door control HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 407 of 1395

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

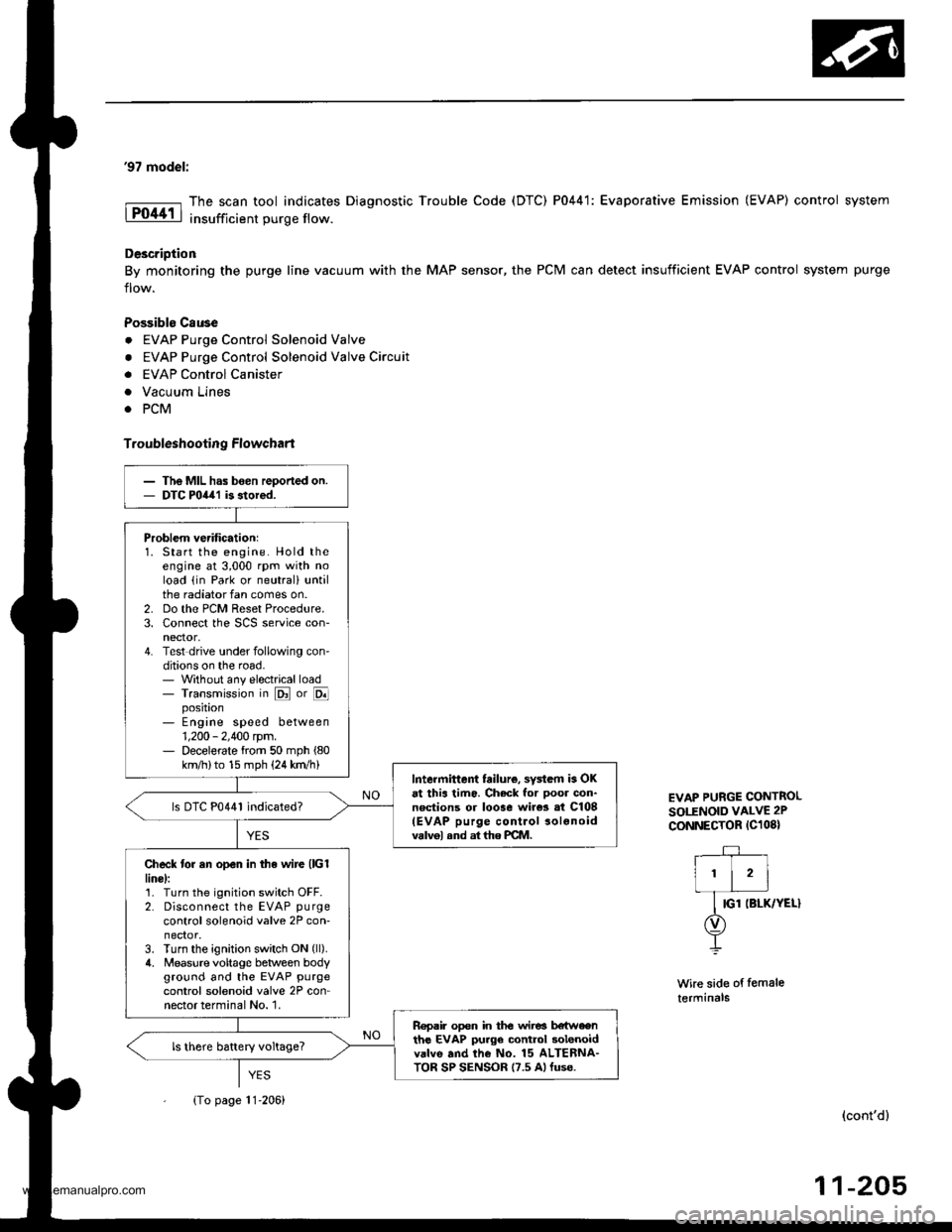

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 983 of 1395

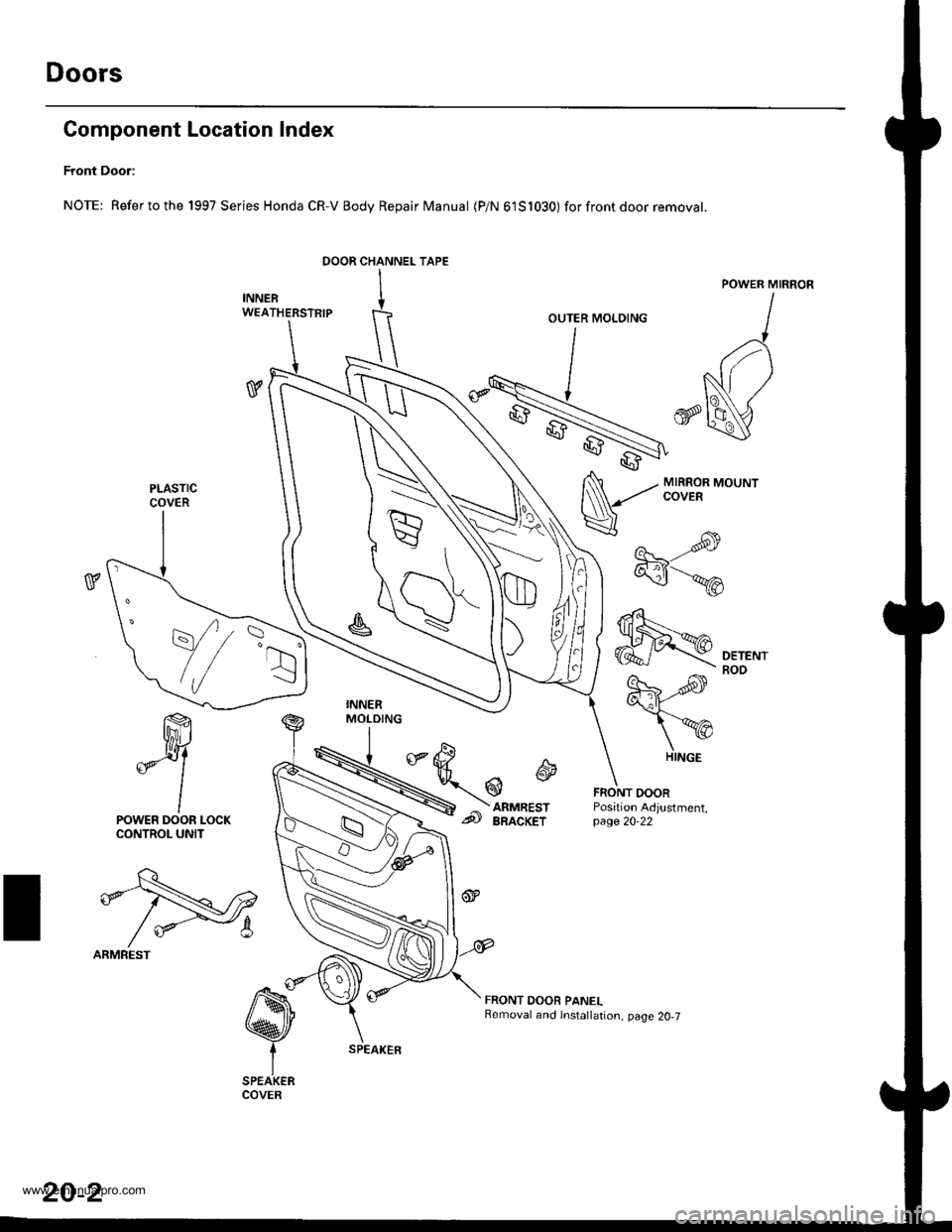

Doors

Component Location Index

Front Door:

NOTE: Refertothe 1997 Series Honda CR-V Body Repair Manual (P/N 61S1030) forfrontdoor removat.

