Main harness HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 394 of 1413

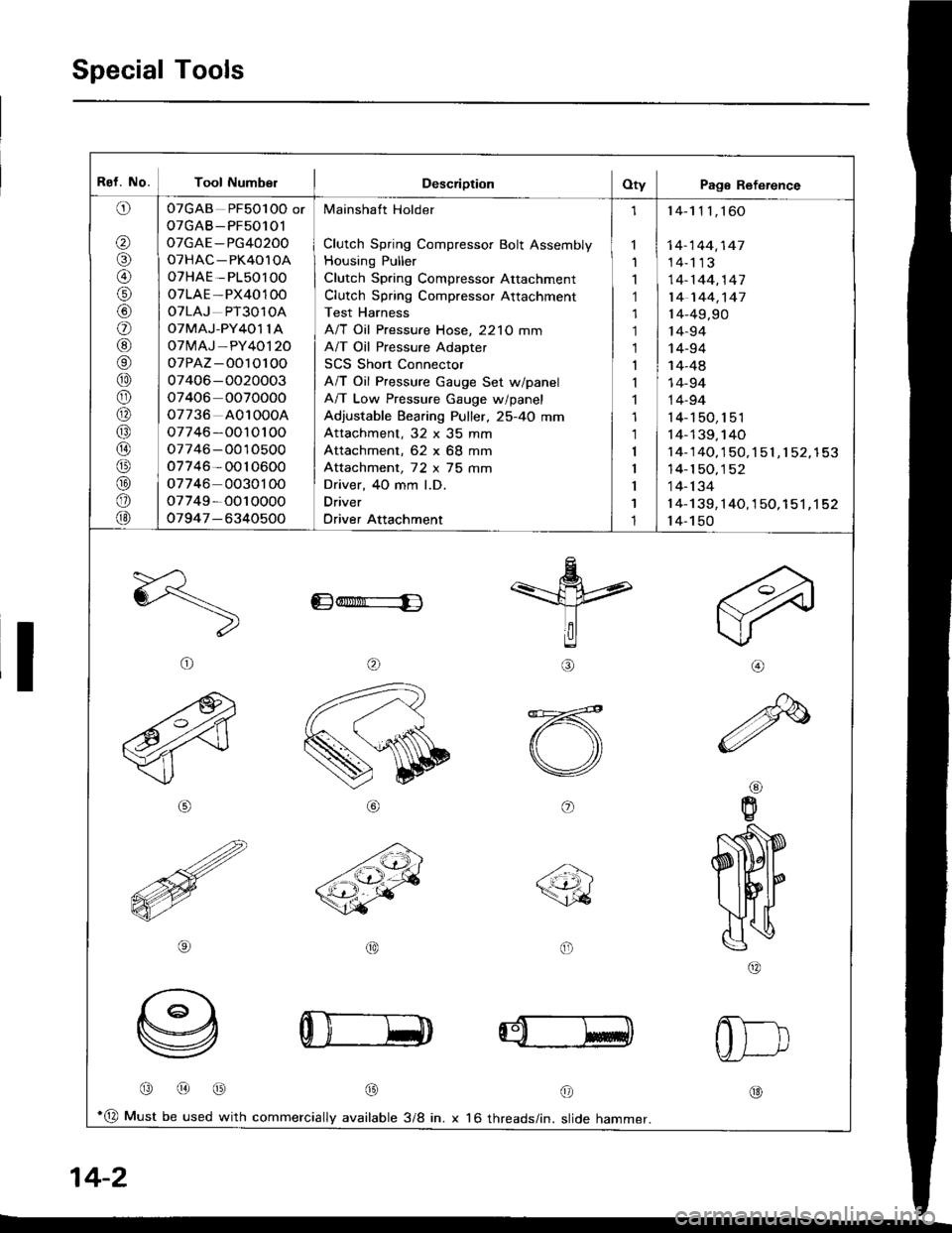

Special Tools

Rol. No. Tool NumbslDescriptionOty Page Reference

o

IA\

,6\

@

€/

o

@rt)

@

@

\9

@

@

@

@

@

@

OTGAB PF50l OO

oTGAB-PF50101

oTGAE-PG40200

oTHAC-PK4010A

oTHAE-PL50lOO

oTLAE-PX40100

OTLAJ PT30l OA

OTMAJ-PY4O'I 1A

oTMAJ-PY40120

oTPAZ -OO10100

07406-OO20003

o7406 0070000

07736 A01000A

o7746-O010100

o7746-O010500

07746-OO10600

07746 0030100

o7749-O010000

07947-6340500

Mainshatt Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Clutch Spring Compressor Attachment

Clutch Spring Compressor Attachment

Test Harness

A/T Oil Pressure Hose, 221O mm

A/T Oil Pressure Adapter

SCS Short Connector

A/T Oil Pressure Gauge Set w/panel

A/T Low Pressure Gauge w/panel

Adjustable Bearing Puller, 25-40 mm

Attachment, 32 x 35 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Driver, 40 mm l.D.

Driver

Oriver Attachment

'I

I

1

1,1

1

1

1,|

1

1

1

1

1

I

I'I

1

14-1 1 1.160

14-144,147

14-1 1 3

14- 144,147

14 144,'t47

14-49,90

14-94

14-94't 4-44

14-94

14-94

14-150,151

14-139,140

14-140.1 50,1 51,1 52, 1 53

14-150,152

14-134

1 4-1 39,'140, 1 50.1 51,1 52

14,150

Edrn$r--€

o

a)

a6l@o

@@@@(r)

*@ Must be used with commercially available 3/8 in. x 16 threads/in. slide hammer.

