Heater hose HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 29 of 1395

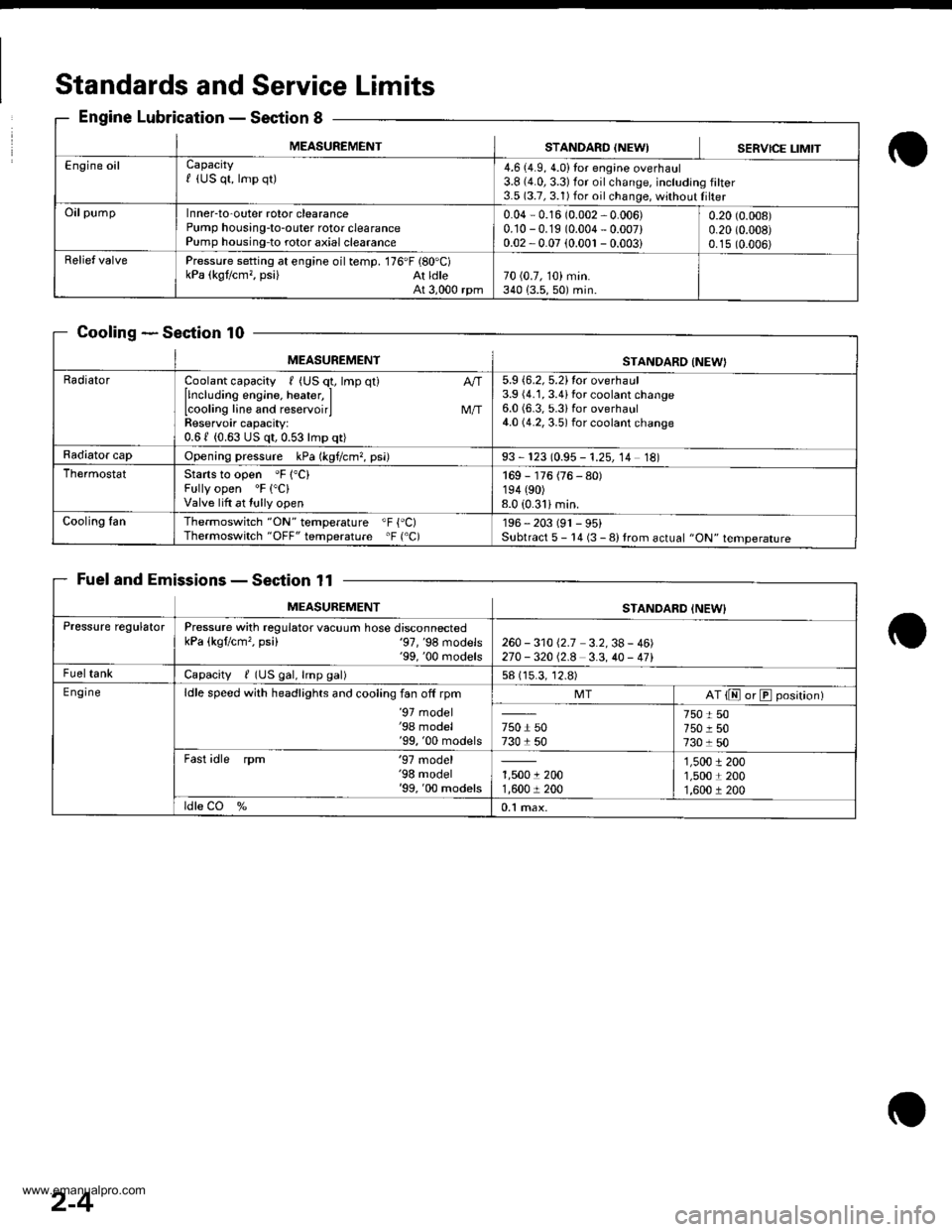

Standards andService Limits

Engine LubricationSection 8

CoolingSection 10

Fuel and EmissionsSection 11

MEASUREMENTSTANDARO {NEWISERVICE LIMIT

Engine oilCapacityf (US qt, lmp qt)4.6 (4.9, 4.0)Ior engine overhaul3.8 {4.0,3.3)for oilchange, including filter3.5 (3.7, 3.1) for oil change, without Iilter

OilpumpInner-to-outer rotor clearancePump housing-to-outer rotor clearancePump housing-to rotor axial clearance

0.04 - 0.16 (0.002 - 0.006)0.10 -0.19 (0.004 - 0.007)0.02 -0.07 (0.001 - 0.003i

0.20 (0.008)

0.20 (0.008)

0.15 (0.006)

Relief valvePressure setting at engine oil temp. 176'F (80'C)kPa (kgt/cm,, psi) At ldleAt 3,000 rpm70 (0.7, 10) min.340 {3.5,50) min.

