Engine ignition system HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 55 of 1395

Starting System

Starter Test

NOTE: The air temperature must be between 59 and'100'F (15 and 38"C) before testing.

Recommended Procedure:

. Use a staner system tester.

. Connect and operate the equipment in accordance

with the manufacturer's instructions.

. Test and troubleshoot as described.

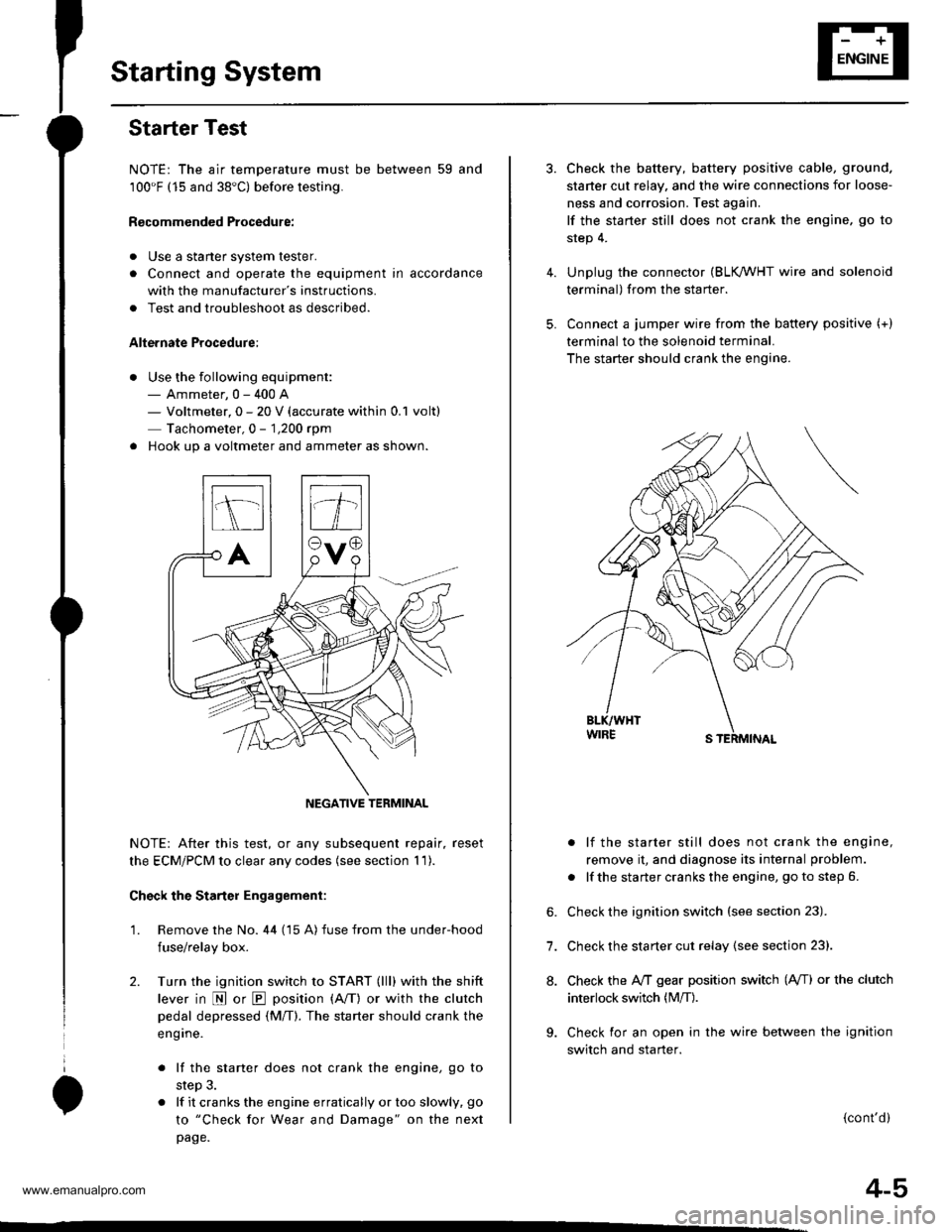

Alte.nate Procedure:

. Use the following equipment:- Ammeter, 0 - 400 A- Voltmeter, 0 - 20 V (accurate within 0.1 volt)

Tachometer,0 - 1,200 rpm

. Hook up a voltmeter and ammeter as shown.

NOTE: After this test, or any subsequent repair. reset

the ECM/PCM to clear any codes (see section 1 1).

Check the Starter Engagement:

'1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box.

2. Turn the ignition switch to START (lll) with the shift

lever in E or E position (A/T) or with the clutch

pedal depressed {M/T). The starter should crank the

eng ine.

. lf the starter does not crank the engine, go to

step 3.

. lf it cranks the engine erratically or too slowly, go

to "Check for Wear and Damage" on the next

page.

NEGATIVE TERMINAL

4.

5.

6.

7.

8.

Check the battery, battery positive cable, ground.

staner cut relay, and the wire connections for loose-

ness and corrosion. Test again.

lf the staner still does not crank the engine, go to

step 4.

