turn signal HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1207 of 1395

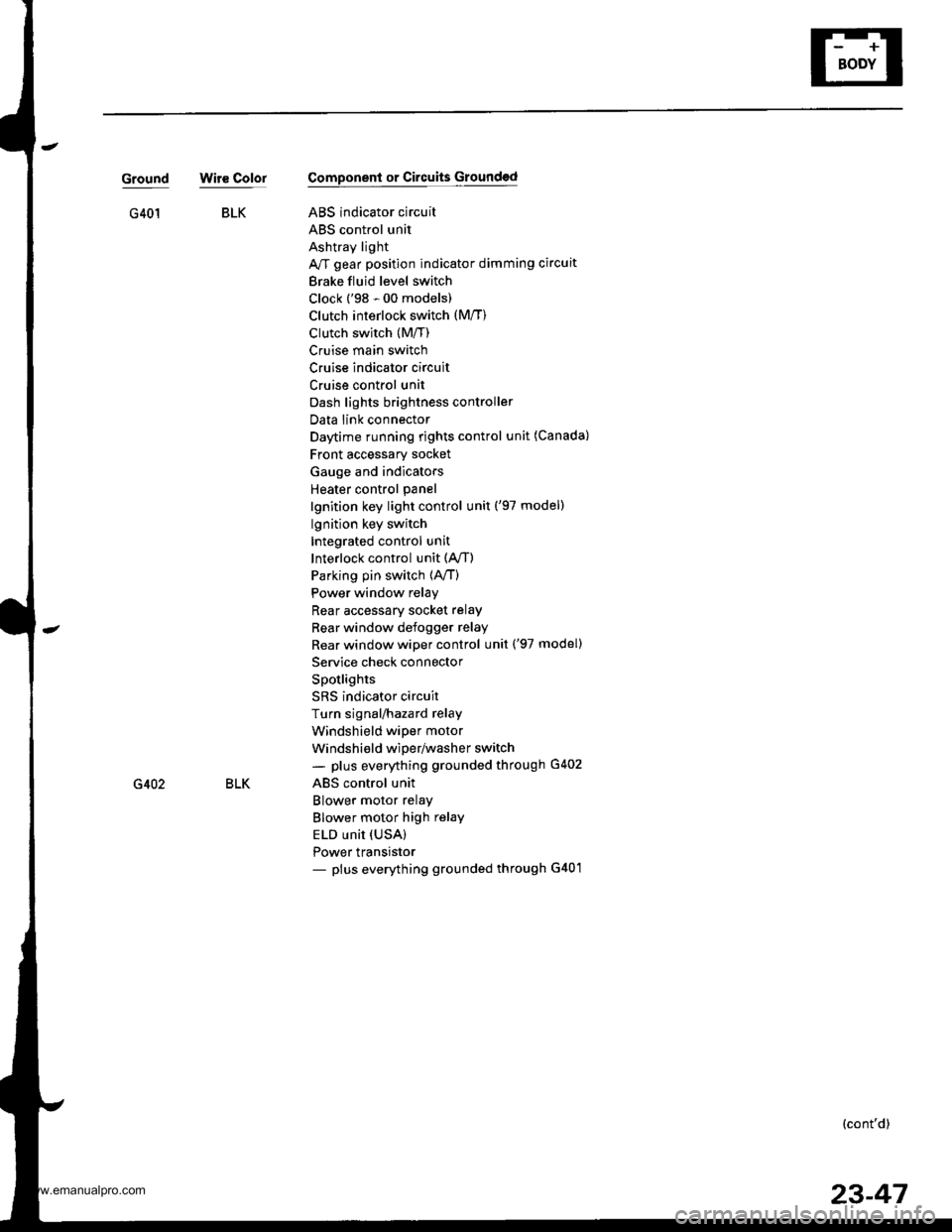

BLKG401

GroundWir€ ColorComponent or Circuits Grounded

ABS indicator circuit

ABS control unit

Ashtray light

A/T gear position indicator dimming circuit

Brake fluid level switch

Clock ('98 - 00 models)

Clutch inrerlock switch (M/T)

Clutch switch (Mff)

Cruise main switch

Cruise indicator circuit

Cruise control unit

Dash lights brightness controller

Data iink connector

Daytime running rights control unit (Canada)

Front accessary socket

Gauge and indicators

Heater control panel

lgnition key light control unit ('97 model)

lgnition key switch

Integrated control unit

Interlock control unit (Ay'T)

Parking pin switch {A,/T)

Power window relay

Rear accessary socket relay

Bear window defogger relay

Rear window wiper control unit ('97 model)

Service check connector

Spotlights

SRS indicator circuit

Turn signal/hazard relay

Windshield wiper motor

Windshield wiper/washer switch- plus everything grounded through G402

ABS control unit

Blower motor relay

Blower motor high relay

ELD unit (USA)

Power transistor- plus everything grounded through G401

BLKG402

{cont'd)

