Rear hatch glass HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 41 of 1395

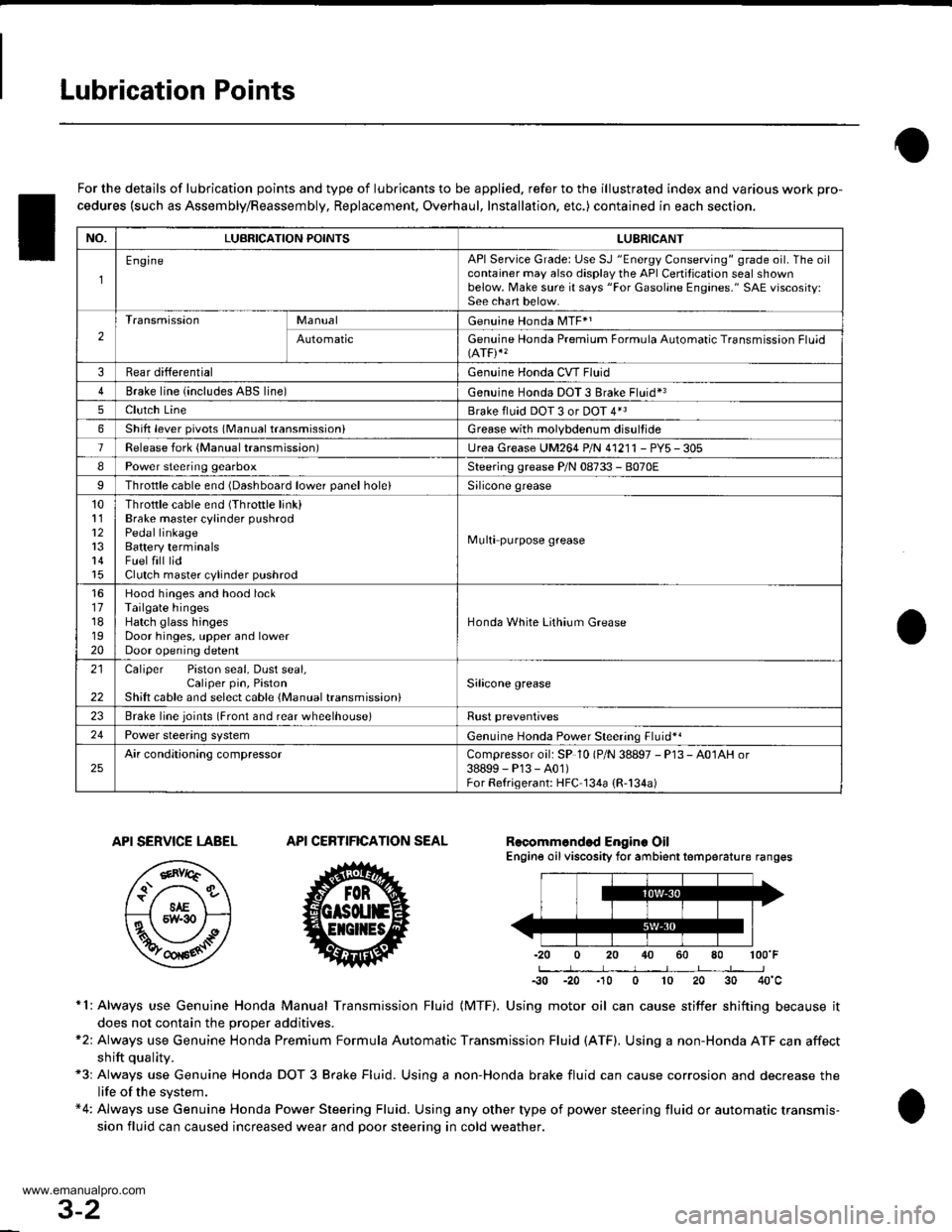

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 982 of 1395

Body

Bumpers

Front Bumper Removal and

fnstaflation .........20-72

Rear Bumper Removal and

fnstaflation .........20-74

'Dashboard

lnstrument Panel Removal and

lnstallation .........20-47

Driver's Dashboard Lower Cover and

Knee Bolster Removal and

Installation .........20-48

Glove Box Removal and

lnstallation .........20-49

Center Pocket Removal and

lnstallation .........20-49

Center Dashboard Lower Cover

Removal and lnstallation ............ 20-50

Center Panel Removal and

lnstallation .........20-50

Power Window Switch Removal and

lnstallation .........20-51

Center Air Vent Removal and

lnstallation .........20-51

Side Air Vent Removal and

fnstallation .........20-52

Side Defogger Trim Removal and

fnstallation .........20-52

Dashboard Removal and

lnstallation .........20-53

Dashboard Frame Replacement ..... 20-55

Doors

Component Location Index

Front Door ,,...,,,,20-2

Rear Door ...........20-4

Tailgate Door ................................ 20-6

Fenderwell

Front Wheelwell Protector

Replacement .....20-89

Inner Fender Replacement .,.....,.,.... 20-89

Rear Wheelwell Protectol

Replacement .....20-90

