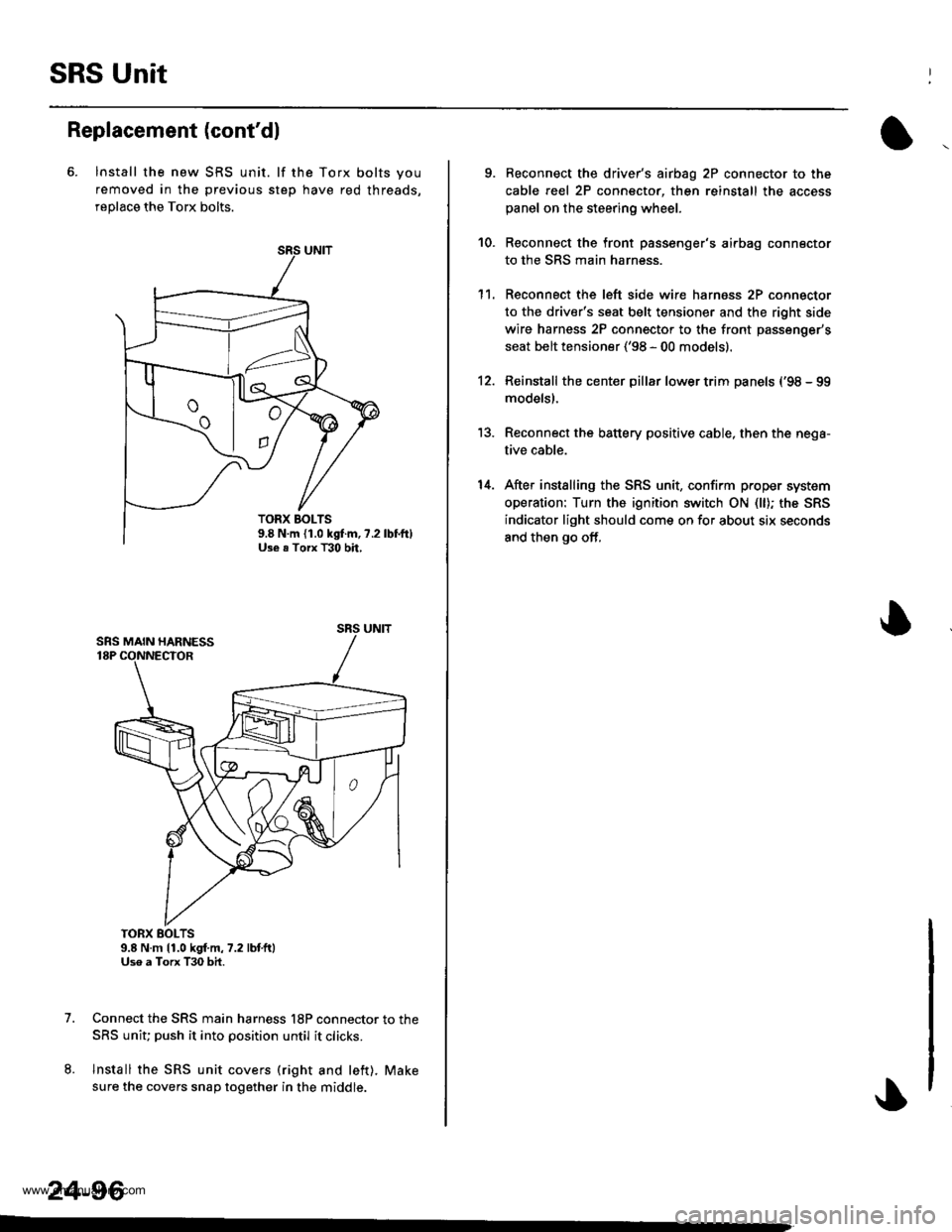

6. lnstall the new SRS unit. lf the Torx bolts you

removed in the previous step have red threads,

replace the Torx bolts.

TORX BOLTS9.8 N.m 11.0 kgf.m,7.2 lbtft)Uso a Torx T30 bit.

Connect the SRS main harness l8P connector to the

SRS uniu push it into position until it clicks.

Install the SRS unit covers (right and left). Make

sure the covers snap together in the middle.

7.

8.

TORX BOLTS9.8 N.m {1.0 kgf.m, ?.2Use . Torx T30 bh,

SRS UNIT

24-96

-

9. Reconnect the driver's aibag 2P connector to the

cable reel 2P connector, then reinstall the access

panel on the steering wheel.