23-47

www.emanualpro.com

Page 1212 of 1395

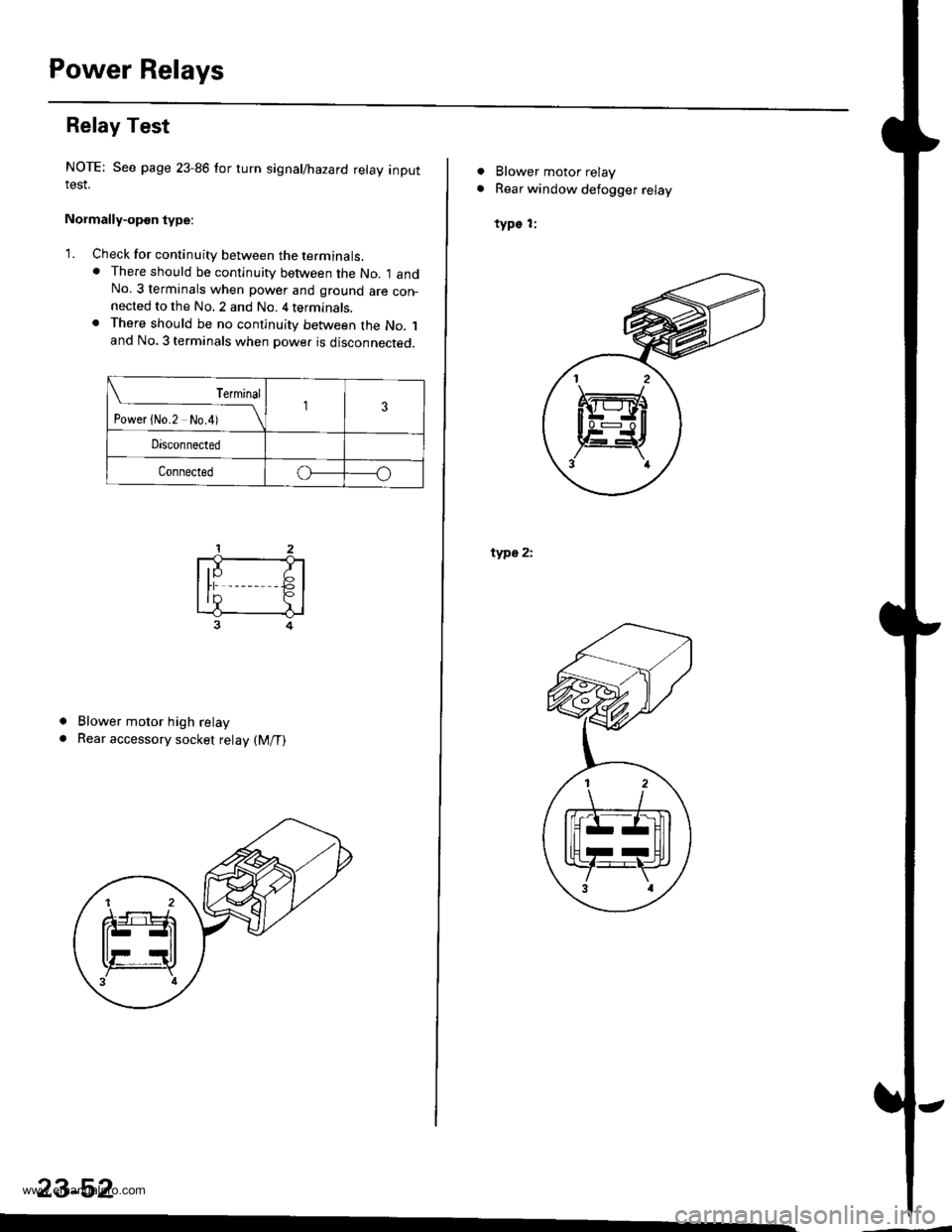

Power Relays

Relay Test

NOTE: See page 23-86 for turn signal/hazard relay inputIESI.

Normally-opon type:

'1. Check for continuity between the terminats.. There should be continuity between the No. I andNo. 3 terminals when power and ground are con-nected to the No. 2 and No. 4 terminals.. There should be no continuity between the No. 1and No. 3 terminals when power is disconnected.

Terminal

t"""r f *r t*i__\l3

Disconnected

Connectedo

a

a

Blower motor high relay

Rear accessory socket relay (M/T)

23-52

ffi

. Blower motor relay

. Rear window defogger relay

type 1:

type 2i

H

al 2 \

Itrrz-Hl

llHrrUll

Y:F,',3 al

www.emanualpro.com

Page 1217 of 1395

l-

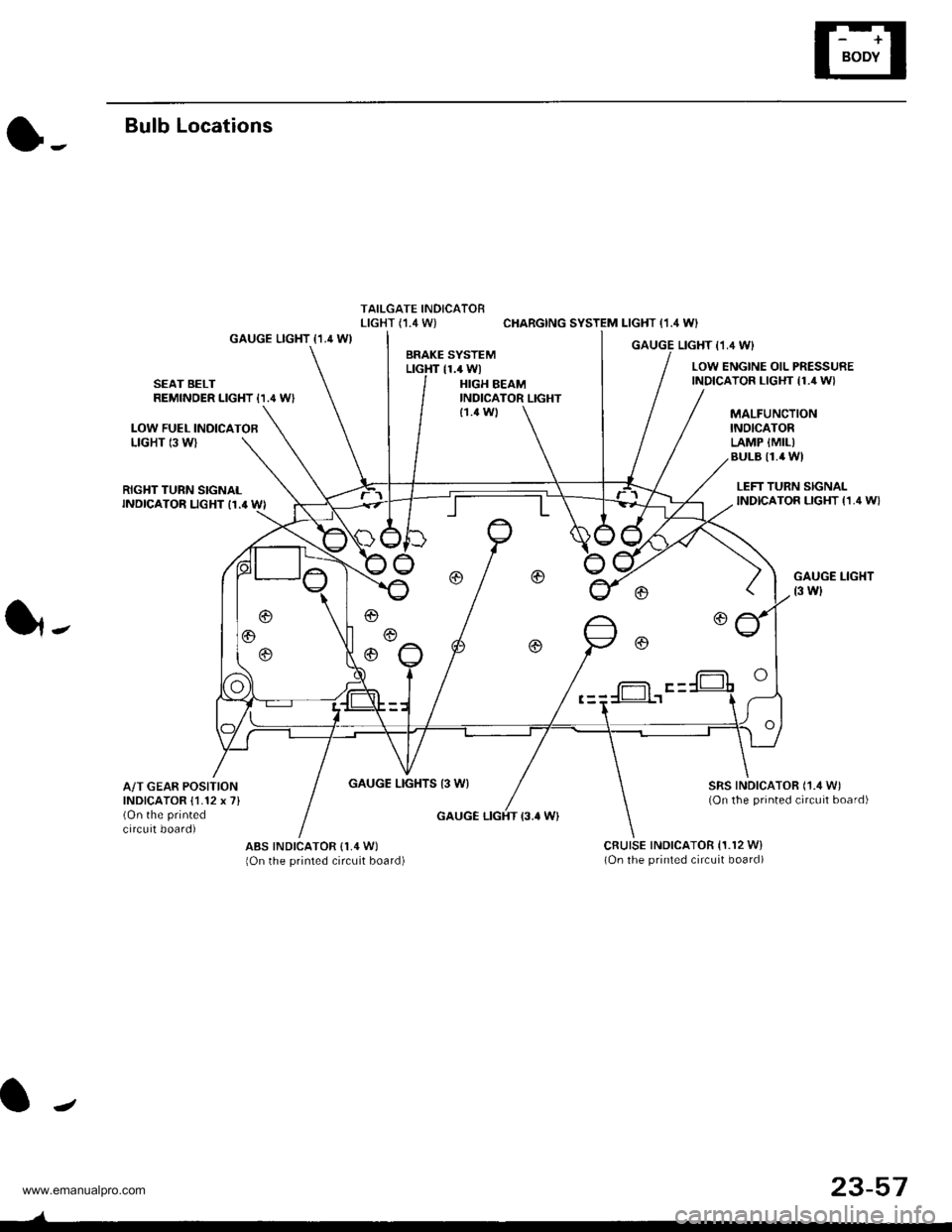

Bulb Locations

TAILGATE INDICATORLIGHT (,I.4 W) CHARGING SYSTEM LIGHT (1.4 WI

GAUGE LIGHT {1.4 WIGAUGE LIGHT I1,4 WIBRAKE SYSTEMLTGHT 11.4 WlLOW ENGINE OIL PRESSUREINDICATOR LIGHT {1./r W}SEAT BELTREMINDER LIGHT {1.' W'HIGH BEAMINDICATOR LIGHT

LOW FUEL INOICATOBLIGHT 13 WI

MALFUNCTIONINOICATORLAMP {MIL)BULB I1.4 WI

{1.4 Wl

RIGHT TURN SIGNALINDICATOR LIGHT I1.' WI

GAUGE LIGHTS 13 WI

LEFT TURN SIGNALINDICATOR LIGHT {1,4 W}

GAUGE LIGHT

t3 wl

SRS INDICATOR ('1./t W)(On the printed circuit board)

1,.

A/T GEAR POSITIONINDICATOR {1.12 x 7}(On the printed

circuit board)GAUGE LIGHT {3.' W}

ABS INDICATOR (1,4 W)

lOn the printed circuit board)cRutsE tNDtcAToR 11.r2 w)(On the printed circuit board)