Fuel Pipe Protector Replacement ... 20-90

Rear Air Outlet Replacement .......... 20-91

*Frame Repair Chart .............................. 20-106

Front Grille

Repf acement .........20-77

Glass

Component Location Index ............ 20-29

Hood

Replacement ......,,,20-75

Adjustment ............20-76

*lnterior Trim

Component Location Index ............ 20-40

Mirrors

Component Location Index .........,,, 20-26

Moldings

Roof Molding Replacement ............ 20-84

Door Moldings Replacement .......... 20-85

Openers

Component Location Index ............ 20-92

Rear Hatch Glass

Replacement .........20-74

Disassembly and Reassembly ........ 20-79

Adiustment ............20-81

Rear Weatherstrip Replacement .... 20-83

Seats

Component Location Index ............ 20-56

Side Sill Panel

Repfacement .........20-87

Spare Tire Cover

Emblem Installation ........................ 20-88

Sub-frame ..................20-104

Wiper/Washer

Component Location lndex ,,,,,....... 20-97

www.emanualpro.com

Page 987 of 1395

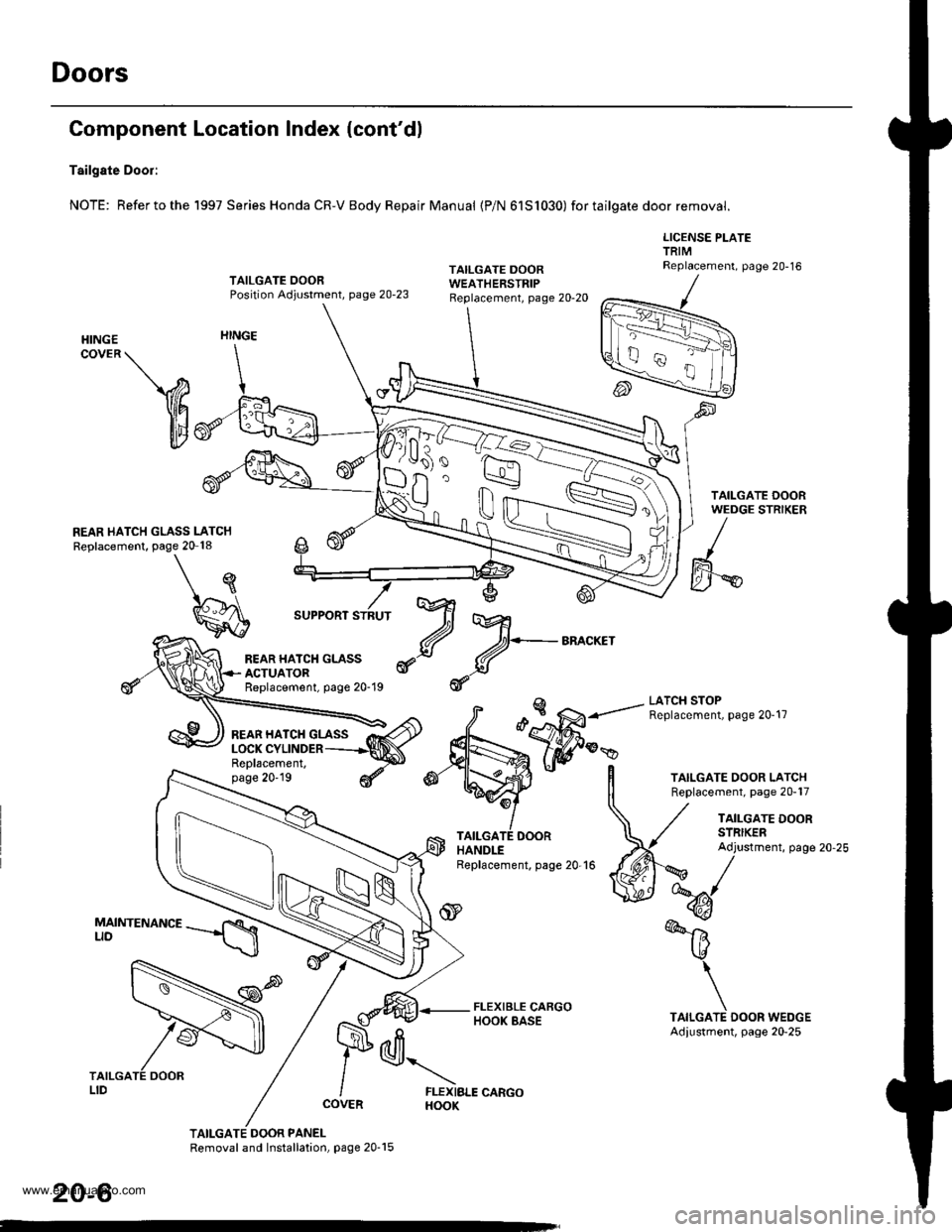

Doors

Component

Tailgate Door:

NOTE: Refer to the

Location Index (cont'dl

1997 Series Honda CR-V Body Repair Manual {P/N 61S1030) for tailgate door removal.

LICENSE PLATETRIMReplacement, page 20-16TAILGATE OOORPosition Adjustment, page 20-23