@

14-2

Page 467 of 1413

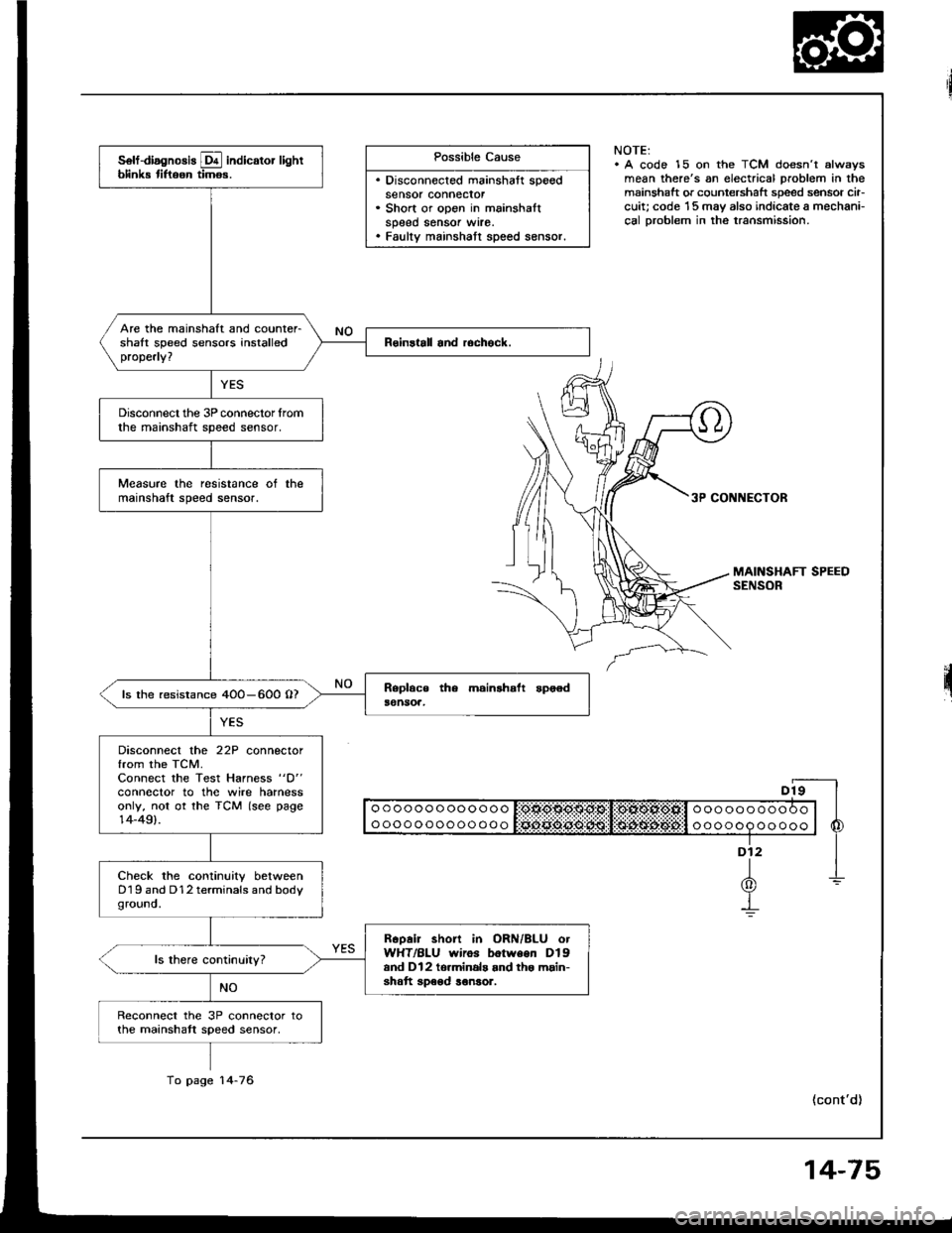

Possible Cause

. Disconnected mainshaft speedsensor connecror. Short or open in mainshaltspeed sensor wrre.. Faulty mainshatt speed sensor.

NOTE:. A code 15 on the TCM doesn't alwsysmean there's an electrical problem in themainshaft or countershaft speed sensor cir-cuit; code '15 may also indicate a mechani-cal Droblem in the transmission.

3P CONNECTOR

II o o o o o o o oo o o o o I:OtlO$O$g:Sl!:OlXOl*Ofill o o o o o o o o o O o | |

I ooooooooooooo l Sciii:ddii:ijii:l:i$idi$;d6#:l o oooop oo ooo | 6

"-f

1-L(0)Y-!

(cont'd)

solf-diagnosis E indicator lightblink tiftoon timos.

Are the mainshaft and counter-shalt speed sensors installedproperly?

Disconnect the 3P connector lromthe mainshaft speed sensor.

Measure the resistance ot themainshaft speed sensor.

ls the resistance 4OO-600 O?

Disconnect the 22P connectorfrom the TCM.Connect the Test Harness "D"

conneclor to the wire harnessonly, not ot the TCM (see page14-49).

Check the continuity betweenD19 and D12 terminals and bodyground.

Rcoair short in ORN/BLU otWHT/BLU wiros botween Dlgand Dl2 to.minals and tho main-shatt speod ronsor.

