Ecm HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 281 of 1413

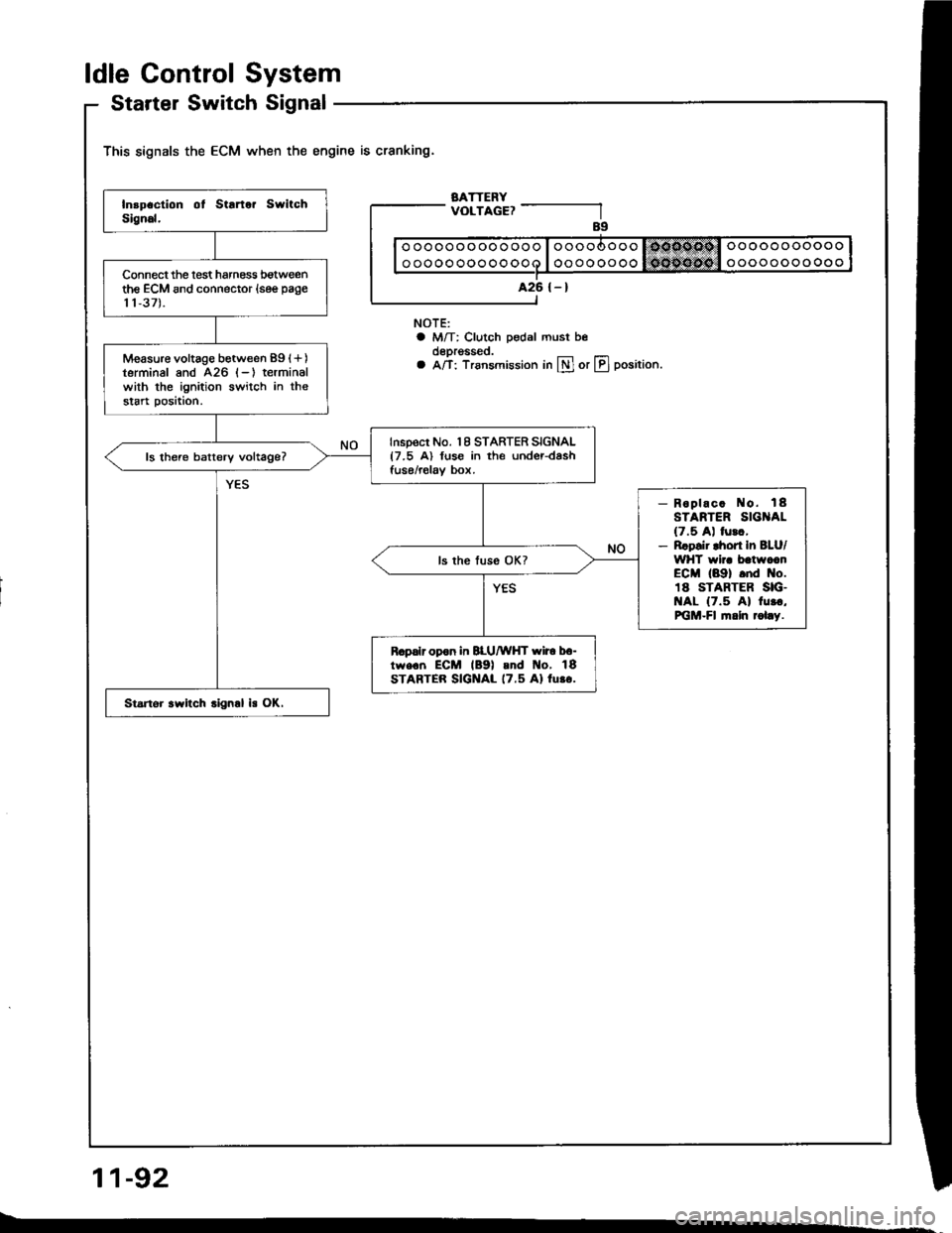

ldle Gontrol System

Startel Switch Signal

This signals the ECM when the engine is cranking.

BATTERYVOLTAGE?

NOTE:a M/T: Clutch pedal must beoeprgsseo.a A/T: Trsnsmission in lll or LIJ position.

11-92

ooooooooooooo

oooooooooooo

A26 {-}Connect the lest harness botweenthe ECM and connector (see page

11,37).

Measure voltage between 89 (+)

terminal and 426 (-) terminalwith the ignition switch in thestart position.