TAILGATE DOORWEATHERSTRIP

HINGECOVER \

V

illt

REAR HATCH GLASS LATCHReplacement, page 20 18

HINGE

\

I

SUPPORT STRUT

€\A

LATCH STOPReplacement, page 20-17

Replacement,page 20'19

TAILGATE DOOR PANELRemoval and Installation, page 20-15

TAILGATE DOOR LATCHReplacement, page 20-17

TAILGATE DOORHANDLEReplacement, page 20-16

TAILGATE DOORSTRIKERAdjustment, page 20-25

k@/

%

-6

\

TAILGATE DOOR WEDGEAdiustment, page 20-25

N

REAR HATCH GLASSACTUATORReplacement, page 20-19

REAR HATCH GLASS

lVr

d+-BA^cKEr

d

d\

FLEXIBLE CARGOHOOK

20-6

www.emanualpro.com

Page 999 of 1395

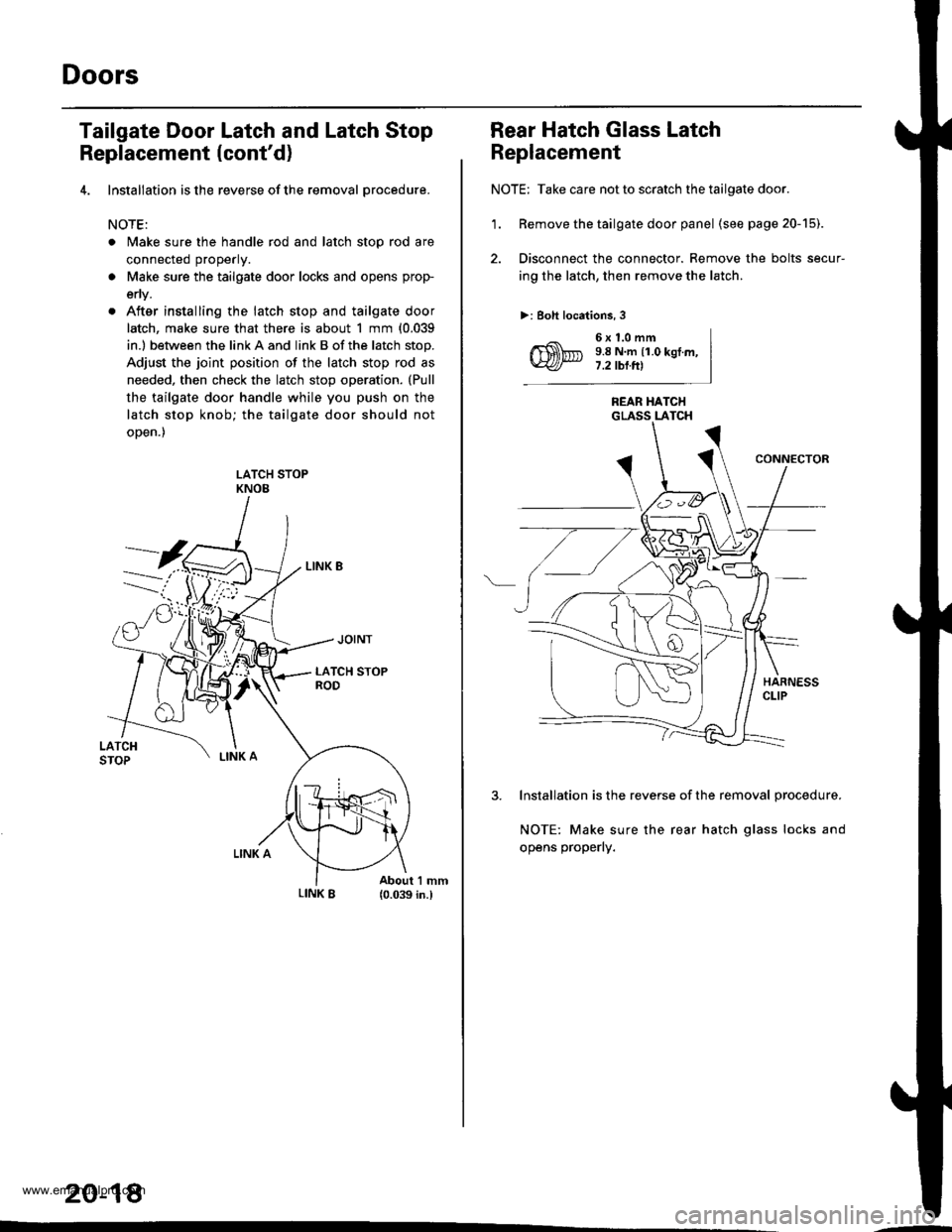

Doors

Tailgate Door Latch and Latch Stop

Replacement (cont'd)

4. lnstallation is the reverse of the removal orocedure.

NOTE:

. Make sure the handle rod and latch stop rod are

connected properly.

a Make sure the tailgate door locks and opens prop-

env.

. After installing the latch stop and tailgate door

latch, make sure that there is about 1 mm {0.039

in.l between the link A and link B of the latch stop.

Adjust the joint position of the latch stop rod as

needed, then check the latch stop operation. (Pull

the tailgate door handle while you push on the

latch stop knob; the tailgate door should not

oDen.)

LATCH STOPKNOE

20-18

Rear Hatch Glass Latch

Replacement

NOTE: Take care not to scratch the tailgate door.

'1. Remove the tailgate door panel (seepage20-15).

2. Disconnect the connector. Remove the bolts secur-

ing the latch, then remove the latch.

>: Boh locations, 3

6x1.0mm9.8 N.m {1.0 kgI.m,7.2 tbl.Itl

REAR HATCHGLASS LATCH

3. Installation is the reverse of the removal procedure.

NOTE: Make sure the rear hatch glass locks and

opens properly.