Reconnect the 3P connector tothe mainshatt speed sensor,

To page 14-76

14-75

Page 476 of 1413

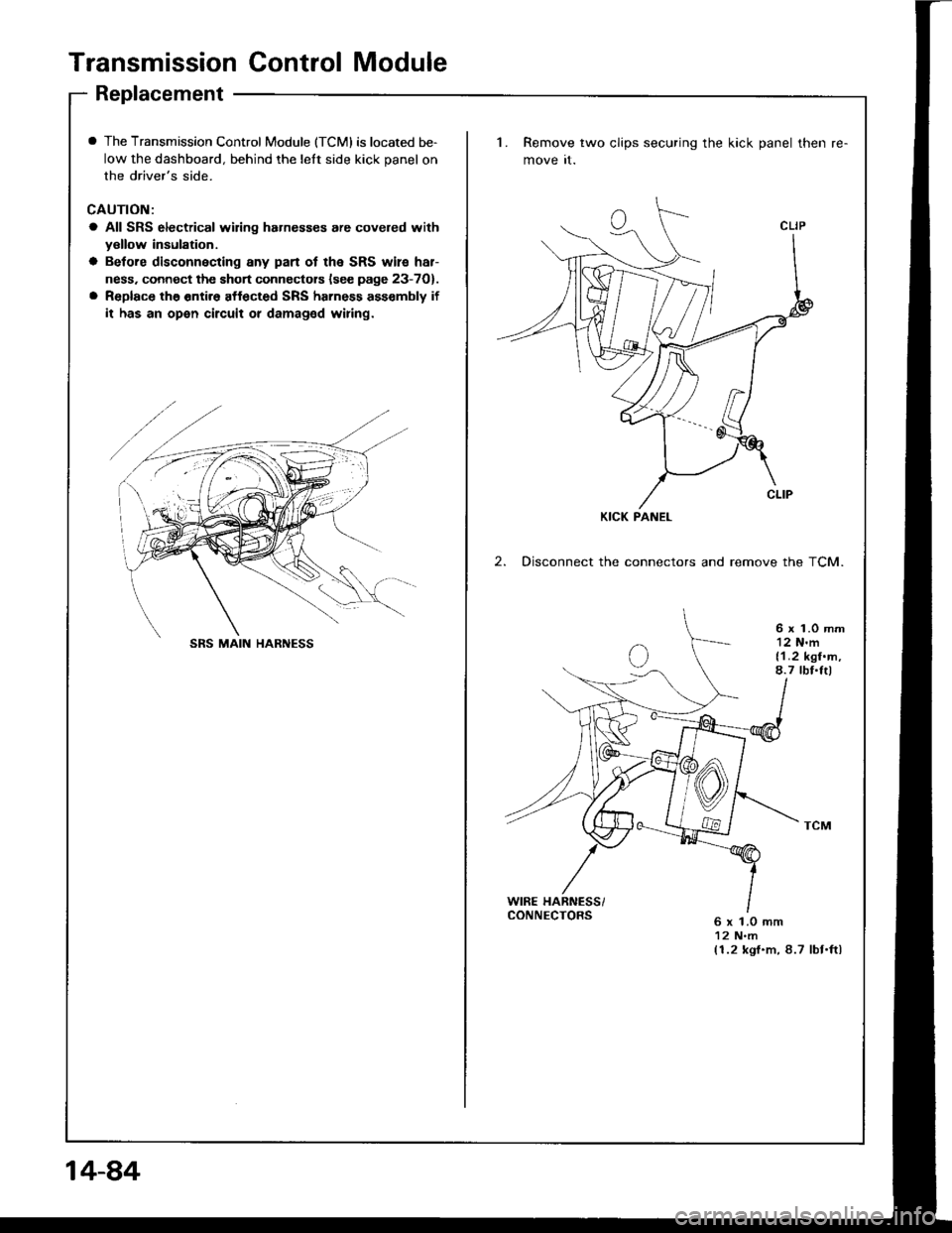

Transmission Control Module

Replacement

I The Transmission Control Module (TCMI is located be-

low the dashboard, behind the lelt side kick panel on

the driver's side.

CAUTION:

a All SRS electrical wiring hahesses are covered withyellow insulation.

a Betore disconnecting any pan ot the SRS wile har-

ness. connect the short connectors lsee page 23-7O).

a Replace the entir6 affected SRS harness ass€mbly if

it has an open circuit or damaged wiring.

1. Remove two clips securing the kick panel then

move it.

2. Disconnect the connectors and remove the TCM.

6 x 1.0 mm12 N'm{1.2 kgf.m,8.7 tbf.Itl

WIRE HARNESS/CONNECTORS6 x 1.0 mm12 N.m(1.2 kgf.m, 8.7 lbt.ftl

KICK PANEL

SRS MAIN HARNESS

14-84

Page 477 of 1413

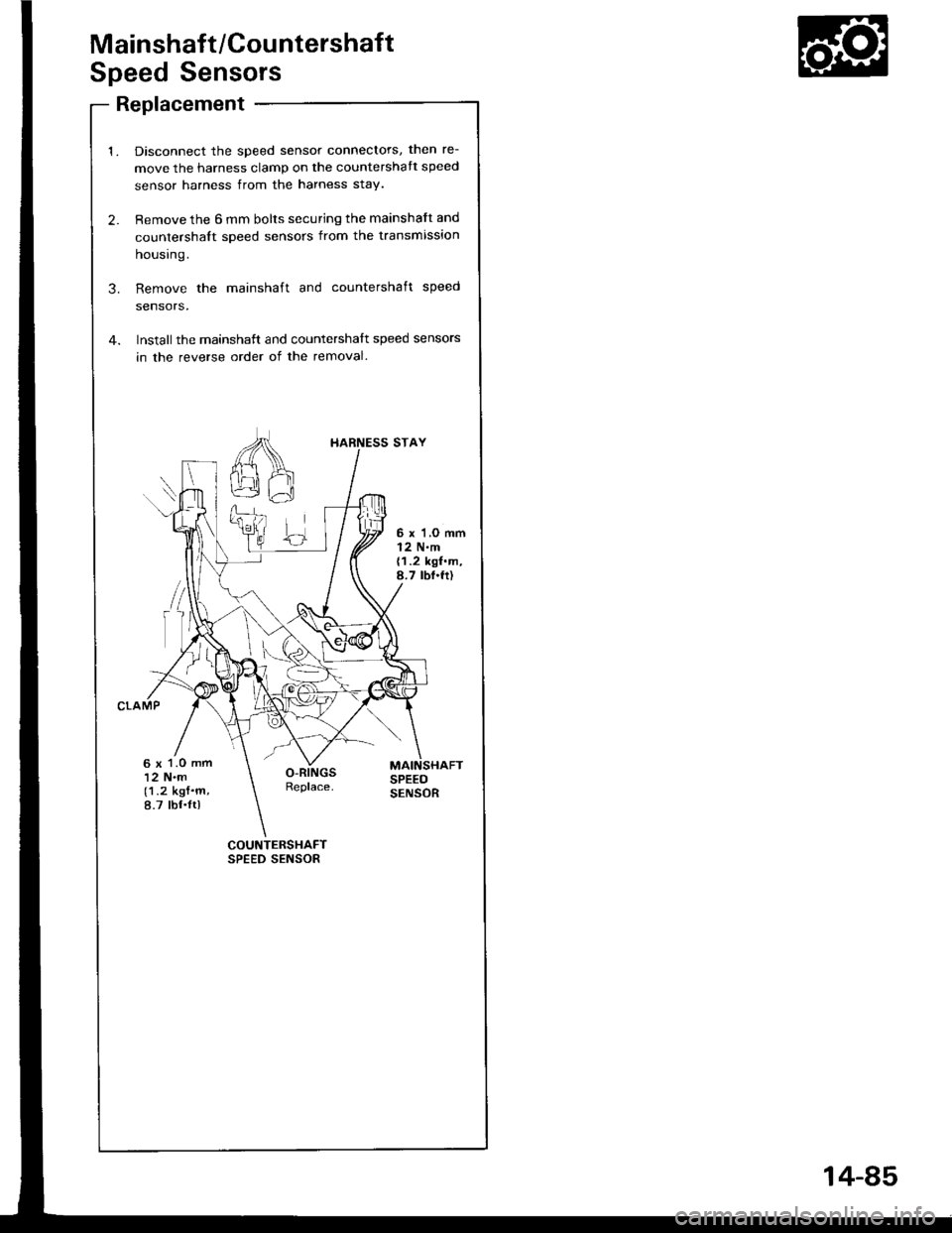

Mainshaft/Countershaft

Speed Sensors

Replacement

Disconnect the speed sensor connectors, then re-

move the harness clamp on the countershatt speed

sensor harness from the harness stay.

Remove the 6 mm bolts securing the mainshaft and

countershalt speed sensors from the transmission

housrng.

Remove the mainshaft and countershaft speed

sensors,

Installthe mainshatt and countershalt speed sensors

in the reverse order of the removal.