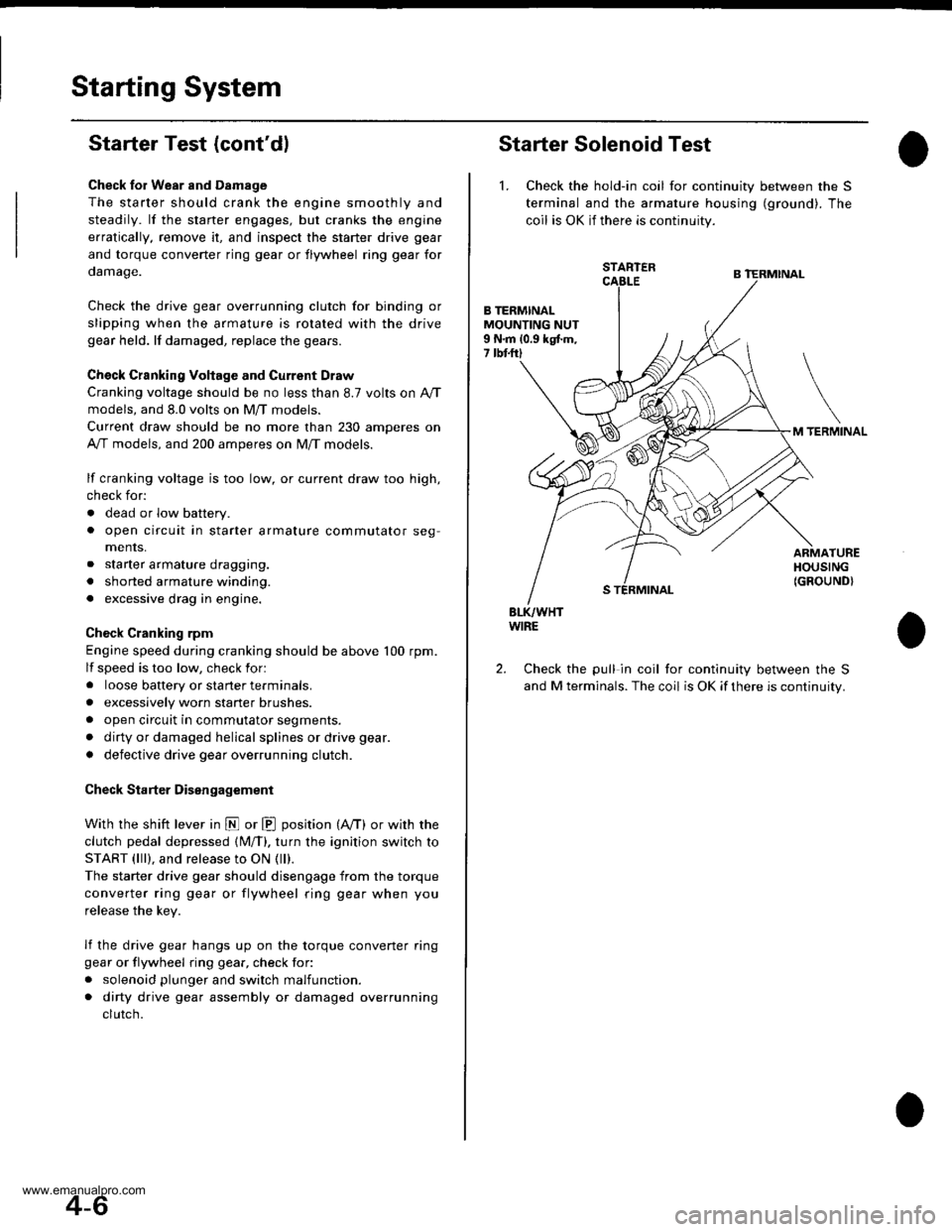

Unplug the connector (BLK /VHT wire and solenoid

terminal) from the starter.

Connect a jumper wire from the baftery positive (+)

terminal to the solenoid terminal.

The starter should crank the engine.

. lf the starter still does not crank the engine,

remove it, and diagnose its internal problem.

. lf the starter cranks the engine, go to step 6.

Check the ignition switch (see section 23).

Check the starter cut relay {see section 23}.

Check the IVT gear position switch (A/T) or the clutch

interlock switch (M[).

Check for an open in the wire between the ignition

switch and starter.

(cont'd)

4-5

www.emanualpro.com

Page 56 of 1395

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 66 of 1395

lgnition System

5.