www.emanualpro.com

Page 1000 of 1395

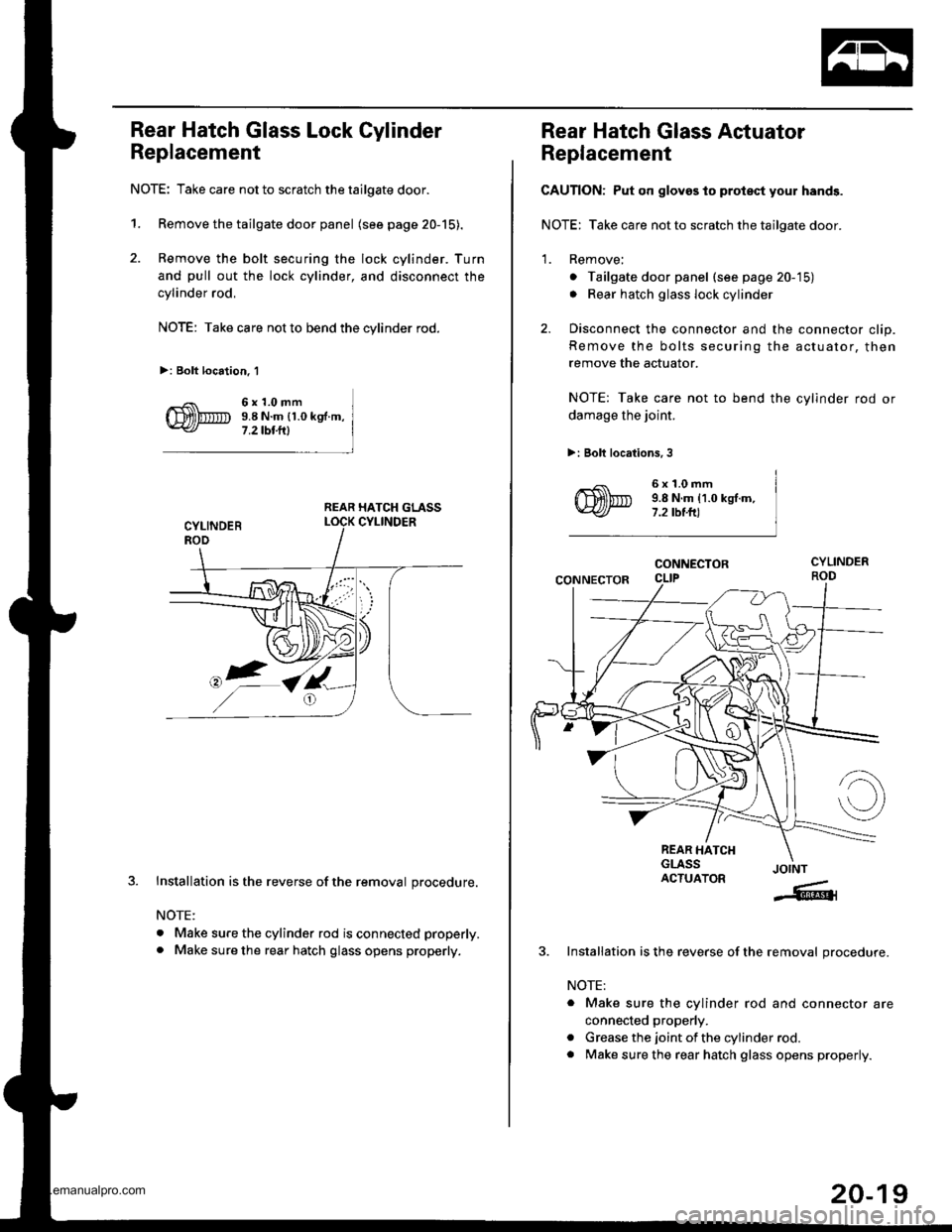

Rear Hatch Glass Lock Cylinder

Replacement

NOTE: Take care not to scratch the tailgate door.

1. Remove the tailgate door panel (see page 20-15).

2. Remove the bolt securing the lock cylinder. Turn

and pull out the lock cylinder, and disconnect the

cylinder rod,

NOTE: Take care not to bend the cylinder rod.

>: Bolt location. 1

6x1.0mm9.8 N.m {1.0 kg .m,

7 .2 tbt.lll

REAR HATCH GLASS

J.Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod is connected properly.

. Make sure the rear hatch glass opens properly.

Rear Hatch Glass Actuator

Replacement

CAUTION: Put on gloves to protsct your hands.

NOTE: Take care not to scratch the tailgate door.

1. Remove;

o Tailgate door panel (see page 20-'15)

. Rear hatch glass lock cylinder

2. Disconnect the connector and the connector clip.

Remove the bolts securing the actuator, then

remove the actuator.

NOTE: Take care not to bend the cylinder rod or

damage the joint.

>: Bolt locations, 3

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 tbt.ft)

CONNECTOR

CONNECTOR

REAR HATCHGLASSACTUATORJOINT

-6{

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the cylinder rod and connector are

connected properly.

. Grease the joint of the cylinder rod.

. Make sure the rear hatch glass opens properly.

20-19

www.emanualpro.com

Page 1016 of 1395

22.