COUNTERSHAFTSPEED SENSOR

I{ARNESS STAY

6 x'l,O mml2 N.m{1.2 kgf.m,8.7 tbf.fr)

6 x 1.O mm12 N.m(1.2 kgf.m,8.7 tbf.ltl

14-85

Page 491 of 1413

Transmission

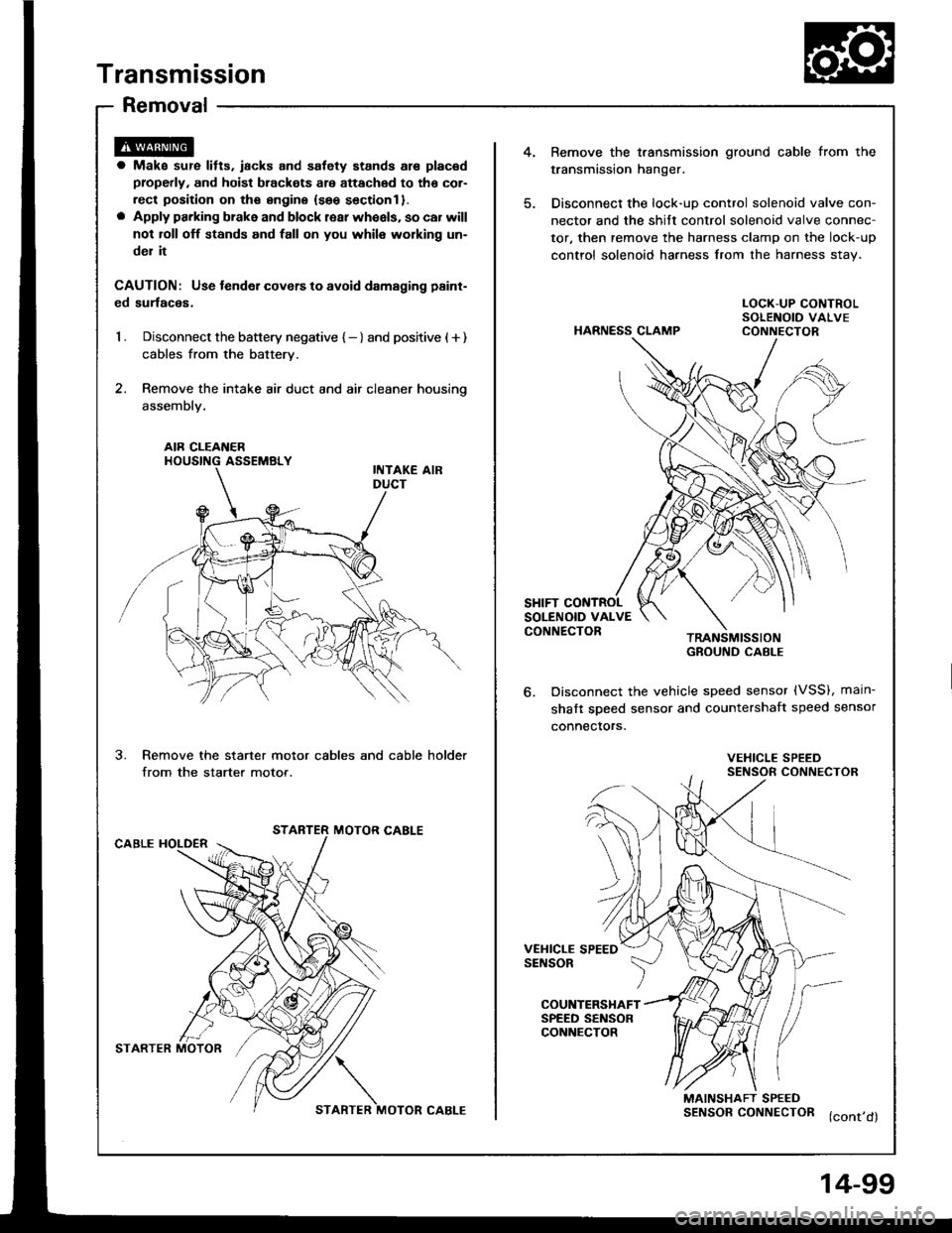

Removal

4.Bemove the t.ansmission ground cable from the

transmission hanger.

Disconnect the lock-uD control solenoid valve con-

nector and the shitt control solenoid valve connec-

tor, then remove the harness clamp on the lock-up

control solenoid harness from the harness stav.

a Make sur€ lifts. iacks and safety stands are placad

properly, and hoist brackots are attachod to tho cor-

rect position on ths sngine {seo sectionl }.o Apply parking brake and block rear wheels, so car will

not roll off stands and fall on you whil6 working un-

del it

CAUTION: Use tender covers to avoid damsging paint-

ed surlaces,

1 . Disconnect the battery negative { - } and positive ( + )

cables from the battery.

2. Remove the intake air duct and air cleaner housino

assembly.

HARNESS CLAMP

LOCK-UP CONTROLSOLENOID VALVECONNECTOR

AIR CLEAI{ERHOUSING ASSEMBLY

SHIFT CONTROLSOLENOID VALVECONNECTORTRANSMISSIONGROUND CABI-E

Disconnect the vehicle speed sensor (VSS), main-

shaft sDeed sensor and countershaft speed sensor

connectors.

3.Remove the starter motor cables and cable holder

from the starter motor.VEHICLE SPEEDSENSOR CONNECTOR

STARTER MOTOR CABLECABLE HOLDER

VEHICLE SPEEDSENSOR

COUNTERSHAFTSPEED SENSORCONNECTOR

MAINSHAFT SPEEDSENSORCONNECTOR (cont,d)