MEASUREMENTSTANDARO INEW}

RadiatorCoolant capacity , (US q1, lmp qt)

llncluding engine, heater, ILcooling line and reservoirlReservoir capacity:0.61 (0.63 US qt,0.53lmp qt)

M/T

5.9 {6.2, 5.2}tor overhaul3.9 (4.1, 3.4ifor coolant change6.0 (6.3, 5.3ifor overhaul4.0 (4.2, 3.5) for coolant change

Radiator capOpening pressure kPa (kgf/cm?, psi)93 - 123 (0.95 - 1.25, 14 18)

ThermostatStarts to open 'F 1"C)Fully open 'F ("C)

Valve lift at tully open

169 - 176 (76 - 80)194 (90)

8.0 (0.31imin.

Cooling fanThermoswitch "ON" temperature "F {'C)Thermoswitch "OFF" temperature 'F ('C)196 - 203 (91 - 95)Subtract 5 - 14 (3 - 8) trom actual "ON" temperature

MEASUREMENTSTANDARD INEW}

Pressure regulatorPressure with regulator vacuum hose disconnectedkPa (kgflcm'�, psi) '97,'98 models'99, '00 rnodels260 - 31012.7 3.2,38- 46)270 -32012.8 3.3,40 - 471

FueltankCapacity / (US gal, lmp gal)58 (15.3, 12.8)

E ngineldle speed with headlights and cooling fan off rpm'97 model'98 model'99, '00 models

MTAT {E or E position)

750 r 50730 1 50

750 t 50750 r 507301 50

Fast idle rpm '97 model'98 model'99, '00 models1,5001 2001,600 r 200

1,5001 2001,5001 2001,600 r 200

ldle CO %0.1 max.

