Mainshaft HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 395 of 1413

The Automatic Transmission is a combination of a 3-e,ement torque convefter and triple-shaft electfonically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator assembly in a single unit, The torque converter is connected

to the engine crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter

is a ring gear which meshes with the starter pinion when the engine is being staned. The entire torque converter assem-

bly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts, the mainshaft. countershaft and sub-shaft. The mainshatt is in line with the

engine crankshaft.

The mainshaft includes the clutches for 1 st, and 2ndl4th, and gears for 3rd. 2nd, 4th, reverse and l st (3rd gear is in-

tegral with the mainshaft, while reverse gear is integral with the 4th gear).

The countershaft includes the 3rd clutch and gears Ior 3rd, 2nd,4th, reverse, lst and parking. Reverse and 4th gears

can be locked to the countershaft at its center, providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the lst-hold clutch and gears for 1st and 4th

The gears on the mainshait are in constant mesh with those on the countershaft and sub-shaft. When certain combina-

tions of gears in the transmission are engaged by the clutches, power is transmitted from the mainshaft to the counter-

shaft via the sub-shatt to provide @, E, tr. tr and @ position.

Electronic Control

The electronic control system consists of the Transmission Control Module {TCM), sensors, and 4 solenoid valves. Shift-

ing and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the left side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, secondary valve body, regulator valve body. servo body, and lock-up valve

body throuqh the respective separator plates.

They are bolted on the torque converter housing.

The main valve body contains the manual valve, 1-2 shift valve, 2-3 shift valve, Clutch Pressure Cont.ol (CPC) valve,

4th exhaust valve, relief valve, and oil pump gears.

The secondary valve body contains the 4-3 kick-down valve,3-2 kick-down valve,2-3 orifice cont.ol valve, 3-4 shitt

valve, orifice control valve. modulator valve, and servo control valve

The regulator valve body contains the pressure regulator valve. lock-up control valve, torque converter check valve, and

cooler check valve.

The servo bodv contains the servo valve which is integrated with the reverse shift fork, throttle valve B, and accumulators.

The lock-ug valve bodv contains the lock-up shift valve and lock-up timing B valve. and is bolted on the secondary valve

body.

Fluid from the regulator passes through the manual valve to the various control valves.

Shitt Control Mochanism

Input to the TCM i.om various sensors located throughout the car determines which shift control solenoid valve should

be activated.

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear.

Lock-up Mechanism

In @ position. in 2nd, 3rd and 4th, and E position in 3rd, pressurized tluid can be drained from the back of the tor-

que converter through an oil passage, causing the lock-up piston to be held against the torque converter cover. As this

takes Dlace, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM

optimizes the timing ol the lock-up mechanism.

