Bleeding HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 189 of 1395

Cooling

f ffustrated Index ........... ..... 1O-2

Radiator

Rep|acement ...........,....,...................... 10-4

Engine Coolant Refilling and

Bleeding ..,.,................. 10-5

Cap Testing .................... 10-7

Testing ......10-7

Thermostat

Rep|acement ....................................... 10-8

Testing ...... 10-9

Water Pump

lllustrated lndex ....,..... .. 10-10

Inspection . 10-1 1

Replacement ....................................,.. 10-1 1

Fan Gontrol

Component Location Index ............... 10-12

Circuit Diagram ............. 10-13

Fan Motor Testing ......... 10-14

Radiator Fan Switch Testing ............. 10-14

Coolant Temperature Gauge

Gauge Testing ............... 10-15

Coolant temperature Sending

Unit Testing ........,....... 10-15

www.emanualpro.com

Page 190 of 1395

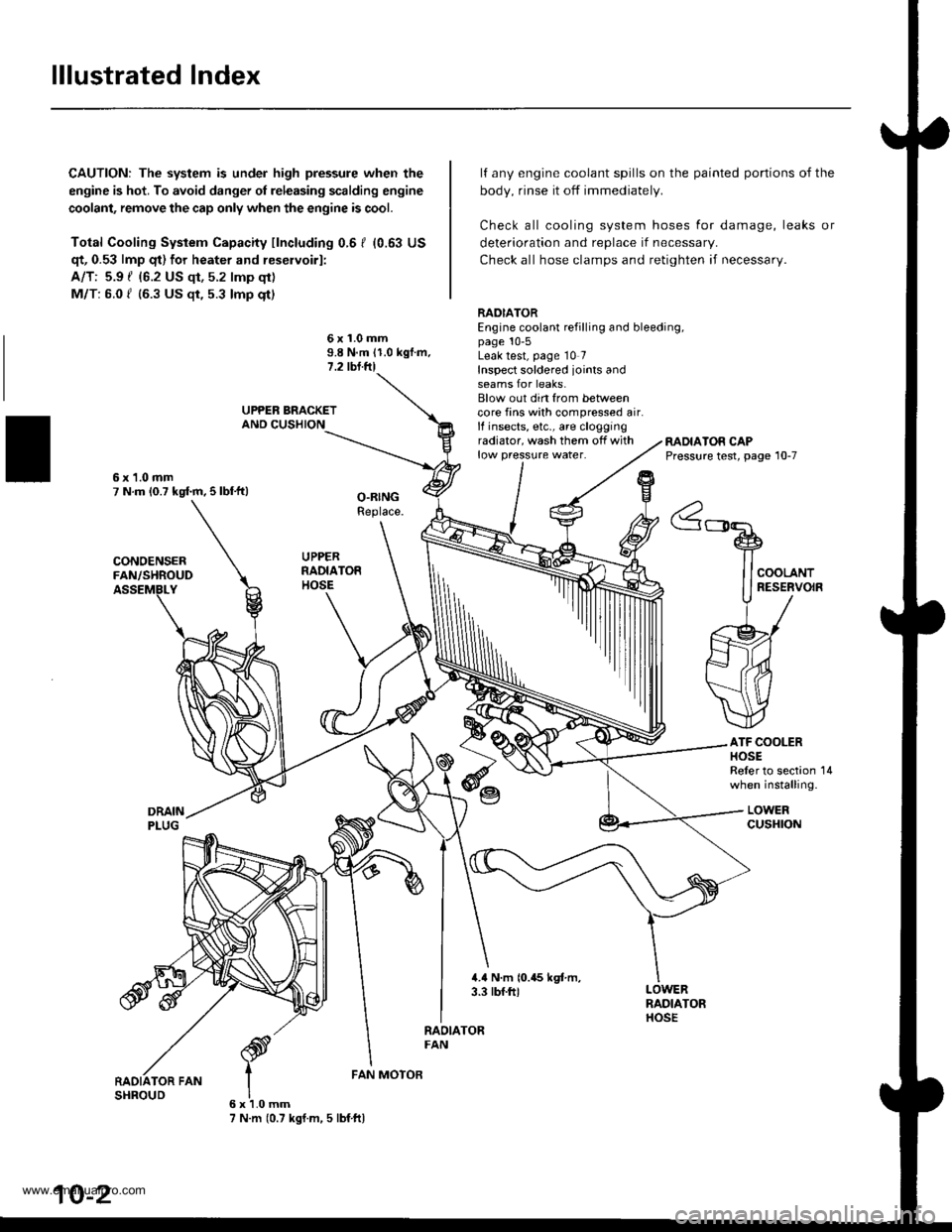

lllustrated Index

CAUTION: The system is under high pressure when the

engine is hot. To avoid danger ol releasing scalding engine

coolant, remove the cap only when the engine is cool.

