Crankshaft speed HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 66 of 1395

lgnition System

5.

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

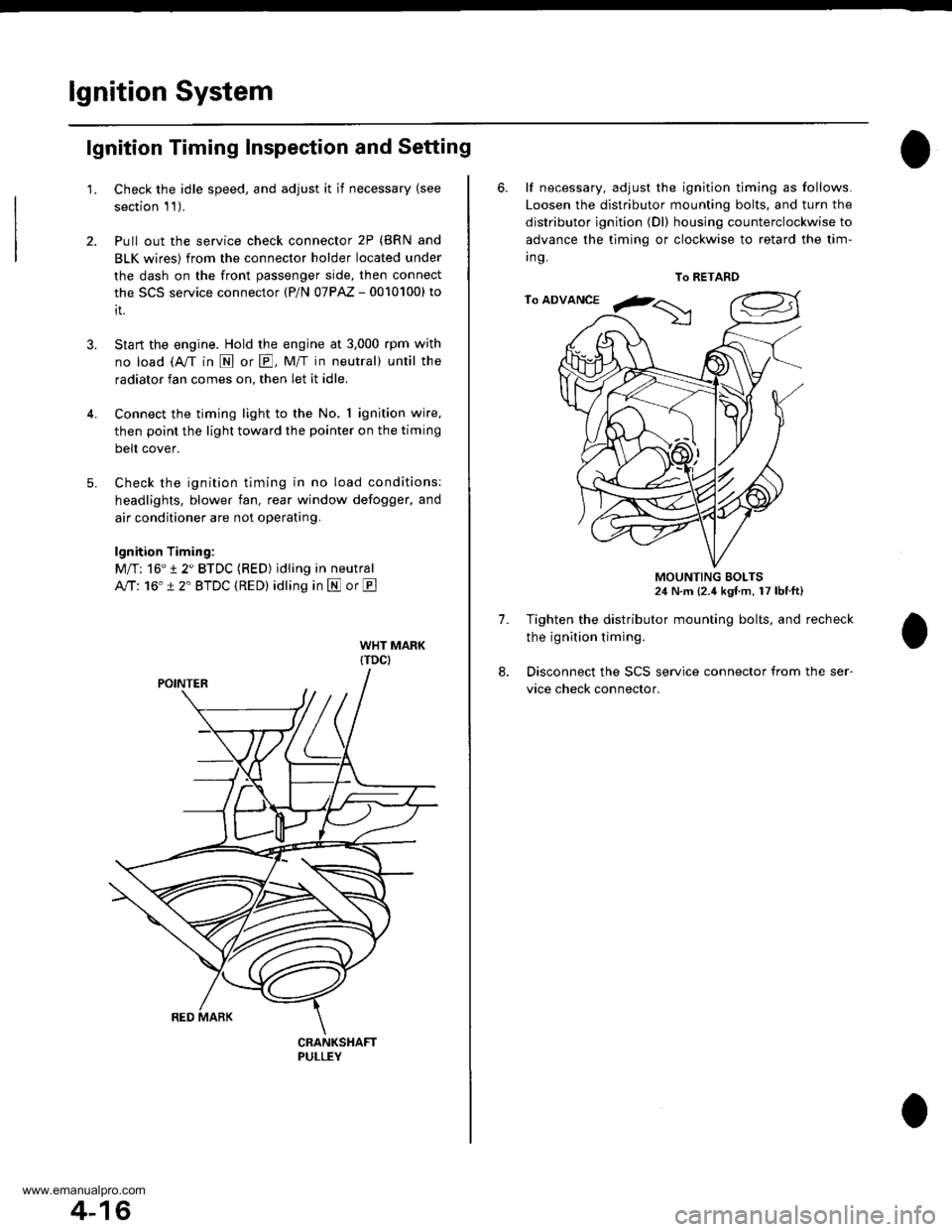

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 114 of 1395

Cylinder Head/Valve Train

Speciaf Tools .............6-2

Valve Clearance

Adiustment ............6-3

Valve Seals

Replacement (cylinder head

removal not requiredl ................. 6-5

Crankshaft Pulley and Pulley Bolt

Replacement .........6-7

Timing Belt

I llustrated lndex ............................... 6-8

Inspection ............., 6-9

Tension Adjustment ........................ 6-9

Removal ...........,..... 6-10

lnstallation .............6-11

Crankshaft Speed Fluctuation (CKFI

Sensor

Replacement .........6-13

Cylinder Head

lllustrated lndex ............................... 6-14

Removal .................6-16

Warpage ................6-27

lnstallation ............. 6-30

Camshafts

lnspection ..............6-22

Valves, Valve Springs and Valve Seals

Removal ................, 6-23

lnstallation ............. 6-29

Valve Guides

Valve Movement ............,,,,.,............ 6-25

Replacement .........6-25

Reaming .................6-27

Valve Seats

Reconditioning ......6-28

www.emanualpro.com

Page 118 of 1395

Valve Seals

Replacement (cylinder head removal not required)