The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

14-3

Page 397 of 1413

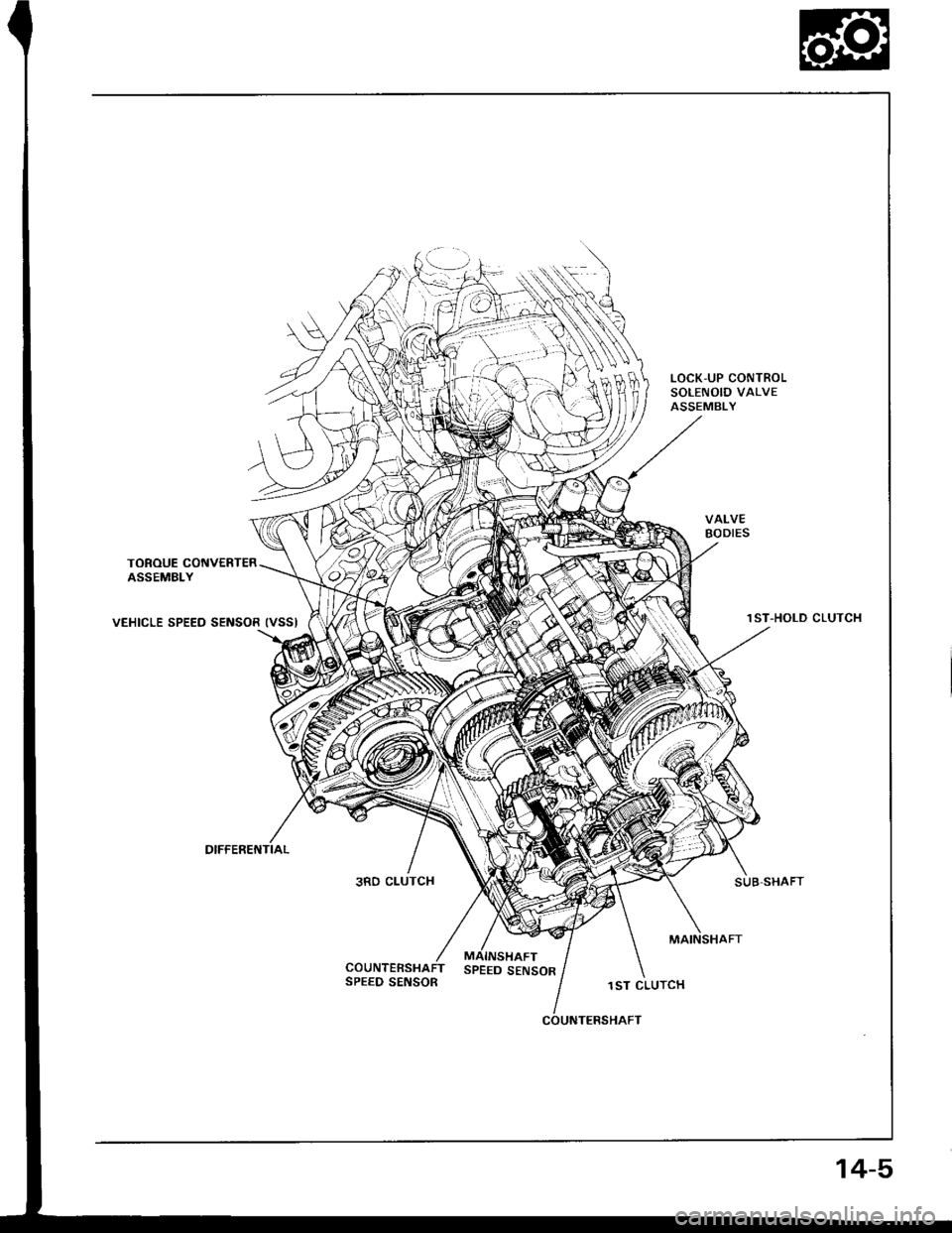

VALVEBODIES

TOROUE CONVERTERASSEMBLY

VEHICLE SPEED SENSOR IVSSI1ST-HOLD CLUTCH

SUB SHAFT3RD CLUTCH

SPEED SENSOR

MAINSHAFT

SPEED SENSOR1ST CLUTCH

COUNTERSHAFT

14-5

Page 398 of 1413

Description

Clutches

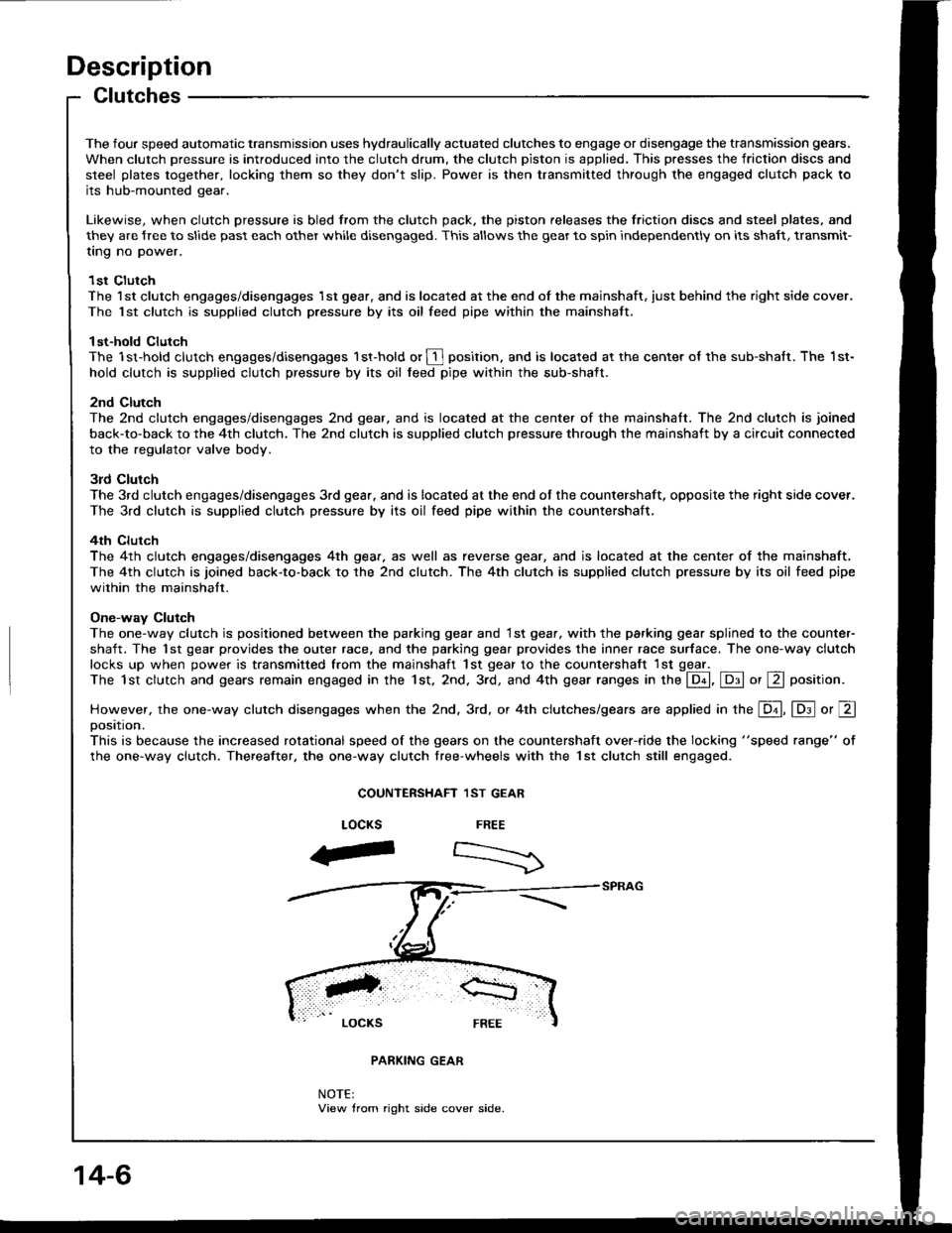

The four speed automatic transmission uses hydraulically actuated clutches to engage or disengage the transmission gears.

When clutch pressure is introduced into the clutch drum, the clutch piston is applied. This presses the iriction discs and

steel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack tojts hub-mounted gear.

Likewise, when clutch pressure is bled from the clutch pack. the piston releases the friction discs and steel plates, and

they are {ree to slide past each other while disengaged. This allows the gear to spin independently on its shaft, transmit-

ting no power.

1st ClutchThe l st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the right side cover.

The 1st clutch is supplied clutch pressure by its oil feed pipe within the mainshaft.

1st-hold clutchThe 1st-hold clutch engages/disengages 1st-hold or I Fosition, and is located at the center ol the sub-shaft. The 1st-

hold clutch is supplied clulch pressure by its oil feed pipe within the sub-shait.