ffi

*Y

lPOWER DOOR LOCKCONTROL UNIT

t\q

efl-Nr2

/ *-8

ARMREST

OOOR CHANNEL TAPE

INNERW€ATHERSTRIP

v

MIRROR MOUNTCOVER

----s-re

"\-,-.*

€fl

FRONT DOORPosition Adjustment,page 20-22

FRONT DOOR PANELRemoval and lnstallation, page 20,7

OUTER MOLDING

PLASTICCOVER

,.r=R

\//

::r

HINGE

20-2

www.emanualpro.com

Page 1100 of 1395

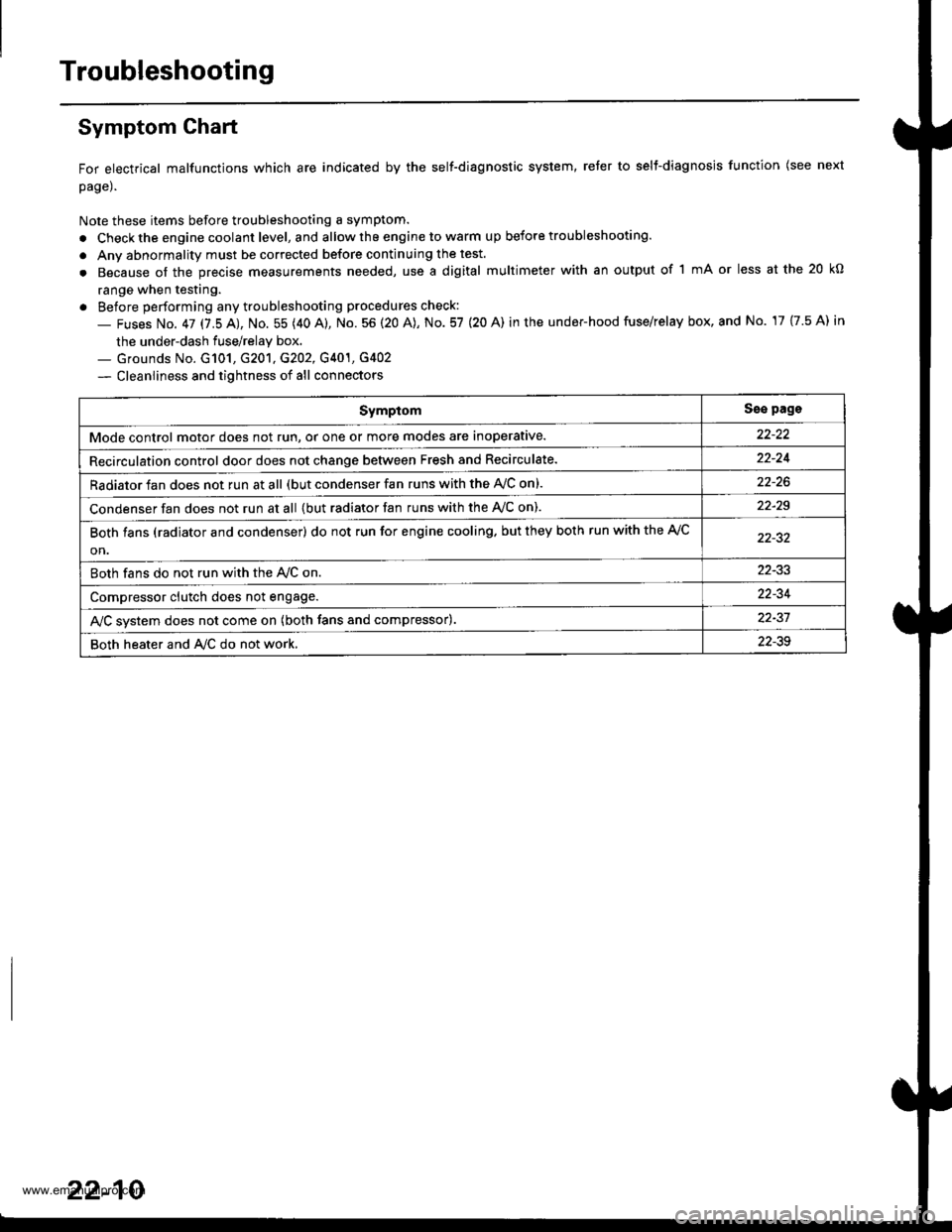

Troubleshooting

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com

Page 1101 of 1395

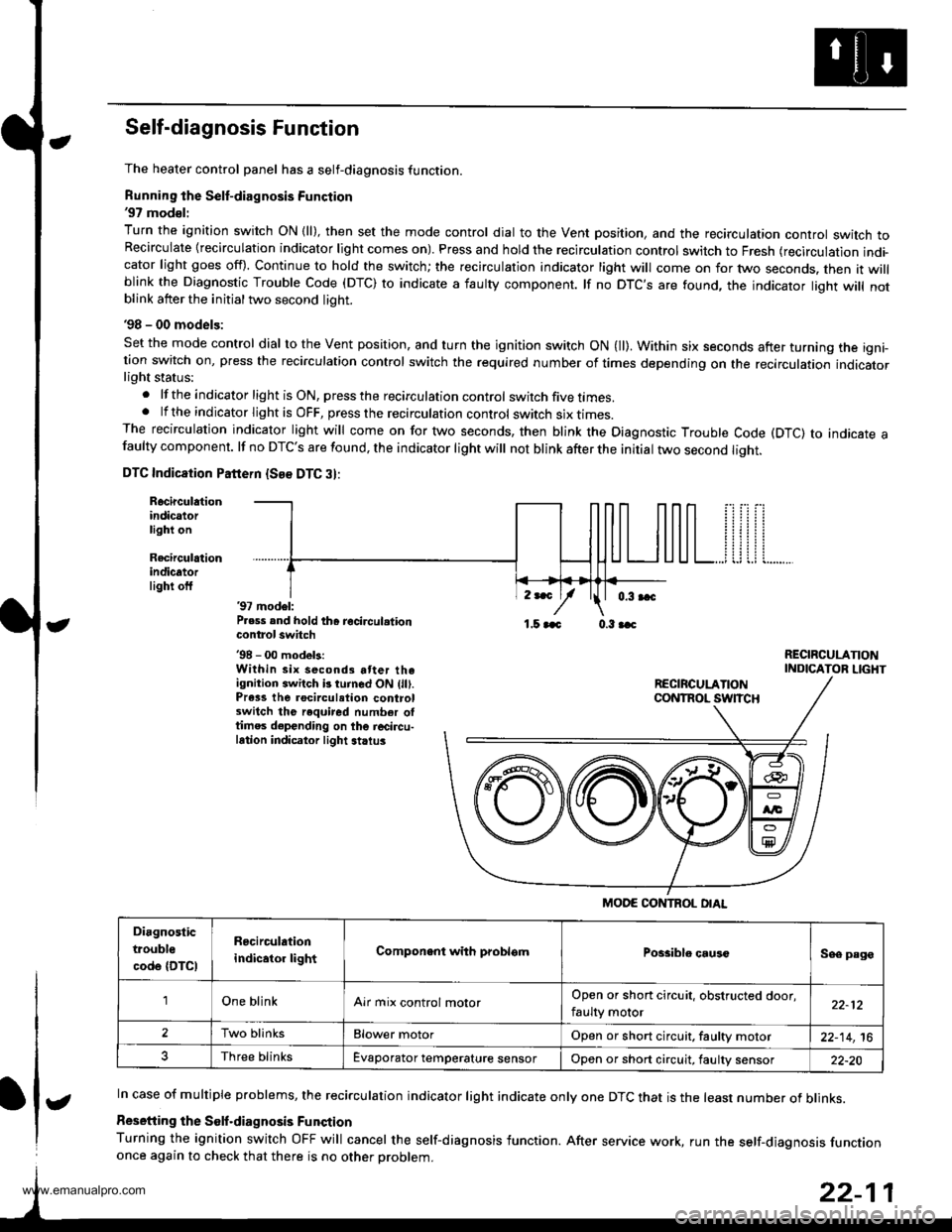

Self-diagnosis Function

The heater control panel has a self-diagnosis function.

Running the Self-diagnosis Function'97 mod€l:

Turn the ignition switch ON {ll), then set the mode control dial to the Vent position, and the recirculation controt switch toRecirculate {recirculation indicator light comes on). Press and hold the recirculation control switch to Fresh (recirculation indi-cator light goes off). Continue to hold the switch; the recirculation indicator light will come on for two seconds. then it willblink the Diagnostic Trouble Code (DTC) to indicate a iaulty component. lf no DTC'S are found, the indicator liqht will notblink atter the initial two second light.

'98 - 00 models:

Set the mode control dial to the Vent position, and turn the ignition switch ON (ll). Within six seconds after turning the igni-tion switch on, press the recirculation control switch the required number of times depending on the recirculation indicatorlight status:

.lftheindicatorlightisON,presstherecirculationcontrol switch five times..lftheindicatorlightisOFF,presstherecirculationcontrol switch six I|mes.The recirculation indicator light will come on for two seconds, then blink the Diagnostic Trouble Code (DTC) to indicate afaulty component. lf no DTC'S are found, the indicator light will not blink after the initial two second liqht.

DTC Indicaiion Pattern {See DTC 3}:

Rocirculationindicatorlight on

Recirculrtionindicatorlighi off'97 model:P.ess and hold th6 recircul.tioncontrol switch'98 - 00 modek:Within six second3 atter theignition switch b turned ON (lll.Prass the rocirculation controlswitch the required number oltimes depending on the r6circu-lation indicator light striu3

,r*

/1.5 aaa 0.3 aac

RECIRCULANONINDICATOR LIGHT

In case of multiple problems, the recirculation indicator light indicate only one DTC that is the least number of blinks.

Resetiing the Solf.diagnosis Funqtion

Turning the ignition switch OFF will cancel the self-diagnosis function. After service work, run the self-diaqnosis functiononce again to check that there is no other Droblem.

