fuel gauge HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 132 of 1395

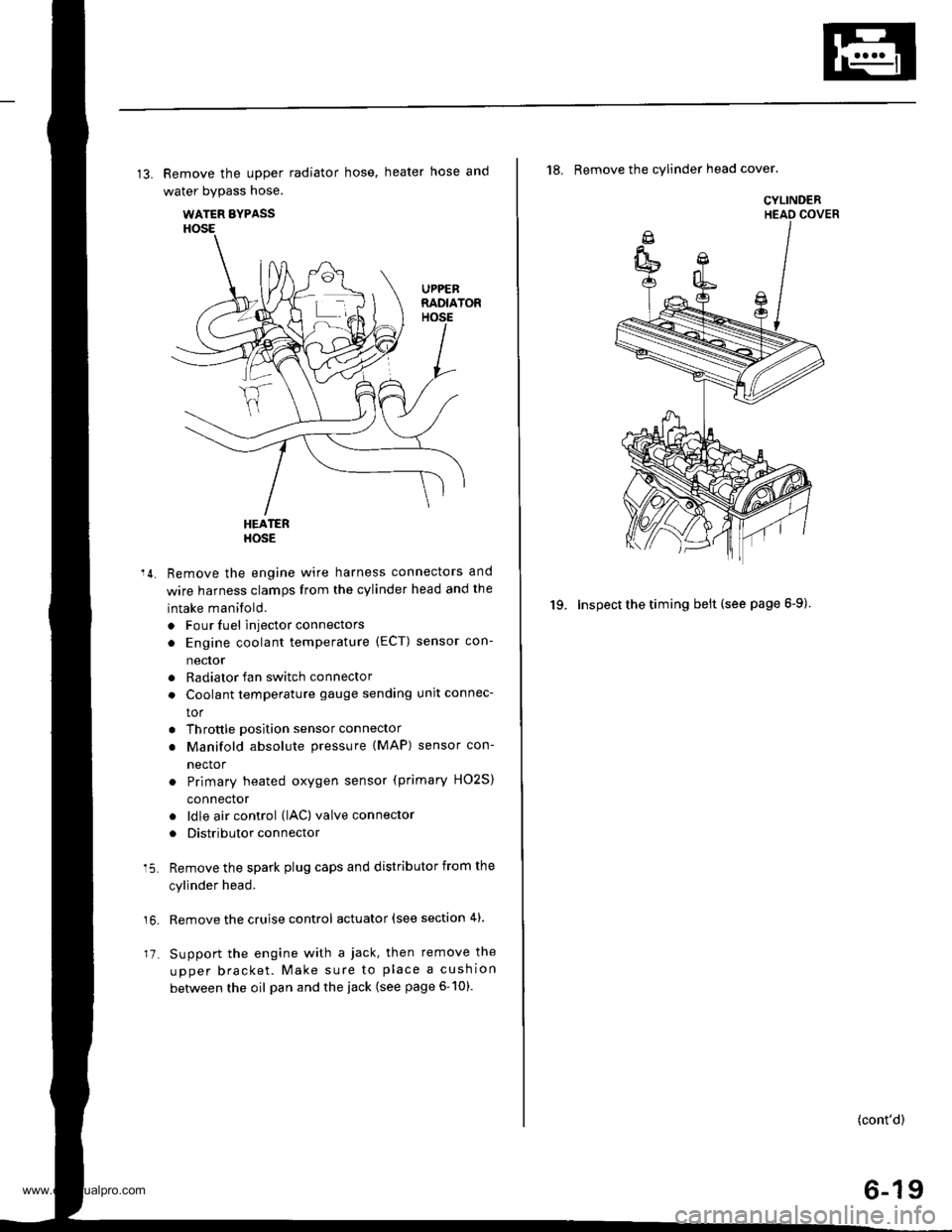

13. Remove the upper radiator hose, heater hose and

water bypass hose.

WATER BYPASS

UPPEBRADIATORHOSE

17

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

neclor

. Radiator fan switch connector

. Coolant temperature gauge sendlng unlt connec-

tor

. Throttle position sensor connector

. Manifold absolute pressure {MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

ldle air control (lAC) valve connector

Distributor connector

Remove the spark plug caps and distributor from the

cylinder head.

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil pan and the iack (see page 6-10).

a

18. Remove the cylinder head cover.

19. Inspect the timing belt (see page 6-9).

CYLINDER

(cont'd)