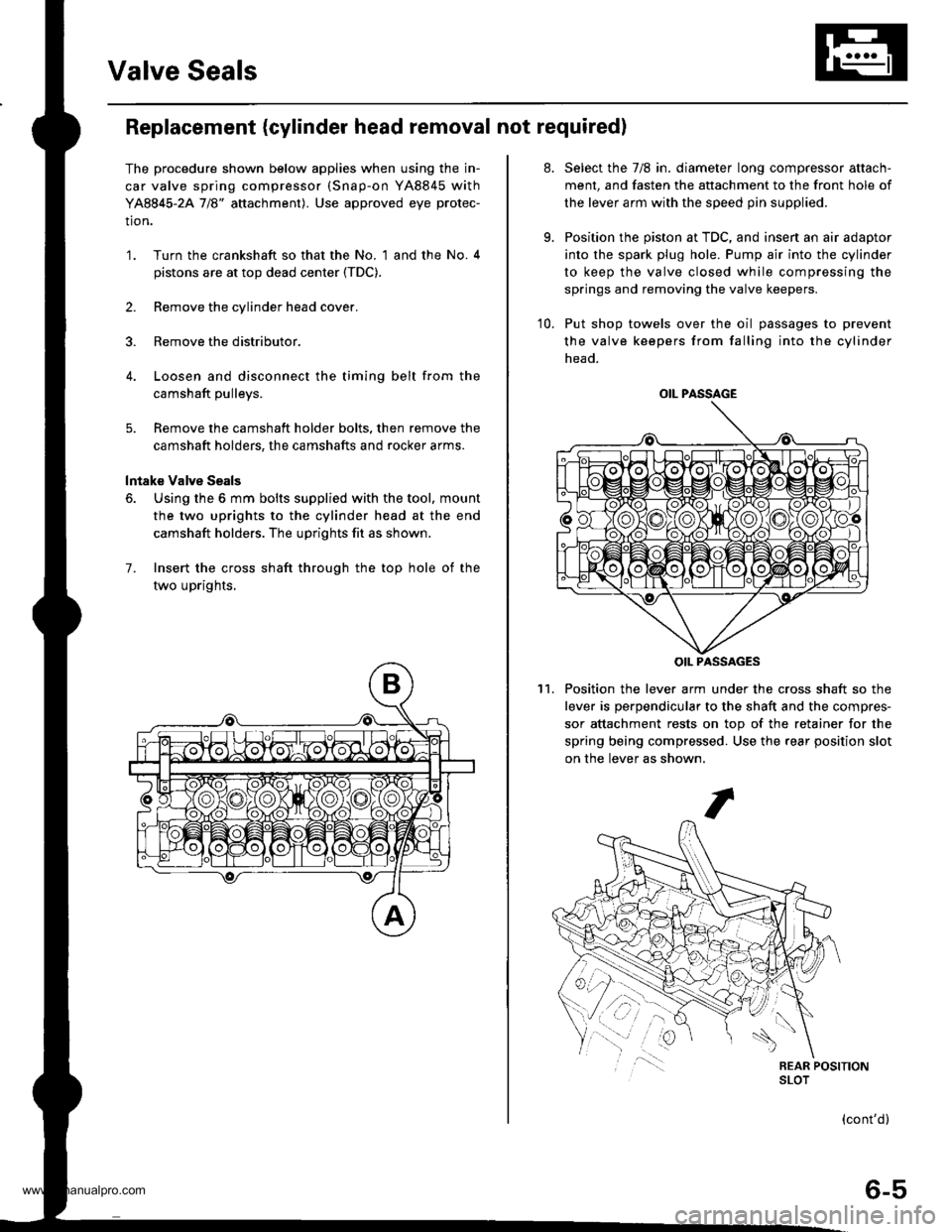

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA8845 with

YA8845-2A 7/8" auachment). Use approved eye protec-

tion.

1. Turn the crankshaft so that the No. 1 and the No. 4

pistons are at top dead center (TDC).

2. Remove the cylinder head cover.

3. Remove the distributor.

4. Loosen and disconnect the timing belt from the

camshaft pulleys.

5. Remove the camshaft holder bolts. then remove the

camshaft holders, the camshafts and rocker arms.

lntake Valve Seals

6. Using the 6 mm bolts supplied with the tool, mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit as shown.

7. Insert the cross shaft through the top hole of the

two uprights,

at.

9.

Select the 7/8 in. diameter long compressor attach-

ment, and fasten the attachment to the front hole of

the lever arm with the speed pin supplied.

Position the piston at TDC, and insen an air adaptor

into the spark plug hole. Pump air into the cylinder

to keep the valve closed while compressing the

springs and removing the valve keepers.

10. Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

head.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the rear position slot

on the lever as shown,

't1.

OIL PASSAGE

OIL PASSAGES

(cont'd)