MODE CONTROL OIAL

Diagnostic

trouble

code {DTCI

R6circulation

indicator lightComponent with problsmPossiblo causcSee page

'lOne blinkAir mix control molorOpen or short circuit, obstructed door,

faulty motor22-12

2Two blinksElower motorOpen or short circuit, faultv motor22-14,16

Three blinksEvaporator temperature sensorOpon or short circuit, faulty sensor22-20

t

www.emanualpro.com

Page 1102 of 1395

Troubleshooting

Air Mix Control Motor

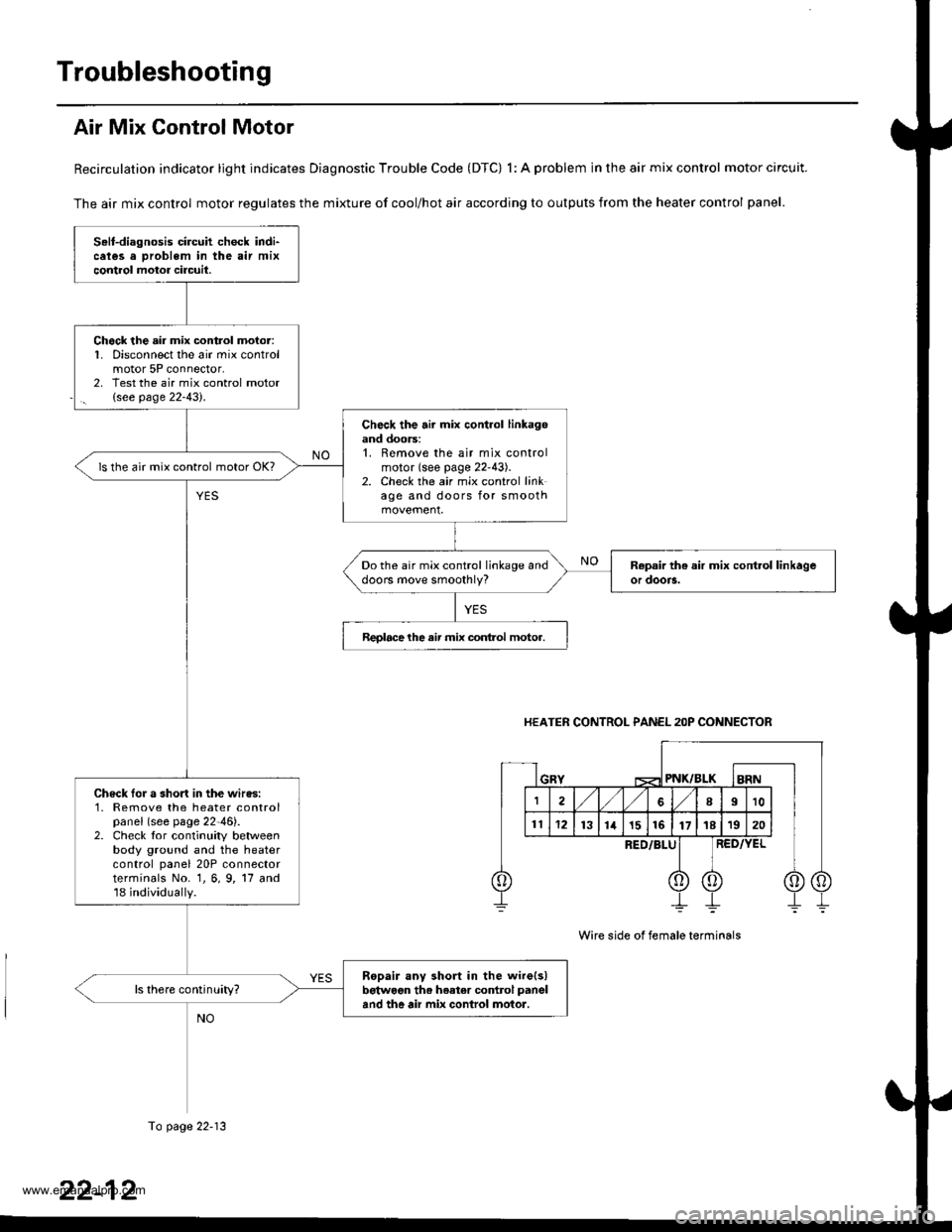

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 1: A problem in the air mix control motor circuit.

The air mix control motor regulates the mixture of cool/hot air according to outputs from the heater control panel.

Selt-diagnosis circuit check indi-cates a Droblem in the air mixcontrol motor circuil.

Chock the air mix control moior:1. Disconnect the air mix controlmotor 5P connector,2, Test the air mix control motor(see page 22-43).

Check the air mix control linkagoand doors:1. Remove the air mix controlmotor (see page 22'43).2. Check the air mix control linkage and doors for smooth

ls the air mix control motor OK?

Do the air mix control linkage anddoors move smoothly?

Reolacelhe air mix conlrol motor.

Check Ior a short in the wires:1- Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenbody ground and the heatercontrol panel 20P connectorterminals No. 1, 6, 9, 17 and18 individually.

Ropair any short in the wire(s)betwoon th. heater co.rtrol panel

and the air mix conlrol motor.