STARTER MOTOR?/\

STARTER MOTOR CABLE

4-99

Page 496 of 1413

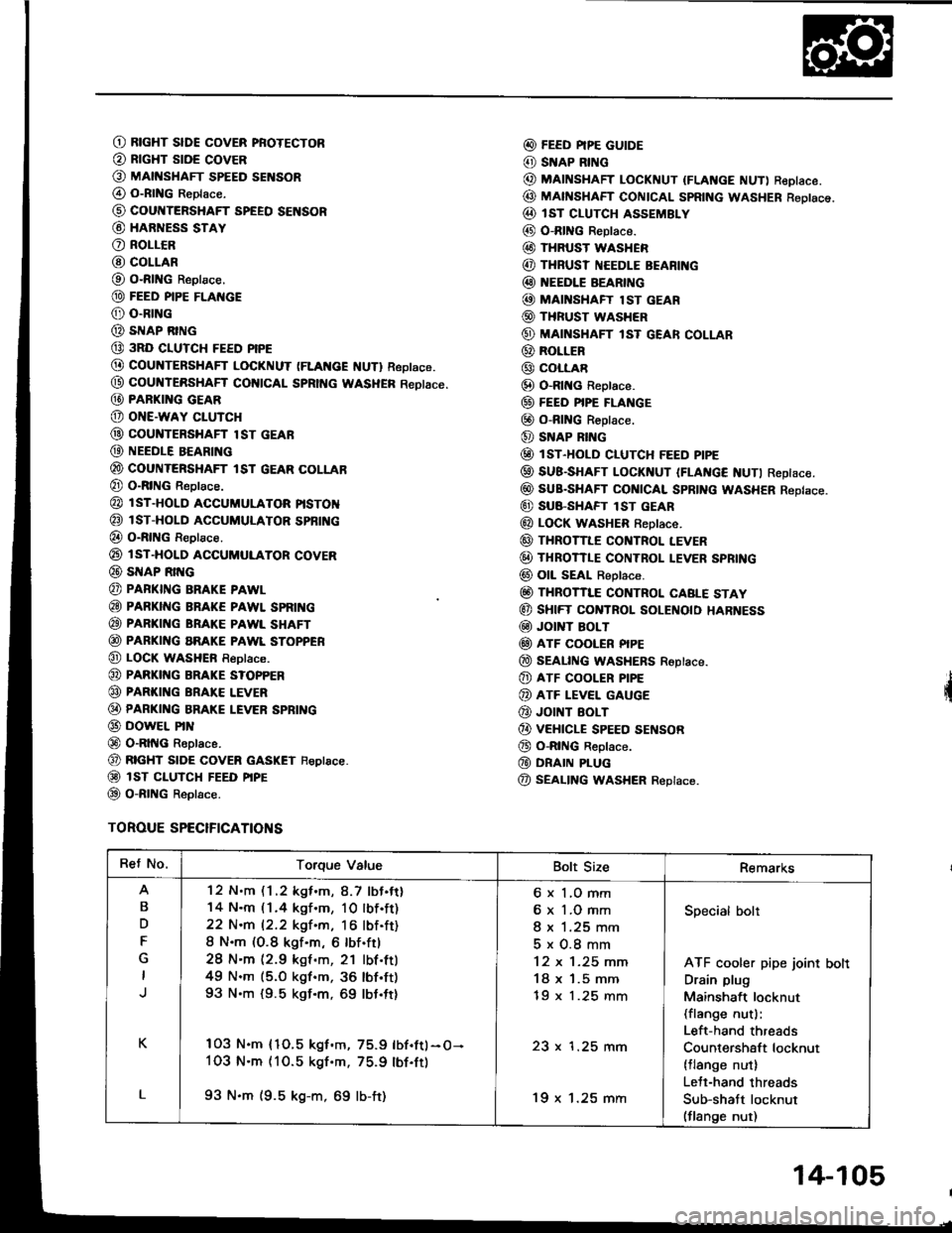

O RtcHT slDE covER pRoTEcToR

@ RrcHT stDE covER

O MAtt{sHAFr spEED sENsoR

@ o-RtNG Reptace.

@ cour{TERSHAFT SPEEO SENSOR

@ HARNESS STAY

O RoLLCR

@ COLLAR

O O-RING Reptace.

@ FEED PIPE FLAI{GE

@ o-RrNG

@ sIrlAP RING

@ 3RD CIUTCH FEED PIPE

@ COUNTERSHAFT LOCKNUT (FLAt{cE f{UTl Reptace.

@ coultTERsHAFf col{tCAL SpRtt{c WASHER Reotace.

@ PARKI G GEAR

@ oNE-waY cLUTcH

@ couNTERsHAFr lsr GEAR

@ NEEDLE BEARING

@ couNTERsHAFr tsr GEAR coLLAB

@ O-RING Reptace.

@ l sT-HoLD accuMuLAToR ptsToN

@ isT-HoLD ACCUMULAToR spBfi{c

@ o-RtNG Reptace.

@ rsT-HoLD ACGUMULAToR covER

@ SNAP Rrr{G

@ PAFKING BRAKE PAWL

@ PARKING BRAKE PAWL SPRII{G

@ PARKING BRAKE PAWL SHAFT

@ PARKING aRAKE PAWL SToPPER

@ LOCK wasHEn Reptace.

@ PARKI G BRAKE s?oPPER

@ PARKING BRAI(E LEVER

@ PARKI G BRAKE LEVER SPBING

@ DowEL PrN

@ O-RltIG Reptace.

@ RTGHT stoE covER GASKET Feptace.

@ isT ct-uTcH FEED ptpE

@ o-RtNG Reptace.

TOROUE SPECIFICATIONS

@ FEED PIPE GUIDE

@ SNAP RING

@ MAINSHAFT LocKNUT {FLANGE NUT) ReDIace.

@ MAfISHAFT CONTCAL SpRtNG WASHER Reotsce.

@ IsT cLUTcH ASSEMBLY

@ O-RING Reptace.

@ THRUST WASHER

@ THRUSI NEEDLE BEARI G

@ EEDLE BEARING

@ MAI'{SHAFT lsT GEAR

@ THRUST WASHER

@ MAINSHAFT lsT GEAR coLLAR

@ RoLLER

@ coLLAR

@ O-Rlt{c Reptace.

@ FEEo PIPE FLANGE

@ o-RING R€ptace.

@ SNAP RING

@ lsr-HoLD cLUTcH FEED ptpE

@ SUB-SHAFT LoCKNUT IFLAt{c€ NUTI Reptace.

@ suB-sHAFr cot{tcAl spRtNG WASHER Reptace.

@ SU8-SHAFT lST GEAR

@ LOCK WASHER f,eptace.

@ THRoTILE cor{TRoL LEVER

@ THRoTTLE coNTRoL I.EVER SPRING

@ oll sEAt Reptace.

@ THRoTTI"E coNTRoL CABLE STAY

@ sHtFT CONTROL SOLEI{O|O HARNESS

@ Jor T BoLT

@ ATF COOLER PIPE

@ SEAL|NG WASHERS Roptace.

@ ATF cooLER P|PE

@ ATF LEVEL GAUGE

@ JOINT EOLT

@ vEHtcLE spEED sEf{soR

@ o-RtNG Reptace.

@ DRAIN PLUG

@ SEALING WASHER Replace.