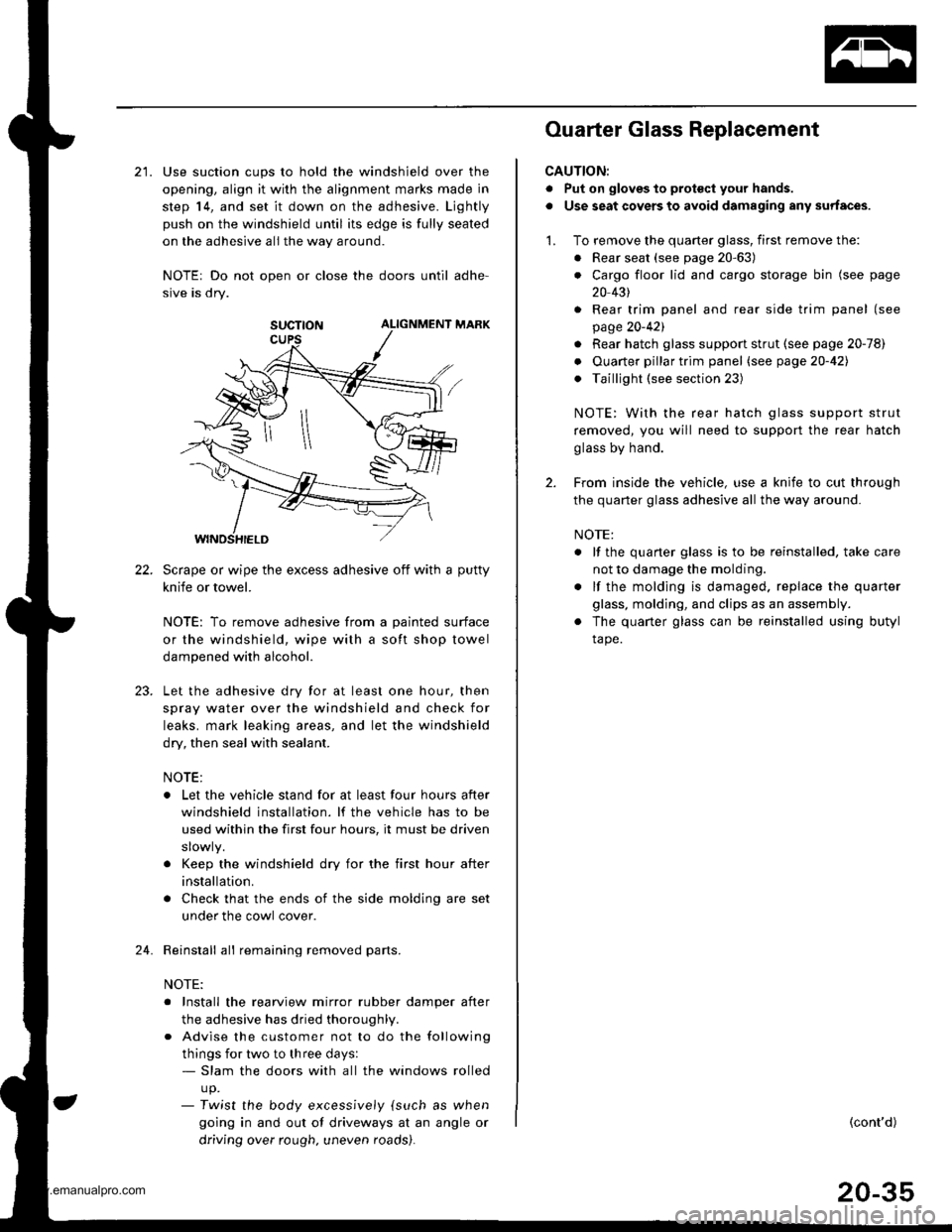

21. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 14, and set it down on the adhesive. Ljghtly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTEr Do not open or close the doors until adhe-

sive is dry.

SUCTTON ALIGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the windshield, wipe with a soft shop towel

dampened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the windshield and check for

leaks. mark leaking areas, and let the windshield

dry, then seal with sealant.

NOTE:

. Let the vehicle stand for at least four hours after

windshield installation. lf the vehicle has to be

used within the first four hours, it must be driven

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl,.

. Advise the customer not to do the following

things for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excess,vely {such as when

going in and out of driveways at an angle or

driving over rough. uneven roads).

24.

Ouarter Glass Replacement

CAUTION:

. Put on gloves to prot€ct your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the quarter glass, first remove the:

. Rear seat (see page 20-63)

. Cargo floor lid and cargo storage bin (see page

20 431

. Rear trim panel and rear side trim panel (see

page 20-421

. Rear hatch glass support strut (see page 20-78)

. Ouarter pillar trim panel (see page20-421

. Taillight (see section 23)

NOTE: With the rear hatch glass support strut

removed, you will need to support the rear hatch

glass by hand.

2. From inside the vehicle, use a knife to cut through

the quarter glass adhesive all the way around.

NOTE:

. lf the quaner glass is to be reinstalled, take care

not to damage the molding.

. lf the molding is damaged. replace the quarter

glass, molding, and clips as an assembly.

. The quarter glass can be reinstalled using butyl

tape.

(cont'd)