6-5

www.emanualpro.com

Page 167 of 1395

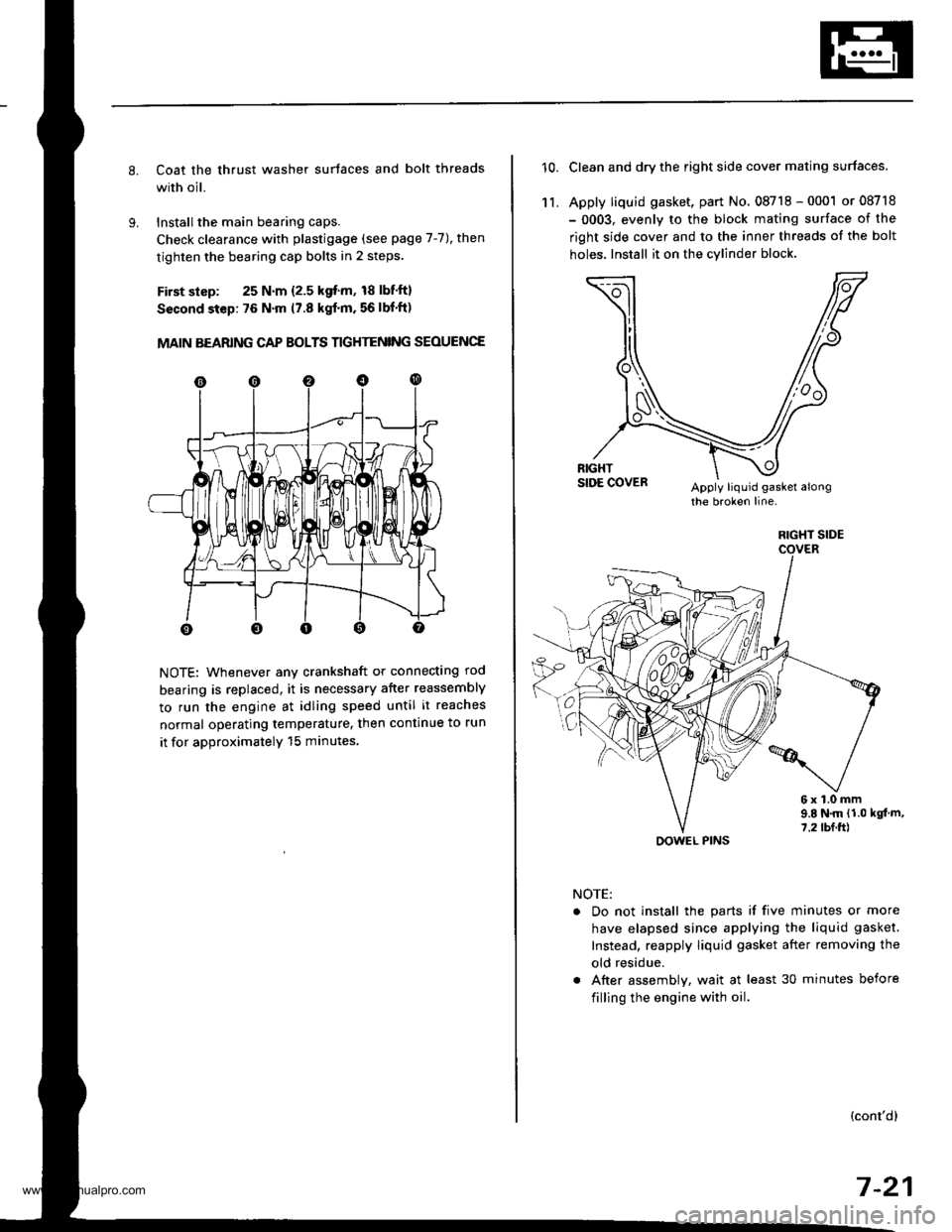

Coat the thrust washer surtaces and bolt threads

with oil.

Installthe main bearing caps.

Check clearance with plastigage (see page 7-7), then

tighten the bearing cap bolts in 2 steps.

First slsp: 25 N.m {2.5 kgf'm, 18 lbf'ft}

Sscond step: 76 N'm (7.8 kgf'm. 56 lbf'ft)

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

NOTE: Whenever any crankshaft or connecting rod

bearing is replaced, it is necessary after reassembly

to run the engine at idling speed until it reaches

normal operating temperature, then continue to run

it for approximatelY 15 minutes.

10.Clean and dry the right side cover mating surfaces.

Apply liquid gasket, part No. 08718 - 0001 or 08718

- 0003, evenly to the block mating surface of the

right side cover and to the inner threads of the bolt

holes. Install it on the cylind€r block

11,

6x1.0mm9.E N.m {1.0 kgt m,7.2 tbf.ft)

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying the liquid gasket.

Instead, reapply liquid gasket after removing the

old residue.

. After assembly, wait at least 30 minutes before

filling the engine with oil.

(cont'dl

7-21

RIGHT SIDE

OOWEL PINS

www.emanualpro.com

Page 206 of 1395

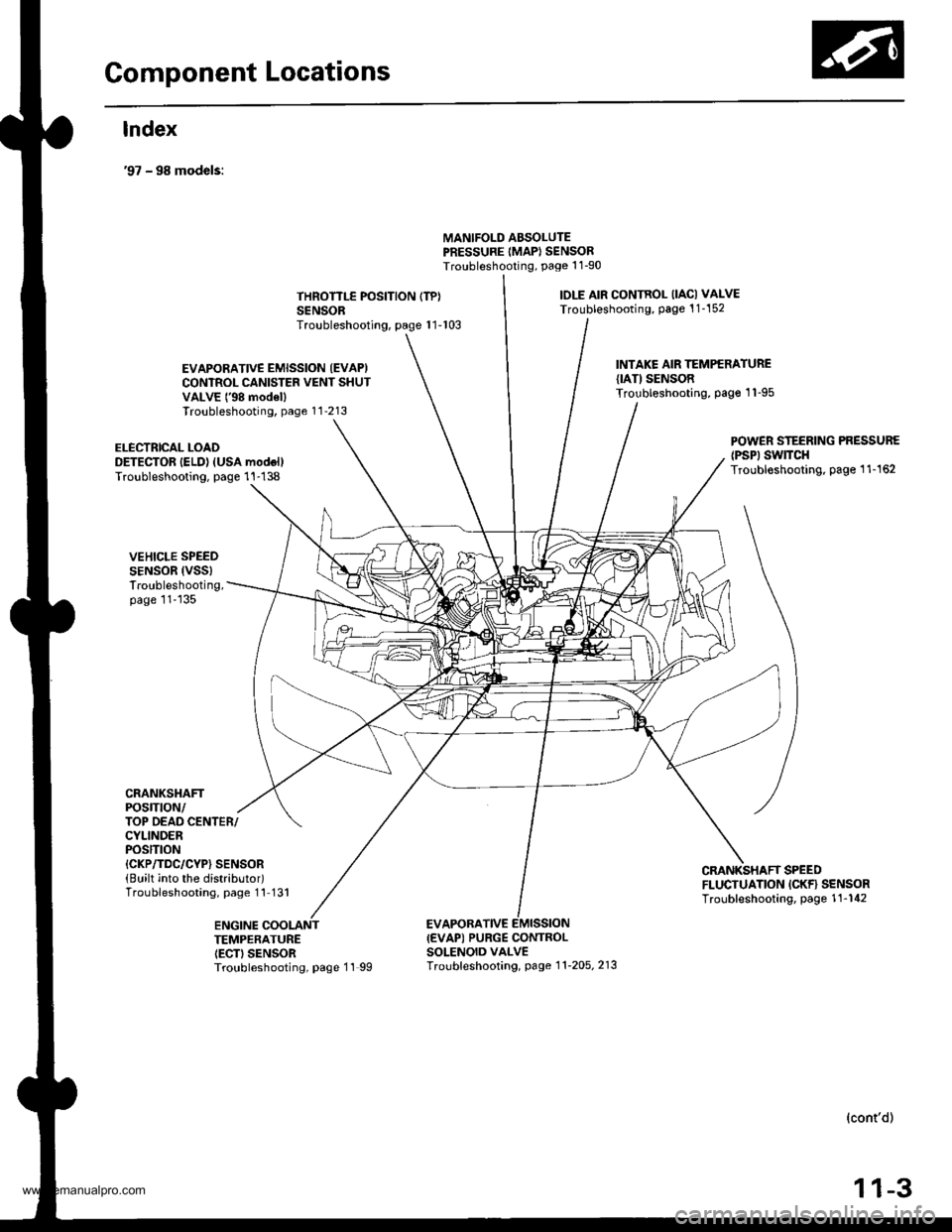

Component Locations

lndex

'97 - 98 models:

MANIFOLD ABSOLUTEPRESSURE IMAP} SENSORTroubleshooting, Page 1 1-90

THROTTLE POSITION (TP}

SENSORTroubleshooting, page 1 1-103

toLE AtR CONTROL llAcl VAI-VE

Troubleshooting, page 1 1-152

EVAPORATIVE EMISSION (EVAP)

CONTROL CANISTER VENT SHUTVALVE t'98 mod€llTroubleshooting, page 11'213

INTAKE AIR TEMPERATUREIIATI SENSORTroubleshooting. page 1 'l -95

ELECTRICAL LOADDETECTOR IELD) (USA modol)Troubleshooting, page 1 1-138

VEHICLE SPEEDSENSOR (VSS)

Troubleshooting,page 11'135

CRANKSHAFTPOSTTtON/

POWER STEERING PRESSURElPsPl swtrcHTroubloshooting, page 1 1-162

TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, page 1 l-131

CMNKSHAFT SPEEDFLUCTUATION ICKF} SENSORTroubleshooting. page 1'!-142

ENGINE COOLANTTEMPERATUREIECTI SENSORTroubleshooting, page 11 99

EVAPORATIVEI€VAP) PURGE CONTROLSOLENOID VALVETroubf eshooting, page 1 1'2o5, 213

(cont'd)

11-3

www.emanualpro.com

Page 207 of 1395

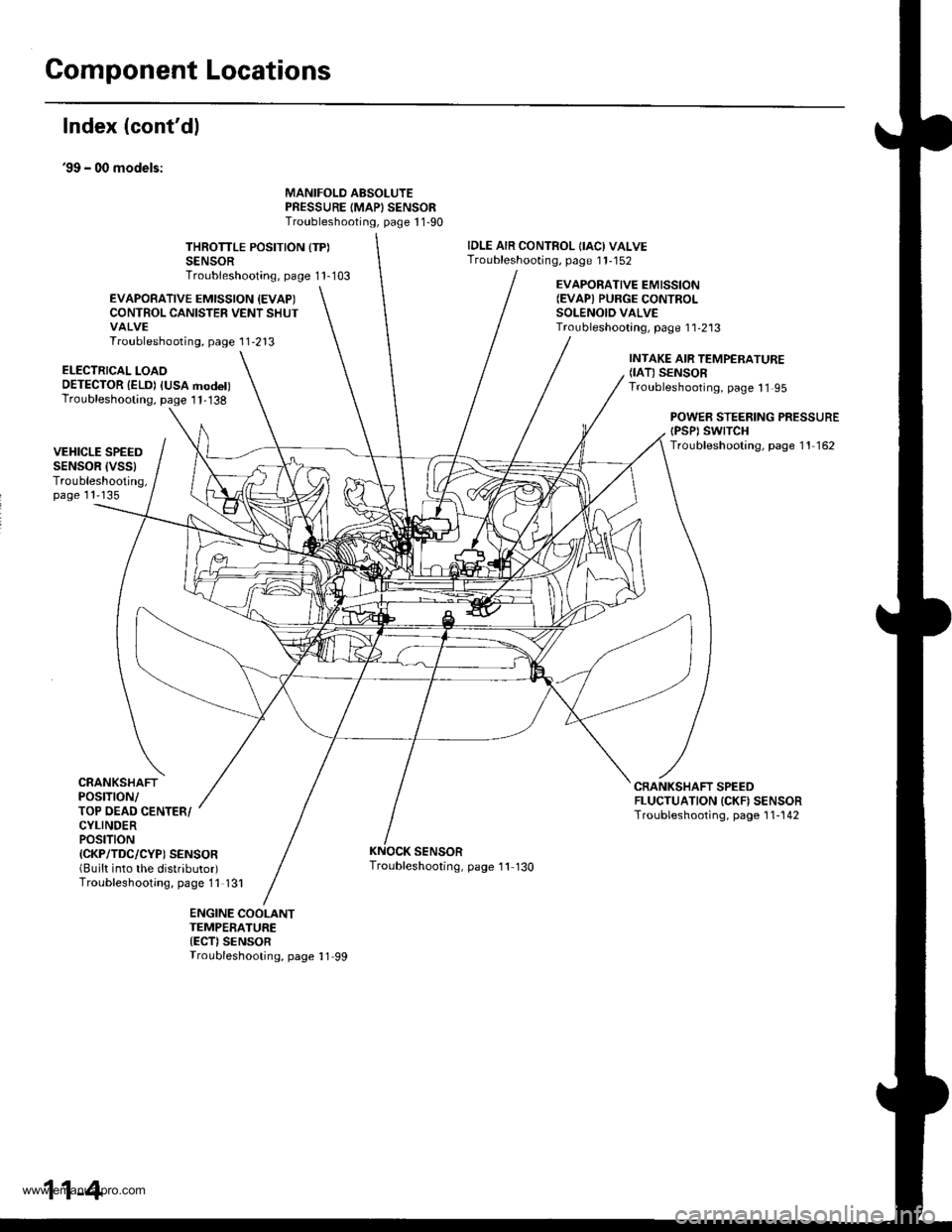

Component Locations

Index (cont'dl

39 - 00 models:

MANIFOLD ABSOLUTEPRESSURE IMAPISENSORTroubleshooting, page 1 1-90

THROTTLE POSITION {TP)SENSORTroubleshooting, page 1 1-103

IDLE AIR CONTROL OACI VALVETroubleshooting, page 1 1-152

EVAPOBATIVE EMISSION {EVAPICONTROL CANISTER VENT SHUTVALVETroubleshooting, page 1 1-213