Inspect No. 18 STARTER SIGNAL{7.5 A) fuse in the under-dashfuse/relav box.ls there batterv voltage?

- Roplac. No. 18STARTER SIG AL(7.5 A) lurc,- Rrpsir lhort In BLU/WHT wir. batwccnECM (89) .nd No.18 STARTER SIG.t{AL {7.5 Al 1u..,PiGM-Fl fi.ln rol.y.

R.palr opon in BLU/WHT wir6 b6-tw€.n ECM lB9l and t{o, 18STARTER SIGNAL 17.5 Al lu.o.

Startor .witch .ign.l is OK.

Page 282 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------.ill]

--

;;;;;;;l w

;:"r"tffa;i

connecrors (see

Turn the ignition switch ON.

Measur HONDA INTEGRA 1994 4.G Repair Manual Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------.ill]

--

;;;;;;;l w

;:"r"tffa;i

connecrors (see

Turn the ignition switch ON.

Measur](/img/13/6067/w960_6067-281.png)

Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------'.ill]

--

;;;;;;;l w

;:"r"tffa;i'

connecrors (see

Turn the ignition switch ON.

Measure voltage between 88 {+ )terminal and A26 {-) terminal.

is high.

o ooooo oooo ooo I oo ooo oo o l.Do€d(iltl ooooooooooo

o oooo ooo ooooQ I oooQ oo oo $aG$ast.l oooooooo oo

A26 l-) Bg l+l

L6s! thsn l.O V?

wire side

Turn the ignition switch OFF.

Disconnect the 2P connector tromthe PSP switch.

ls there less than 1.0 V?

Tu.n the ignition switch ON.

Turn steering wheel slowly.ls there less than 1.O V?

Measure voltage between B8 (+)

terminal and 426 (-) termanalwhile steering wheel is turning.

Ropair opon in GRN wire betwssnECM {88} and PSP srYilch ot BLKwi.o botw6cn PSP switch andG301 (locatod at loft ongin6 com-partm6ntr.

Disconnect the 2P connector lromthe PSP switch.PSP switch signal is OK.

Repair short in GRN wi.e botwoonECM {881 and PSP switch.ll wiro i3 OK, substitute a known-good ECM and.ocheck. lIproscribod vollage is now available, replaco tho original ECM.