20-35

www.emanualpro.com

Page 1022 of 1395

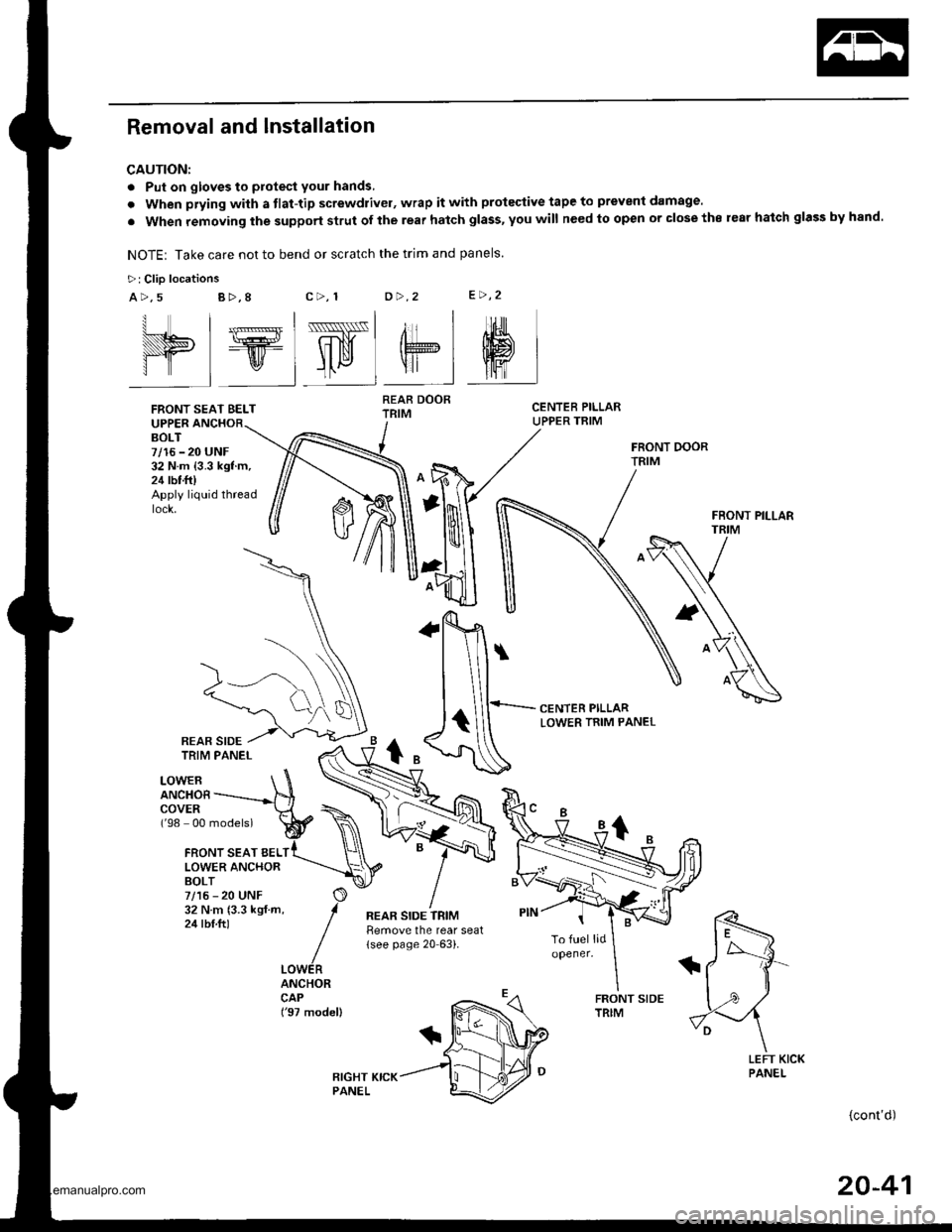

Removal and Installation

CAUTION:

. Put on gloves to protect your hands,

. When prying with a tlat-tip screwdrivel, wrap it with protective tape to prevent damage.

. When removing the support strut of the rear hatch glass, you will need to open or close the rear hatch glass by hand.

NOTE: Take care not to bend or scratch the trim and panels.

>: Clio locations

a>,5c>, 1o>.2e>,2B >,8

UPPERBOLT7/16 - 20 UNF32 N.m {3.3 kgf.m,24 rbt.ft)Apply liquid thread

CENTER PILLARLOWER TRIM PANEL

LOWERANCHOBCOVER('98 00 models)

{cont'd)

I l_lss-l , | 'rrl

elElw"lel sl

FRONT SEAT BELT

FRONT SEAT BELLOWER ANCHORBOLT7/15 - 20 UNF32Nm(3.3kgf.m,24 tbt.ftl

ANCHORCAP('97 model)

REAR DOORTRIM

REAR SIDE TRIMtlemove the rear seat(see page 20 63).

REAR SIDE

20-41

www.emanualpro.com

Page 1023 of 1395

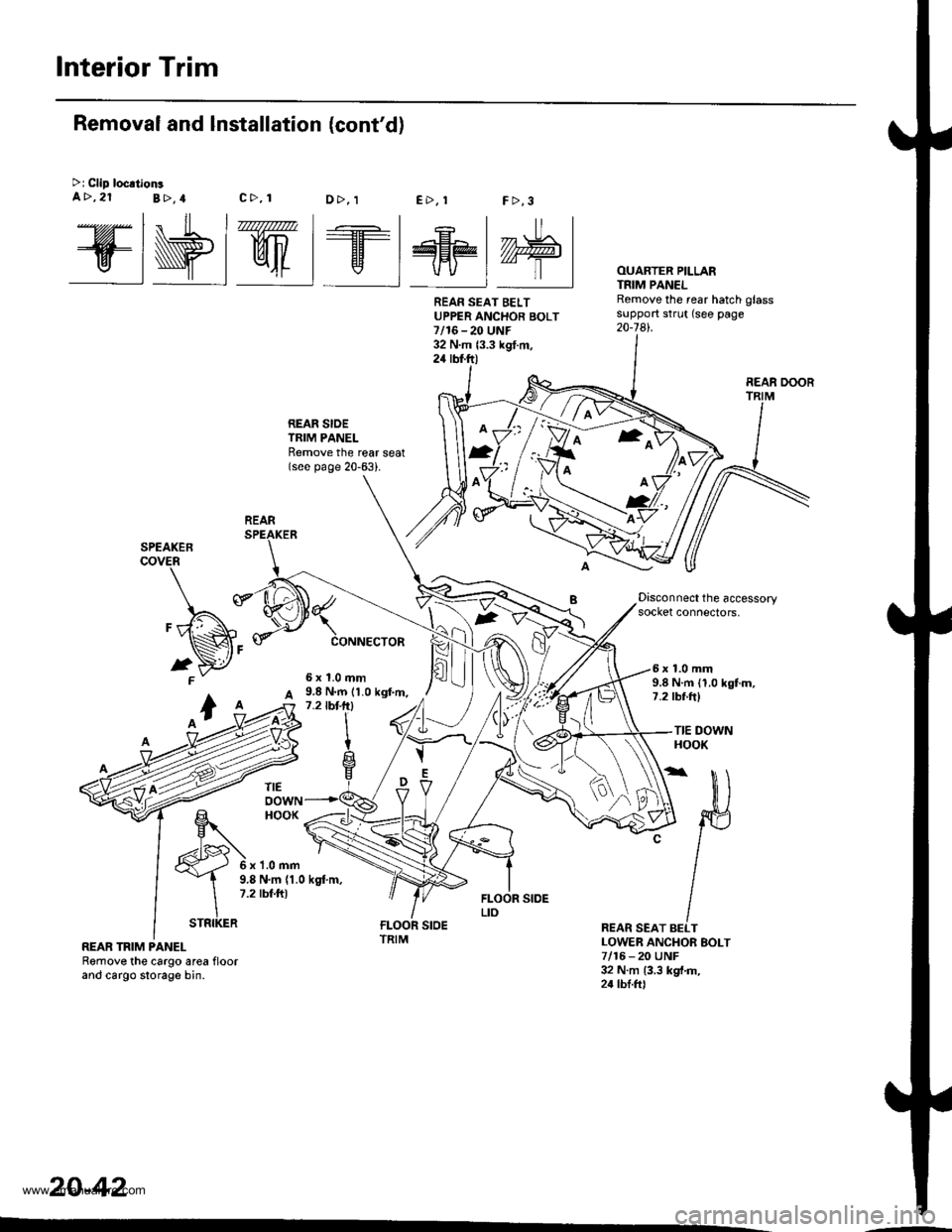

Interior Trim

@wt we@M

REAR SIOETRIM PANELRemove the reat seat(see page 20-63).