EVAPORATIVE EMISSION(EVAPI PURGE CONTROI-SOLENOID VALVETroubleshootang, page 1 1-2'13

ELECTRICAL LOAOOETECTOR {ELD) IUSA modet)Troubleshooting, page I 1-138

INTAKE AIR TEMPERATURE(IAT) SENSORTroubleshooting, page 11 95

POWEB STEERING PRESSUREtPsPt swtTcHTroubleshooting, page 11 162VEHICLE SPEEDSENSOR IVSSITroubleshooting,page 11'135

CRANKSHAFTPOSTTTON/TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP) SENSOR(Built into the distributor)Troubleshooting, page 11 131

CRANKSHAFT SPEEDFLUCTUATION ICKN SENSORTroubleshooting, page 1 1-142

SENSORTroubleshooting, page '11 130

ENGINE COOLANTTEMPERATURE{ECT)SENSORTroubleshooting, page 11 99

11-4

www.emanualpro.com

Page 213 of 1395

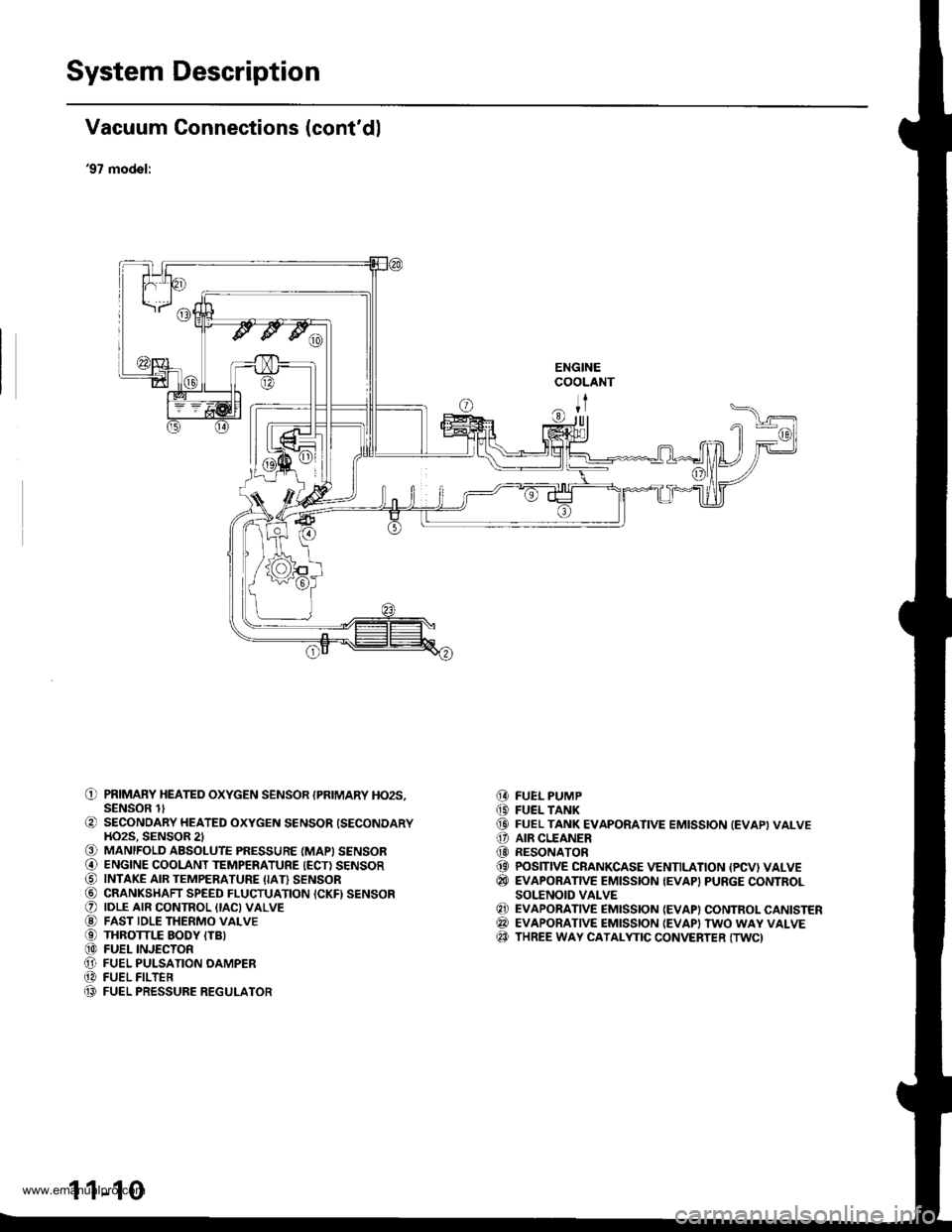

System Description

Vacuum Connections (cont'dl

'97 model:

ENGINECOOLANT

ITr|ll

O PRIMARY HEATED oxYGEN sENsoR {PRIMARY Ho2s,SENSOR lt

O SECONDARY HEATED oxYGEN sENsoR {SECoNDARYHO2S. SENSOR 2l€) MANIFOLD ABSOLUTE PRESSURE (MAPI SENSOR@ ENGINE cooLANT TEMPERATURE {EcT} sENsoRO INTAKE AIR TEMPERATURE (IAI} sENsoR@ CRANKSHAFT SPEED FLUCTUATION ICKFI SENSORO |DLE ArR coNTRoL {tAc)vALvE@ FAST IDLE THERMo vALvEO THRoTTLE EoDY ITB)@ FUEL INJEcTonO FUEL PULSATIoN oAMPER@ FUEL FILTEn(} FUEL PRESSURE REGULATOR

FUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPIVALVEAIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION {PCVI VALVEEVAPORATIVE EMISSION {EVAP} PURGE CONTROLSOI.'ENOID VALVEEVAPORATIVE EMISSION {EVAP) CONTROL CANISTEREVAPORATIVE EMISSION {EVAPI TWO WAY VALVETHREE WAY CATALYTIC CONVERTER (TWC)