2-4

www.emanualpro.com

Page 105 of 1395

rd

te

n-

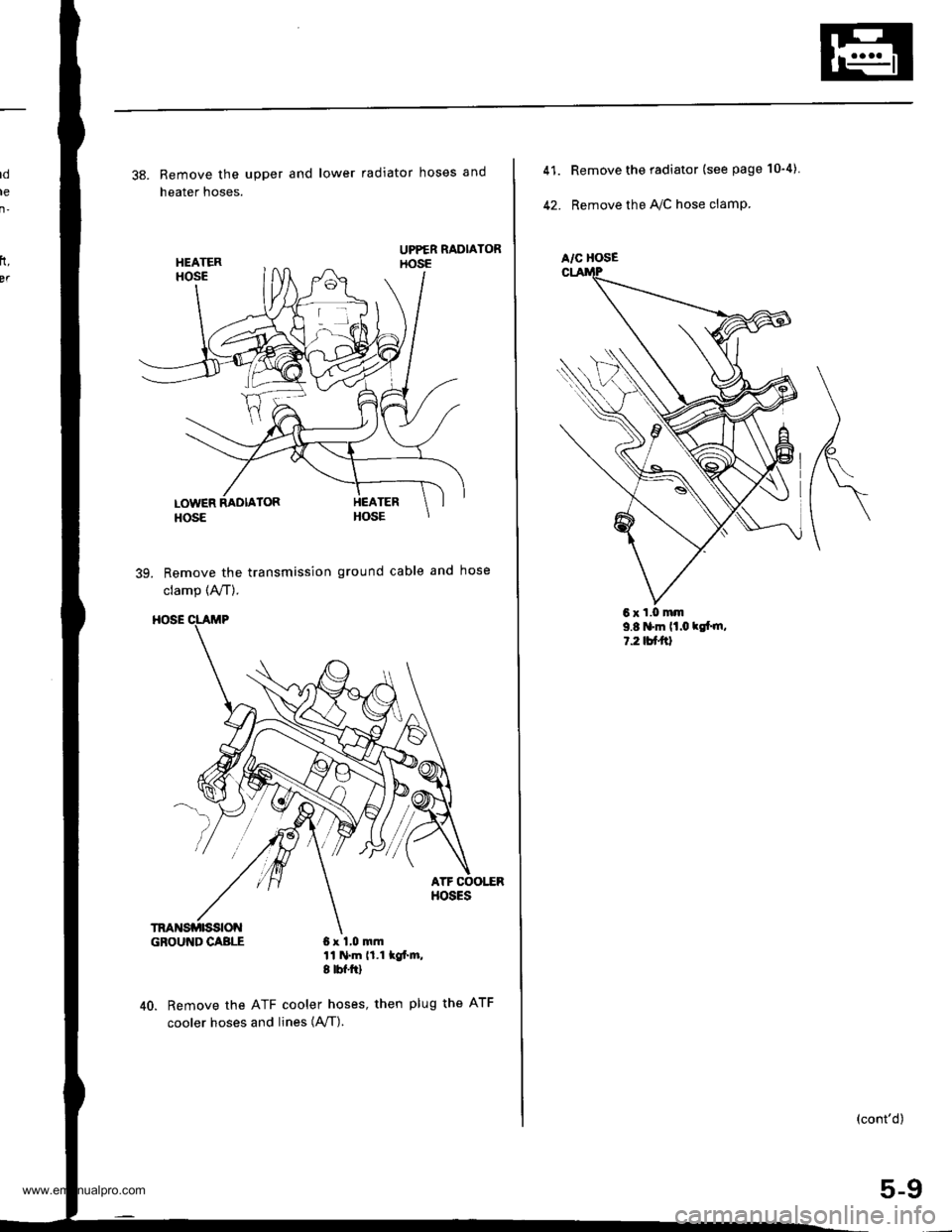

38. Remove the upper and lower radiator hoses and

heater hoses.

39. Remove the transmission ground cable and hose

clamp (A,/T).

GBOUI{DCABLE 6x 1,0 mm11 N.m 11.1 lof'm,I tbf.ftl

40. Remove the ATF cooler hoses, then plug the ATF

cooler hoses and, n"" lAfI).

rt,

BT

6xl,0mm

A/C HOSE

41.

42.

Remove the radiator (see page 10"4).

Remove the IVC hose clamp.

9.8 'm lt.o klt m,l.2tutal

(cont'd)