FCONNECTOR

2

OUARTER PILLARTNIM PANELRemove the rear hatch glasssupport strut (see page20-741.

Removal and Installation (cont'd)

>i Clip loc.tionsa>,21B>,4c>, 1E>. !F >,3D>, 1

Disconnect the accessorysocket connectors,

9.8 N.m (1.0 kgf.m,1.2lbt-lrl

5x1.0mm6x1.0mm9.8 N.m (1.0 kgtm,7.2 tbf ftl

TIE DOWNHOOK

6x1.0mm

TIEoowNHOOK

v

O\A

D

REAR SEAT BELTLOWER ANCHOR EOLT7/16 - 20 UNF32 N.m {3.3 kgt.m,24 tbl.frl

9.8 N.m (1.0 kgt m,7.2 tbf.ft)

REAR TRIM PANELRemove the cargo area floorand cargo slorage bin.

20-42

REAN SEAT BELTUPPER ANCHOR BOLT7/16-20 UNF32 N.m {3.3 kgt.m,24 rbt.ft)

REAR DOOR

REAR

ffi

STRIKER

www.emanualpro.com

Page 1025 of 1395

lnterior Trim

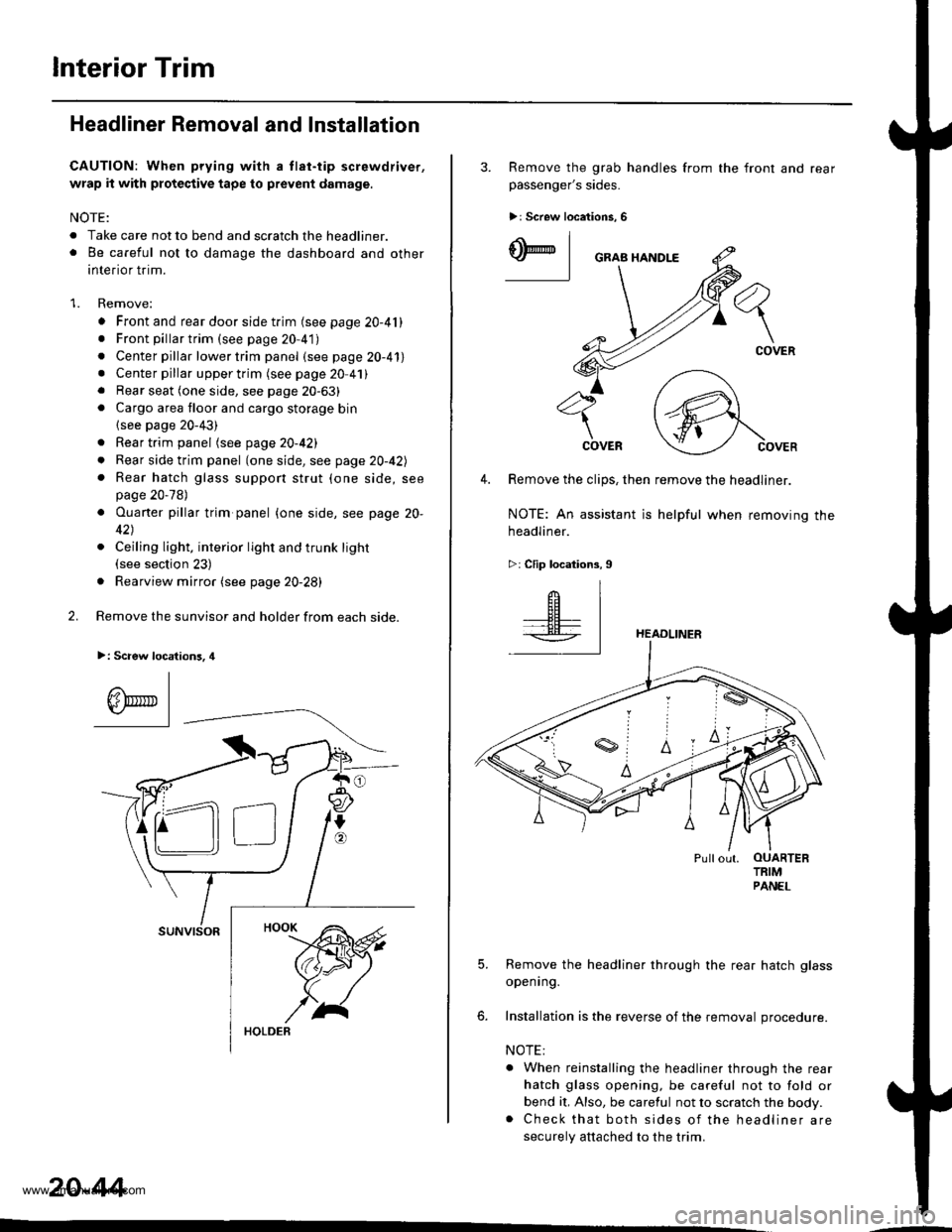

Headliner Removal and Installation

CAUTION: When prying with a tlat-tip screwdriver,

wrap it with protective tape to prevent damage.

NOTE:

. Take care not to bend and scratch the headliner.o Be careful not to damage the dashboard and other

interior trim.

1. Remove:

. Front and rear door side trim (see page 20-41). Front pillartrim (see page 20-41)

. Center pillar lower trim panel (see page 20-41). Center pillar upper trim (see page 20 41). Rear seat (one side, see page 20-63). Cargo area floor and cargo storage bin

{see page 20-43)

. Rear trim panel (see page 20-421

. Rear side trim panel (oneside, see page 20-42l,

. Rear hatch glass support strut (one side, seepage 20-78)

. Ouaner pillar trim panel {one side, see page 20-

42)

. Ceiling light, interior light and trunk light(see section 23)

. Rearview mirror (see page 20-28)

2. Remove the sunvisor and holder from each side.

>: Scaew location3, 4

I

A\"r- |Yr* || -

suNvtsoR

20-44

3. Remove the grab handles from

passenger's sides.