GRN

PSP SWITCH

11-93

Page 284 of 1413

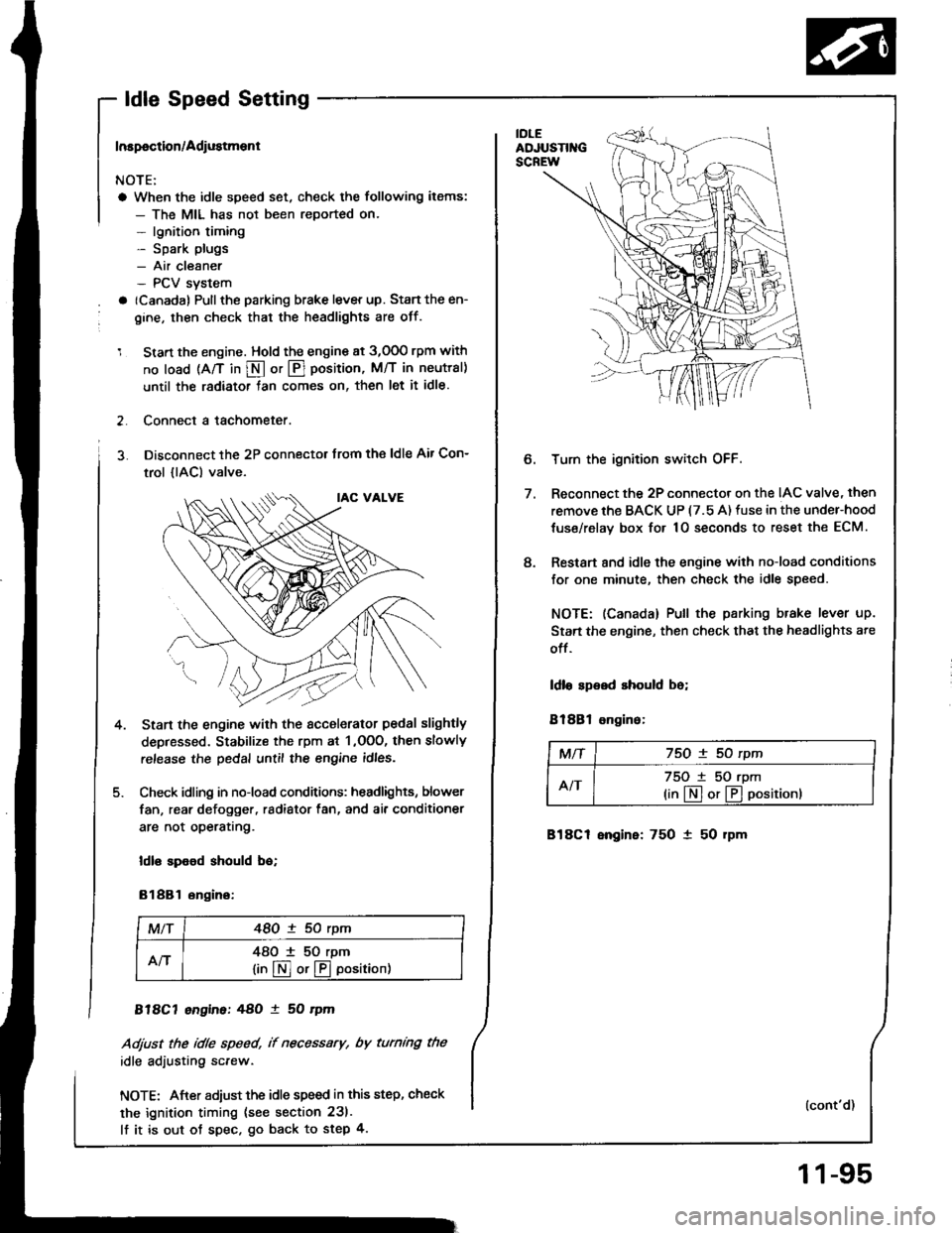

- ldle Speed Setting

Inspoction/Adiustment

NOTE:

a When the idle speed set, check the following items:

- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV svstem

a (Canada) Pullthe parking brake lever up. Stan the en-

gine, then check that the headlights are off.

1 Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in S or @ position, M/T in neutral)

until the radiator tan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the 2P connectot trom the ldle Air Con-

trol {lAC) valve.

Start the engine with the sccelerator pedal slightly

depressed. Stabilize the rpm at 1 ,OOO, then slowly

release the pedal until the engine idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and ai. conditioner

are not operatrng.

ldl€ spood should bo;

81881 ongino:

MlT48O ! 50 rym

An48O I 50 rpm

lin@or@oosition)

818C7 engine:48O ! 50 rym

Adjust the idle speed, if necessary, by turnmg the

idle adiusting screw.

NOTE: After adiust the idle speed in this step, check

the ignition timing (see section 231.

lf it is out ot spec. go back to step 4.

4.

e

Turn the ignition switch OFF.

Reconnect the 2P connector on the IAC valve, then

remove the BACK UP (7.5 A) fuse in the under-hood

tuse/relav box for 1O seconds to reset the ECM.

Restart 8nd idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights ate

off.

ldlo speed should be;

81881 ongino:

MTf75O ! 50 rpm

AIT75O t 50 rpm

(in[]or@positionl

818C1 engine: 750 1 50 rpm

(cont'd)