Ret No.Torque ValueBolt SizeRemarks

B

D

F

K

L

'12 N.m (1 .2 kgf .m, 8.7 lbJ.tt)

14 N.m (1.4 kgf.m, 10lbf.ft)

22 N.m 12.2 kgf.m, 16 lbf.ft)

8 N.m (O.8 kgf.m, 6 lbf.ftl

28 N'm (2.9 kgf .m, 21 lbf.ttl

49 N.m (5.O kgf.m, 36 lbf'ft)

93 N.m {9.5 kgf.m, 69 lbt.ft}

103 N.m {1O.5 kgf.m, 75.9 lbf.ftl-O-

1O3 N.m (10.5 kgf'm. 75.9 lbf.ft)

93 N.m (9.5 kg-m, 69 lb-ft)

6 x 1,O mm

6 x 1.O mm

I x 1.25 mm

5x0.8mm

12 x 1-25 mm

18 x '1.5 mm

tY x t.z5 mm

23 x 1.25 mm

'19 x 1.25 mm

Specialbolt

ATF cooler pipe joint bolt

Drain plug

Mainshaft locknut(flange nut):

Left-hand threads

Countershaft locknut(tlange nut)

Lett-hand threads

Sub-shatt locknut(flange nut)

14-105

Page 557 of 1413

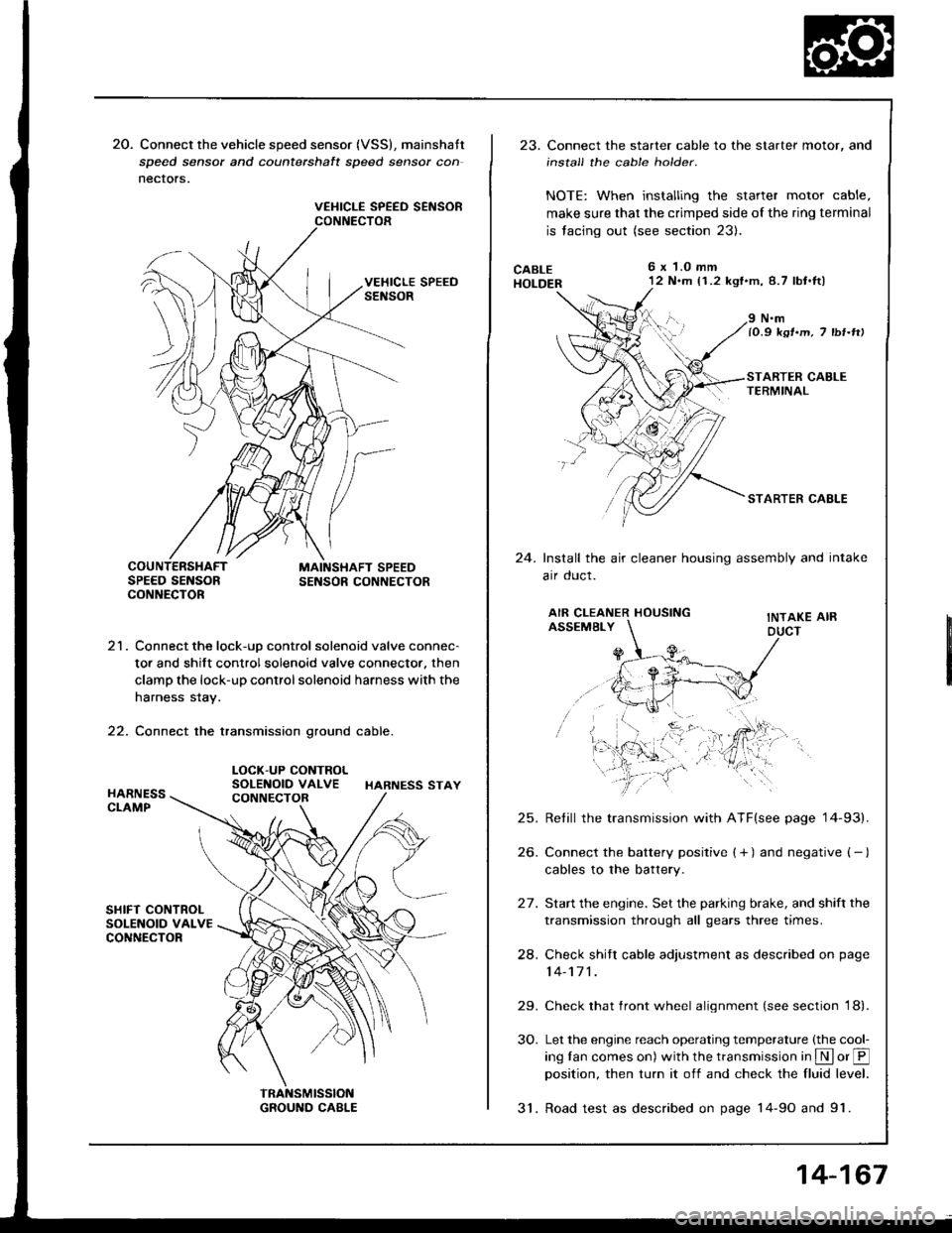

20. Connect the vehicle speed sensor (VSS), mainshatt

speed sensor and counterchalt speed sensor con

nectors.

VEHICLE SPEED SEiISORCONNECTOR

21. Connect the lock-uD control solenoid valve connec-

tor and shift control solenoid valve connector. then

clamp the lock-up control solenoid harness with the

harness stay.

22. Connect the transmission ground cable.

LOCK-UP CONTROLSOLENOID VALVE HARNESS STAY

23. Connect the starter cable to the starter motor, and

install the cable holder.

NOTE: When installing the starter motor cable,

make sure that the crimped side of the ring terminal

is facing out (see section 23).

CABLEHOLDER

6x 1.0 mm'12 N.m (1.2 kgf'm,8.7 lbt.tl)

24.

N.mlO.9 ksr.m, 7 tbr-rtt

STARTER CAELE

Install the air cleaner housing assembly and intake

arr oucl.

AIR CLEANER HOUSINGASSEMBLYINTAKE AIRDUCT

25.

26.

24.

29.

30.

Retill the transmission with ATF(see page '14-93).

Connect the battery positive ( + ) and negative ( - )

cables to the battery.

Start the engine. Set the parking brake, and shift the

transmission through all gears three times.

Check shitr cable adjustment as described on page

14-171 .

Check that front wheel alignment (see section 18).

Let the engine reach operating temperature (the cool-

ing tan comes on) with the transmission in S or @position, then turn it off and check the fluid level.