>r Screw locations, 6

the front and rear

ry_l

COVER

4. Remove the clips, then remove the headliner.

NOTE: An assistant is helpful when removing the

headliner.

>: Clip locations,9

HEADLINER

Pullout. OUARTERTRIMPANEL

5. Remove the headliner through the rear hatch glass

openrng.

6. Installation is the reverse of the removal procedure.

NOTE:

. When reinstalling the headliner through the rear

hatch glass opening, be careful not to fold or

bend it, Also, be careful not to scratch the body.. Check that both sides of the headliner are

securely attached to the trim.

www.emanualpro.com

Page 1029 of 1395

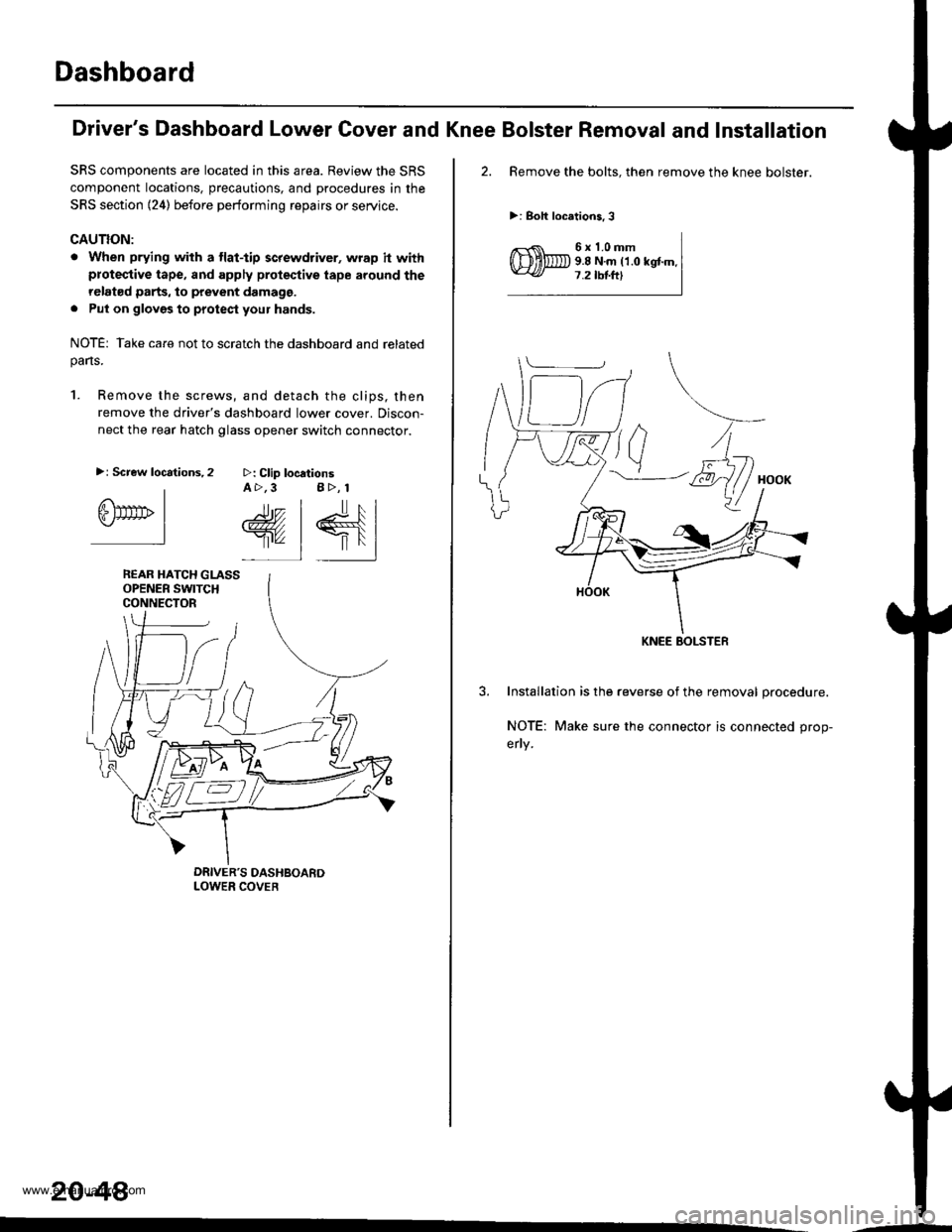

Dashboard

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

GAUTION:

. When prying with a tlat-tip screwdriver, wrap h withproteqtive tape, and apply protective tape around the

relat€d parts, to prevent damage,

. Put on glovgs to protect your hands.

NOTE: Take care not to scratch the dashboard and relatedpans.

1. Remove the screws, and detach the clips, then

remove the driver's dashboard lower cover. Discon-

nect the rear hatch glass opener switch connector.

>: Clip locationsA >,3 B>, 1

rr.- | lr, l

@, | €{lr'" 1 |'l

>: Screw locations,2

IGlTtrrrb I.-l

REAR HATCH GLASSOPENER SWITCHCONNECTOR

20-48

'-

Driver's Dashboard Lower Cover and Knee Bolster Removal and Installation

2. Remove the bolts. then remove the knee bolster.

>: Boh locations,3

6x1.0mm9.8 N.m ('1.0 kgtm.7.2 tbtftl

3. Installation is the reverse of the removal procedure.

NOTE: Make sure the connector is connected prop-

erly.

KNEE BOLSTEF

www.emanualpro.com