HEATER CONTROL PANEL 2OP CONNECTOR

PNK/BLK

RED/BLU

Wire side of female terminals

To page 22-13

www.emanualpro.com

Page 1105 of 1395

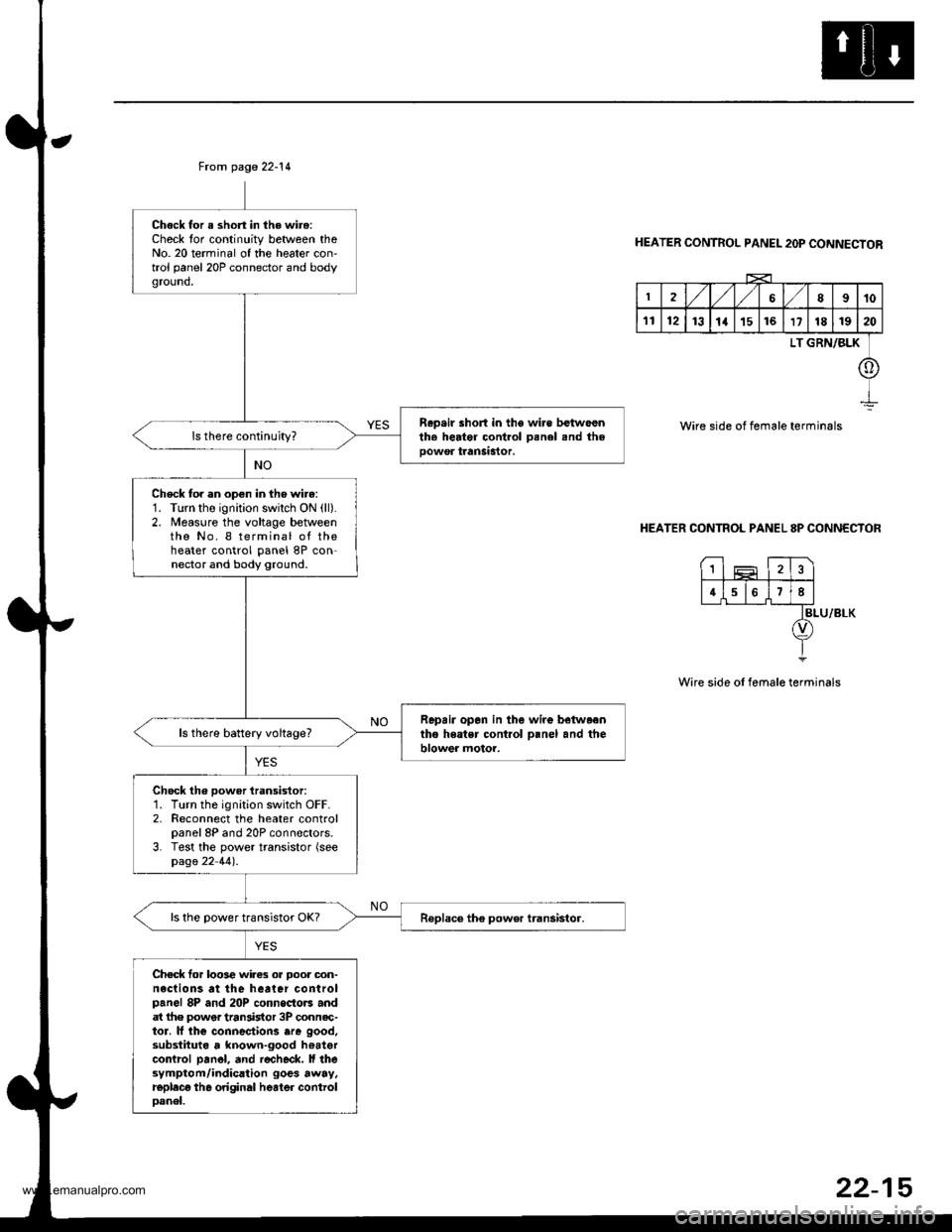

From page 22-14

Chock for a short in the wire:Check tor continuity between theNo. 20 terminal of the heater con'trol panel 20P connector and bodyground,

R.p.ir short in the wire betwoenth. herter control Denel snd theoowor tranSastor.

Check to. an open in the wire:1. Turn the ignition swilch ON (ll).

2. Measure the voltage betweenthe No. I terminal of theheater control panel 8P con-nector and body ground.

Repair opan in the wire betwaentho heatsr cont.ol o.nel and theblower motor.ls there battery voltage?

Chock th6 power iransistor:1. Turn the ignition switch OFF.2. Reconnect the heater controlpanel 8P and 20P connectors.3. Test the power transistor (seepage 22 44).

ls the power transistor OK?

Chec* for loo3e wires or Door oon-neclions at the heater controlpanel 8P and 20P connoctors andat lhe power tran3istor 3P connec-tor. lf lhe connectiorc are good,substituta , known-good hoatercontrcl pan6l, and r€check. ll thesymptom/indication goes away.replecg th6 original heater controloanel.