@(D(D

o@(}

@

@@@

1 1-10

www.emanualpro.com

Page 215 of 1395

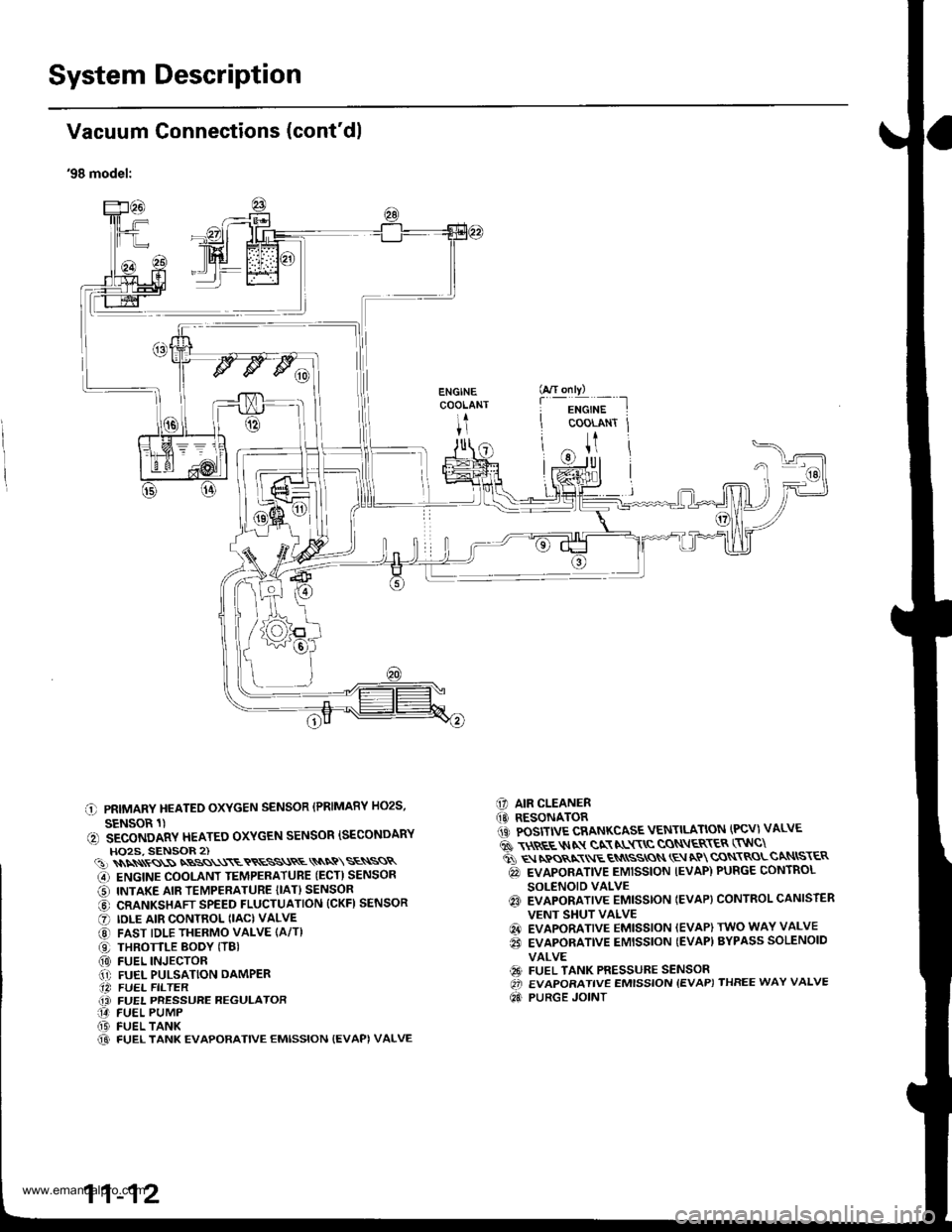

System Description

I

I

I

Vacuum Connections (cont'dl

'98 model:

C PRIMARY HEATEO OXYGEN SENSOR (PRIMARY HO2S,

SENSOR 1)(, SECONDARY HEATEO OXYGEN SENSOR ISECONDARYHO2S, SENSOR 2)(!)\\\\ss\SNBSS\\\ETRESS\RE\\NQ\SE\SSR

G) ENGINE COOLANT TEMPERATUBE (ECT) SENSOR

O INTAKE AIR TEMPERATURE {IAT} SENSOR

@ CRANKSHAFT SPEED FLUCTUATION (CKFI SENSOR

O IDLE AIR CONTROL (IAC) VALVE

@ FAST IDLE THERMO VALVE (A/T)

O THROTTLE BODY (TBI(0) FUEL INJECTOR.1' FUEL PULSATION DAMPER.14 FUEL FILTER(i FUEL PRESSURE REGULATOR14 FUEL PUMP(D FUEL TANK@ FUEL TANK EVAPORATIVE EMISSION {EVAPI VALVE

C] AIR CLEANER(O RESONATOR1iC POSITIVE CRANKCASE VENTILATION (PCV) VALVE

6 \$REE$IN gN NL$\C CON\ER\ER (TNC\

ti q rpos,xr E qN

ssros \E aP cqN\RoLcaNtsr€R

@ EVAPORATIVE EMISSION IEVAP) PURGE CONTROL

SOLENOID VALVEq3 EVAPORATIVE EMISSTON IEVAP} CONTROL CANISTER

VENT SHUT VALVE

@ EVAPORATIVE EMISSION (EVAP) TWO WAY VALVE

€i EVAPORATIVE EMISSION {EVAP) BYPASS SOLENOID

VALVE

€9 FUEL TANK PRESSURE SENSOROi EVAPORATIVE EMISSION {EVAP) THREE WAY VALVE

Qd PURGE JOINT

G/T only)