Total Cooling System Capacity fincluding 0.6 I (0.63 US

qt, 0.53 lmp qt) for heater and reservoirl:

A/T: 5.9 { {6.2 US qt, 5.2 lmp qt)

M/T: 6.0 f (6.3 US $, 5.3 lmp qt)

deterioration and replace if necessar,.

Check all hose clamps and retighten if necessary.

lf any engine coolant spills on the

body, rinse it off immediately.

Check all cooling system hoses

painted portions of the

for damage, leaks or

6x1.0mm9.8 N.m 11.0 kgf.m.1.2 tbl.ftl

RADIATOREngine coolant refilling and bleeding,page 10-5Leak test, page 10 7Inspect soldered joints andseams for leaks.Blow out din from betweencore fins with compressed air.lf insects, etc., are cloggingradiator, wash them off withlow pressure water.RADIATOR CAPPressure test, page 10-7

ATF COOLERHOSEReler to section 14when installing.

LOWERcusHroN

6x1.0mm7 N.m (0.7 kgf.m, 5 lbf ftl

FAN MOTOR

10-2

www.emanualpro.com

Page 193 of 1395

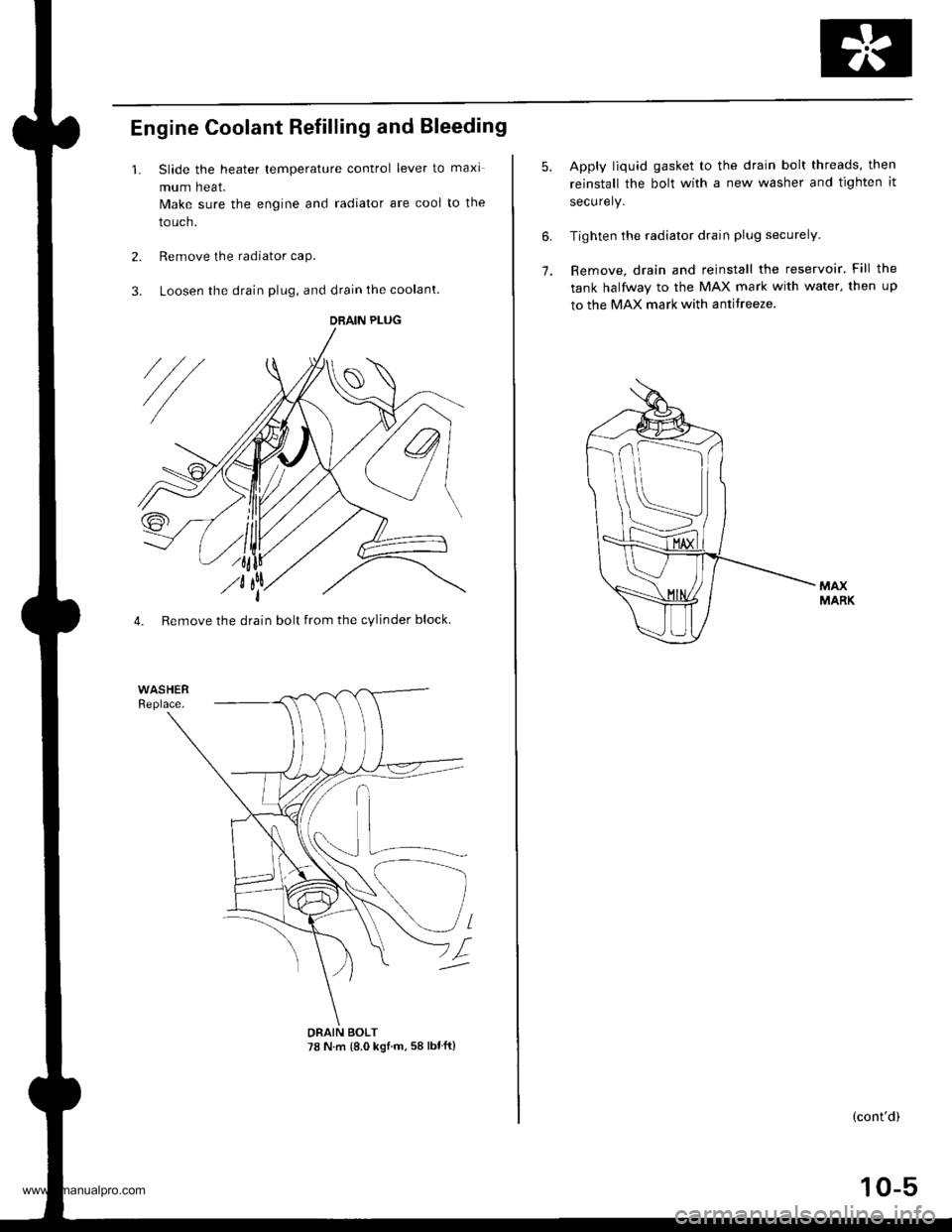

Engine Coolant Refilling and Bleeding

1. Slide the heater lemperature control lever to maxi

mum heat.

Make sure the engine and radiator are cooi to the

touch.

2. Remove the radiator caP.

3. Loosen the drain plug, and drain the coolant.

4. Remove the drain bolt from the cylinder block.

DRAIN PLUG

DRAIN BOLT78 N.m {8.0 ksl.m, 58 lbtft}

10-5

6.

7.

Apply liquid gasket to the drain bolt threads, then

reinstall the bolt with a new washer and tighten it

securely.

Tighten the radiator drain plug securely.

Remove, drain and reinstall the reservoir' Fill the

tank halfway to the MAX mark with water, then up

to the MAX mark with antitreeze.

(cont'd)