5-9

www.emanualpro.com

Page 132 of 1395

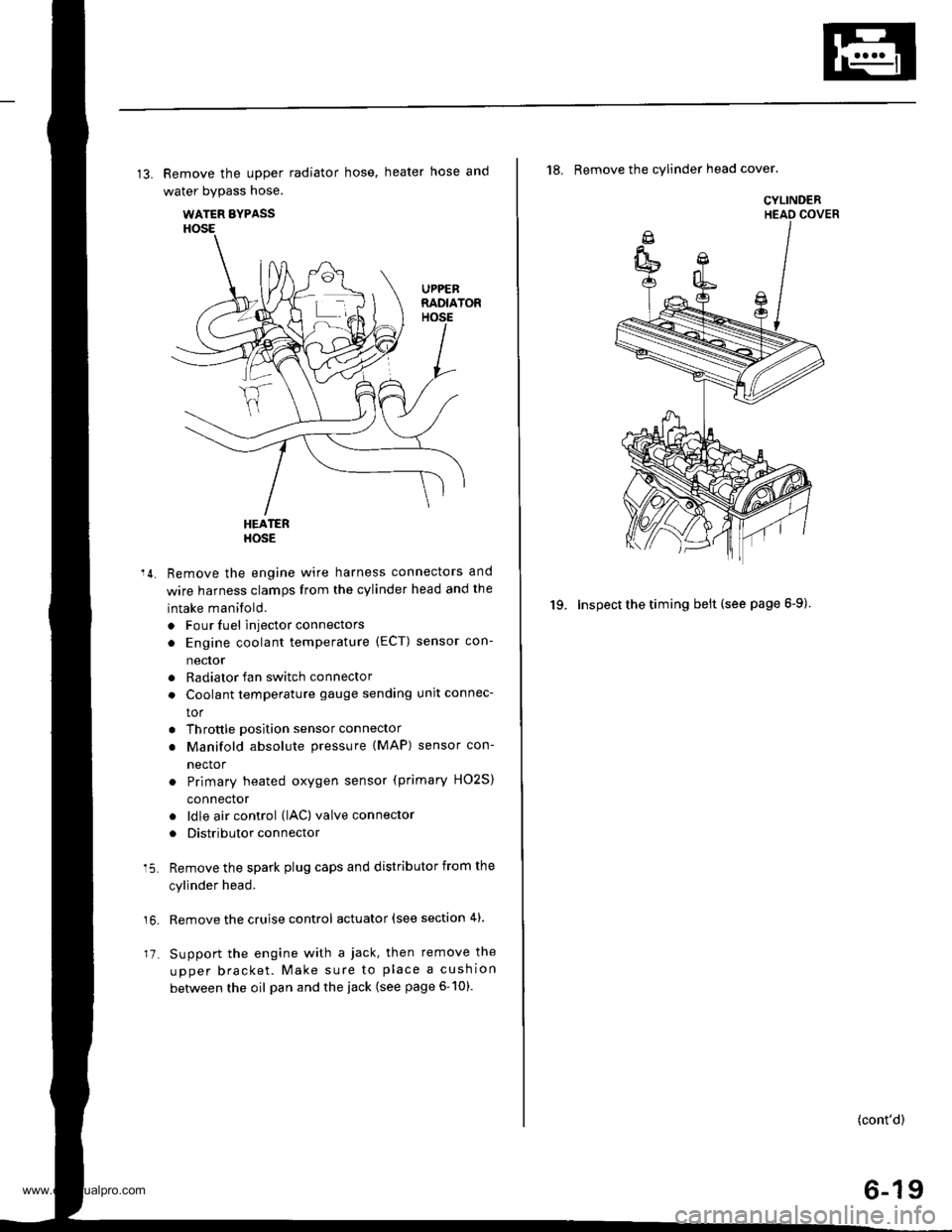

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 190 of 1395

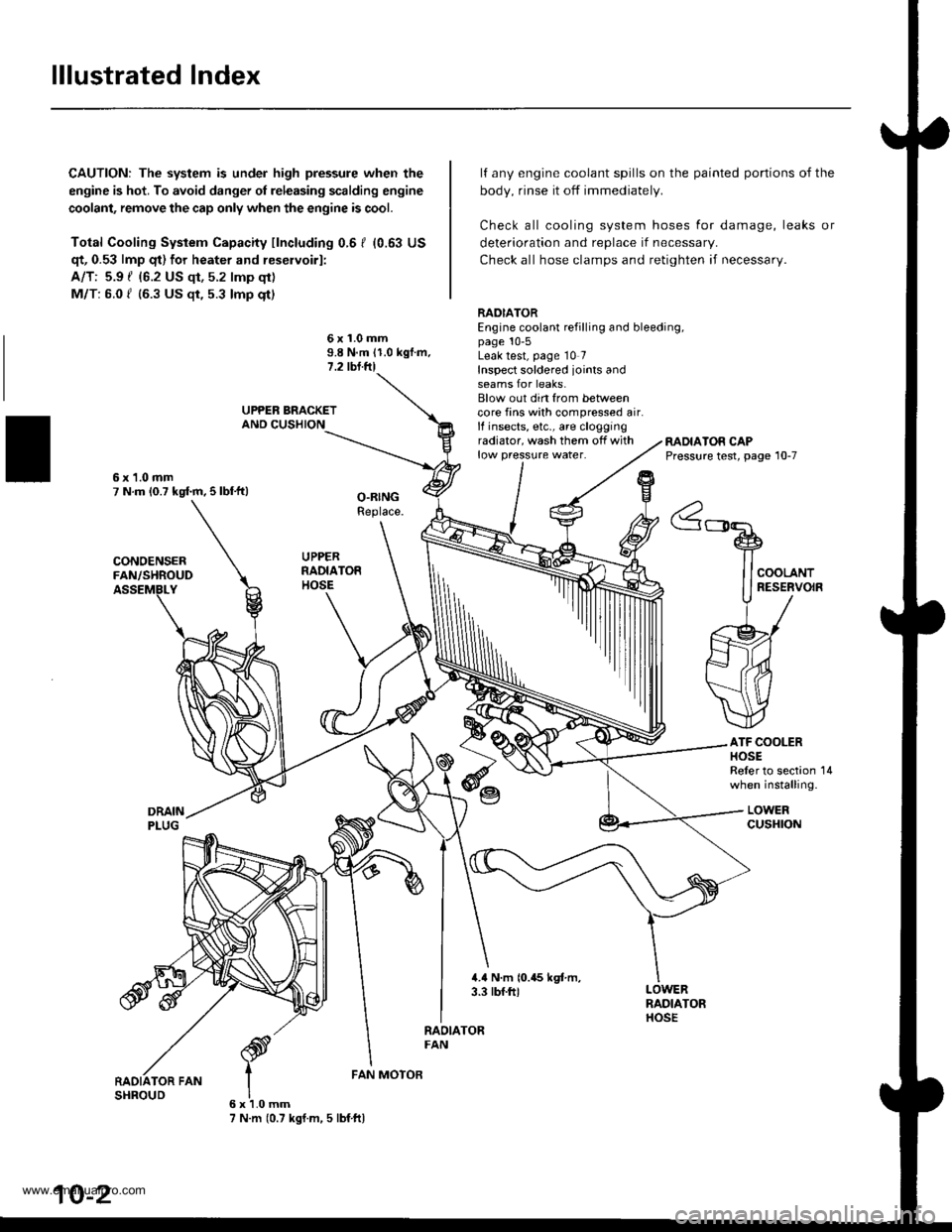

lllustrated Index

CAUTION: The system is under high pressure when the

engine is hot. To avoid danger ol releasing scalding engine

coolant, remove the cap only when the engine is cool.

Total Cooling System Capacity fincluding 0.6 I (0.63 US

qt, 0.53 lmp qt) for heater and reservoirl:

A/T: 5.9 { {6.2 US qt, 5.2 lmp qt)

M/T: 6.0 f (6.3 US $, 5.3 lmp qt)

deterioration and replace if necessar,.

Check all hose clamps and retighten if necessary.

lf any engine coolant spills on the

body, rinse it off immediately.

Check all cooling system hoses

painted portions of the

for damage, leaks or

6x1.0mm9.8 N.m 11.0 kgf.m.1.2 tbl.ftl

RADIATOREngine coolant refilling and bleeding,page 10-5Leak test, page 10 7Inspect soldered joints andseams for leaks.Blow out din from betweencore fins with compressed air.lf insects, etc., are cloggingradiator, wash them off withlow pressure water.RADIATOR CAPPressure test, page 10-7

ATF COOLERHOSEReler to section 14when installing.

LOWERcusHroN

6x1.0mm7 N.m (0.7 kgf.m, 5 lbf ftl

FAN MOTOR

10-2

www.emanualpro.com

Page 318 of 1395

PGM-FI System

Primary Heated Oxygen Sensor (Primary HO2S) lSensor 1) (cont'd)