2nd ClutchThe 2nd clutch engages/disengages 2nd gear, and is located at the center of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied clutch pressure through the mainshaft by a circuit connected

to the regulator valve body.

3rd Clutch

The 3rd clutch engages/disengages 3rd gea.. and is located at the end oJ the countershaft, opposite the right side cover.

The 3rd clutch is supplied clutch pressure by its oil feed pipe within the countershaft,

4th clurch

The 4th clutch engages/disengages 4th gear. as well as reverse gear, and is located at the center of the mainshaft.

The 4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied clutch pressure by its oil feed pipe

within the mainshalt.

One-way Clutch

The one-way clutch is posjtioned between the parking gear and 1st gear. with the parking gear splined to the counter-

shaft. The 1st gear provides the outer race, and the parking gear provides the inner race surface. The one-way clutch

locks up when power is transmitted from the mainshaft 1st gear to the countershaft lst ggel _The 1st clutch and gears remain engaged in the 1st. 2nd. 3rd, and 4th gear ranges in the @, E or E position.

However, the one-way clutch disengages when the 2nd. 3rd, or 4th clutches/gears are applied in the E, lD.l o, Eoosttton.

This is because the increased rotational speed of the gears on the countershaft over-ride the locking "speed range" of

the one-way clutch. Thereafter, the one-way clutch free-wheels with the lst clutch still engaged.

COUNTERSHAFT 1ST GEAR

FREE

:>

LOCKS

aF

NOTE:View trom right side cover side.