www.emanualpro.com

Page 194 of 1395

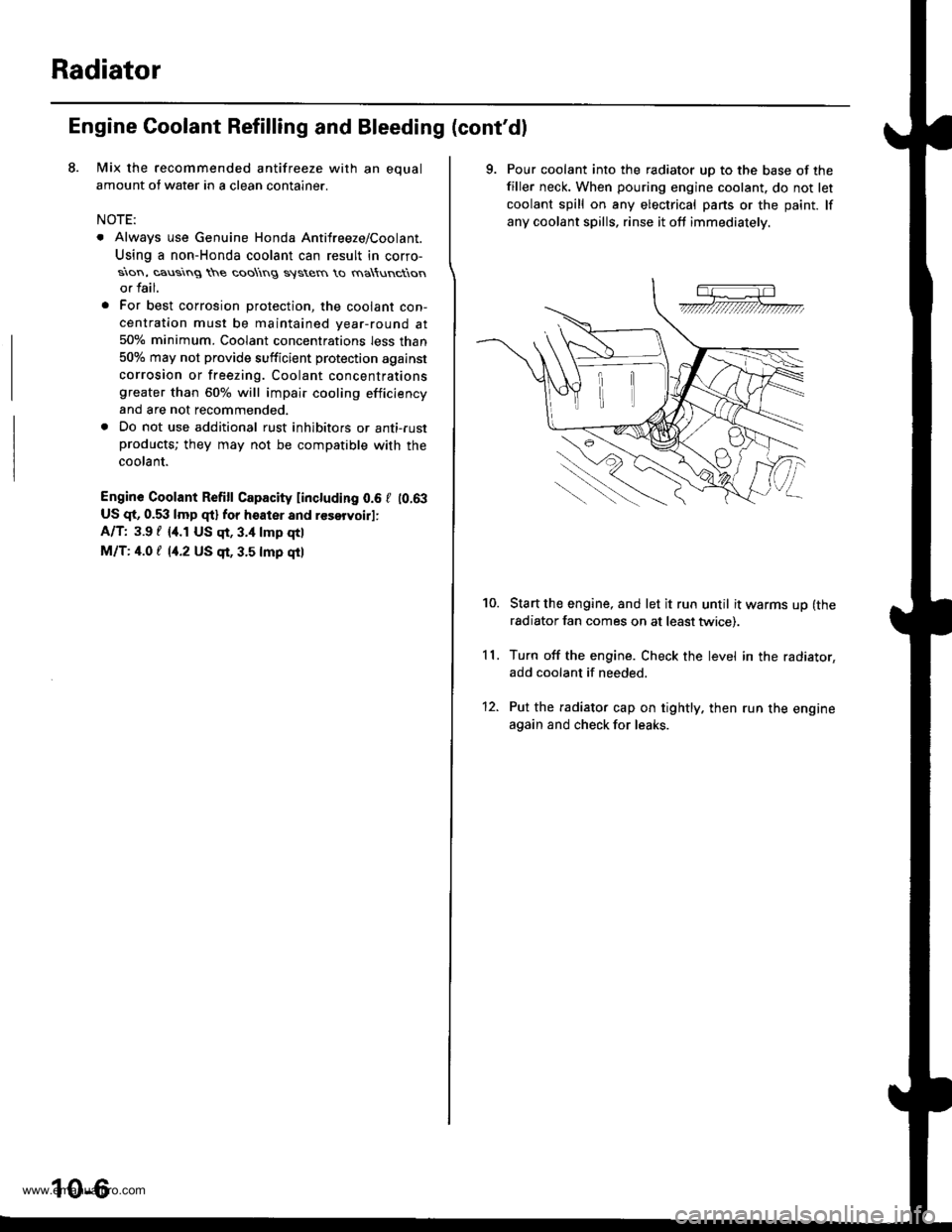

Radiator

Engine Coolant Refilling and Bleeding (cont'dl

Mix the recommended antifreeze with an equal

amount of water in a clean container.

NOTE:

. Always use Genuine Honda Antifreeze/Coolant.

Using a non-Honda coolant can result in corro-s\on, ca

sng t\e coo\

g sys\em \o ma\lunct\on

o. fail.

For best corrosion protection, the coolant con-

centration must be maintained year-round at50% minimum. Coolant concentrations less than

50% may not provide sufficient protection against

corrosion or freezing. Coolant concentrationsgreater than 60% will impair cooling efficiency

and are not recommended.

Do not use additional rust inhibitors or anti-rustproducts; they may not be compatible with the

coolant.

Engine Coolant Refill Capacity Iincluding 0.6 / 10.63US $, 0.53 lmp qtl for hoater and ressrvoirl:

A/T: 3.9 f {4.1 US $, 3.4 lmp qtl

M/T: 1.O t 14.2 US $, 3.5 lmp qrl

10-6

9. Pour coolant into the radiator uD to the base of the

filler neck. When pouring engine coolant. do not let

coolant spill on any electrical pans or the paint. lf

any coolant spills, rinse it oft immediately.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

Turn off the engine. Check the level in the radiator,

add coolant if needed.

Put the radiator cap on tightly. then run the engine

again and check for leaks.

11.

10.

12.

www.emanualpro.com

Page 925 of 1395

Brakes

Special Tools ............. 19-2

Component Locations

lndex ................ ...... 19-3

Inspection and Adlustment

Brake System Rubber Parts

and Brake Booster ..........,,,.......... 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19'7