HEATER CONTROL PANEL 2OP CONNECTOR

2,/1,/l/68910

1112131a151617181920

LT GRN/BLK

o

Wire side of female terminals

HEATER CONTROL PANEL 8P CONNECTOR

BLU/8LK

Wire side of female terminals

1

4678

22-15

www.emanualpro.com

Page 1112 of 1395

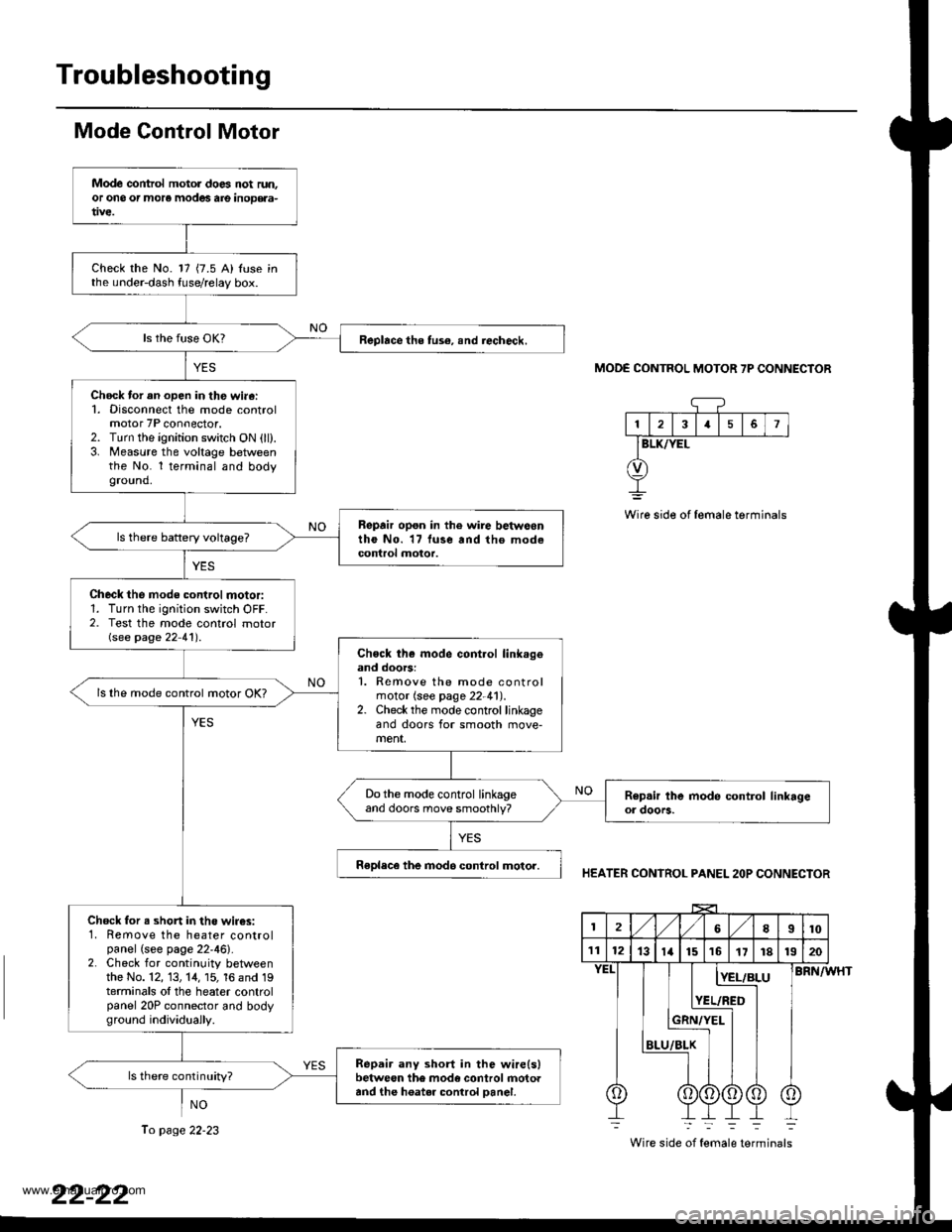

Troubleshooting

Mode Control Motor

NO

MODE CONTROL MOTOR 7P CONNECTOR

13I5

BLK/YEL

Wire side of female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

BRN/WHT

Wire side of female terminals

Mode control motol does not run.or ono or more modes are inoD€aa-

Check the No. 17 {7.5 A) Iuse inthe under-dash fuse/relay box.

Replace the tus€, snd iecheck.

Chock tor an open in th€ wi.6:1. Disconnect the mode controlmotor 7P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. l terminal and bodyground.

Repair opon in the wire betwoontho No. 17 luse and tho modecontrol motor.

Check the mode control motor:1. Turn the ignition switch OFF.2. Test the mode control motorGee page 22 41') .

Chock th€ mode cont.ol link.geand doors:1. Remove the mode controlmotor (see page 22-41).2. Check the mode control linkageand doors for smooth move-ment,

ls lhe mode control motor OK?

Do the mode control linkageand doors move smoothly?

Replece the inod6 control motor.

Chock for s shon in the wir€s:1. Remove the heater controlpanel (see page 22'46).2. Check for continuity betweenthe No. 12, 13, 14, 15, 16 and 19terminals ol the heater controlpanel 20P connector and bodyground individuaily.

Repair any short in the wire(slbetween the mode control rnotoaand the h6ater control Danel.

ls there continuity?

2l,/1,/8I10

111213ta151617r81320

BLU

[E!r!