f-= F -

J

23-57

www.emanualpro.com

Page 1235 of 1395

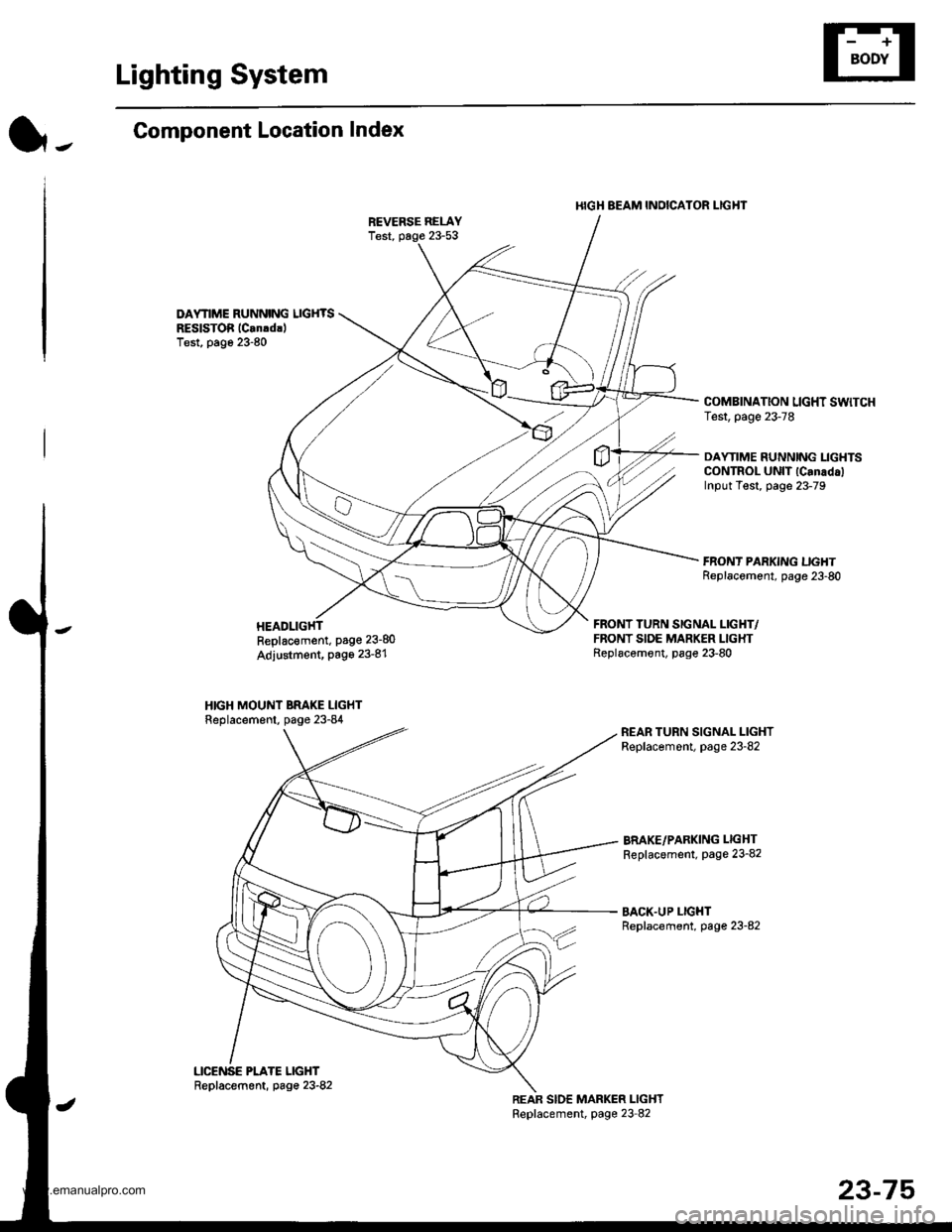

Lighting System

l-.Component Location Index

DAYNME RUNNING LIGHTSREslsToi lCan!drlTest, page 23-80

I{IGH BEAM INOICATOR I-IGHT

COMBINATION LIGHT SWTCHTest, page 23-78

DAYTIME RUNNING LIGHTSCONTROL UNIT lCanadalInput Test, page 23-79

Replac€ment, Page 23-80

Adjustment, Page 23-81

HIGH MOUNT BRAKE LIGHTReplacement, page 23-84

FRONT TURN SIGNAL LIGHT/FRONT SIDE MARKER LIGHTReplacemont, page 23-80

BRAKE/PARKING LIGHT

Replacement, page 23-82

BACK.UP LIGHTReplacement, page 23-82

23-75

www.emanualpro.com

Page 1240 of 1395

Lighting SystemHeadlights

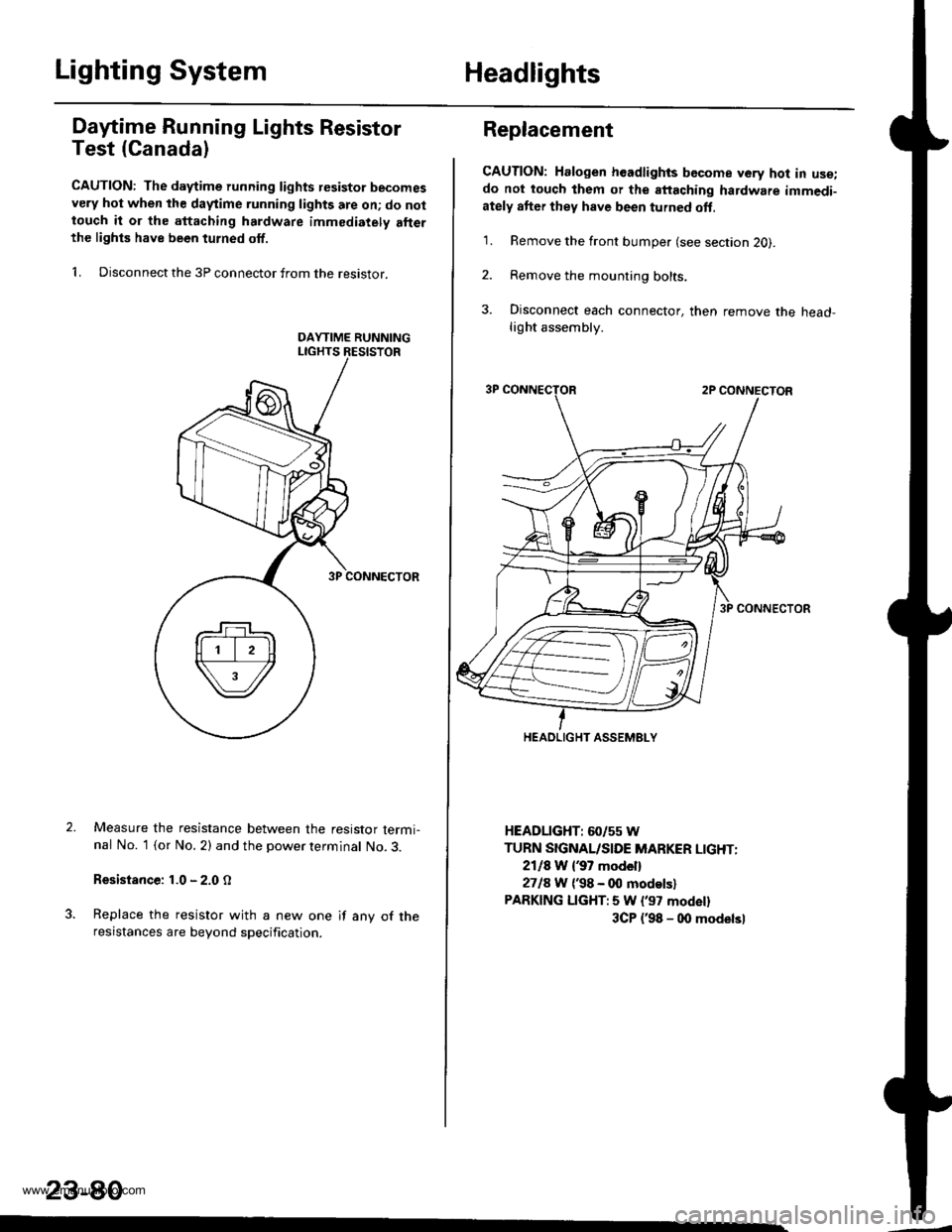

Dafime Running Lights Resistor

Test (Canada)

CAUTION: The d.ytime running lights resistor becomesvery hot when the daytime running lights are on; do nottouch it or the attaching hardware immediately allerthe lighls have been turned off.