Brake System Indicator ................... 19-8

Front Brake Pads

Inspection and Replacement .......... 19-9

Front Brake Disc

Disc Runout Inspection ................... 19-11

Disc Thickness and

Parallelism Inspection ........,........ 19-1 1

Front Brake Caliper

Disassembly/Reassembly ............... 19-12

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-13

Master Cylinder

Inspection/Disassembly .............. 19-14

Pushrod Clearance Adiustment ...... 19-14

Brake Booster Inspection ...,.,,,,....... 1 9-1 5

Rear Drum Brakes

Inspection .............. 19-15

Brake Shoes

Replacement ..... 19-r 8

Wheel Cylinder Replacement ......... 19-20

Brake Hoses/Lines

Inspection/Torque Specifications ... 19-21

Hose Replacement ....,...,............. ..,,, 19-22

Parking Brake Cable

Inspection and Replacement .......... 19-23

www.emanualpro.com

Page 931 of 1395

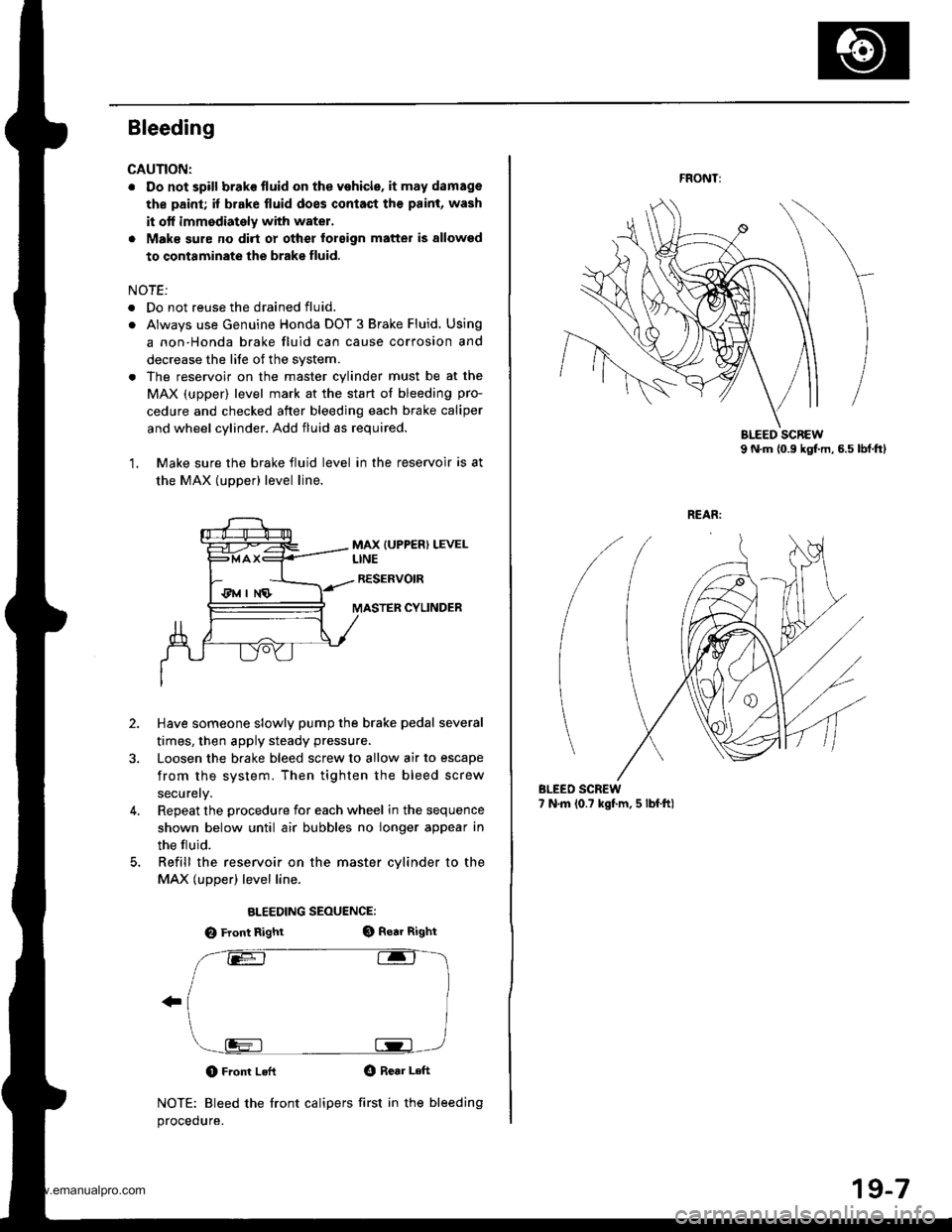

Bleeding

CAUNON:

. Do not spill brake tluid on the vehicle. it may damage

the paint; if brake fluid does contaqt th€ paint, wash

it otf immodiately with water.

. Maks sure no dirt oy other forsign matter is allowsd

to contaminate the brake fluid.

NOTE:

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the svstem.

. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of bleeding pro-

cedure and checked after bleeding each brake caliper

and wheel cylinder. Add fluid as required.

1, Make sure the brake fluid level in the reservoir is at

the MAX (uDDer) level line.

MAX {UPPER) LEVELLINE

RESERVOIR

MASTER CYLINDER

2.

3.

Have someone slowly pump the brake pedal several

times, then apply steady pressu.e.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the tluid.

Refill the reservoir on the master cvlinder to the

MAX (upper) level line.

ALEEDING SEOUENCE:

O Front RightGt Rear Right

O Front LeflO Rear Left

NOTE: Bleed the front calipers first in the bleeding

procedure.

4.