6-19

www.emanualpro.com

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 205 of 1395

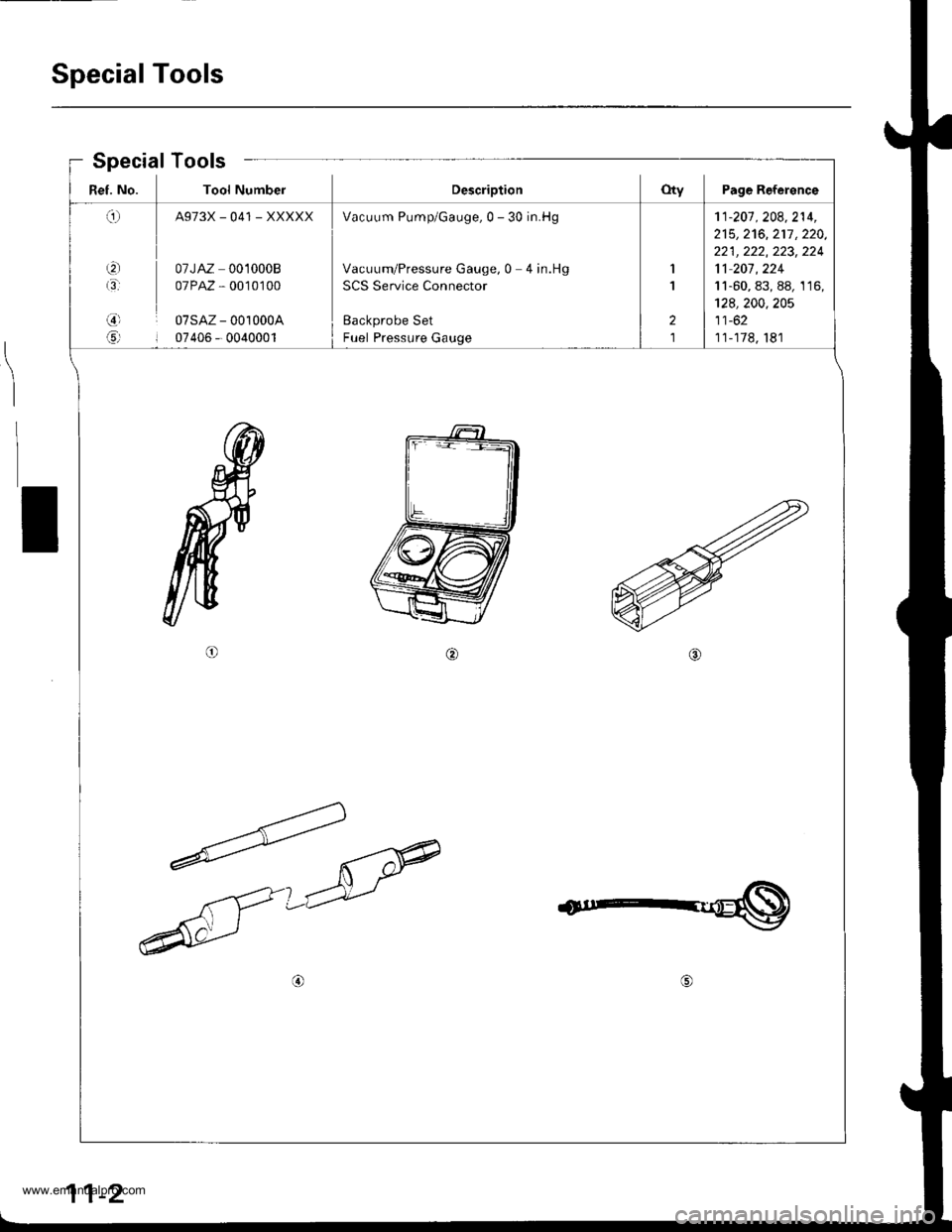

Special Tools

Ref. No. Tool NumberDescriptionOty Page Reference

q

t3'

,3)l

6rl

A973X_041 _XXXXX

07JAZ 0010008

07PAZ , 0010100

07sAz - 001000A

07405 - 0040001

Vacuum Pump/Gauge,0 - 30 in.Hg

Vacuum/Pressure Gauge, 0 4 in.Hg

SCS Service Connector

Backprobe Set

Fuel Pressure Gauge

1

1

2

1

'11-201 . 208,214,

215,2't6,217 ,220,

221 , 222, 223, 224

11 207 , 224

11-60, 83, 88, 1 16,

128,200,205

11-62

11-178, 181

Special Tools

I

11-2

www.emanualpro.com

Page 210 of 1395

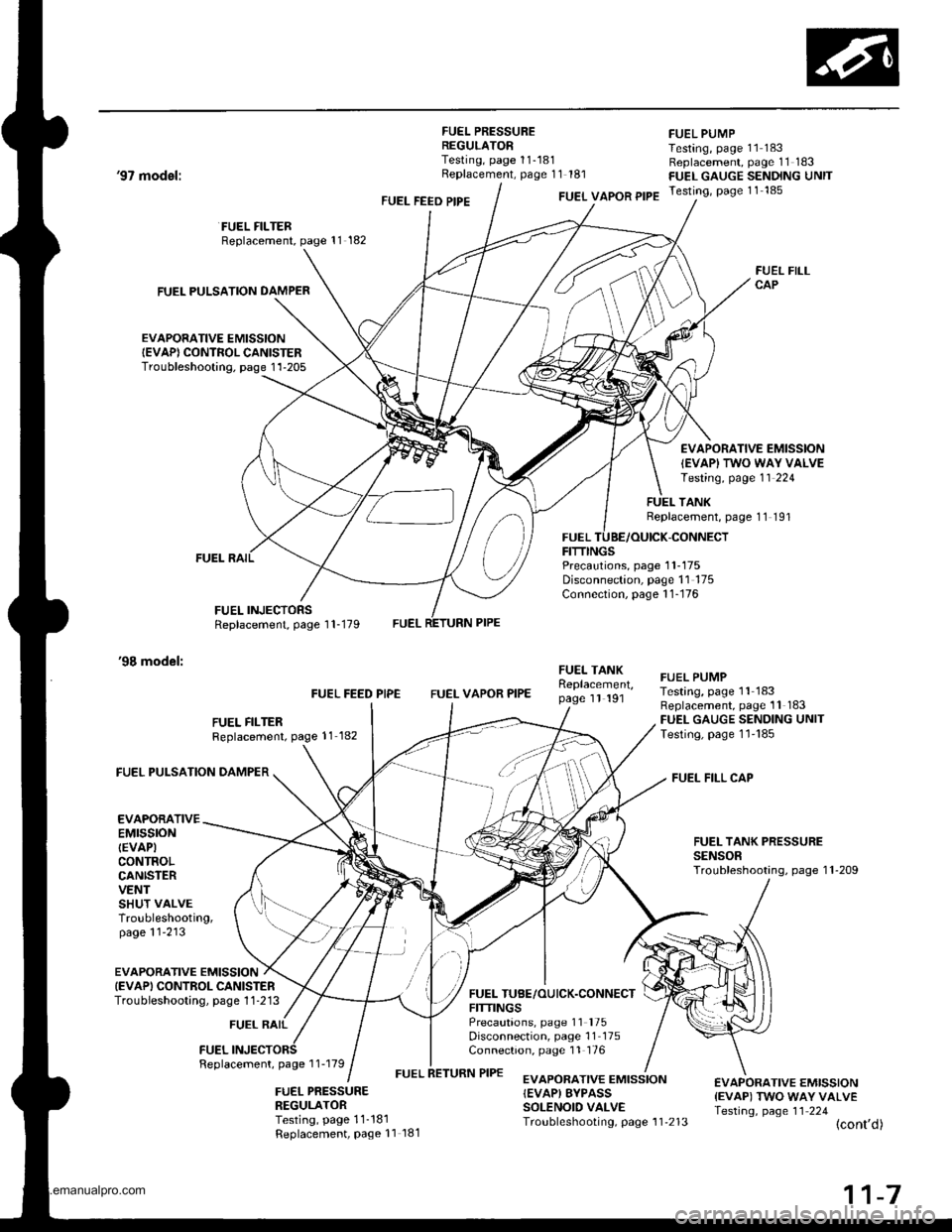

FUEL PRESSUREREGULATORTesting, page 11-181Replacement, page 11 181

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 11 185

'97 model:

'98 model:

FUEL PULSATION DAMPER

EVAPORATIVE EMISSIONIEVAP) CONTROL CANISTERTroubleshooting. page 1'l-205

FUEL FILTERReplacement, page 11 182

FUEL INJECTORSReplacement, page 1 1-179

FUEL FEED PIPEFUEL VAPOR PIPE

FUELFITTINGS

FUEL FILLCAP

EVAPORATIVE EMISSION

IEVAPI TWO WAY VALVETesting, page 11 224

TANKReplacement, page 11 191

-CONNECT

Precautions, page 1 1-175Disconnection, page 11 175Connection, page 1 1-176

FUEL FILTERReplacement, page 11 182

FUEL FEED PIPEFUEL VAPOR PIPE

FUEI- TANKReplacement,page 1l 191

FUEL TUBE/OUICK.CONNECTFITTINGSPrecautions, page 11 '175

Disconnection, page 11 175Connection, page 11 176

FUEL PUMPTesting, page 11 183Replacement, page 11 183FUEL GAUGE SENDING UNITTesting, page 1l'185

FUEL FILL CAP

FUEL TANK PRESSURESENSORTroubleshooting, page 1 l-209

FUEL PULSATION DAMPER

EVAPORATIVEEMTSSTONIEVAPICONTROLCANISTERVENTSHUT VALVETroubleshooting,page 11'213

EVAPORATIVE EMISSIONIEVAPI CONTROL CANISTERTroubieshooting, page 1 1 -213

FUEL RAIL

FUELFeplacement, page 1 1-179

FUEL PRESSURENEGULATORTesting, page 11-181Replacement, Page 11 181

EVAPORATIVE EMISSION{EVAP) EYPASSSOLENOID VALVETroubleshooting, page 1 1'213

€VAPORATIVE EMISSION{EVAP) TWO WAY VALVETesting, page 11 224(cont'd)

www.emanualpro.com

Page 211 of 1395

Gomponent Locations

Index lcont'd)

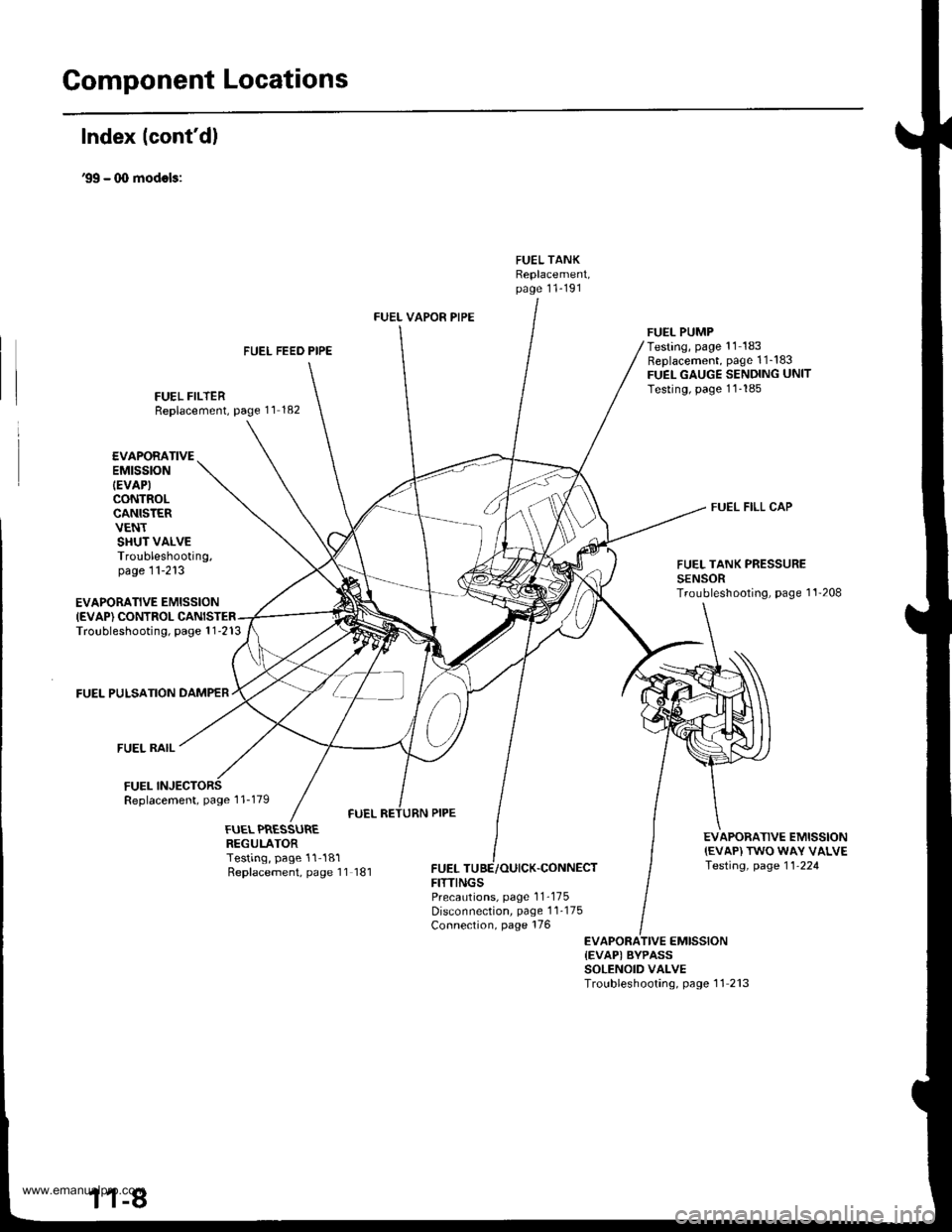

'99 - (X) modols:

FUEL TANKReplacement,page 11-191

FUEL FEED PIPE

FUEL FILTERReplacement, page 11 182

FUEL VAPOR PIPE

FUELFITTINGS

FUEL PUMPTesting, page '11 183Replacement, page 1 1_183FUEL GAUGE SENDING UNITTesting, page 11-185

FUEL FILL CAP

EVAPORATIVE EMISSIONIEVAP) CONTROLTroubleshooting, page 1 1-213

FUEL PULSATION DAMPER

FUEL RAIL

FUELReplacement, page 1 1-179

EVAPORATIVEEMtSStON

IEVAP)CONTROLCANISTERVENTSHUT VALVETroubleshooting,page 11-213FUEL TANK PRESSURESENSORTroubleshooting, page 1'l'208

EVAPORATIVE EMISSION{EVAP) TWO WAY VALVETesting, page 11-224

FUEL PRESSUREREGULATORTesting, page 11-181Replacement, page 11 181,CONNECT

PrecaLrtions, page 1 1-175Disconnection, page 1 1-175Connection, page 176

EVAPORATIVE EMISSION{EVAPI BYPASSSOLENOID VALVETroubleshooting, page 11 213

www.emanualpro.com

Page 285 of 1395

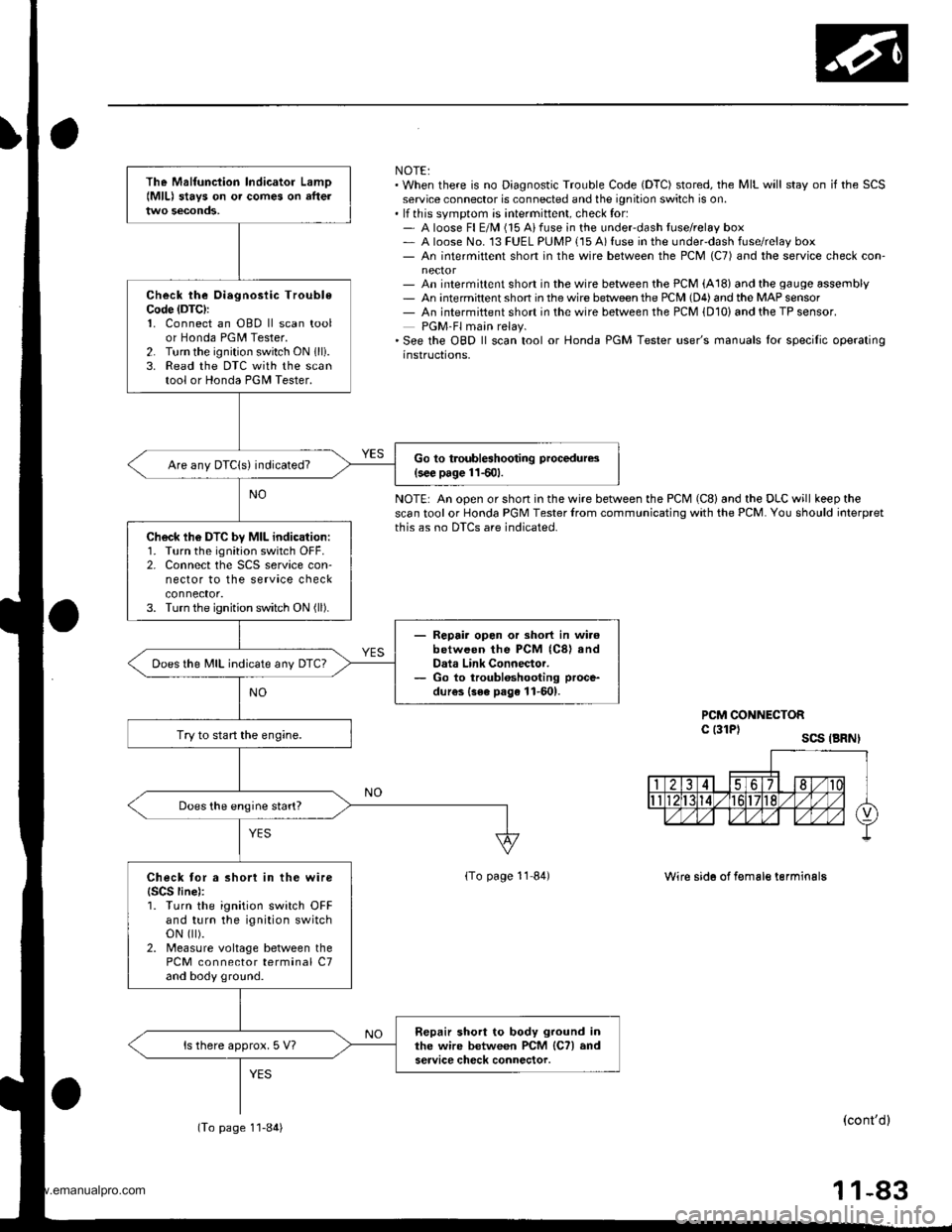

NOTE:. When there is no Diagnostic Trouble Code (DTC) stored, the MIL will stay on if the SCSservice connector is connected and the ignition switch is on.. lf this svmotom is intermittent, check for:- A loose Fl E/M (15 Aifuse in the underdash tuse/relay box- A loose No. 13 FUEL PUMP {15 A) fuse in the under-dash fuse/relay box- An intermittent short in the wire between the PCM (C7) and the service check con-

- An intermittent short in the wire between the PCM (A18) and the gauge assembly- An intermittent shon in the wire betlveen the PCM (D4) and the MAP sensor- An intermiftent short in the wire between the PCM {D10) and the TP sensor.PGM-Fl main relay.'See the OBD ll scan tool or Honda PGM Tester user's manuals lor specilic operatinginstructions,

NOTE: An open or short in the wire between the PCM (C8) and the DLC will keep thescan tool or Honda PGM Tester lrom communicating with the PCM. You should ioterpretthis as no DTCS are indicated.