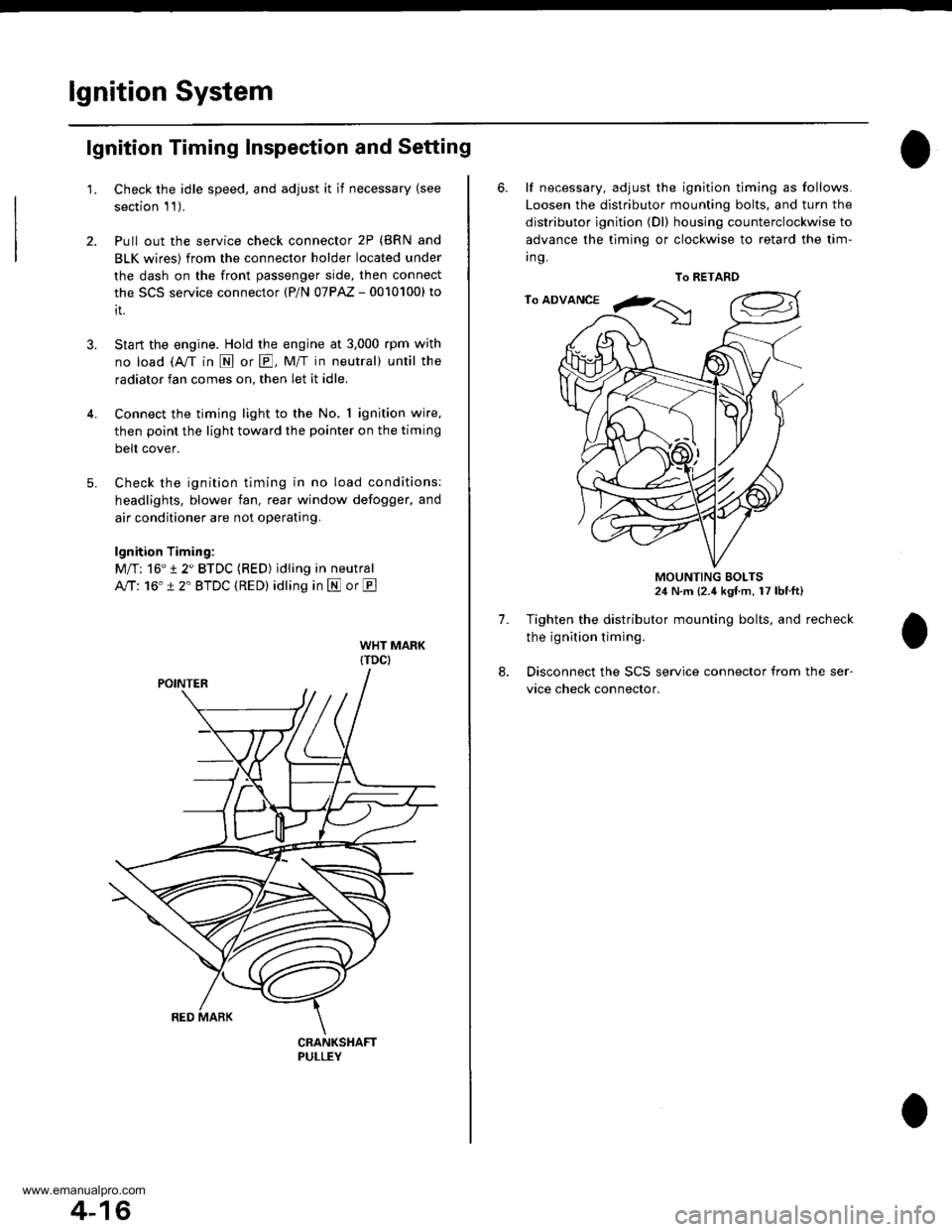

lgnition Timing Inspection and Setting

2.

1.Check the idle speed, and adjust it if necessary (see

section 1 1).

Pull out the service check connector 2P (BRN and

BLK wires) from the connector holder located under

the dash on the front passenger side, then connect

the scs service connector (P/N 07PAz - 0010100) to

it.

Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in N or E, Mff in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. I ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights, blower fan, rear window defogger, and

air conditioner are not operating.

lgnition Timing:

M/T: 16" 12" BTDC (RED) idling in neutral

AlTt'16" !2" BTDC (RED) idling in E or E

CRANKSHAFTPULLEY

4-16

6. lf necessary, adjust the ignition timing as follows.

Loosen the distributor mounting bolts, and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing or clockwise to retard the tim-

t no,

7.

8.

MOUNTING BOLTS24 N.m {2.4 kgf m, 17 lbtft}

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

To RETARD

www.emanualpro.com

Page 74 of 1395

Gharging System

Troubleshooting

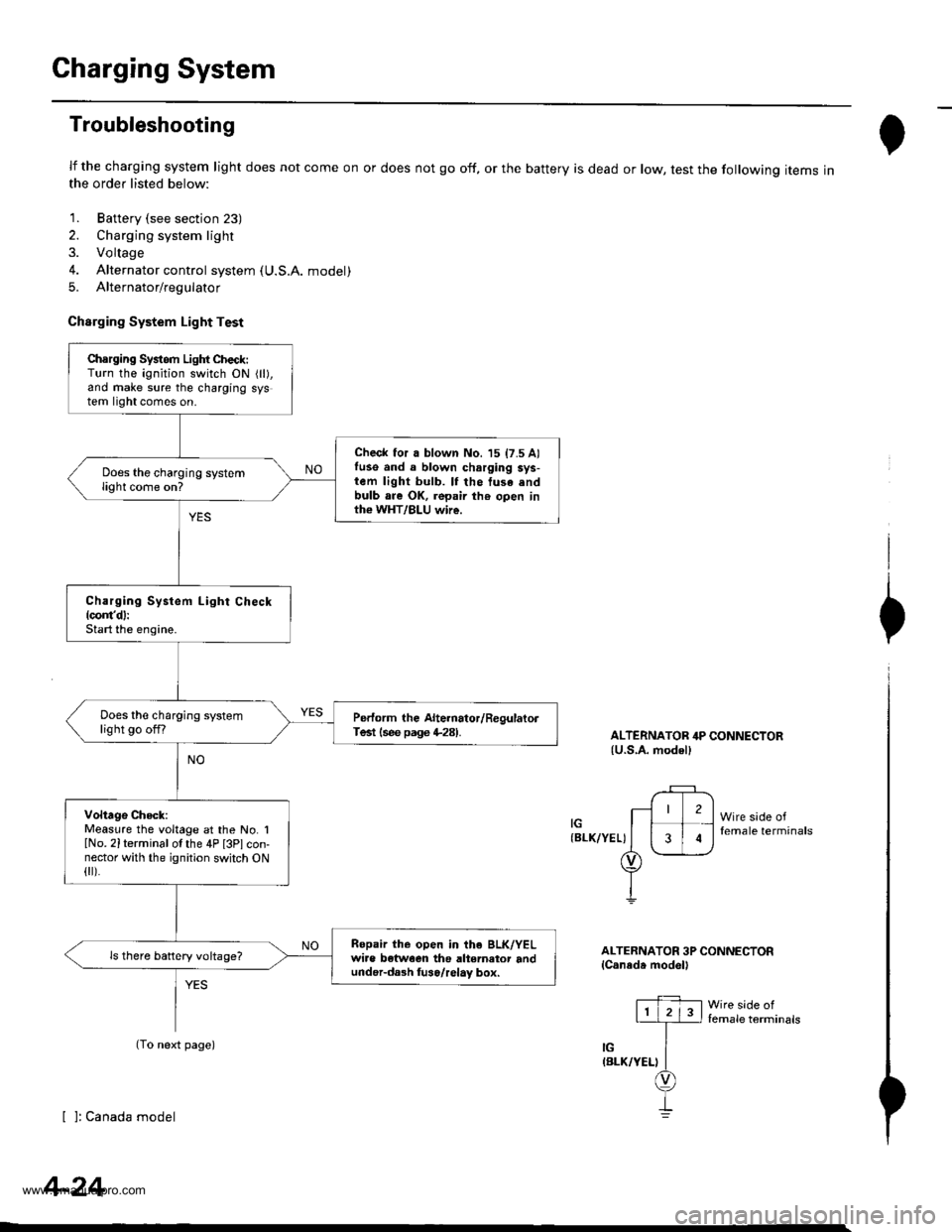

lf the charging system light does not come on or does not go off, or the battery is dead or low, test the following items inthe order listed below:

1. Battery (see section 23)

2. Charging system light

3. Voltage

4. Alternator control system (U.S.A. model)

5. Alternator/regulator

Charging System Light Test

ALTERNATOR 4P CONNECTOR{U.S,A. modell

(BLK/YEL)

2

3

Wire sade offemale terminals

I

I

I

ALTERNATOR 3P CONNECTORlCaneda model'

Iemale terminals

[ ]: Canada model

Chsrging Systom Light Check:Turn the ignition switch ON {ll),and make sure the charging system light comes on.

Check for a blown No. 15 17.5 Alfuse and a blown charging sys-tem light bulb. lf the tusa .ndbulb are OK, repair th€ open inth€ WHT/BLU wire.

Does the charging systemlight come on?

Charging System Light Check{com'd}:Start the engine.

Does the charging systemlight go offfPerform the Alte.nator/RegulatorTest lsee page +281.

Voltage Check:Measure the voltage at the No. IlNo. 2iterminal of the 4P [3Plcon-nector with the ignition switch ON{ ).

Ropair the open in the BLK/YELwiae betwoen the altemator andunder-da3h luso/relay box.

ls there battery voltage?

(To next page)

4-24

www.emanualpro.com

Page 203 of 1395

Goolant Temperature Gauge

Gauge Testing

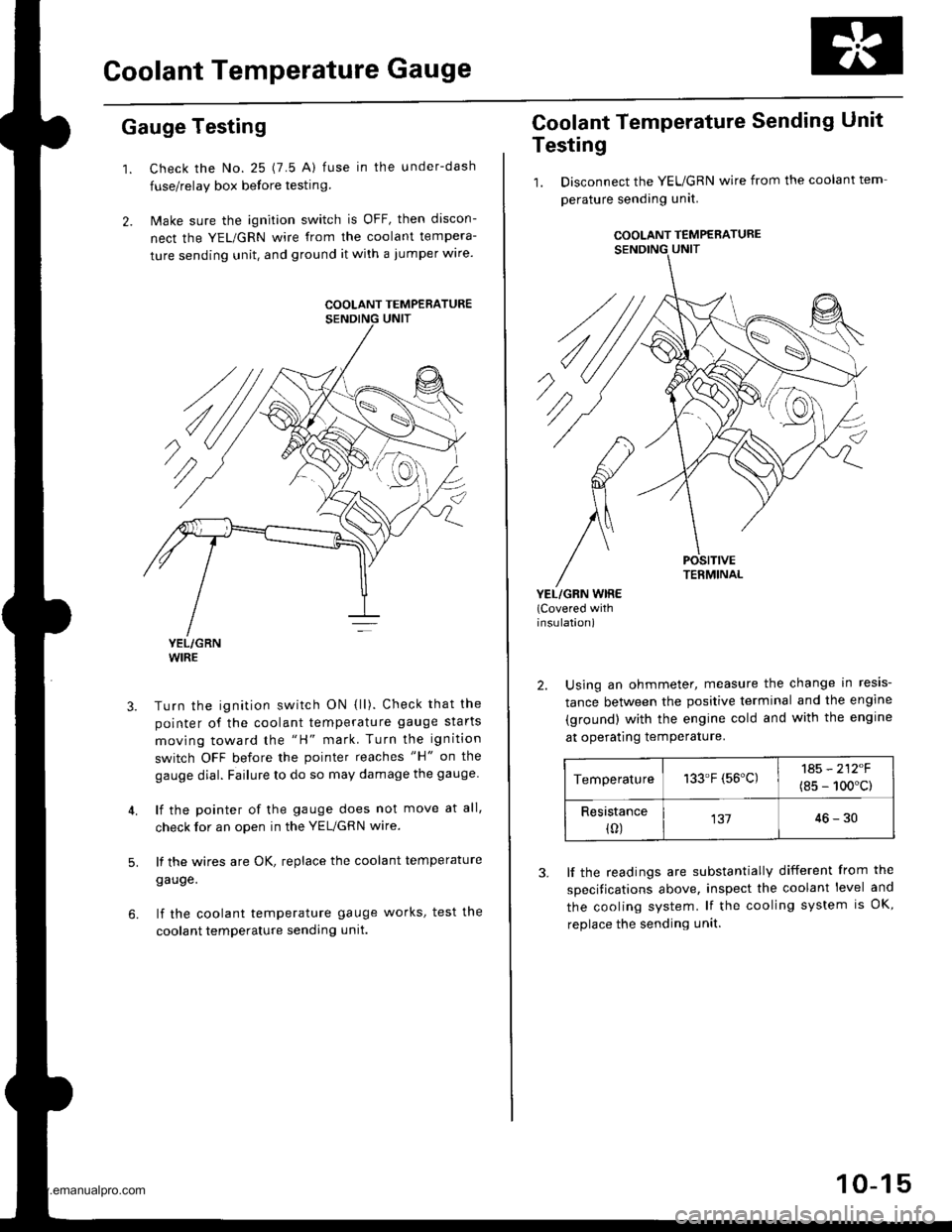

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testin9.

