Overhaul

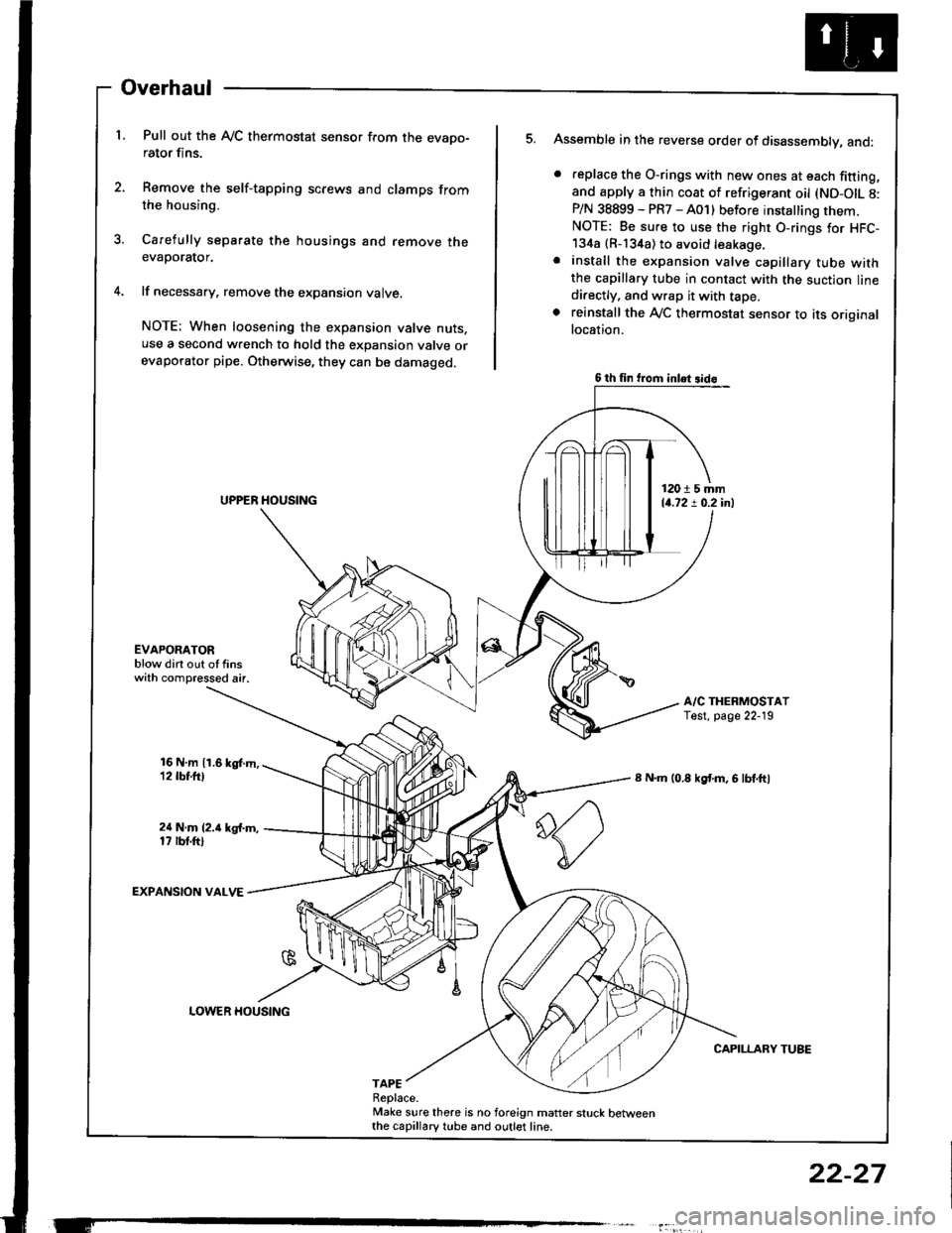

L Pull out the Ay'C thermostat sensor from the evapo-rator fins.

2. Remove the self-tapping screws and clamps fromthe housing.

3. Carefully separate the housings and remove theevaporator.

4. lf necessary, remove the expansion valve.

NOTE: When loosening the expansion valve nuts.use a second wrench to hold the expansion valve orevaporator pipe. Otherwise, they can be damaged.

Assemble in the reverse order of disassembly, and:

. feplace the O-rings with new ones at each fitting,and apply a thin coat of refrigerant oil (ND-OIL 8:P/N 38899 - PR7 - A01) before installing them.NOTE: Be sure to use the right O-rings for HFC-134a {R-134a) to avoid leakage.. install the expansion valve capillary tube withthe capillary tube in contact with the suction linedi.ectly, and wrap it with tape.. reinstall the Ay'C thermostat sensor to its originallocation.

A/C THERMOSTATTest. page 22-19

8 N.m (0.8 kgf'm, 6 lbf.ftl

CAPILLARY TUBE

5.

EVAPOAATORblow dirt out of finswith compressed air.