PCM CONNECTORc l3lPl scs .BRNI

lTo page 11 84)Wire sid6 of f€male terminalg

(cont'dl

11-83

The Malfunciion lndicator Lamo{MlL) stavs on o. comes on afteltwo seconds,

Check the Oiegnosiic TroubleCode (DTC):

1. Connect an OBD ll scan toolor Honda PGM Tester.2. Turn the ignition switch ON 1lli.3. Read the DTC with the scantool or Honda PGII Tester.

Go to troubleshooting procedures(s€€ page 11501.Are any DTCIs) indicated?

Ch6ck lh6 DTC by MIL indication:1. Turn the ignition switch OFF.2. Connect the SCS service con-nector to the service checkconnector.3. Turn the ignition switch ON (ll).

- Repair opon or short in wi.6between the PCM (C8) andData Link Connector.- Go to troubloshooting proce-

dur€s {3ee page 11-601.

Does the MIL indicate any DTc?

Try to start the engine.

Does the engine start?

Check tor a short in the wire{SCS line):1. Turn the ignition switch OFFand turn the ignition switchoN flt).2. Measure voltage between thePCM connector terminal C7and body ground.

Repair short to body ground inthe wire between PCM lCTl andservice check connector.ls there approx. 5 V?

(To page 1'l-84)

www.emanualpro.com

Page 288 of 1395

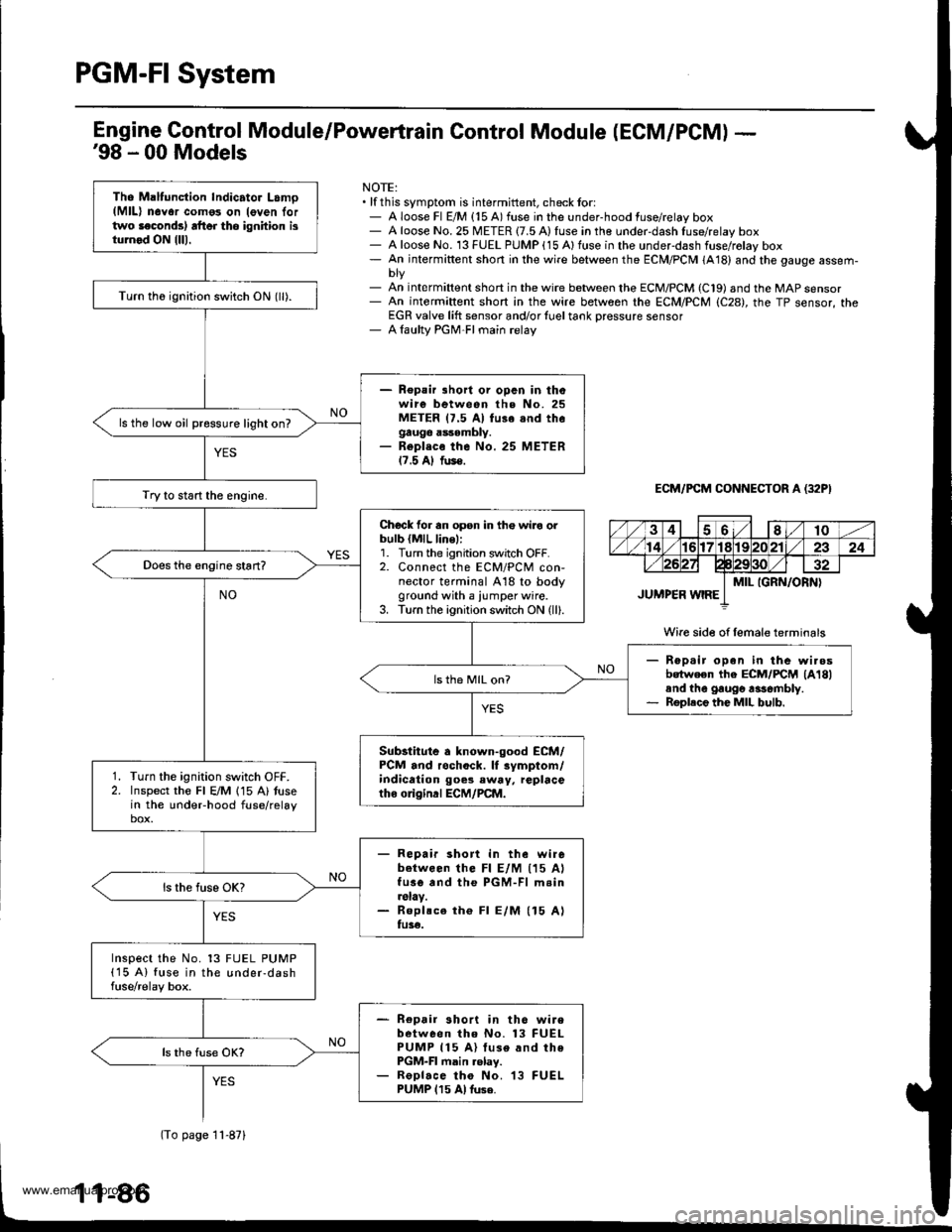

PGM-FI System

Tho Maltunction Indicator Lamo(MlL) n6Yor como3 on leven lortwo laconds) rft6r tho ignhion isturnod ON {lll.

Turn th6 ignition switch ON (ll).

- Repair lhort or opcn in thowire between the No. 25METER 17.5 Al fu3e snd thegauge assembly.- Repl.co the No. 25 METER17.5 Al fus€.

ls the low oil pressure light on?

Try to start the engine.