1. Disconnect the 3P connector from the resistor.

Measure the resistance between the resistor termi-nal No. 1 (or No. 2) and the power terminal No. 3.

Resistance: 1.0 - 2.0 O

Replace the resistor with a new one if any of theresistances are beyond specification.

23-80

Replacement

CAUTION: Halogen headlights bGcome very hot in use;do not touch them or the attaching hardware immedi-ately after they have been turned oft.

1. Remove the front bumper (see section 2O).

2. Remove the mounting bolts.

3. Disconnect each connector, then remove the head-light assembly.

HEADLIGHT: 60/55 W

TURN SIGNAL/SIDE MARKER LIGHT:

2118 W {37 model}

2718 W ('98 - 00 modelsl

PARKING LIGHT:5 W l'97 modell

3CP {'98 - 00 modelsl

HEADLIGHT ASSEMELY

www.emanualpro.com

Page 1245 of 1395

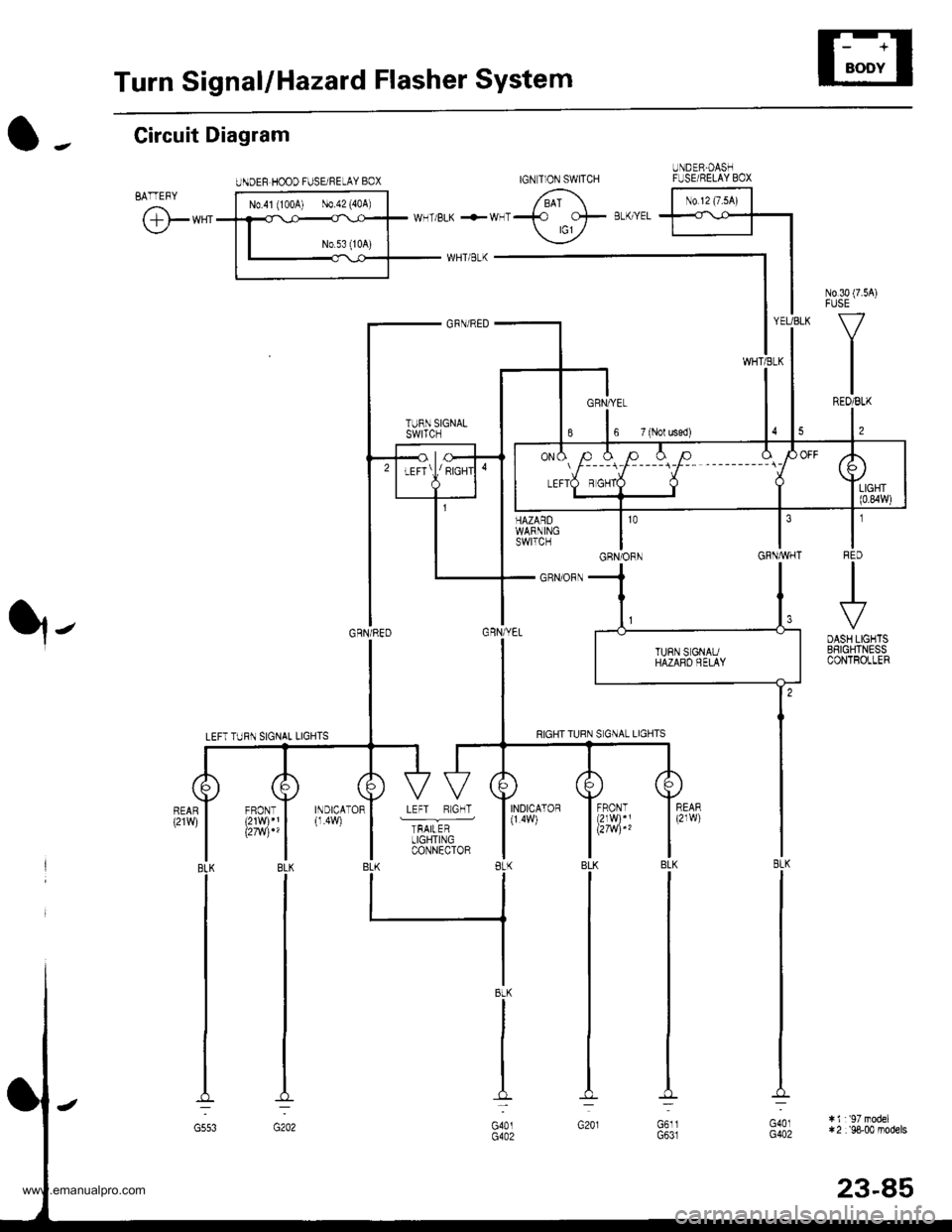

Turn SignallHazard Flasher System

UNDEF HOOD FUSE/NELAY BOX

N0.30 (7.54)FUSE

V

IREO/BLK

l,

t'IFqD

.+

DASH LIGHTSBSIGHTNESSCONTROLLER

HAZARDWARNINGswtTcH

_ GRN/ORN

YEUBLK

WHTiELK

GRNAVHT

O -. Circuit Diagram

BATTEFY

@**'

q-

103

GRN/ORN

INDICATOR

TFAILERLIGHTINGCONNECTOR

INDICATOR(1.4W)