14-6

Page 399 of 1413

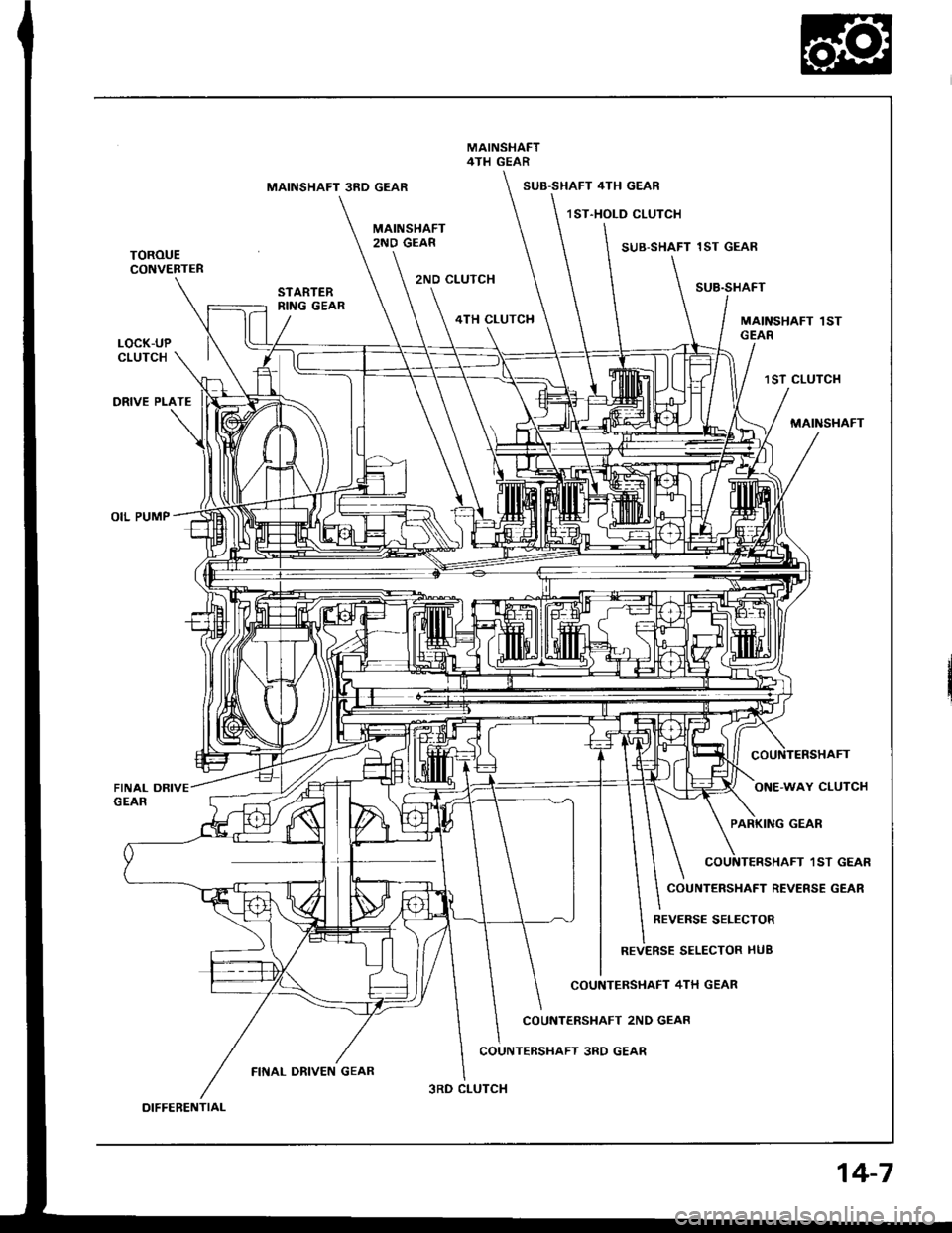

MAINSHAFT4TH GEAR

MAINSHAFT 3RD GEARSUB.SHAFT 4TH GEAR

lST,HOLD CLUTCHMAINSHAFT2ND GEARTOROUECONVERTER

SUB-SHAFT 1ST GEAR

SUB.SHAFT2ND CLUTCHSTARTERNING GEAR

LOCK-UPCLUTCH

4TH CLUTCHMAINSHAFT 1STGEAR

DRIVE PLATE

1ST CLUTCH

MAINSHAFT

ONE-WAY CLUTCH

PARKING GEAR

,I ST GEAR

COUNTERSHAFT REVERSE GEAR

REVERSE SELECTOR

REVERSE SELECTOR HU8

COUNTERSHAFT 4TH GEAR

COUNTERSHAFT 2ND GEAR

COUNTERSHAFT 3RD GEAR

DIFFERENTIAL

FINAL DRIVEN GEAR

3RD CLUTCH

14-7

Page 402 of 1413

Description

Power Flow lcont'dl

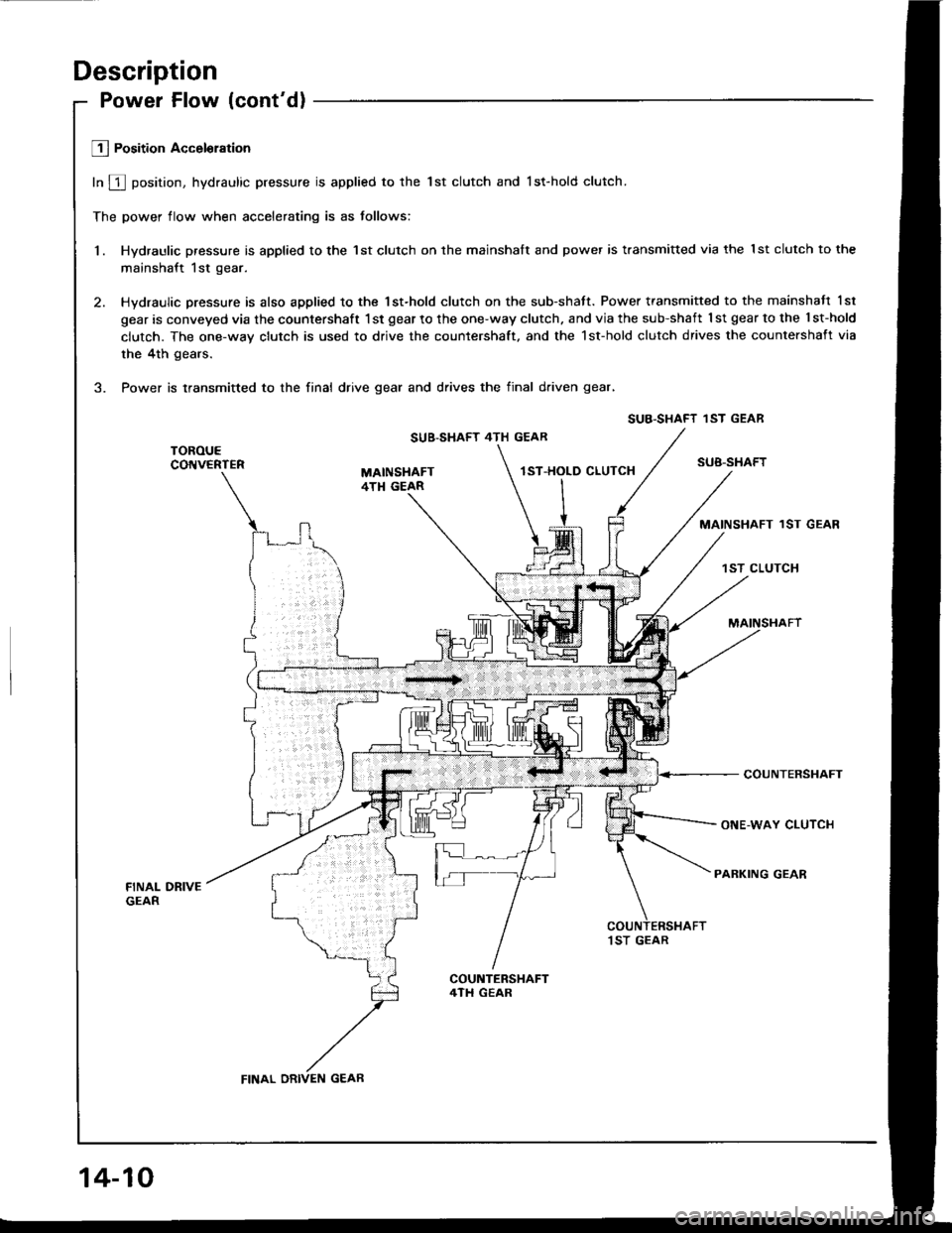

Lll Position Acceloration

In f position, hydraulic pressure is applied to the lst clutch and lst-hold clutch.

The power flow when accelerating is as tollows:

1. Hydraulic pressure is applied to the 1st clutch on the mainshalt and power is transmitted via the lst clutch to the

mainshaft 1st gear.

2. Hydraulic pressure is also applied to the 1st-hold clutch on the sub-shatt. Power transmitted to the mainshaft 1sl

gear is conveyed via the countershaft 1st gear to the one-way clutch. and via the sub-shaft 1 st gear to the l st-hold

clutch. The one-way clutch is used to drive the countershaft. and the 1st-hold clutch drives the countershaft via

the 4th gears.