Chock for an opsn in th€ wiro orbulb {MlL line,:1. Turn the ignition switch OFF.2. Connect the ECM/PCM con-nector terminal A18 to bodyground with a iumper wire.3. Turn the ignition switch ON (ll).

Rep.ir open in the wi.osbotween the ECM/FCM lA18land the gaugo rasombly.Roplece the MIL bulb.

ls th6 MIL on?

Substitute a known-good ECM/PCM and rochock. lf rymptom/indication goes eway, replacetho o gind ECM/PCM.

Turn the ignition switch OFF.Inspect the Fl E/M 115 A) tusein the undeFhood fuse/relaybox.

- Repair short in the wirebetween lhe Fl E/M (15 AlfusG and the PGM-Fl m.in.slay.- Roplsce th€ Fl E/M (15 Alfu3€.

Inspect the No. 13 FUEL PUMP(15 A) fuse in the under-dashfuse/relay box.

- Repair short in th6 wirebetween tho No. 13 FUELPUMP 115 A) luse and thePGM-FI main .elay.- ReDlace tho No. 13 FUELPUMP 115 Al tuse.

Engine Gontrol Module/Powertrain Control Module (ECM/PCM) -'98 - 00 Models

NOTE:. lf this symptom is intermittent, check tor:- A loose Fl E/M {15 A) fuse in the under-hood fuse/relay box- A loose No. 25 METER {7.5 A) fuse in the under-dash fuse/relay box- A loose No. 13 FUEL PUMP (15 Alfuse in the underdash fuse/rolay box- An intermiftent short in the wire between the ECM/PCM (A18) and the gauge assem-

- An int€rmiftent short in the wire between the ECM/PCM (C19) and the MAP sensor- An intermiftent short in the wire between rhe ECM/PCM (C28), the TP sensor, theEGR valve lift sensor and/or {uel tank Dressure sensor- A laulty PGM-FI main relay

ECM/PCM CONNECTOR A (32P}

Wire side of female terminals

(To page 11-871

www.emanualpro.com

Page 380 of 1395

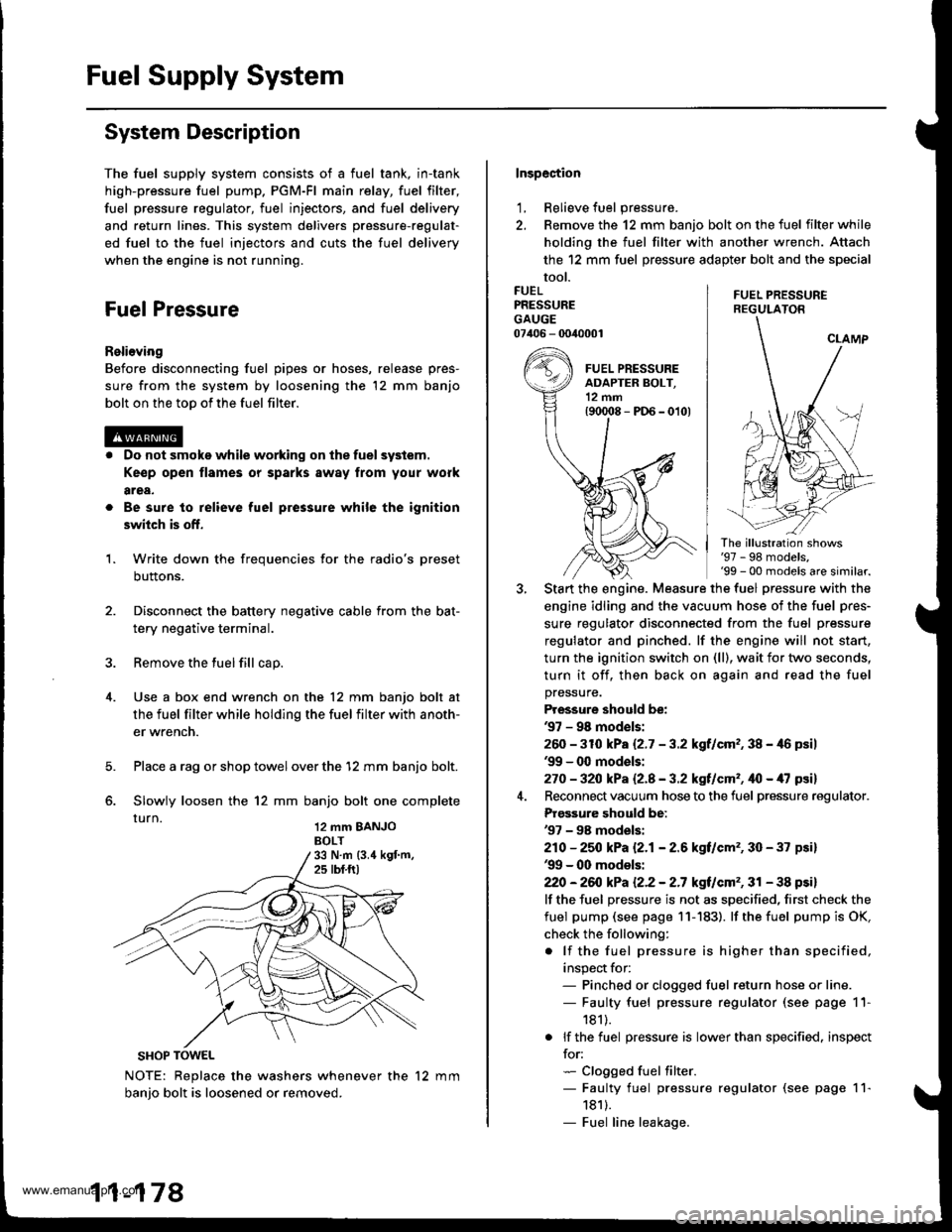

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump. PGM-Fl main relay, fuel filter,

fuel pressure regulator, fuel injectors, and fuel delivery

and return lines. This system delivers pressure-regulat-

ed fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

Fuel Pressure

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on the too of the fuel filter.

Do not smoke while working on the fuel system.

Ke€p open flames or sparks away from your work

area,

Be sure to relieve fuel pressure while the ignition

switch is off.