BLK

G553

IGN T]ON SWITCHUNDER.OASHFUSE/RELAY BOX

No 12 (7.sA)

l----r-l-----i-F-- --------_ \

BtK

G401G402

:i1r'97model*2 :'98-00 models

23-85

www.emanualpro.com

Page 1246 of 1395

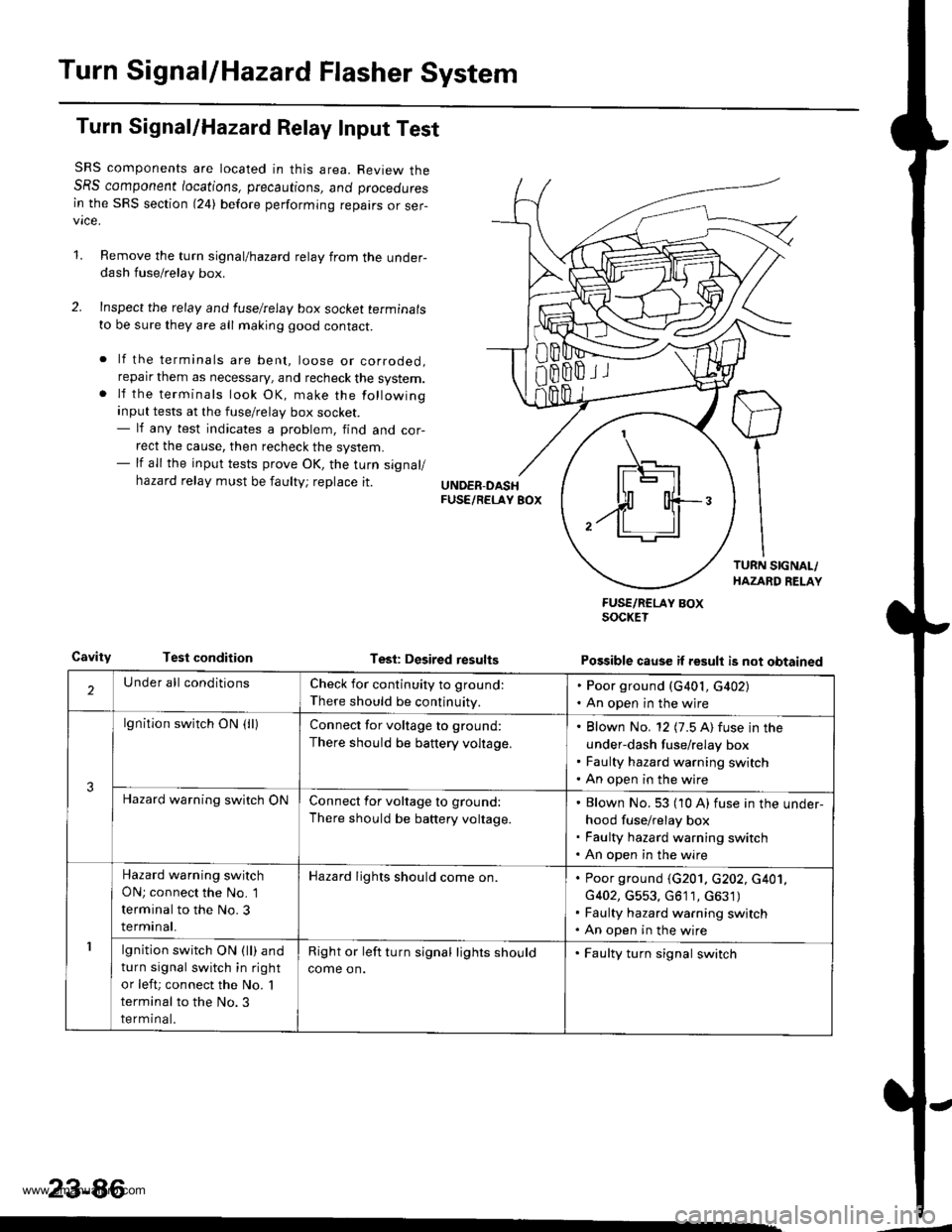

Turn SignallHazard Flasher System

Turn Signal/Hazard Relay Input Test

SRS components are located in this area. Review theSRS component /ocations, precautions, ano proceoures

in the SRS section (24) before performing repairs or ser-vice.

1.Remove the turn signal/hazard relay from the under-dash fuse/relay box.

Inspect the relay and luselrelay box socket terminals

to be sure they are all making good contact.

lf the terminals are bent, loose or corroded,reparr them as necessary, and recheck the system.lf the terminals look OK, make the following

input tests at the fuse/relay box socket.- lf any test indicates a problem, find and cor-

rect the cause, then recheck the system.- lf all the input tests prove OK, the turn signal/

hazard relay must be faulty; replace it.

CavityTest conditionTesl: Desired results

FUSE/RCLAY BOXSOCKET

Possible cause if result is not obtained

'1

IF\_-'l -]l

$ o{+-/ll ll

2Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402). An open in the wjre

3

lgnition switch ON (lllConnect for voltage to ground:

There should be battery voltage.

Blown No. 12 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty hazard warning switch

An open in the wire

Hazard warning switch ONConnect for voltage to ground:

There should be battery voltage.

Blown No. 53 (10 A) fuse in the under-

hood fuse/relay box

Faulty hazard warning switch

An open in the wire

1

Hazard warning switch

ON; connect the No. 1

terminal to the No. 3

terminal.