3. Power is transmitted to the finai drive gear and drives the final d.iven gear,

SUB-SHAFT 4TH GEAR

SUB-SHAFTlST-HOLD CLUTCH

MAINSHAFT 1ST GEAR

1ST CLUTCH

COUNTERSHAFT

ONE-WAY CLUTCH

PARKING GEAR

,I ST GEAR

SUB.SHAFT 'IST GEAR

FINAL DRIVEN GEAR

14-10

Page 403 of 1413

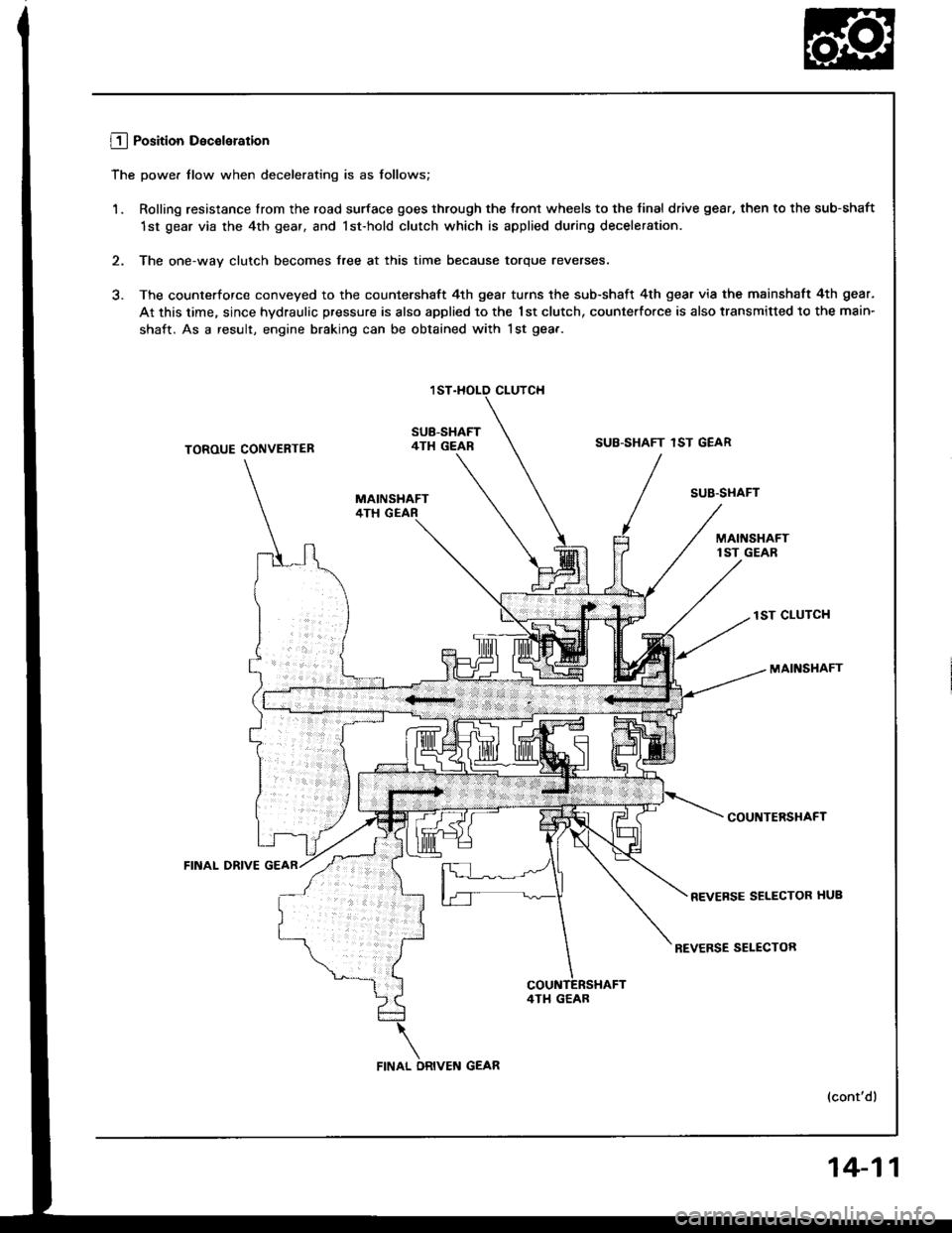

L!_j Position Deceleration

The power tlow when decelerating is as follows;

1. Rolling resistance lrom the road surface goes through the tront wheels to the final drive gear, then to the sub-shaft

1st gear via the 4th gear, and lst-hold clutch which is applied during deceleration.

2. The one-way clutch becomes free at this time because torque reverses.

3. The counterforce conveyed to the countershaft 4th gear turns the sub-shaft 4th gear via the mainshaft 4th gear.

At this time, since hydraulic pressure is also applied to the 1st clutch, counterfo.ce is also transmitted to the main-

shaft. As a result, engine braking can be obtained with lst gea.-

CLUTCH

SUB-SHAFT4TH GEARSUB-SHAFT 1ST GEARTOROUE CONVENTER

FINAL DRIVE

SUB'STIAFT

lST CLUTCH

MAINSHAFT

COUNTERSHAFT

REVEFSE SELECTOR HUB

REVERSE SELECTOR

(cont'dl

4TI1 GEAB

14-11

Page 404 of 1413

Description

Power Flow (cont'd)