16 N,m 11.6 kgl.m,12 tbt.ttl

24 N.m (2.i1 kg{.m,17 rbt.ftl

EXPANSION VALVE

TAPEReplace.Make sure there is no foreign matter stuck betweenthe capillary tube and outlet line.

6 th fin trom inlet 3id6

12015 mm14.72 ! 0.2 inl

LOWER HOUSING

22-27

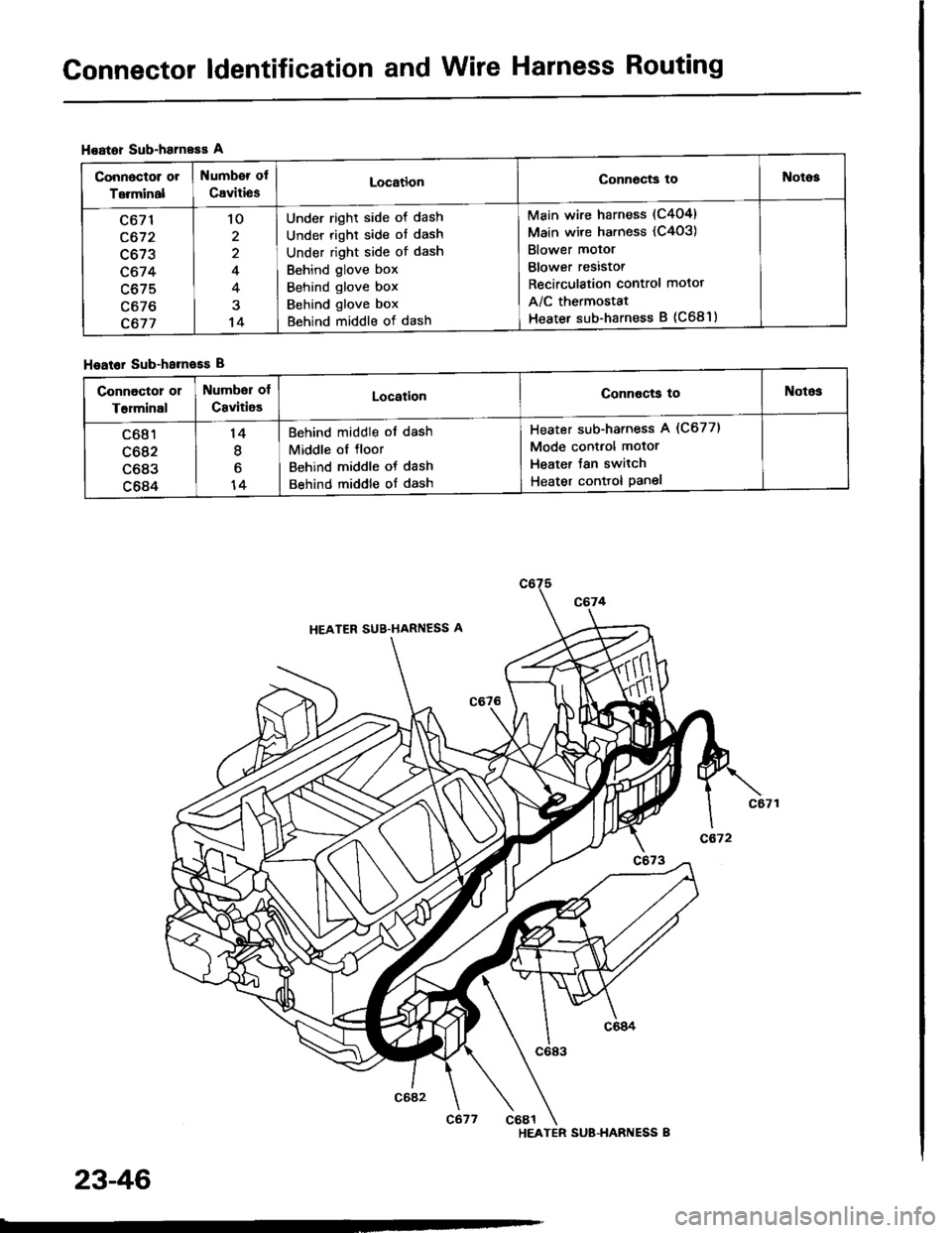

Connector ldentification and Wire Harness Routing

Hoator Sub-harneEs A

Hoator Sub-hameEs B

Connoctor or

Terminal

Numb€r of

CavitiesLocationConn6cts toNotog

c671

c672

c673

c674

c675

c676

c677

'lo

2

4

4

14

Under right side ot dash

Under right side of dash

Under right side of dash

Behind glove box

Behind glove box

Behind glove box

Behind middle of dash

Main wire harness (C404)

Main wire harness (C4o3)

Blower motor

Blower resistor

Recirculation control motot

A/C thermostat

Heater sub-harness B (C681)

connoctor 01

T6rminal

Number of

CavitioELocationConnocts toNotos

c681

c682

c683

c684

14

I

6

14

Behind middle of dash

Middle ol floor

Behind middle of dash

Behind middle of dash

Heater sub-harness A (C677)