2. Make sure the ignition switch is OFF, then discon-

nect the YEL/GRN wire from the coolant tempera-

ture sending unit. and ground it with a jumper wire.

YEL/GRNWIRE

Turn the ignition switch ON {ll). Check that the

pointer of the coolant temperature gauge starts

moving toward the "H" mark. Turn the ignition

switch OFF before the pointer reaches "H" on the

gauge dial. Failure to do so may damage the gauge.

lf the pointer of the gauge does not move at all,

check for an open in the YEL/GRN wire.

lf the wires are OK, replace the coolant temperature

gauge.

lf the coolant temperature gauge works, test the

coolant temperature sending unit.

5.

COOLANT TEMPERATURE

Coolant Temperature Sending Unit

Testing

1. Disconnect the YEUGRN wire from the coolant tem

perature sending unit.

COOLANT TEMPERATURE

POSITIVETERMINAL

YEL/GRN WIRE(Covered withinsulation)

2. Using an ohmmeter, measure the change in resis-

tance between the positive terminal and the engine

(ground) with the engine cold and with the engine

at operating temPerature.

Temperature133.F (56'C)1A5 - 212F

(8s - 100'c)

Resistance(0)13746-30

3. lf the readings are substantially different from the

specitications above, inspect the coolant level and

the cooling system. lf the cooling system is OK,

replace the sending unit.

10-15

www.emanualpro.com

Page 268 of 1395

Troubleshooting

Troubleshooting Procedures (cont'd)

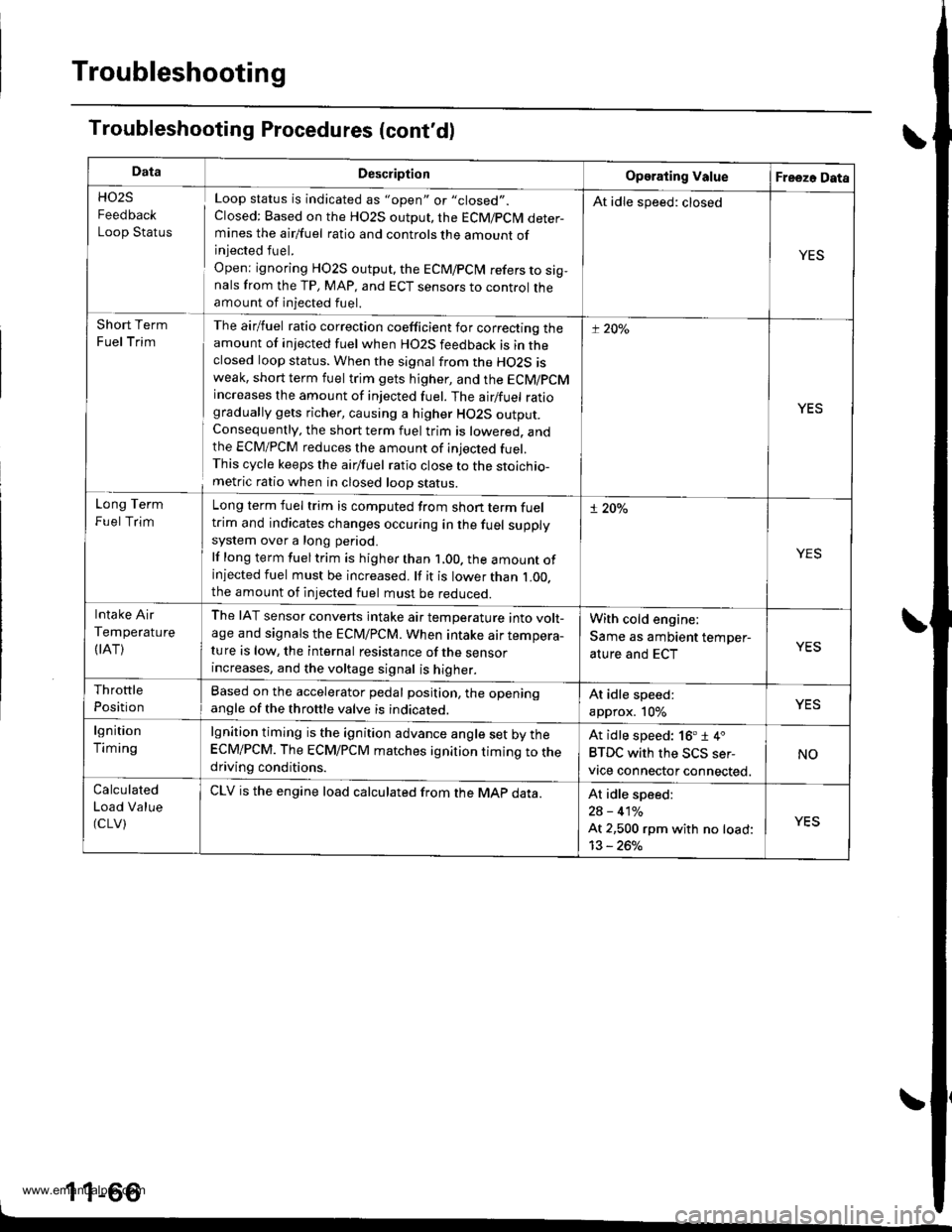

DataDescliptionOperating ValueFreezo Data

HO2S

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the HO2S output, the ECM/pCM deter-mines the airlfuel ratio and controls the amount ofinjected fuel.

Open: ignoring HO2S output, the ECM/pCiM refers to sig,nals from the TP, MAP, and ECT sensors to control theamount of injected fuel.

At idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correction coefficient for correcting theamount of injected fuel when HO2S feedback is in theclosed loop status. When the signal from the HO2S isweak, short term fuel trim gets higher, and the ECM/PCMincreases the amount of injected fuel. The airlfuel ratiogradually gets richer, causing a higher HO2S output.Consequently. the short term fuel trim is lowered. andthe ECM/PCM reduces the amount of injected fuel.This cycle keeps the airfuel ratio close to the stoichio-metric ratio when in closed looD status.

t:20y"

YES

Long Term

Fuel Trim

Long term fuel trim is computed from shon term fueltrim and indicates changes occuring in the fuel supplysystem over a long period.

lf long term fuel trim is higher than 1,00. the amount ofinjected fuel must be increased. lf it is lower than L00.the amount of injected fuel must be reduced.

! 20%

Intake Air

Temperature

(IAT)

The IAT sensor converts intake air temperature into volt-age and signals the ECrU/PCM. When intake air tempera-ture is low, the internal resistance of the sensorincreases, and the voltage signal is higher.

With cold engine:

Same as ambient temper-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position, the openingangle of the throttle valve is indicateo.At idle speed:

approx. 10%

lgnition

Timing

lgnition timing is the ignition advance angle set by theECM/PCM. The ECM/PCM matches ignition timing to thedriving conditions.

At idle speed: 16'1 4.

BTDC with the SCS ser-

vtce connector connected.

NO

Calculated

Load Value(cLV)

CLV is the engine load calculated from the MAp data.At idle speed:

2A - 410/o

At 2,500 rpm with no load:

13 - 260/o

YES

_

1 1_66

www.emanualpro.com

Page 282 of 1395

PGM-FI System

System Description

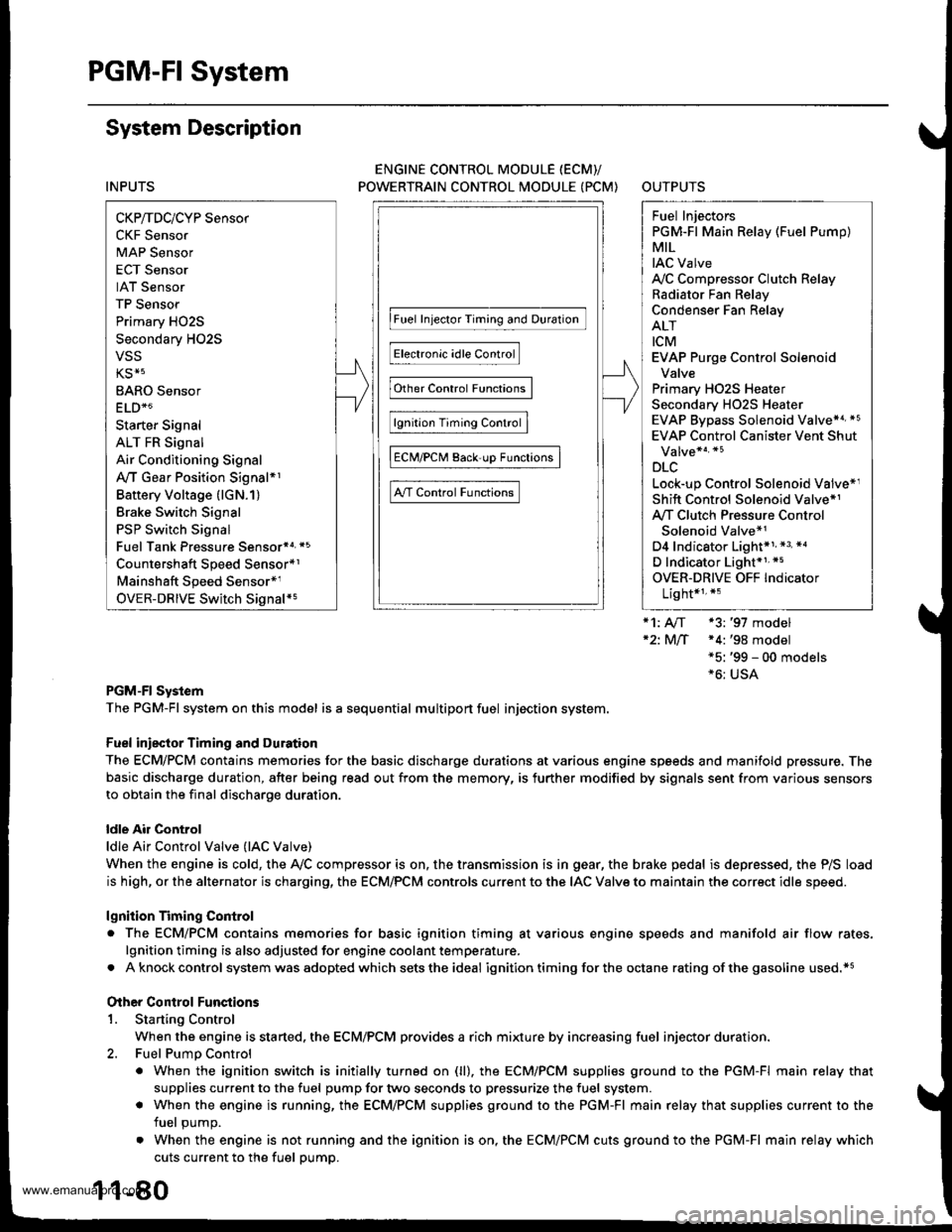

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 284 of 1395

PGM-FI System

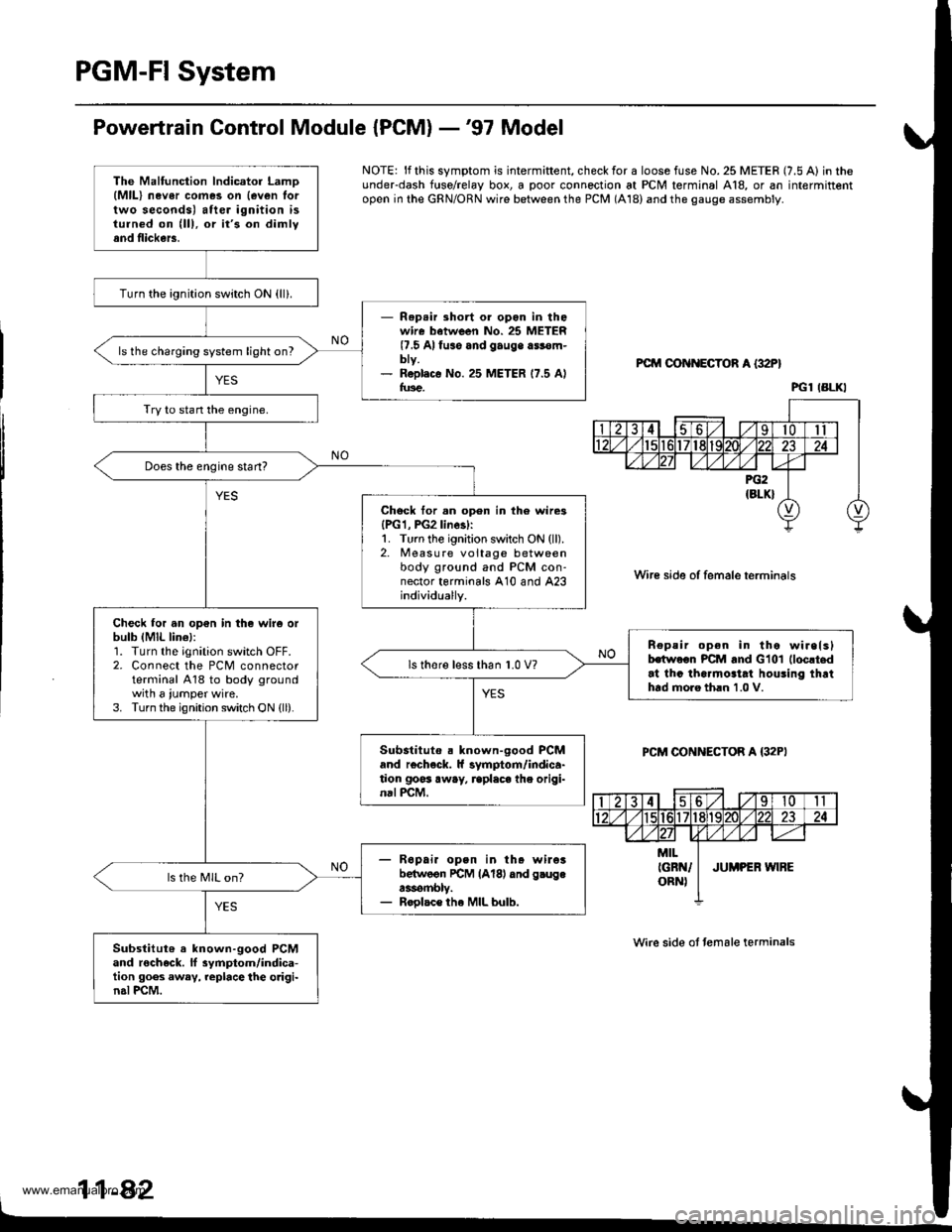

Powertrain Control Module {PCM} -'97 Model

NOTE: lf this symptom is intermiftent, check for a loose fuse No. 25 METER (7.5 A) in theunderdash f{rse/relay box, a poor connection at PCM terminal A18, or an intermittentopen in the GRN/ORN wire between the PCM (A18) and the gauge assembly.

PCM OON ECTOR A {32P}

Wire side of female terminals

PCM CONNECTOR A {32PI

Wire side ot temale terminals

11-42

The Malfunction lndicator LamD(MlL) nev6r comes on {even lortwo seconds) after ignition isturned on (lll, or it's on dimlyand flickers.

Turn the ignition switch ON {ll}.

- Rep.ir short or opon in thowire batween No. 25 METER(7.5 Alfuso and gauge a$€m-bty.- R6pl.c€ No. 25 METER 17.5 Alfus€.

ls the charging system light on?

Try to stan the engine.

Does the engine start?

Chock tor.n open in th6 wire3{PG1, PG2linesl:1. Turn the ignition switch ON (ll).2. Measure voltage betweenbody ground and PCM con-nector terminals A10 and A23individually.

Check for an op€n in the wir6 orbulb (MlL lin€l:1. Turn the ignition switch OFF.2. Connect the PCM connectorterminal A18 to body groundwith a iumper wire.3. Turn the ignition switch ON {ll).

n€peir open in tho wirelslhwoon PCM and Glol (loc!t.d

at thc tha.mo3tat houling thrthtd moro th.n 1.0 V.

ls thore l€ss than 1.0 V?

Substituto . known-good PCMand r€check. ll symptom/indica-tion goss away, rcplaca the origi-nal PCM.

- R6pai. open in th. wileibelwoon rcM lAl8l dnd g.ugea3rombly.- Roolac€ the MIL bulb.

ls the MIL on?

Substitut6 a known-good PCMand rocheck. ll 3ymptom/indica-tion goes away, replace the o.igi-n.l PCM.