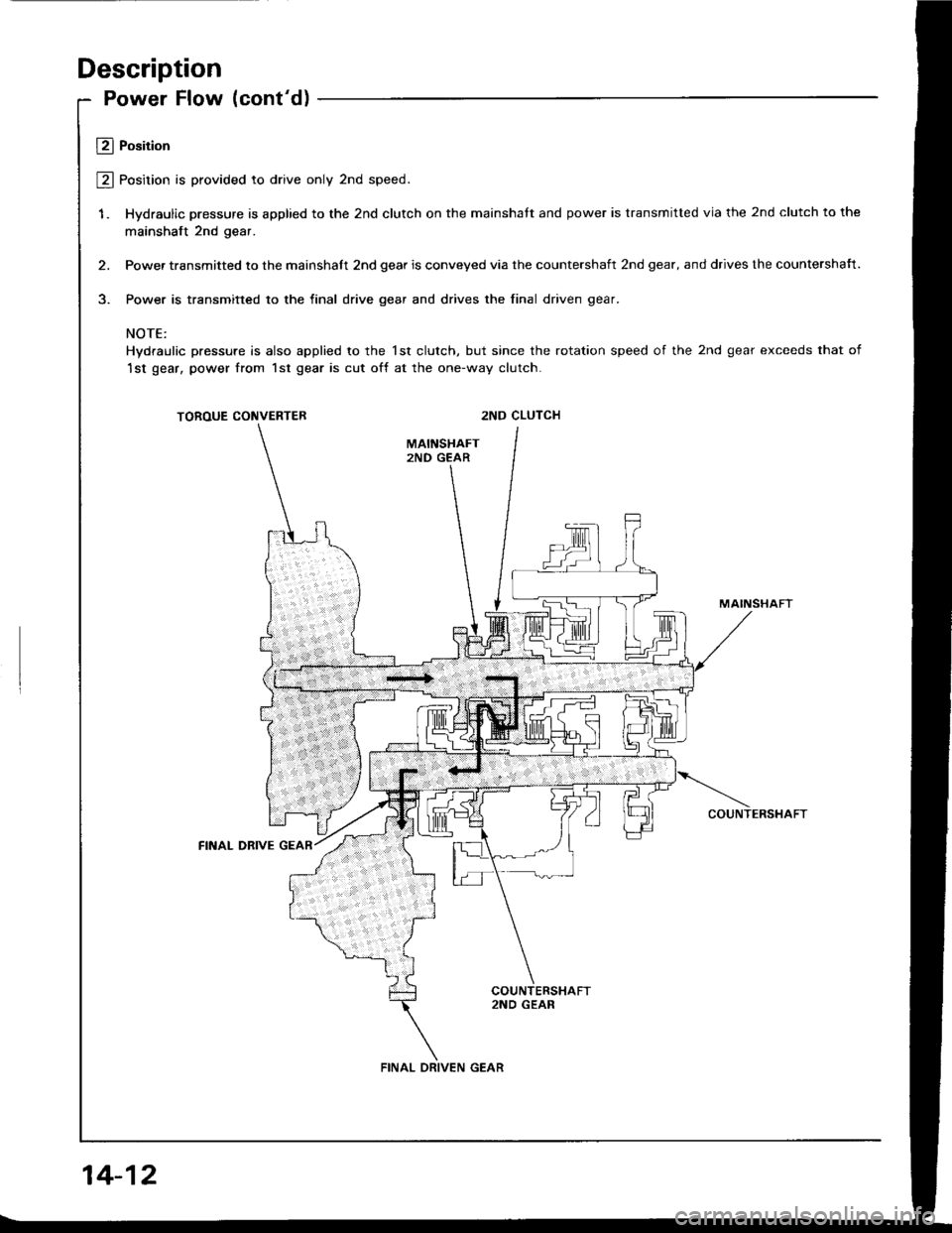

Ll Position

@ Position is provided to drive only 2nd speed.

1. Hydraulic pressure is applied to the 2nd clutch on the mainshatt and power is transmitted via the 2nd clutch to the

mainshaft 2nd gear.

2. Power transmitted to the mainshalt 2nd gear is conveyed via the countershaft 2nd gear, and drives the countersha{t.

3. Power is transmitted to the final drive gear and drives the final driven gear.

NOTE:

Hydraulic pressure is also applied to the lst clutch, but since the rotation speed of the 2nd gear exceeds that of

1st gear, power from 1st gear is cut off at the one-way clutch.