Write down the frequencies for the radio's preset

buttons.

Disconnect the battery negative cable from the bat-

tery negative terminal.

Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the '12 mm banjo bolt.

Slowly loosen the 12 mm banjo bolt one complete

rurn 12 mm BANJoBOLT

1.

SHOP TOWEL

NOTE: Replace the washers whenever the 12 mm

banio bolt is loosened or removed.

11-178

Inspection

1, Relieve fuel pressure.

2. Remove the 12 mm banjo bolt on the fuel filter while

holding the fuel filter with another wrench. Attach

the 12 mm fuel pressure adapter bolt and the special

tool.

FUEL PRESSUREREGULATON

FUELPRESSUREGAUGE07406 - 0040001

The illustration shows'97 - 98 models,'99 - 00 models are similar.

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch on (ll), wait for two seconds,

turn it off, then back on again and read the fuel

pressure.

Pressure should be:'97 - 98 mod€ls:

260 -31O kPa 12.7 - 3.2 kgf/cm,, 38 - 46 psil'99 - 0O models:

270 - 32O kPa Q.A - 3.2 kgf/cm'�, ifo - /U psil

Reconnect vacuum hose to the fuel pressure regulator.

Prgs3ure should be:'97 - 98 models:

210 - 25O kPa 12.1- 2.6 kgf/cm'�, 30 - 37 psi)'99 - 00 models:

22O -26iJ kPa 12.2 - 2.7 kgt/cm'�, 31 - 38 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11- 183). lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-

181).

. lf the fuel pressure is lower than specified. inspect

for:- Clogged fuel filter.- Faulty fuel pressure regulator (see page 11-

1811.- Fuel line leakage.

www.emanualpro.com

Page 383 of 1395

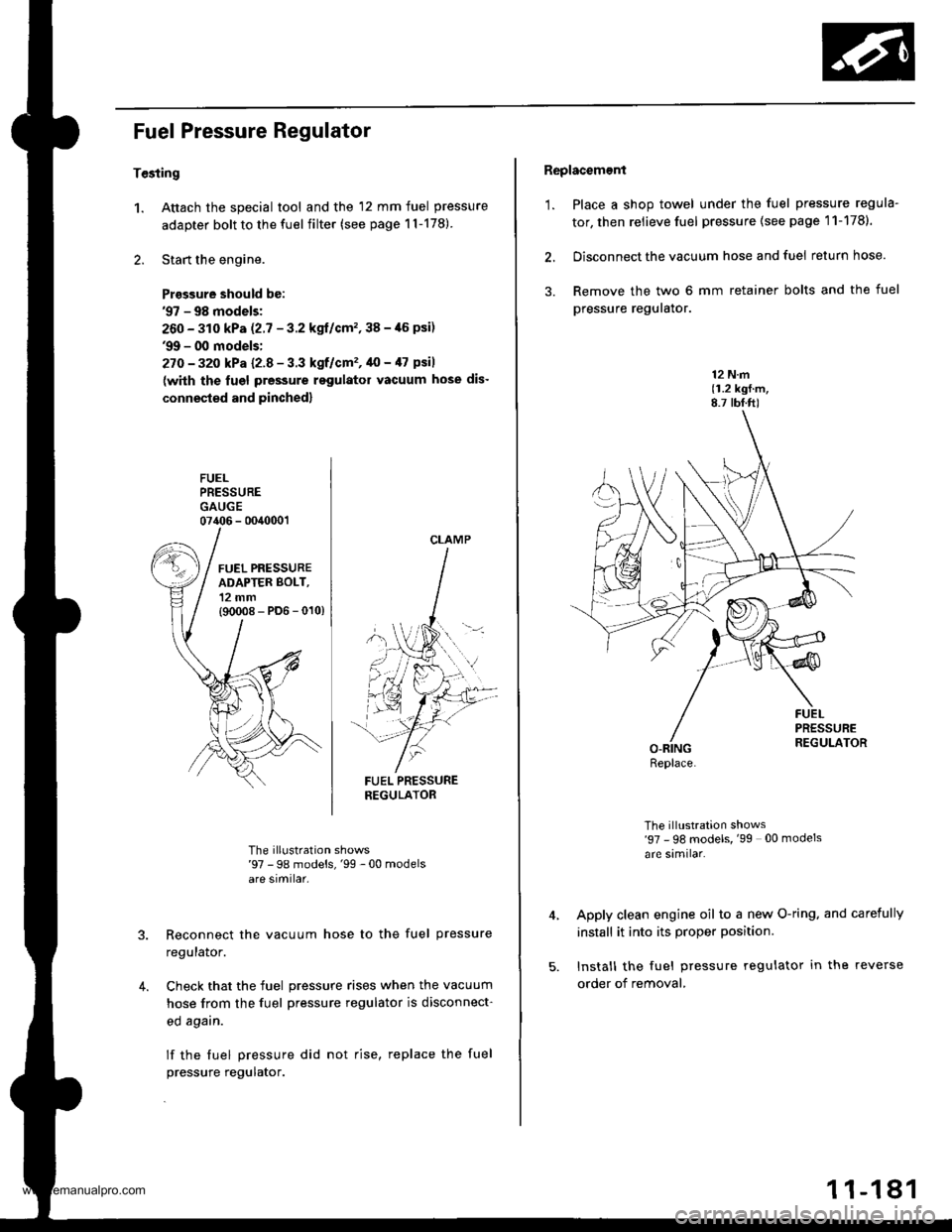

Fuel Pressure Regulator

Tesiing

1. Attach the special tool and the 12 mm fuel pressure

adapter bolt to the fuel filter (see page 1l-178)

2. Start the engine.

Prasgure should be:'97 - 98 models;

260 - 310 kPa (2.7 - 3.2 kgl/cm'�,38 -,16 psi)'9!t - 00 models:

27O - 32o kPa l2-8 - 3.3 kgf/cm'�, 40 - /l7 psil

(with the lugl pressure rsgulator vacuum hose dis-

connested and pinched)

FUELPRESSUREGAUGE07406 - 0040001

FUEL PRESSURENEGULATOR

The illustration shows'97 - 98 models,'99 -00 modelsare similar.