PGl IBLKI

www.emanualpro.com

Page 288 of 1395

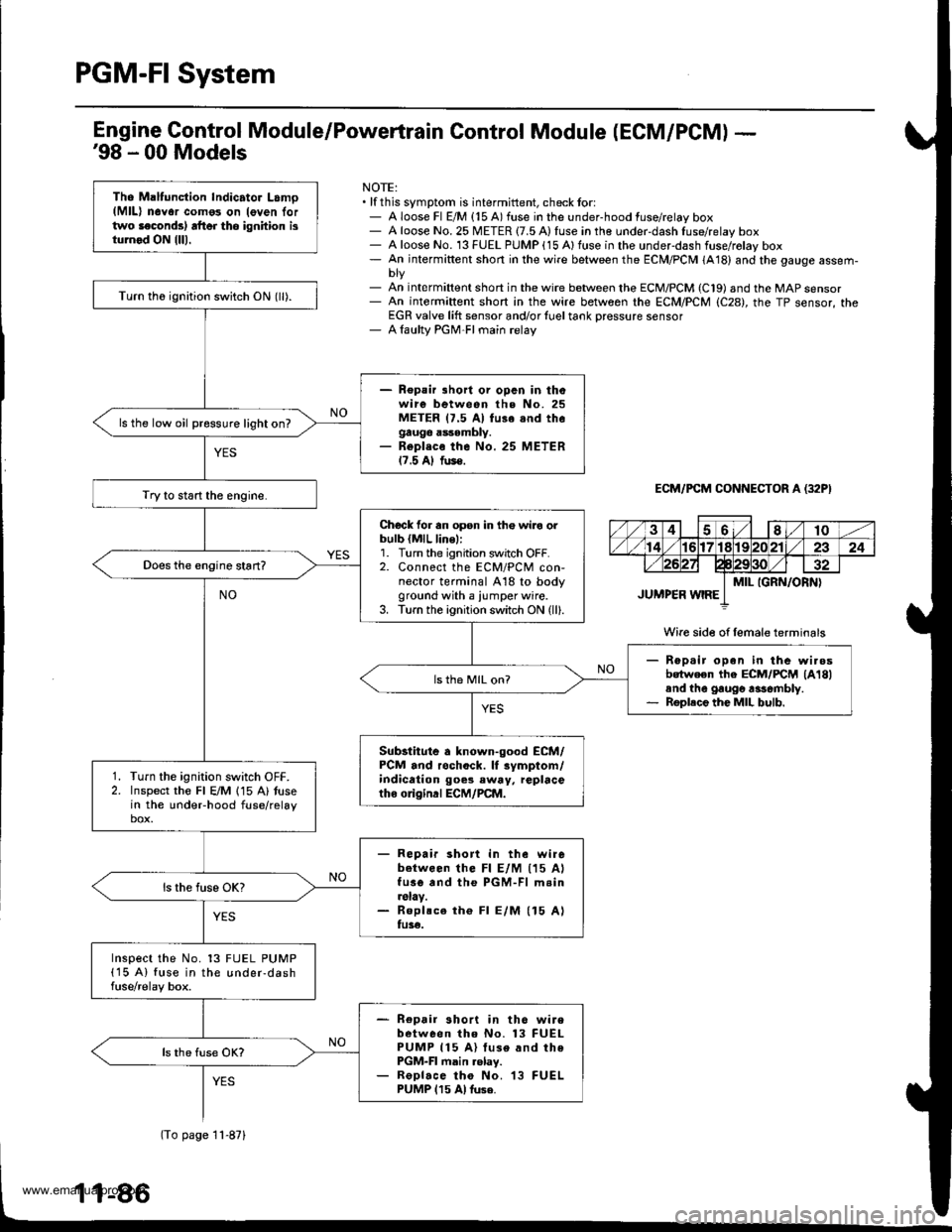

PGM-FI System

Tho Maltunction Indicator Lamo(MlL) n6Yor como3 on leven lortwo laconds) rft6r tho ignhion isturnod ON {lll.

Turn th6 ignition switch ON (ll).

- Repair lhort or opcn in thowire between the No. 25METER 17.5 Al fu3e snd thegauge assembly.- Repl.co the No. 25 METER17.5 Al fus€.

ls the low oil pressure light on?

Try to start the engine.

Chock for an opsn in th€ wiro orbulb {MlL line,:1. Turn the ignition switch OFF.2. Connect the ECM/PCM con-nector terminal A18 to bodyground with a iumper wire.3. Turn the ignition switch ON (ll).

Rep.ir open in the wi.osbotween the ECM/FCM lA18land the gaugo rasombly.Roplece the MIL bulb.

ls th6 MIL on?

Substitute a known-good ECM/PCM and rochock. lf rymptom/indication goes eway, replacetho o gind ECM/PCM.

Turn the ignition switch OFF.Inspect the Fl E/M 115 A) tusein the undeFhood fuse/relaybox.

- Repair short in the wirebetween lhe Fl E/M (15 AlfusG and the PGM-Fl m.in.slay.- Roplsce th€ Fl E/M (15 Alfu3€.

Inspect the No. 13 FUEL PUMP(15 A) fuse in the under-dashfuse/relay box.

- Repair short in th6 wirebetween tho No. 13 FUELPUMP 115 A) luse and thePGM-FI main .elay.- ReDlace tho No. 13 FUELPUMP 115 Al tuse.

Engine Gontrol Module/Powertrain Control Module (ECM/PCM) -'98 - 00 Models

NOTE:. lf this symptom is intermittent, check tor:- A loose Fl E/M {15 A) fuse in the under-hood fuse/relay box- A loose No. 25 METER {7.5 A) fuse in the under-dash fuse/relay box- A loose No. 13 FUEL PUMP (15 Alfuse in the underdash fuse/rolay box- An intermiftent short in the wire between the ECM/PCM (A18) and the gauge assem-

- An int€rmiftent short in the wire between the ECM/PCM (C19) and the MAP sensor- An intermiftent short in the wire between rhe ECM/PCM (C28), the TP sensor, theEGR valve lift sensor and/or {uel tank Dressure sensor- A laulty PGM-FI main relay

ECM/PCM CONNECTOR A (32P}

Wire side of female terminals

(To page 11-871

www.emanualpro.com