f

-i*'";-t

COOLANT Jt

U

11-12

www.emanualpro.com

Page 217 of 1395

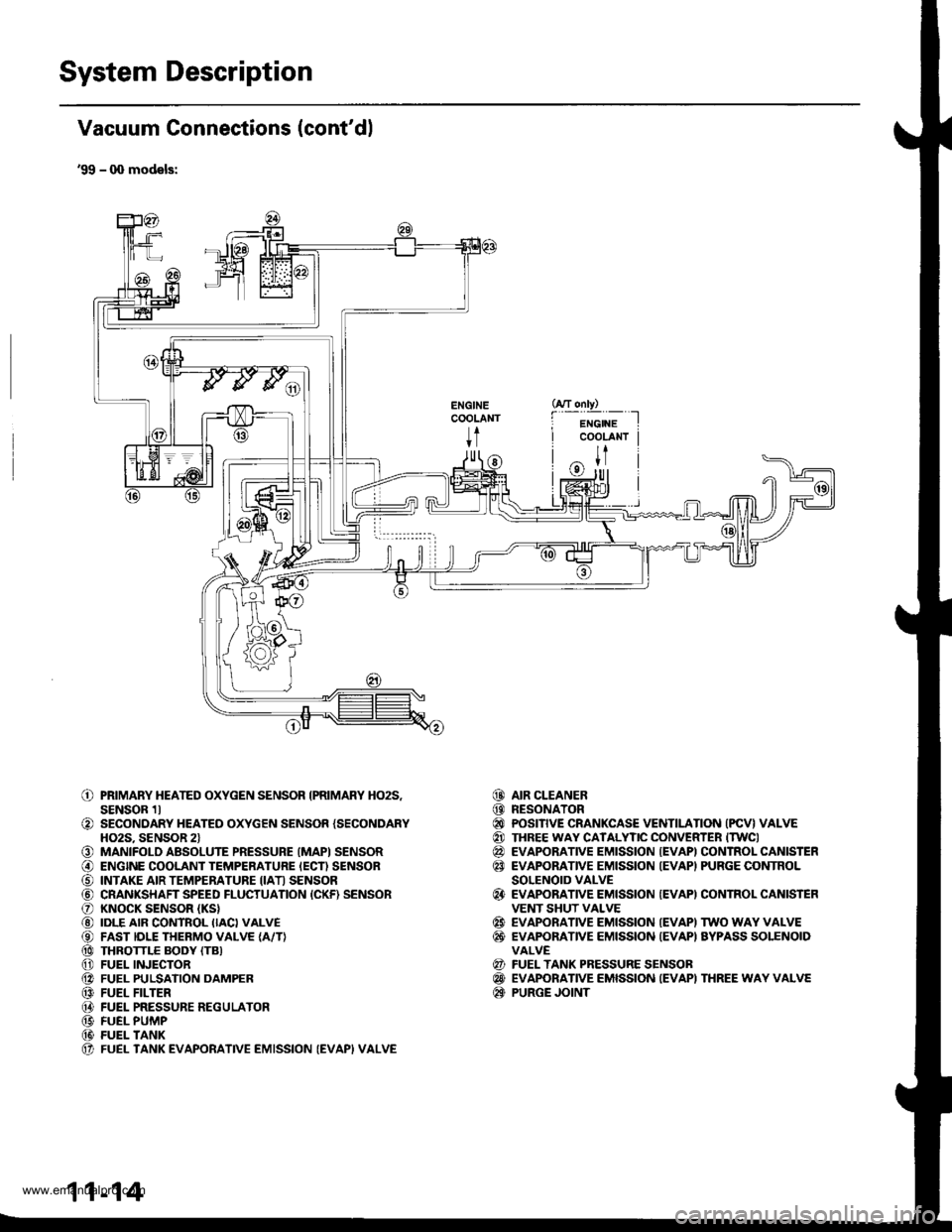

System Description

Vacuum Connections (cont'dl

'99 - q) models:

ENGINECOOLANT

t

o

o

o@

o@@@@@@@@@(t

PRIMARY HEATED OXYGEN SENSOR IPRIMARY HO2S,SENSOR 1lSECONDARY HEATED OXYGEN SENSOR {SECONDARYHO2S. SENSOR 2lMANIFOLD ABSOLUTE PRESSURE (MAPI SENSORENGINE COOLANT TEMPERATURE IECN SENSORINTAKE AIR TEMPERATURE IIATI SENSORCRANKSHAFT SPEED FLUCTUATION {CKF) SENSORKNOCK SENSOR (KS}

IDLE AIR CONTROL IIACI VALVEFAST IDLE THERMO VALVE {A/T}THROTTLE BODY (TB}

FUEL INJECTORFUEL PULSATION DAMPERFUEL FILTERFUEL PRESSURE REGULATORFUEL PUMPFUEL TANKFUEL TANK EVAPORATIVE EMISSION (EVAPI VALVE

AIR CLEANERRESONATORPOSITIVE CRANKCASE VENTILATION (PCV} VALVETHREE WAY CATALYTIC CONVERTER ITWCIEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEREVAPORATIVE EMISSION IEVAPI PURGE CONTROLSOLENOID VALVEEVAPORATIVE EMISSION {EVAPI CONTROL CANISTEFVENT SHUT VALVEEVAPORATIVE EMISSION IEVAPI TWO WAY VALVEEVAPONANVE EMISSION {EVAPI AYPASS SOLENOIDVALVEFUEL TANK PRESSURE SENSOBEVAPORATIVE EMISSION IEVAPI THREE WAY VALVEPURGE JOINT