Mode control motor

Heater Jan switch

Heater conttol Panel

HEATER SUB-HARI{ESS B

23-46

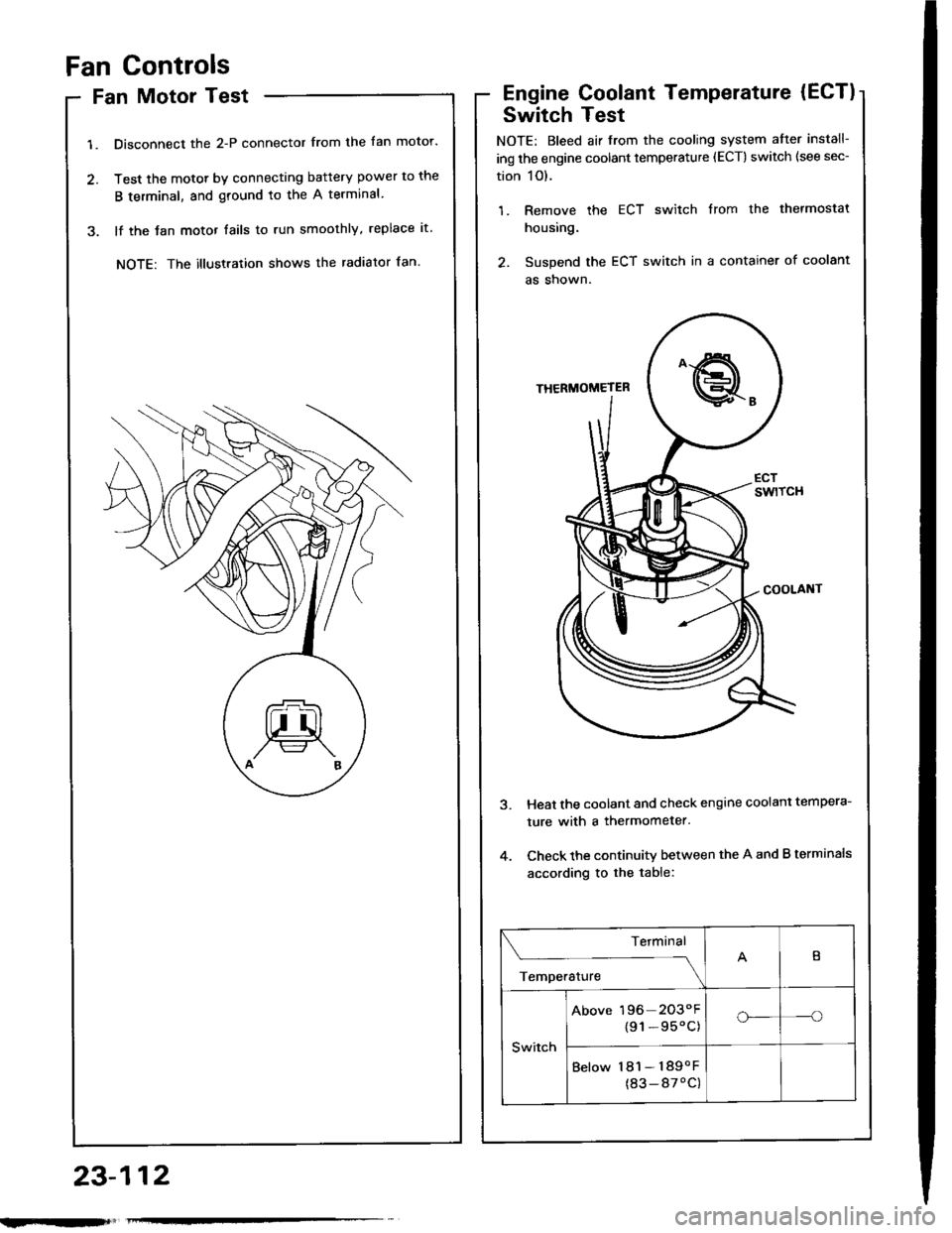

Fan Controls

Fan Motor Test

1. Disconnect the 2-P connector from the fan motor.

2. Test the motot by connecting battery power to the

B terminal, and ground to the A terminal

3. lf the Jan motor fails to run smoothly, replace it.

NOTE: The illustration shows the radiator fan.

Engine Coolant Temperature (ECT)

Switch Test

NOTE: Bleed air from the cooling system atter install-

ing the engine coolant temperature (ECT) switch (see sec-

tion 1O).

1. Remove the ECT switch from the thermostat

housing.

2. Suspend the ECT switch in a container of coolant

as shown.

Heat the coolant and check engine coolanl tempera-

ture with a thermometer.

Check the continuity between the A and B terminals

according to the table:

Terminal

;;,".,"---\

B

Switch

Above 196 2O3"F

{91-95'C)o_-o

Below 181- 189oF

(83-87'C)

23-112