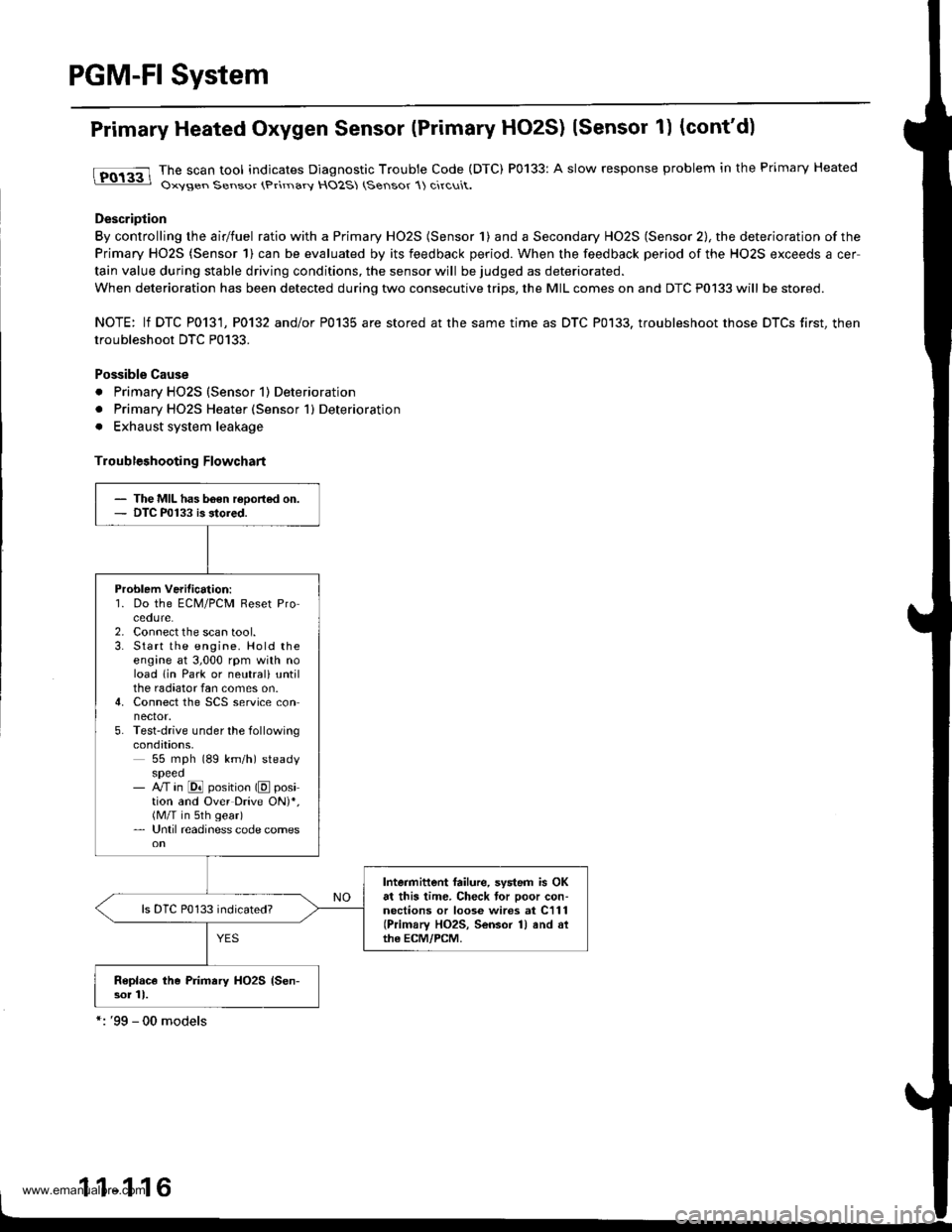

tFO133 lhe scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary Heated: Oxysen Sensor (Primarv HO2S (Sensor 1) circuit.

Description

By controlling the airlfuel ratio with a Primary HO2S (Sensor 1) and a Secondary HO2S (Sensor 2), the deterioration of the

Primary HO2S (Sensor 1) can be evaluated by its feedback period. When the feedback period of the HO2S exceeds a cer

tain value during stable driving conditions, the sensor will be judged as deteriorated.

When deterioration has been detected during two consecutive trips, the MIL comes on and DTC P0133 will be stored.

NOTE: lf DTC P0131, P0132 and/or P0135 are stored at the same time as DTC P0133. troubleshoot those DTCS first, then

troubleshoot DTC P0133.

Possible Cause

. Primary HO2S (Sensor 1) Deterioration

. Primary HO2S Heater (Sensor 1) Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has b6€n reoorted on.- DTC P0133 is stored.

Problem Verilication:'1. Do the ECM/PCM Reset Procedure.2. Connect the scan tool.3. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutrali untilthe radiator fan comes on.4. Connect the SCS service connector.5. Test-drive under the followingcondations,55 mph (89 km/h) steadyspeed- M in @ position (E position and Over Drive ON)*,(M/T in sth gear)- Until readiness code comes

Intermittent failure, system is OKat this time. Check tor poor con-nections or loose wires at C111(Primary HO2S, Sensor 1) and althe ECM/PCM.

Replace the Primary HO2S {Sen-sor 11.

1 1-1 16

www.emanualpro.com

Page 326 of 1395

PGM-FI System

Fuel Supply System

[POliil The"""ntool indicates Diagnostic Troubte Code (DTC) p0'171:Thefuet system istoo lean.

[Fo17ZJ rh""""ntool indicates Diagnostic Troubte code {DTc) p0172:Thefuel svstem istoorich.

Description

By monitoring the Long Term Fuel rrim, long term malfunctions in the fuel system will be detected.lf a malfunction has been detected during two consecutive trips, the MIL will come on and DTc p0171 and/or pol72 will bestored.

NOTE: lf someof the DTCS listed below are stored atthesametimeas DTC P017'l and/or p0172, troubleshoot those DTcsfirst, then troubleshoot DTC P0171 and/or PO1i2.

P0107, P0108, P1128, P'1129: MAP Sensor

P0135: Primary HO2S (Sensor 1)Heater

P0137, P0138: Secondary HO2S {Sensor 2)P0141: Secondary H02S (Sensor 2) Heater

P0441*r: EVAP System lnsufficient Purge FtowP1456*,, P'l457 *?i EVAP System Insufficient purge Ftow