31. Road test as described on page 14-9o and 91.

14-167

Page 562 of 1413

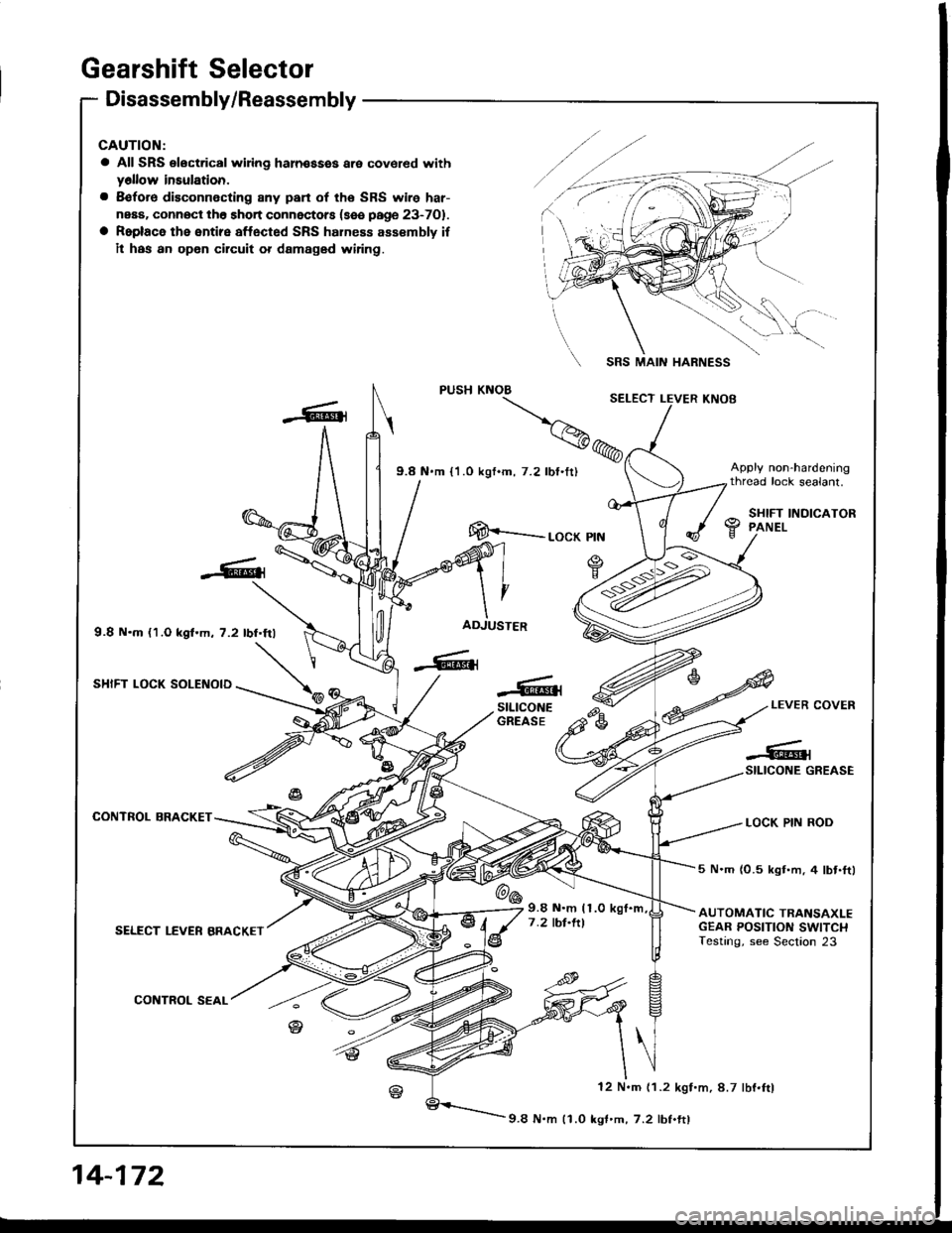

Gearshift Selector

Disassembly/Reassembly

CAUTION:

a All SRS electrical wiing haln€ssss are covered withy6llow insulation.

a 8€fore disconnecting 8ny pan of the SRS wire har-

neaa. connOct th6 short connectors (sse page 23-701.

a Roplace the entire affected SRS hahess assembly if

il has an opon circuit or damaged wiring.