Hazard lights should come on.Poor ground (G201. c202, c401,

G402, G553, G611, c631)

Faulty hazard warning switch

An open in the wire

lgnition switch ON (ll) and

turn signal switch in right

or left; connect the No. 'l

terminal to the No.3

terminal.

Right or left turn signal lights should

come on.

. Faulty turn signal switch

23-86

www.emanualpro.com

Page 1247 of 1395

![HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

Turn Signal Switch Test

1.

4.

Remove the drivers dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors HONDA CR-V 2000 RD1-RD3 / 1.G Service Manual

Turn Signal Switch Test

1.

4.

Remove the drivers dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors](/img/13/5778/w960_5778-1246.png)

Turn Signal Switch Test

1.

4.

Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

Remove the steering column covers {see section

17]-.

Disconnect the 4P and 7P connectors from the

switch.

Remove the screws, and slide the switch toward the

driver's door.

Check for continuity between the terminals in each

switch position according to the table.

Position

Terminal12

RIGHTo-

Neutral

LEFTo---o

q

tl-

swtTcH

Hazard Warning Switch Test

1. Remove the center panel {see section 20).

2. Remove the two screws, then remove the switch

from the center air vent.

HAZARD

Check for continuitv between the terminals in each

switch position according to the table.

Terminal

t**--\

2357810

OFF(9U(_)

ONo@oooo

lNol us€d)

23-87

www.emanualpro.com

Page 1314 of 1395

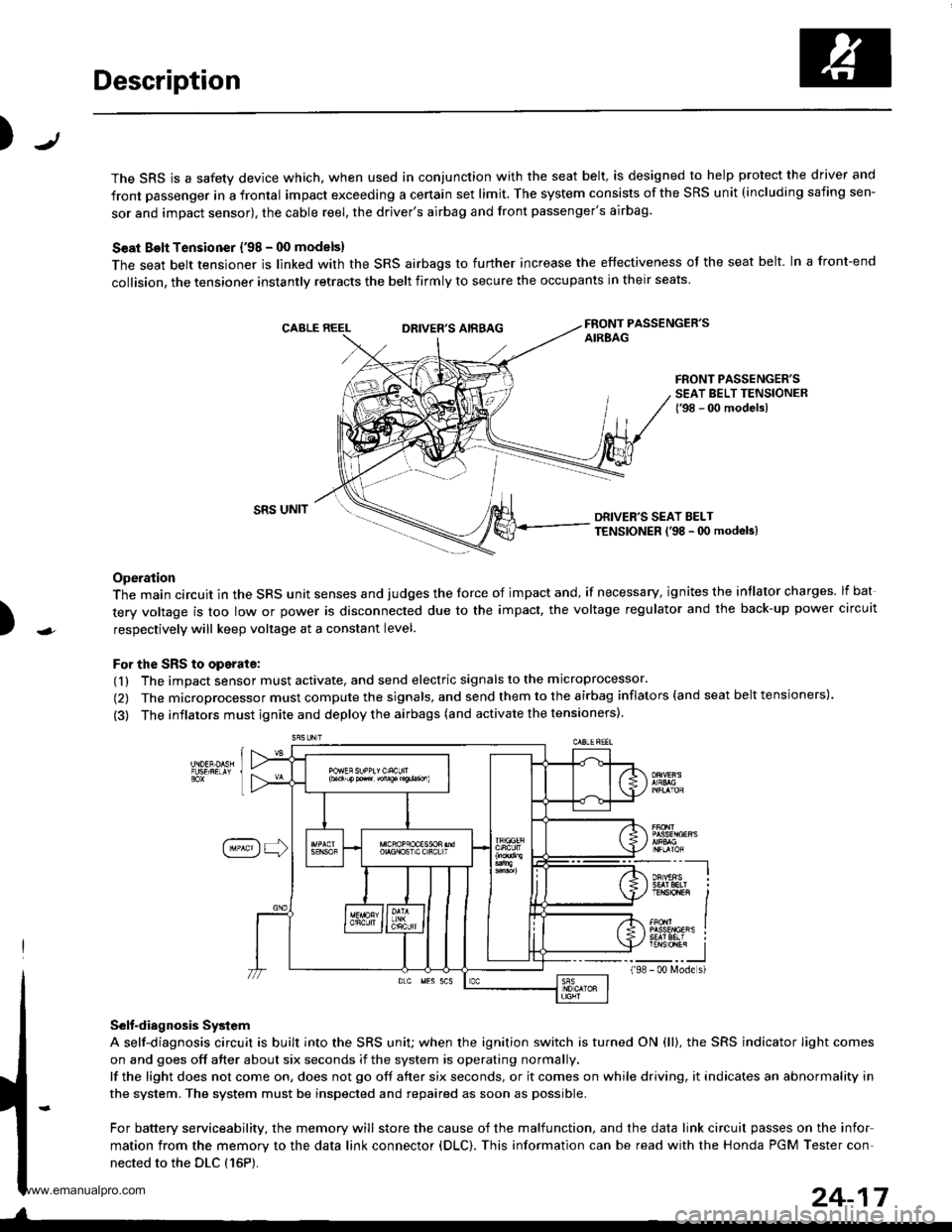

Description

J)