@@@@@@

@

@@

@@@

11-14

www.emanualpro.com

Page 267 of 1395

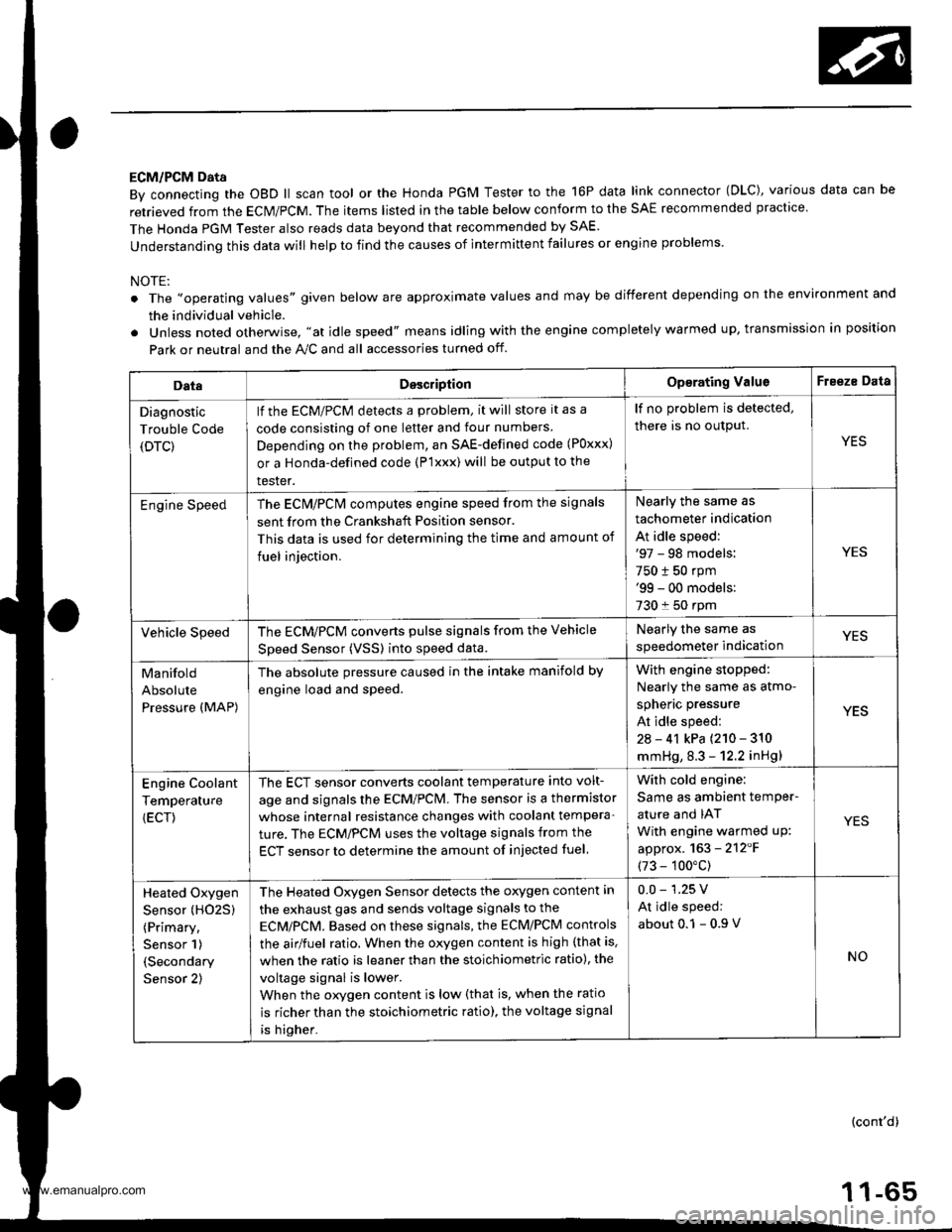

ECM/PCM Data

By connecting the OBD ll scan tool or the Honda PGM Tester to the 16P data link connector (OLC), various data can be

retrieved from the ECM/PCM. The items listed in the table below conform to the SAE recommended practice

The Honda PGM Tester also reads data beyond that recommended by SAE.

understanding this data will help to find the causes of intermittent failures or engine problems.

NOTE:

The ',operating values" given below are approximate values and may be different depending on the environment and

the individual vehicle.

Unless noted otherwise. "at idle speed" means idling with the engine completely warmed up, transmission in position

Park or neutral and the A,./C and all accessories turned otf.

DataDesc.iptionOp€rating ValuoFreeze Data

Diagnostic

Trouble Code

(DTC)

lf the ECM/PCM detects a problem, it will store it as a

code consisting of one letter and tour numbers

Depending on the problem, an SAE-defined code (Poxxx)

or a Honda-defined code (P'lxxx) will be output to the

tester.

lf no problem is detected,

there is no output.

YES

Engine SpeedThe ECN4/PCN4 computes engine speed from the signals

sent from the Crankshaft Position sensor.

This data is used for determining the time and amount of

fuel iniection.

Nearly the same as

tachometer indication

At idle speed:'97 - 98 models:

750 t 50 rpm'99 - 00 models:

730 f 50 rpm

YES

Vehicle SpeedThe ECM/PCM converts pulse signals from the Vehicle

Speed Sensor (VSSI into speed data.

Nearly the same as

speedometer indicationYES

Manifold

Absolute

Pressure (MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engin6 stopped:

Nearly the same as atmo-

spheric pressure

At idle speed:

2a - 41 kPa {210 - 310

mmHg, 8.3 - 12.2 inHg)

YES

Engine Coolant

Temperature

{ECT)

The ECT sensor converts coolant temperature into volt-

age and signals the ECM/PCM. The sensor is a thermistor

whose internal resistance changes with coolant tempera-

ture. The ECM/PCM uses the voltage signals from the

ECT sensor to determine the amount of injected fuel

With cold engine:

Same as ambient temPer-

ature and IAT

With engine warmed uP:

approx. 163 - 2'12'F

(73 - 100"c)

YES

Heated Oxygen

Sensor (HO25)

(Primary,

Sensor 1)

(Secondary

Sensor 2)

The Heated Oxygen Sensor detects the oxygen content in

the exhaust gas and sends voltage signals to the

ECMiPCM. Based on these signals, the ECM/PCM controls

the airlfuel ratio. When the oxygen content is high (that is.

when the ratio is leaner than the stoichiometric ratio), the

voltage signal is lower.

When the orygen content is low (that is, when the ratio

is richer than the stoichiometric ratio), the voltage signal

is higher.

0.0 - 1.25 V

At idle speed:

about 0.1 - 0.9

NO

(cont'd)

1 1-65

www.emanualpro.com