9.8 N.m {1.O kgf.m, 7.2 lbf.frl

SHIFT LOCK SOLENOID

CONTROL BRACKET

SELECT LEVER BRACKET

CONTROL SEAL

SRS MAIN HARNESS

[E--__ rocK ptN

ADJUSTER

-6{stLtcoNEGREASEe-LEVER COVER

LOCK PIN ROD

-#qSILICONE GREASE

@6

5 N.m (0.5 kgt.m, 4 lbt.ftl

AUTOMATIC TRANSAXLEGEAR POSITION SWITCHTesting, see Section 23

9.8 N.m (1.0

7 .2 tbt.ltl

12 N.m (1.2 kgf.m, 8.7 lbf.ftl

9.8 N.m 11.0 kgf'm,7.2 lbf.ftl

14-172

Page 563 of 1413

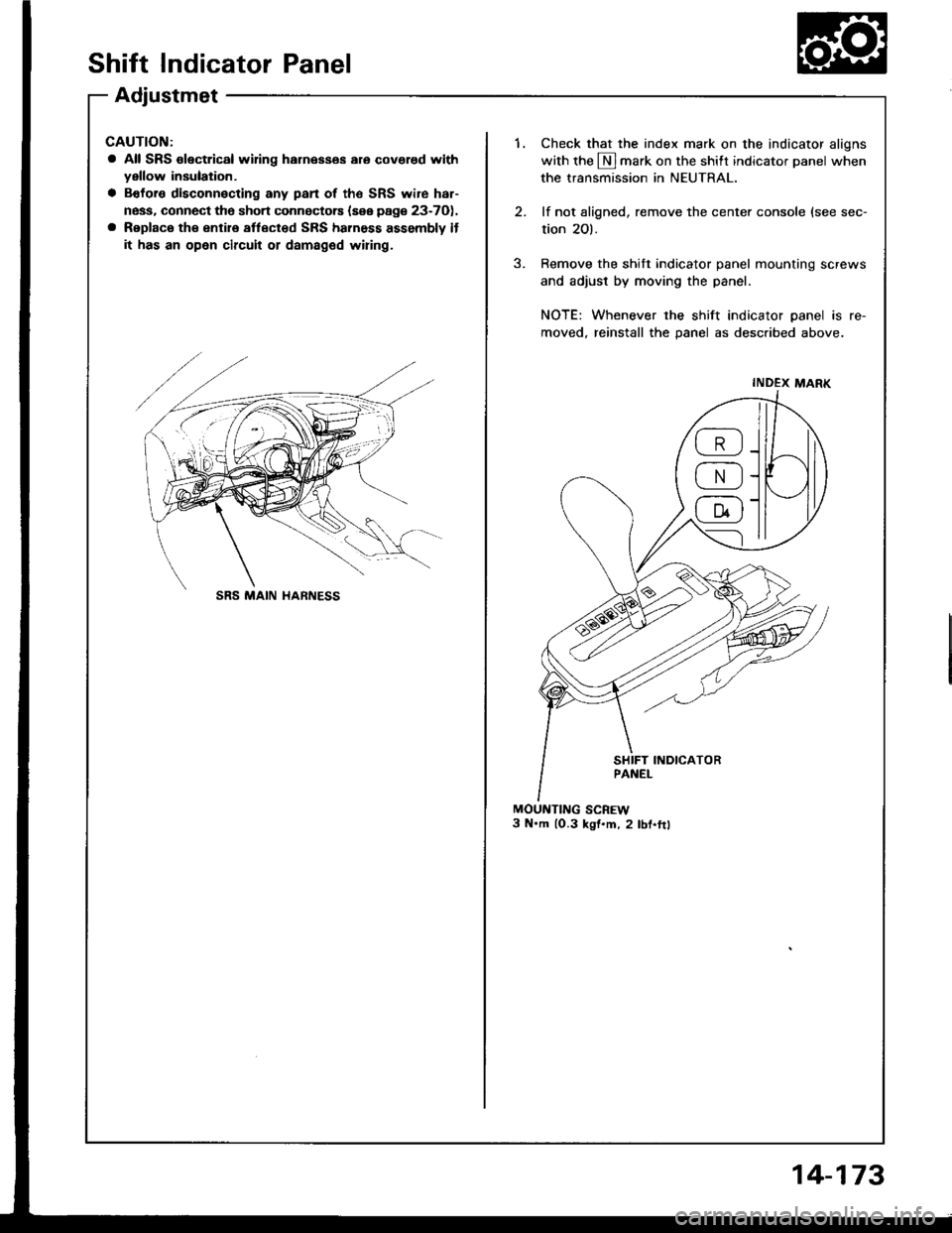

Shift Indicator Panel

Adjustmet

CAUTION:

a All SRS olectrical wifng harnesses aro covered withyellow insulation.

a Bofors disconnecting any pan of the SRS wire har-

ness, connect tho sho.t connectors {sse page 23-7O),

a Replace the entire aflect€d SRS harness assembly if

it has an open circuit or damaged wiring,

1.Check that the index mark on the indicator aligns

with the N]mark on the shift indicator panel when

the transmission in NEUTRAL.

lf not aligned, remove the center console (see sec-

tion 2O).

Remove the shift indicator panel mountinq screws

and adjust by moving the panel.

NOTE: Whenever the shift indicator panel is re-

moved, reinstall the panel as described above.

MOUNTING SCREW3 N'm lO.3 kst.m, 2 lbf.ftt

INDEX MARK

@

@

@

SRS MAIN HARNESS

14-173

Page 635 of 1413

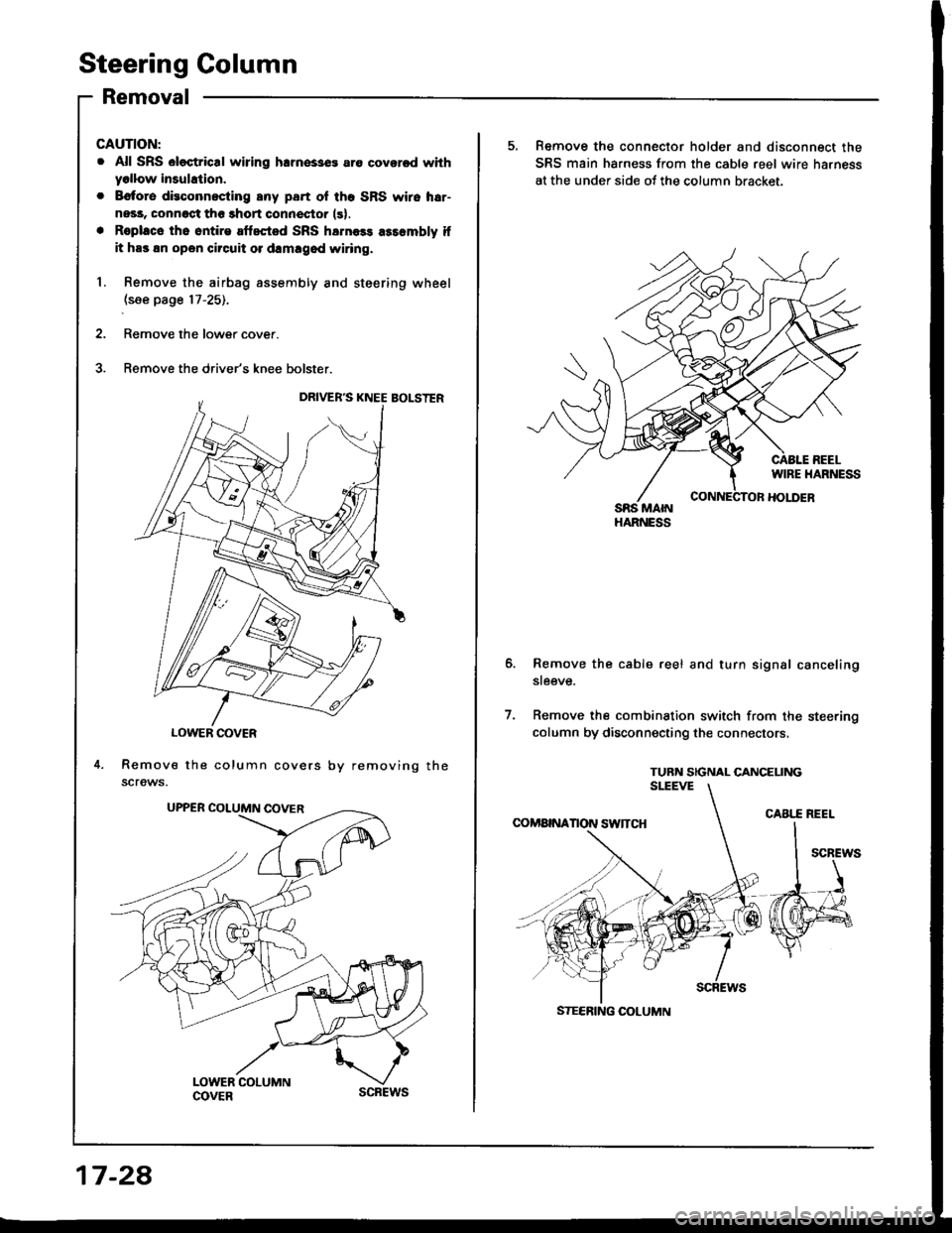

Steering Golumn

Removal

LOWER COVER

Remove the column covers

screws.

CAUTION:

. All SRS el€ctrical wiring hlrnesses are coversd withyollow insuhtion.

. Bctore dieconnocting any part ol tho SRS wiro h!r-

nesa, connoct the thort connector (s).

. Roplace tho ontire aftected SRS harness asr€mbly if

it has !n open circuit or d!mlgod wiring.

Remove the airbag assembly and steering wheel

.(see page 17-25).

Remove the lower cover.

Remove the driver's knee bolster.

by re mov in g the

17-2A

scREws

5. Remove the connector holder and disconnect the

SRS main harness from the cable reel wire ha.ness

at the under side ot the column bracket.

HARNESS

Remove the cable reel and turn signal canceling

steeve.

Remove the combination switch from the steering

column by disconnecting the connectors,

TURN SIGNAL CANCELINGSlTEVE

COMA|NANON SW]TCH

7.

CABI..E REEL

STEERING COLUMN