TOROUE CONVERTER2ND CLUTCH

MAINSHAFT

COUNTERSHAFT

FINAL DBIVE

2ND GEAR

FINAL DRIVEN GEAR

14-12

Page 405 of 1413

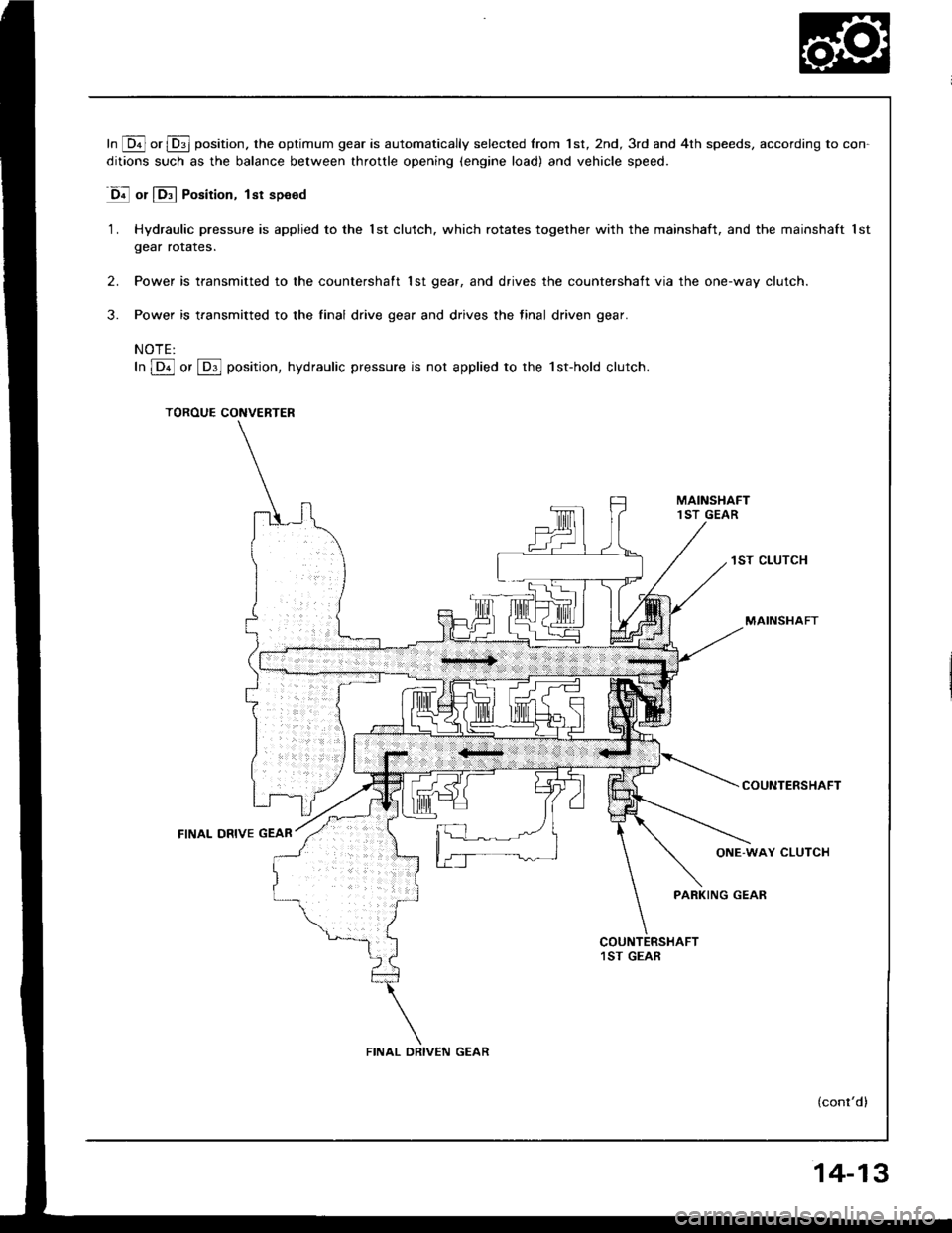

In [Q! or l!31 position. the optimum gear is automatically selected from 1st, 2nd, 3rd and 4th speeds, according to con-

ditions such as the balance between throttle opening (engine load) and vehicle speed.

D! or lE.l Position, lst speed

1. Hydraulic pressure is applied to the lst clutch. which rotates together with the mainshaft, and the mainshaft lst

gear rorares.

2. Power is transmitted to the countershaft 1st gear, and drives the countershaft via the one-way clutch.

3. Power is transmitted to the final drive gear and drives the final driven gear.

NOTE:

In lDil or [Dl]l position, hydraulic pressure is not applied to the 1st-hold clutch.

TOROUE CONVERTER

1ST CLUTCH

MAINSHAFT

COUNTERSHAFT

(cont'd)

FINAL DRIVE GEAR

FINAL DRIVEN GEAR

14-13

Page 406 of 1413

Description

Power Flow (cont'd)

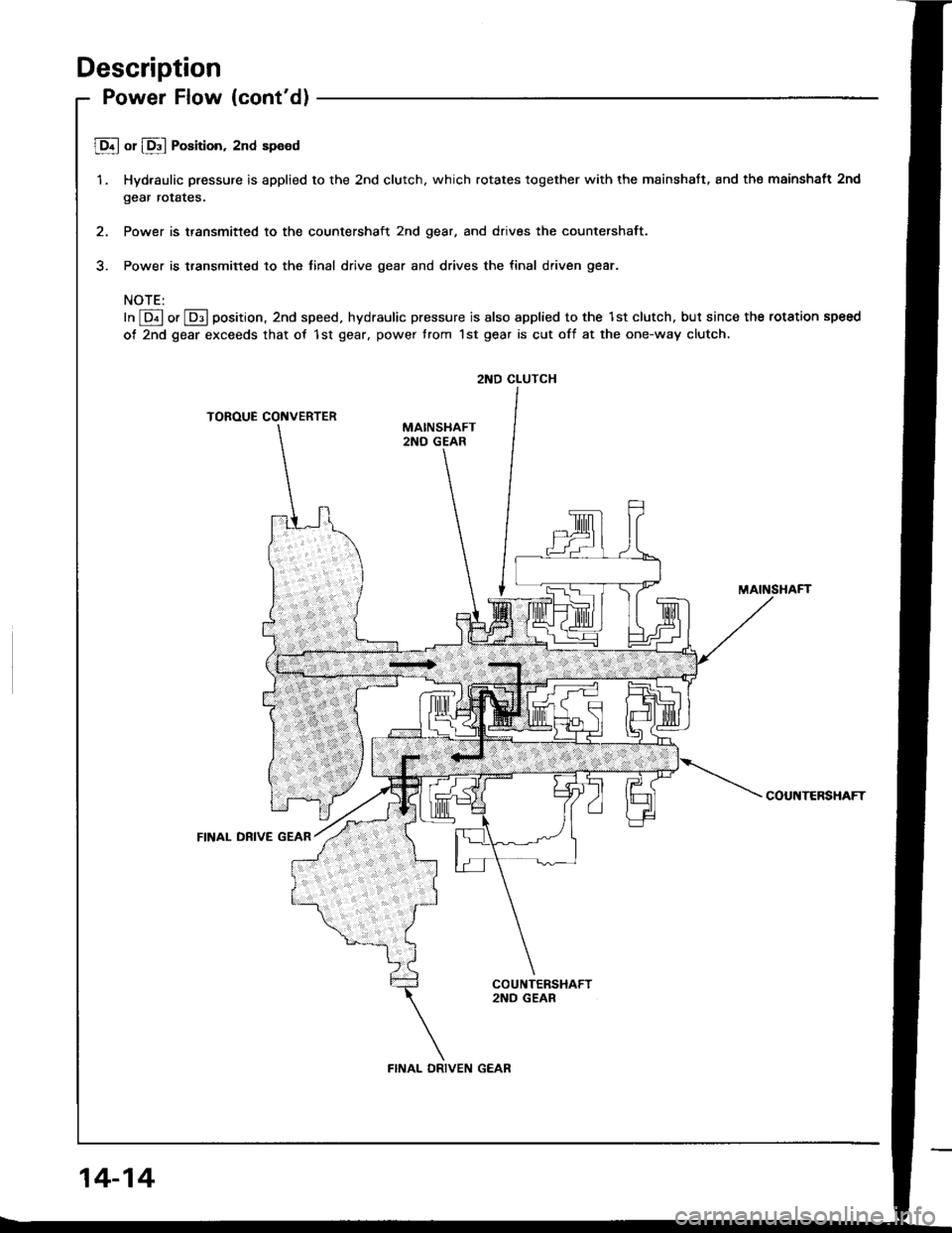

JD.l or lD"l Position, 2nd speed

1. Hydraulic pressure is applied to the 2nd clutch, which rotates together with the mainshaft, and the mainshatt 2nd

gear rotates.