YEL/RED

Ii

To page 22-23

www.emanualpro.com

Page 1114 of 1395

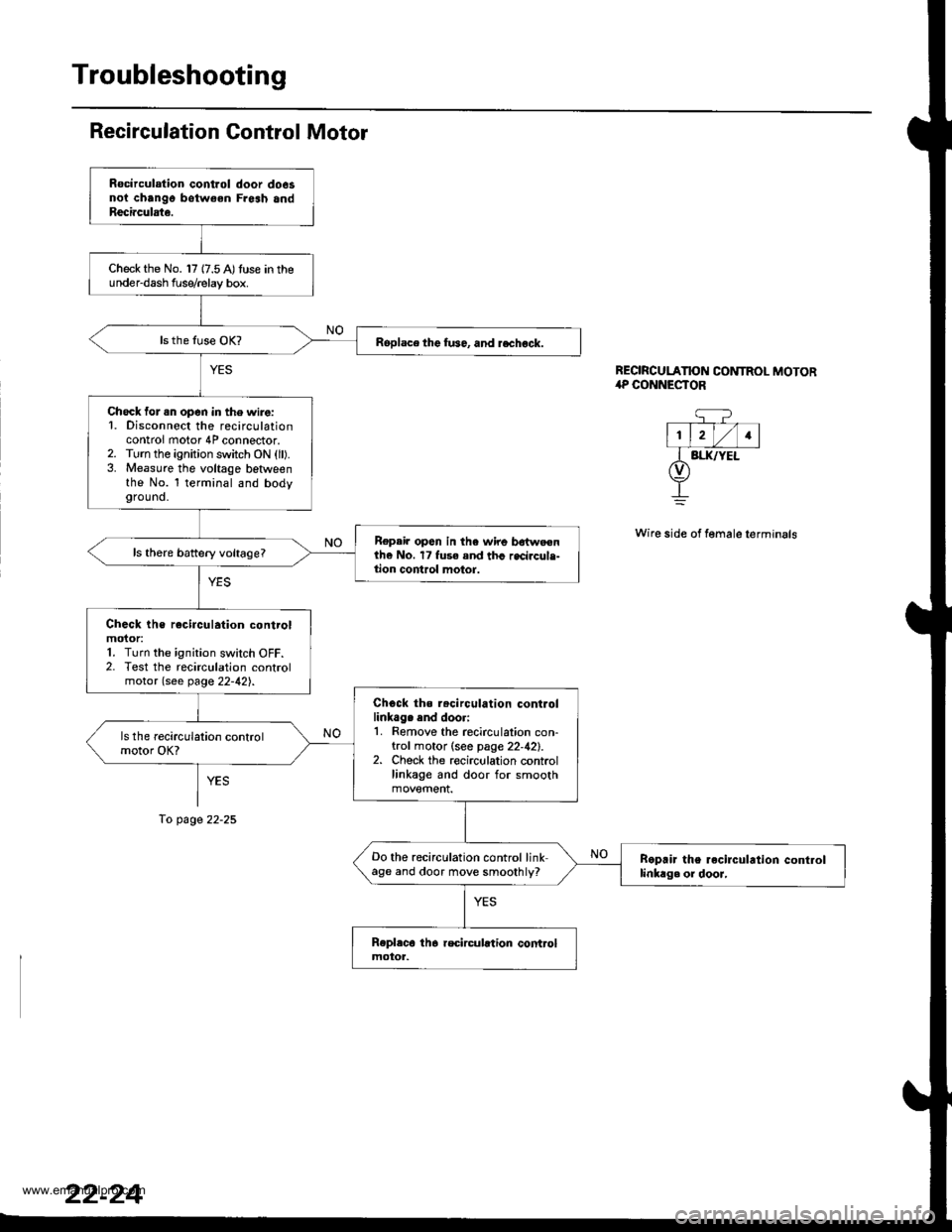

Troubleshooting

Recirculation Gontrol Motor

YES

To page 22-25

REORCULATION CONTROL MOTOR,rP CONNESTOR

q?- T--- V-l

l1, lrl/l1lI BI.IUYEL(v)

+

Wire side of female terminals

Rocirculation control door do6snoi chango botw€en Fresh andReci.culate.

Check the No. 17 {7.5 A)tuse in theunder-dash f use/relay box.

Roplace the fu36, and rechock.

Check for .n open in the wire:1. Disconnect the recirculationcontrol motor 4P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betlveenthe No. l terminal and bodyground.

Repair op6n in the wire bdtweenthe No. 17 fuse and thc recircule-tion control motor.

Check the rocirculation controlmoior:1. Turn the ignition switch OFF.2. Test the recirculation controlmotor (see page 22-42).

Chock ths r.circulation controllinkag. end doori1. Remove the recirculation con-trol motor (see page 22,42).2. Check the recirculation controllinkage and door for smooth

Do the recirculation control linkage and door move smoothly?Boprir the recirculrtion controllinkag. or dooJ,

www.emanualpro.com

Page 1131 of 1395

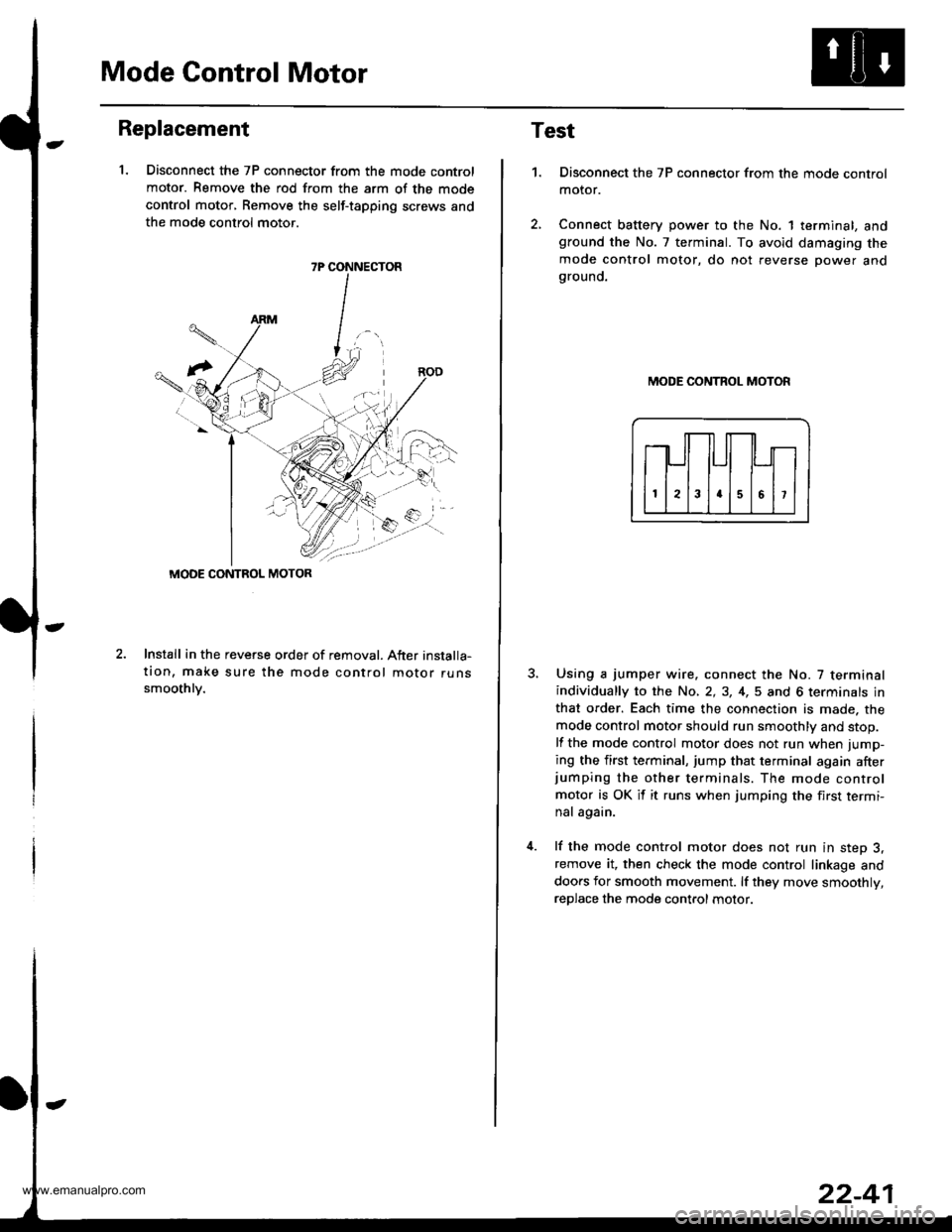

Mode Control Motor

Replacement

1. Disconnect the 7P connector from the mode control

motor. Remove the rod from the arm of the mode

control motor, Remove the self-tapping screws and

the mode control motor.