Possible Cause

DTC P0171

too lean

*1: '97 model*2: '98 - 00 models

Fuel Pump insufficient flow/pressure

Fuel Feed Line clogged. leaking

Fuel Pressure Regulator stuck openFuel Filter clogged

Fuel Injector clogged, air leakage

Gasoline doesn't meet Owner's Manual spec.Primary HO2S (Sensor 1) deteriorated

Valve Clearance

Exhaust leak

Fuel Pressure Regulator clogged, stuck closedFuel Return Pipe clogged

Fuel Injector leaking

Gasoline doesn't meet Owner's Manual spec.Primary H02S (Sensor 1) deteriorated

EVAP Purge Control Solenoid Valve leaking, stuck openedValve Clearance

DTC P0172

flch

11-124

www.emanualpro.com

Page 402 of 1395

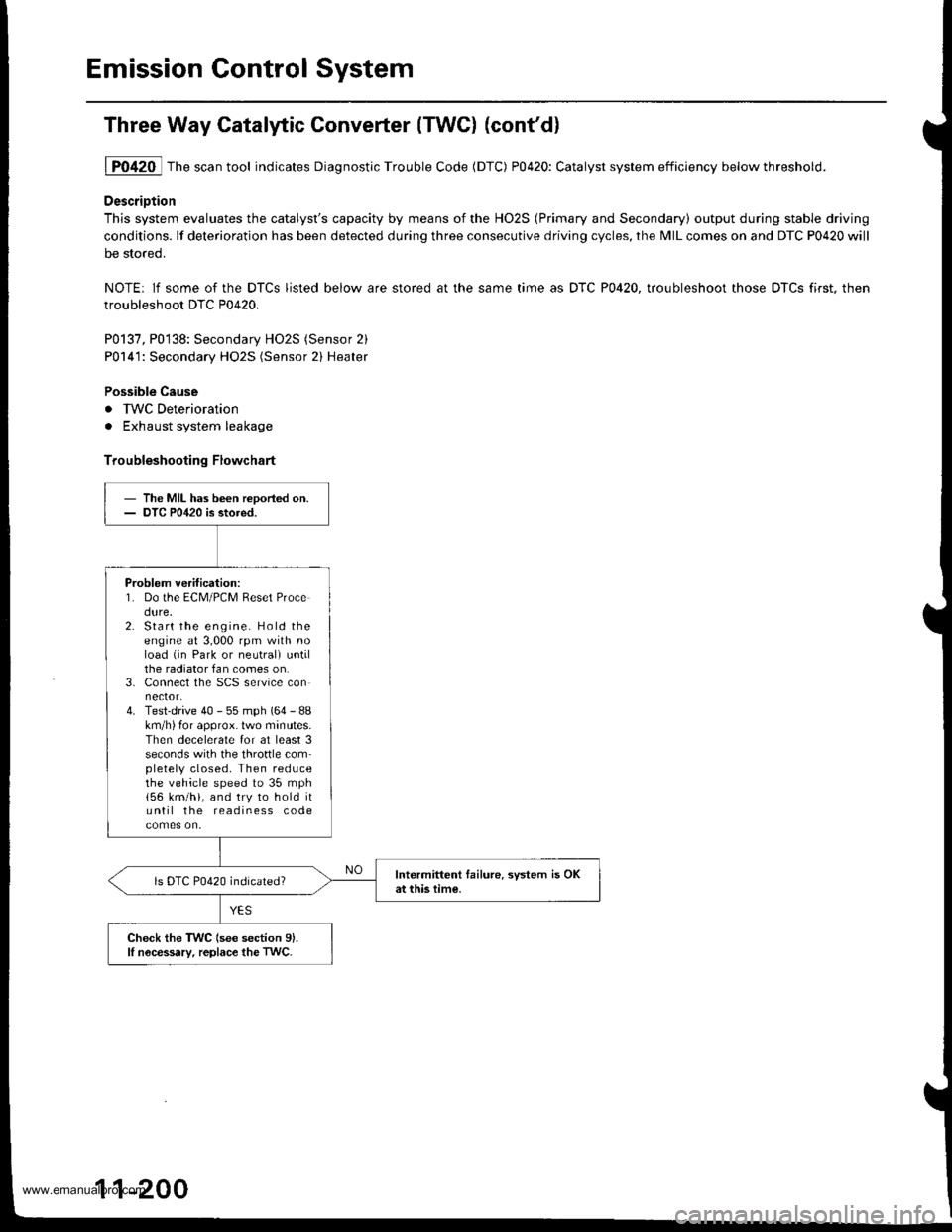

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 1141 of 1395

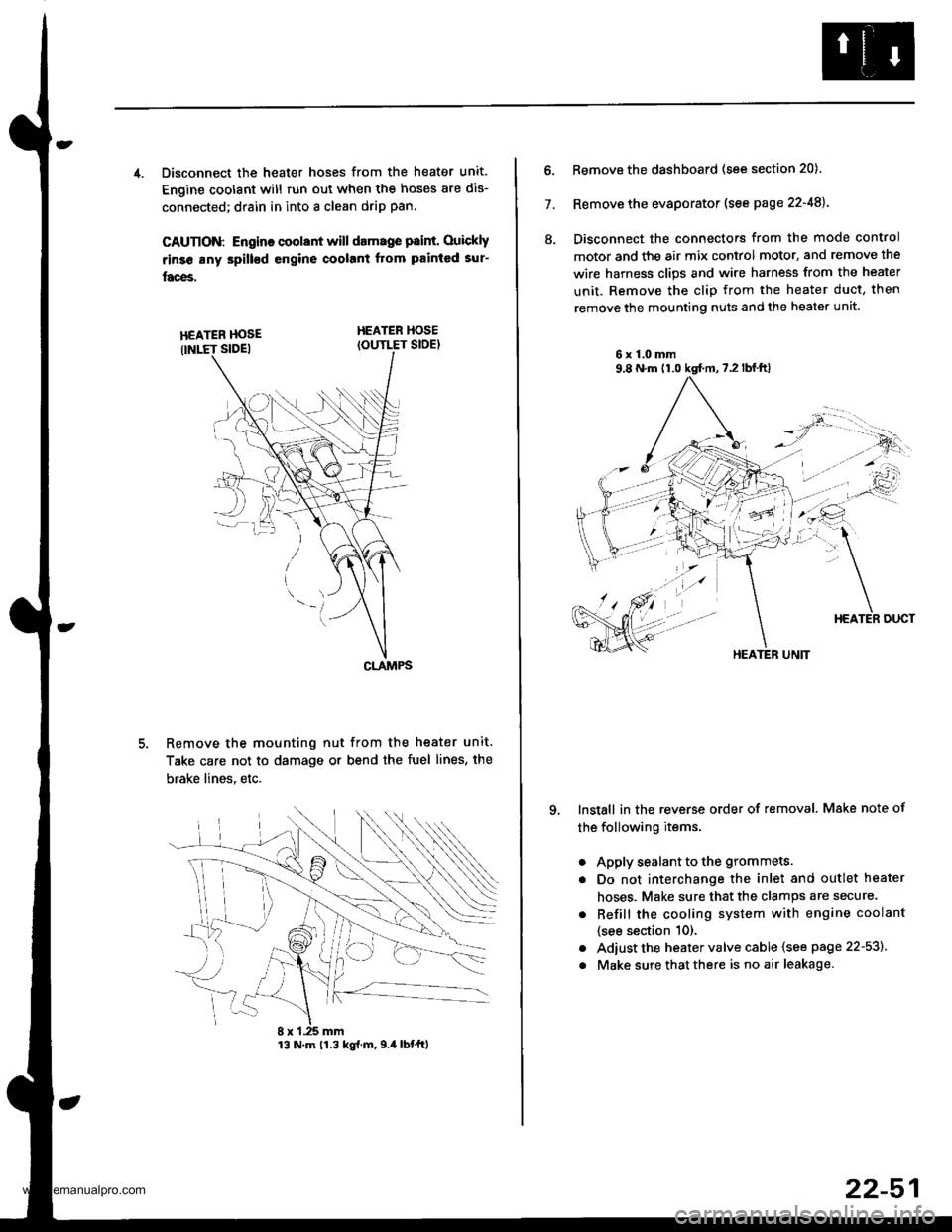

4. Disconnect the heater hoses from the heater unit.

Engine coolant will run out when the hoses are dis-

connected; drain in into a clean drip pan.

CAUTION: Engino coolant will damage p8int. Ouickly

rinse any spill€d engine coolant Itom painted sur-

faces.

HEATER HOSEIOUTLET SIDE)

Remove the mounting nut from the heater unit.

Take care not to damage or bend the fuel lines, the

brake lines. etc.

CLAMPS

13 N.m 11.3 kg{.m,9.4 lbtftl

22-51

7.

ll.

Remove the dashboard (see section 20).

Remove the evaporator (see page 22-48).

Disconnect the connectors from the mode control

motor and the air mix control motor, and remove the

wire harness clips and wire harness from the heater

unit. Remove the clip from the heater duct, then

remove the mounting nuts and the heater unit

6x1.0mm9,8 N.m (1.0 kgt m,7.2lblft)

qInstall in the reverse order of removal. Make note of

the following items.

a

a

a

a

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

{see section 10).

Adiust the heater valve cable (see page 22-53).

Make sure that there is no air leakage.

HEATER UNIT

www.emanualpro.com