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com

Page 1325 of 1395

Troubleshooting

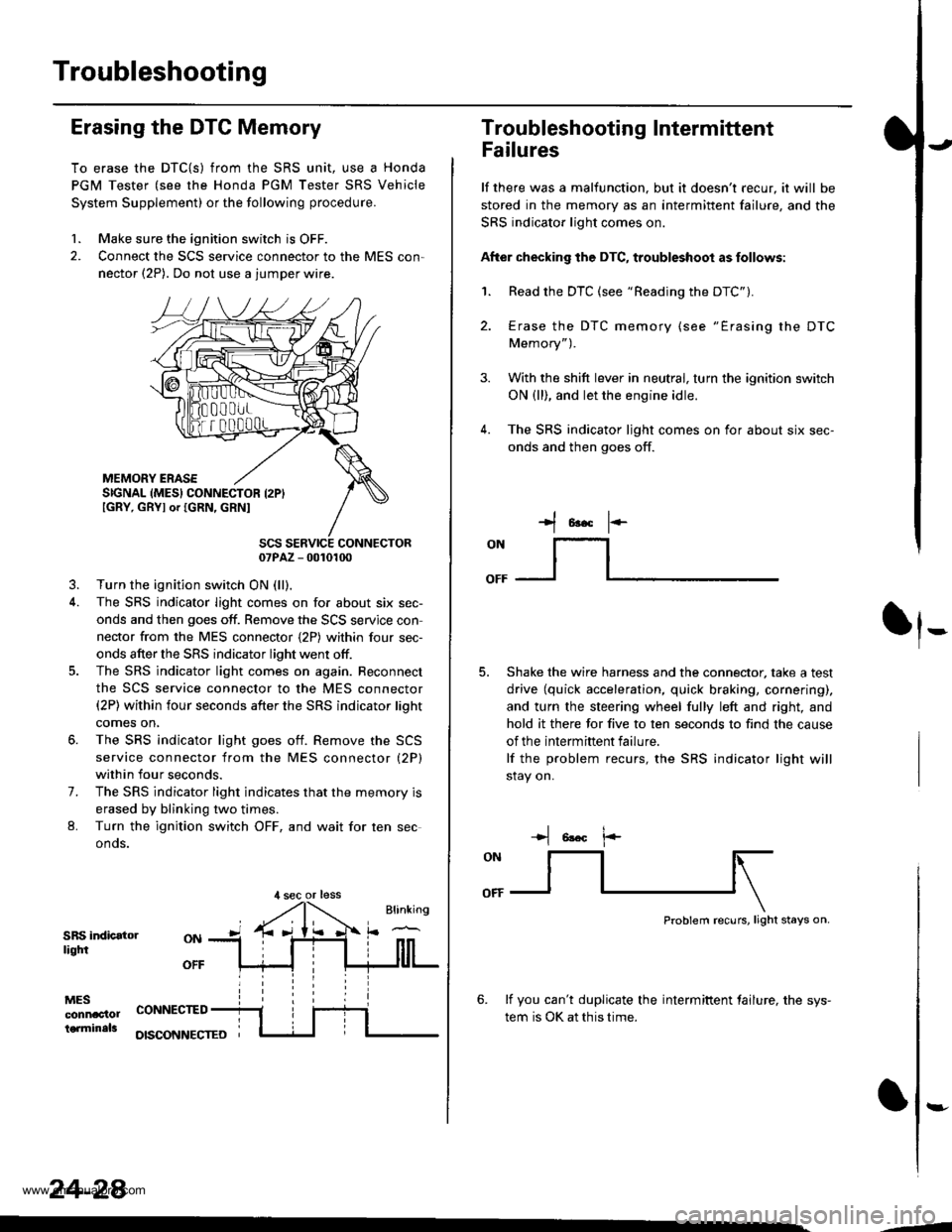

Erasing the DTC Memory

To erase the DTC{S) from the SRS unit, use a Honda

PGM Tester (see the Honda PGM Tester SRS Vehicle

System Supplement) or the following procedure.

1. Make sure the ignition switch is OFF.

2. Connect the SCS service connector to the MES con,

nector (2P). Do not use a jumper wire.

MEMORY ERASESIGNAL (MES} CONNECTOR I2PIIGRY, GRYI or IGRN, GRNI

SCS SERVICE CONNECTOR07PAZ - 0010100

3. Turn the ignition switch ON (ll),

4. The SRS indicator light comes on for about six sec-

onds and then goes off. Remove the SCS servjce con

nector from the MES connector {2P) within four sec-

onds after the SRS indicator light went otf.

5. The SRS indicator light comes on again. Reconnect

the SCS service connector to the MES connector(2P) within four seconds after the SRS indicator lioht

comes on,

6. The SRS indicator light goes otf. Remove the SCS

service connector from the MES connector (2P)

within four seconds.

7. The SRS indicator light indicates that the memory is

erased by blinking two times.

L Turn the ignition switch OFF, and wait for ten sec

onos.

SRS indicatorliqtfi

MESconnac'lolterminals

OFF

CONNECTED

OISCONNECTEO

24-28

,l sec or less

3.

Troubleshooting Intermittent

Failures

lf there was a malfunction. but it doesn't recur, it will be

stored in the memory as an intermittent failure, and the

SRS indicator light comes on.

After checking the DTC, troubleshoot as follows:

1. Read the DTC (see "Reading the DTC").

4.

Erase the DTC memory (see "Erasing the DTC

Memory").

With the shift lever in neutral, turn the ignition switch

ON (ll), and let the engine idle.

The SRS indicator ljght comes on for about six sec-

onds and then goes off.

t*F

ON

lt--- _l

Shake the wire harness and the connector, take a test

drive (quick acceleration, quick braking, cornering),

and turn the steering wheel fully left and right, and

hold it there for five to ten seconds to find the cause

of the intermittent failure.

lf the problem recurs, the SRS indicator light will

stay on.

-+t 6!.c l.-

Problem recurs, light stays on.

6. lf you can't duplicate the intermiftent tailure, the sys-

tem is OK at this time.

:-

-4

www.emanualpro.com