Reconnect the vacuum hose to the fuel pressure

regulalor.

Check that the fuel pressure rises when the vacuum

hose from the fuel pressure regulator is disconnect-

ed agarn.

lf the fuel pressure did not rise, replace the fuel

pressure regulator.

4.

CLAMP

Replacement

'1. Place a shop towel under the fuel pressure regula-

tor, then relieve fuel pressure (see page 11-1781.

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts and the fuel

pressure reguralor.

12 N.m(1.2 kgf.m,8.7 tbf.ft)

The illustration shows'97 - 98 models, '99 00 models

are similar.

Apply clean engine oil to a new O-ring. and carefully

install it into its proper position.

Install the fuel pressure regulator in the reverse

order of removal,

Replace.

1 1-181

www.emanualpro.com

Page 386 of 1395

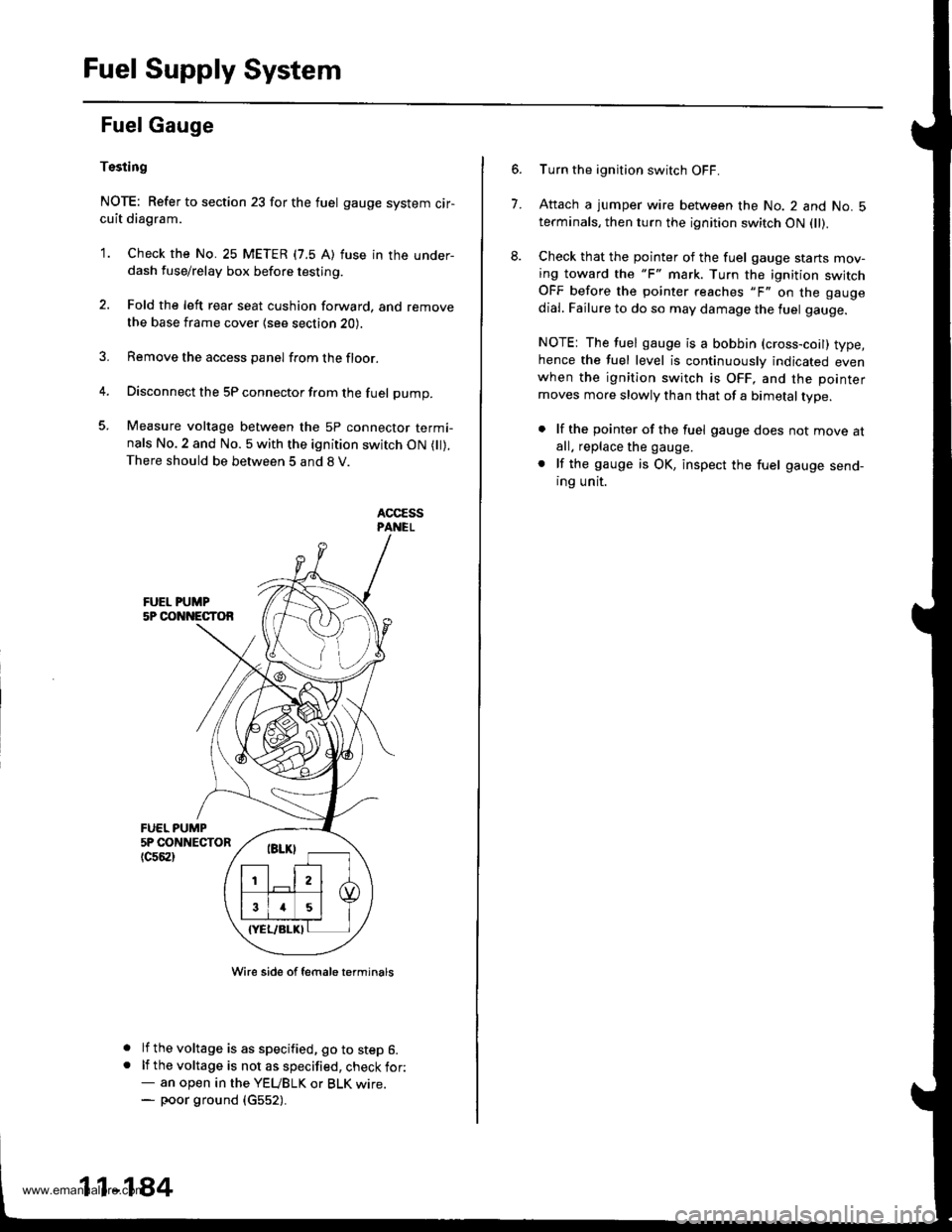

Fuel Supply System

Fuel Gauge

Tssting

NOTE: Refer to section 23 for the fuel gauge system cir-cuit diagram.

'1. Check the No. 25 METER (7.5 A) fuse in the under-dash fuse/relay box before testing.

2. Fold the left rear seat cushion forward, and remove

the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector from the fuel pump.

5. Measure voltage between the 5P connector termi-nals No.2 and No. 5 with the ignition switch ON ( ).There should be between 5 and 8 V.

FUEL PUMP5P CONNECTOR

tc56al

a

a

Wire side of female t€rminals

lf the voltage is as specified, go to step 6.lf the voltage is not as specified, check for:- an open in the YEUBLK or BLK wrre.- poor ground (c552).

11-184

7.

Turn the ignition switch OFF.

Attach a jumper wire between the No. 2 and No. 5terminals, then turn the ignition switch ON fll).

Check that the pointer of the fuel gauge starts mov-ing toward the "F" mark. Turn the ignition switchOFF before the pointer reaches "F" on the gauge

dial. Failure to do so may damage the luel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,hence the fuel level is continuously indicated evenwhen the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetal type.

. lf the pointer of the fuel gauge does not move atall. replace the gauge.

. lf the gauge is OK, inspect the fuel gauge send-ing unit.

www.emanualpro.com