Reconnect the front passenger's airbag connector

to the SRS main harness.

Reconnect the left side wire harness 2P connector

to the driver's seat belt tensioner and the right side

wire harness 2P connector to the front passenger's

seat belt tensioner ('98 - 00 models).

Reinstall the center pillar lower trim panels {'98 - 99

modelsl.

Reconnect the battery positive cable, then the nega-

tive cable.

After installing the SRS unit, confirm proper system

operation: Turn the ignition switch ON (ll); the SRS

indicator light should come on for about six seconds

and then go off,

10.

1't.

12.

13.

14.

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

Disposal (cont'dl

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

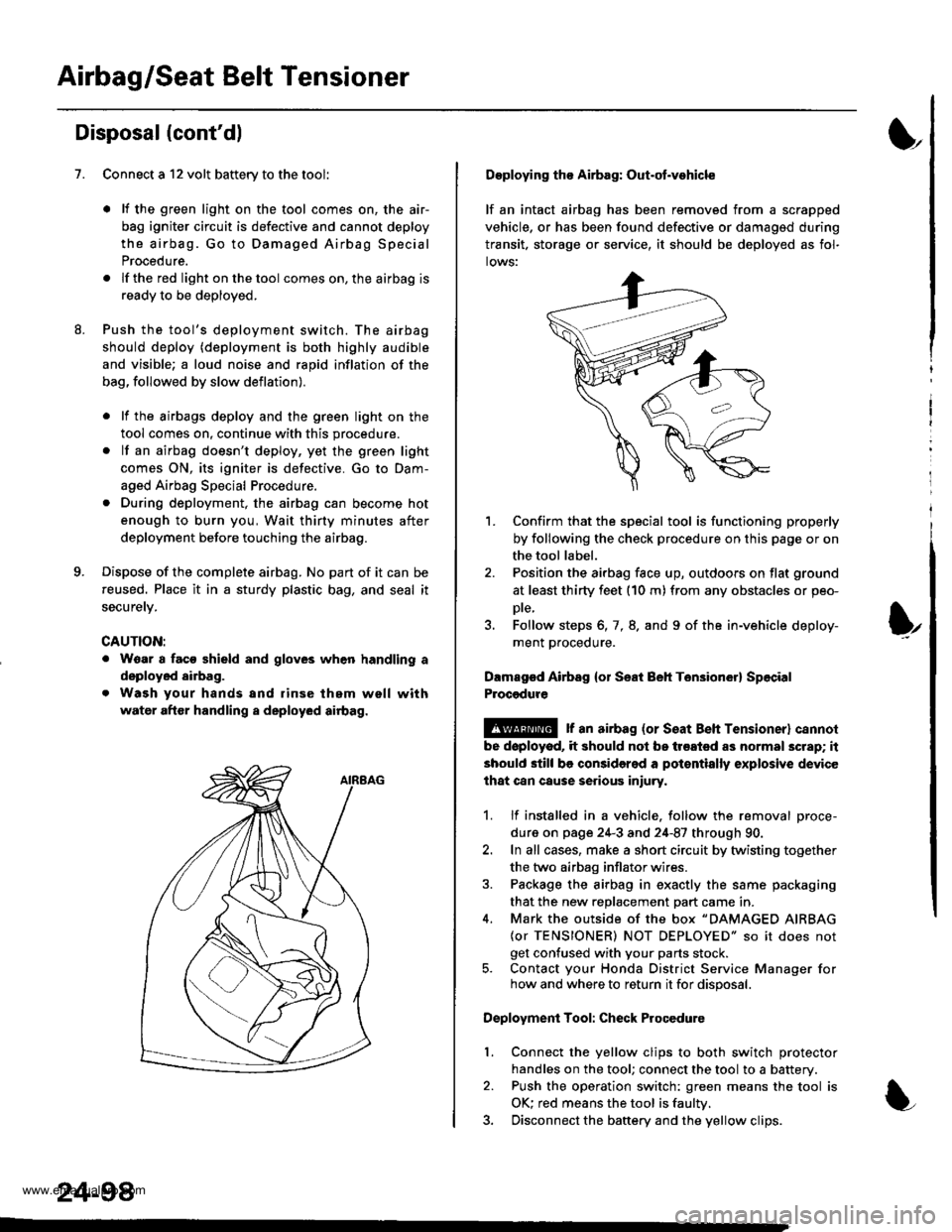

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com