2. Power is transmitted to the countershaft 2nd gear, and drives the countershaft.

3. Power is transmitted to the tinal drive gear and drives the final driven gear.

NOTE:

In @ or @ position, 2nd speed, hydraulic pressure is also applied to the lst clutch. but since the rotation speed

of 2nd gear exceeds that of 1st gear. power trom lst gear is cut off at the one-way clutch.

TOROUE CONVERTER

MAINSHAFT

COUNTERSHAFT

FINAL DRIVE GEAR

2ND CLUTCH

FINAL DRIVEN GEAR

14-14

Page 407 of 1413

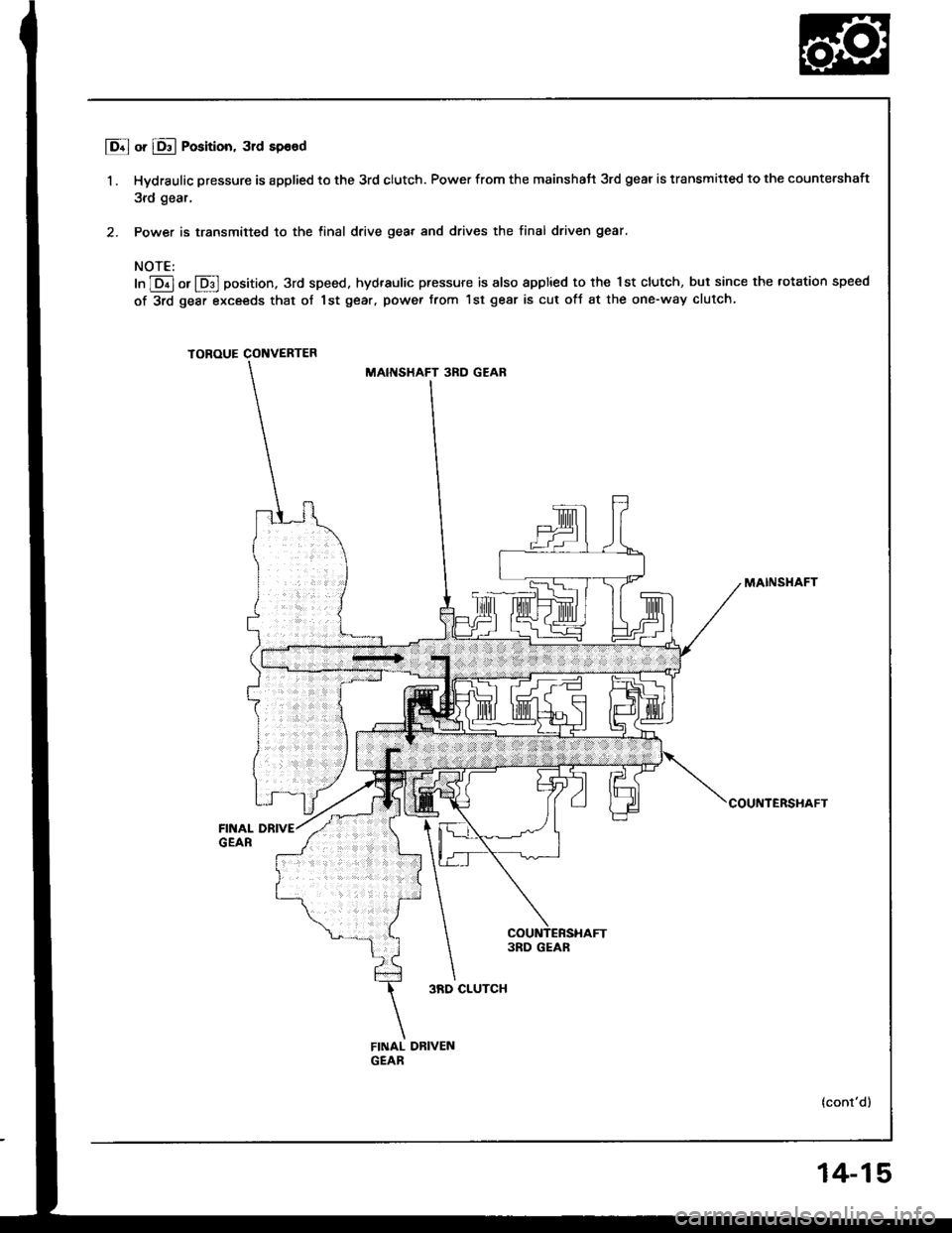

I o.l or 16ll Position, 31d sp€od

1 . Hydraulic pressure is applied to the 3rd clutch. Power from the mainshatt 3rd gear is transmitted to the countershaft

3rd gear,

2. Power is transmitted to the tinal drive geat and drives the final driven gear.

NOTE:

In ]Dil or lDJl position. 3rd speed. hydraulic pressure is also applied to the Ist clutch, but since the rotation speed

of 3rd gear exceeds that of 1st gear, power trom lst gear is cut ofJ at the one-way clutch,

TOROUE CONVERTER

MAINSHAFT 3RD GEAR

MAINSHAFT

COUNTERSHAFT

FINAL DRIVEGEAR

3RD CLUTCH

FINAL DBIVENGEAR

14-15