FRONT:

BLEEO SCREW7 N.m (0.? kgf.m, 5 lbf.ftl

19-7

www.emanualpro.com

Page 952 of 1395

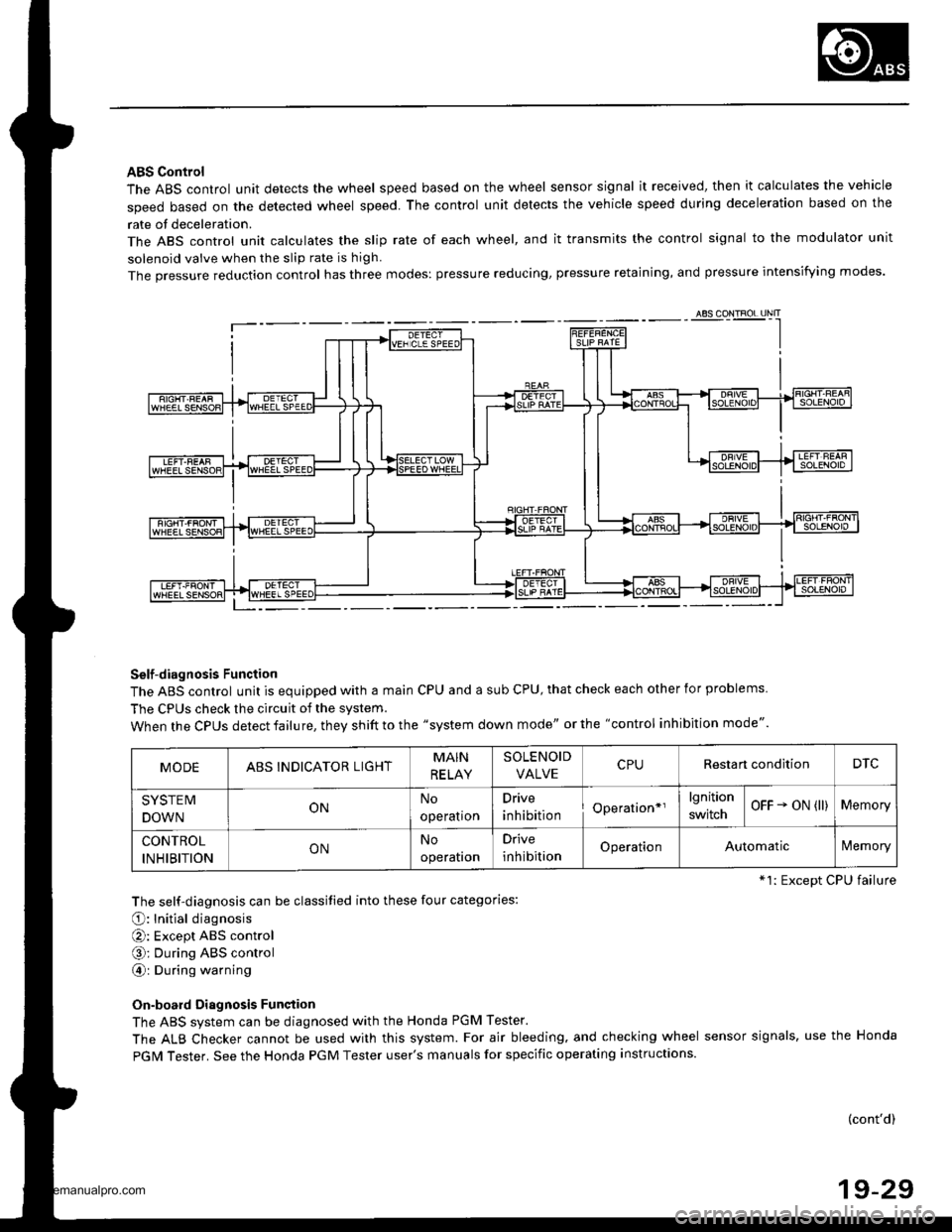

ABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehicle

speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on the

rate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unit

solenoid valve when the slip rate is high

The pressure reduction control has three modes: pressure reducing, pressure retaining, and pressure intensi{ying modes.

Self-diagnosis Function

The ABS control unit is equipped with a main cPU and a sub cPU, that check each other for problems.

The CPUs check the circuit of the system.

When the CPUS detect failure, they shift to the "system down mode" or the "control inhibition mode".

The self-diagnosis can be classitied into these four categories:

O: Initial diagnosis

O: Except ABS control

O; During ABS control

@: During warning

On-board Diagnosis Function

The ABS system can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding. and checking wheel sensor signals, use the Honda

PGIM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

(cont'd)

19-29

ABS CONTROL I-INIT

MODEABSINDICATOR LIGHTMAIN

RE LAY

SOLENOID

VALVERestan conditionDTC

SYSTEM

DOWNONNo

operatron

Drive

inhibitionOperation*rlgnition

switchOFF - oN (ll)Memory

CONTROL

INHIBITIONONNo

operaton

Drive

inhibitionOperationAutomaticlVemory

*1: Except CPU failure

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com