2.Install in the reveGe order of removal. After installa-

tion, make sure the mode control motor runssmoothlv.

7P CONNECTOR

MODE CONTROL MOTOR

Test

1.Disconnect the 7P connector from the mode control

motor.

Connect battery power to the No. 1 terminal, andground the No. 7 terminal. To avoid damaging the

mode control motor, do not reverse power andgrouno.

MODE CONTROL MOTOR

Using a jumper wire. connect the No. 7 terminalindividually to the No, 2,3, 4,5 and 6 terminals in

that order. Each time the connection is made. the

mode control motor should run smoothly and stop.

lf the mode control motor does not run when jump-

ing the first terminal, jump that terminal again afterjumping the other terminals. The mode control

motor is OK it it runs when jumping the first termi-

nal again.

lf the mode control motor does not run in step 3,remove it, then check the mode control linkage and

doors for smooth movement. lf they move smoothly,

reDlace the mode control motor.

www.emanualpro.com

Page 1132 of 1395

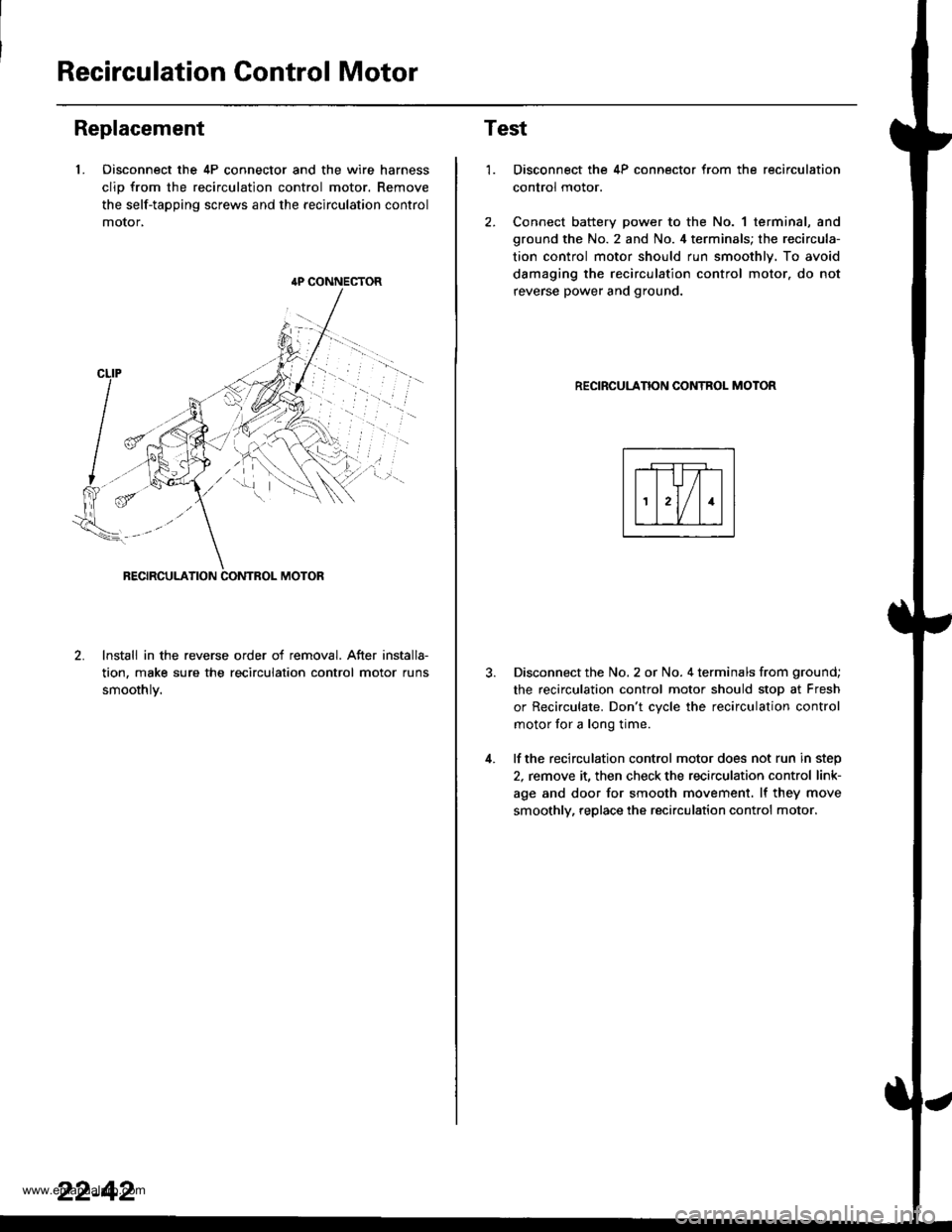

Recirculation Control Motor

Replacement

1. Oisconnect the 4P connector and the wire harness

clio from the recirculation control motor. Remove

the self-tapping screws and the recirculation control

motor,

lnstall in the reverse order of removal. After installa-

tion, make sure the recirculation control motor runs

smoothlv.

{P CONNECTOR

22-42

Test

1.

4.

Disconnect the 4P connector from the recirculation

control motor.

Connect battery power to the No. 1 terminal, and

ground the No. 2 and No. 4 terminals; the recircula-

tion control motor should run smoothly. To avoid

damaging the recirculation control motor. do not

reverse power and ground.

RECIRCULANON CONTROL MOTOR

Disconnect the No. 2 or No. 4 terminals from ground;

the recirculation control motor should stop at Fresh

or Recirculate. Don't cvcle the recirculation control

motor for a long time.

lf the recirculation control motor does not run in step

2, remove it, then check the recirculation control link-

age and door for smooth movement. lf they move

smoothly, replace the recirculation control motor.

www.emanualpro.com