11-95

Page 291 of 1413

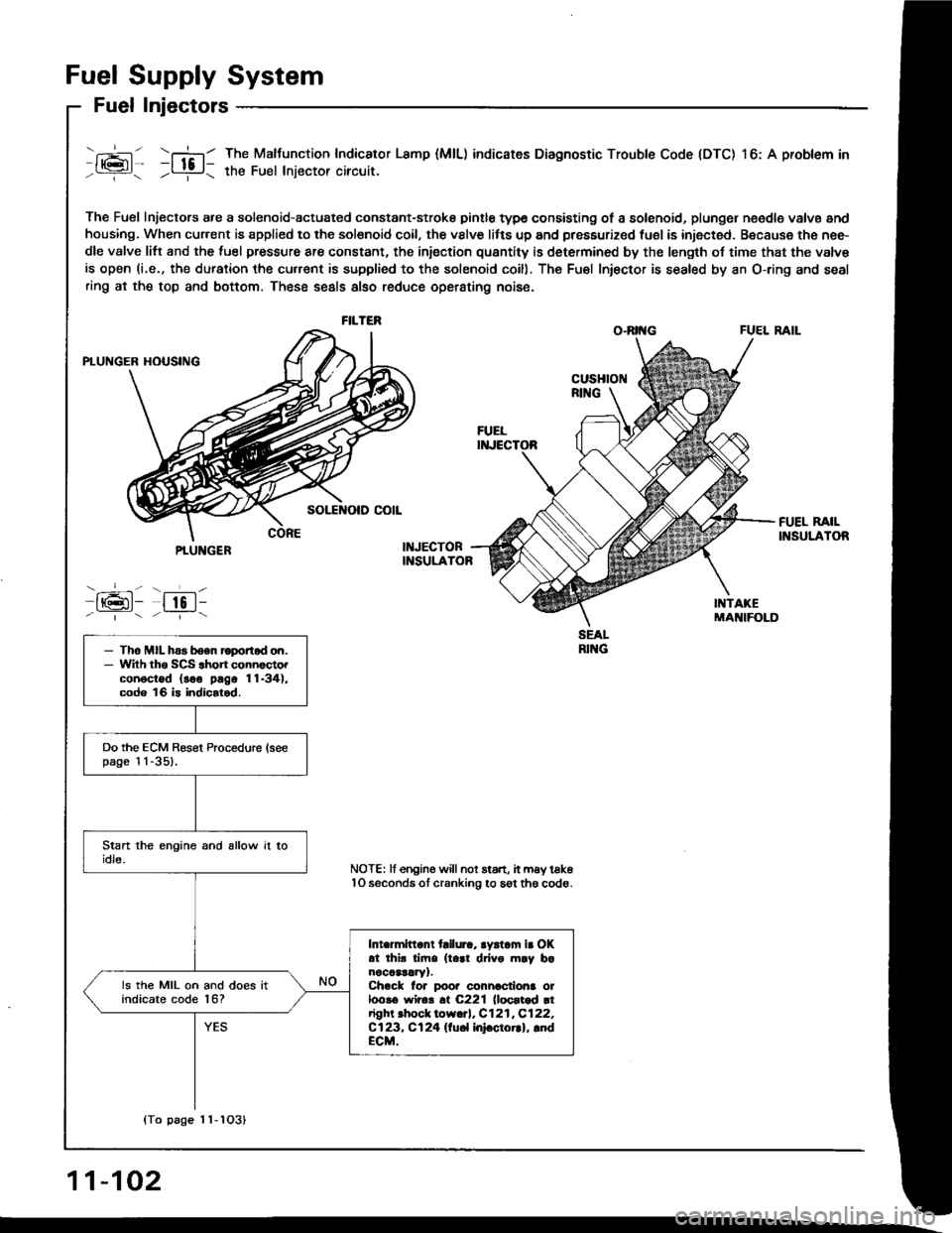

Fuel Supply System

Fuel Injectors

- --l- - \-l-l

116l- -ltc l-/---r- / ---i- \

The Fuel Injectors a.e a solenoid-actuated constant-stroke pintle type consisting of a solenoid, plungel n€edle valvs and

housing. When cur.ent is applied to the solsnoid coil, the vslve litts up and pressurized fuel is injected. Because the nee-

dle valve litt and the luel pressure are constant, the iniection quantity is determined by the length of time that the valv€

is open (i.e., the duration the cu.rent is supplied to the solenoid coill. The Fu€l Iniector is sealed by an O-ring and seal

ring at the top and bottom. These seals also reduce operating nois6.

O.RII{G FUEL RAIL

The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) l6: A problem in

the Fuel lniector circuit.

FILTER

PTUNGER

-_-- - ___L-

IrGl- lto l--|.---:_-

- Tho MIL has boen roportod on.- Wilh tho SCS .hon connocto.conoctod (soo pago 11-34),code 16 is indicalod.

Do the ECM Besel Procedure (seepage l l -351.

Intermittant tailura, aystam ir OKat thir tim. (t..1 drivo m.y b.nocaar!ry1.Ch.ck lor poor connactiona ot100!6 wir6!.t C221 (loortod rtright .hock low.rl, C121,C122,Cl23, Cl24 llu6l InFctorrl, lndECM.

ls the MIL on and does itindicate code l6?

NOTE: lf engine willnot start, it may tak6lO seconds ol cranking to sgt th6 code.

{To page 1 1-1O31

11-102

Page 293 of 1413

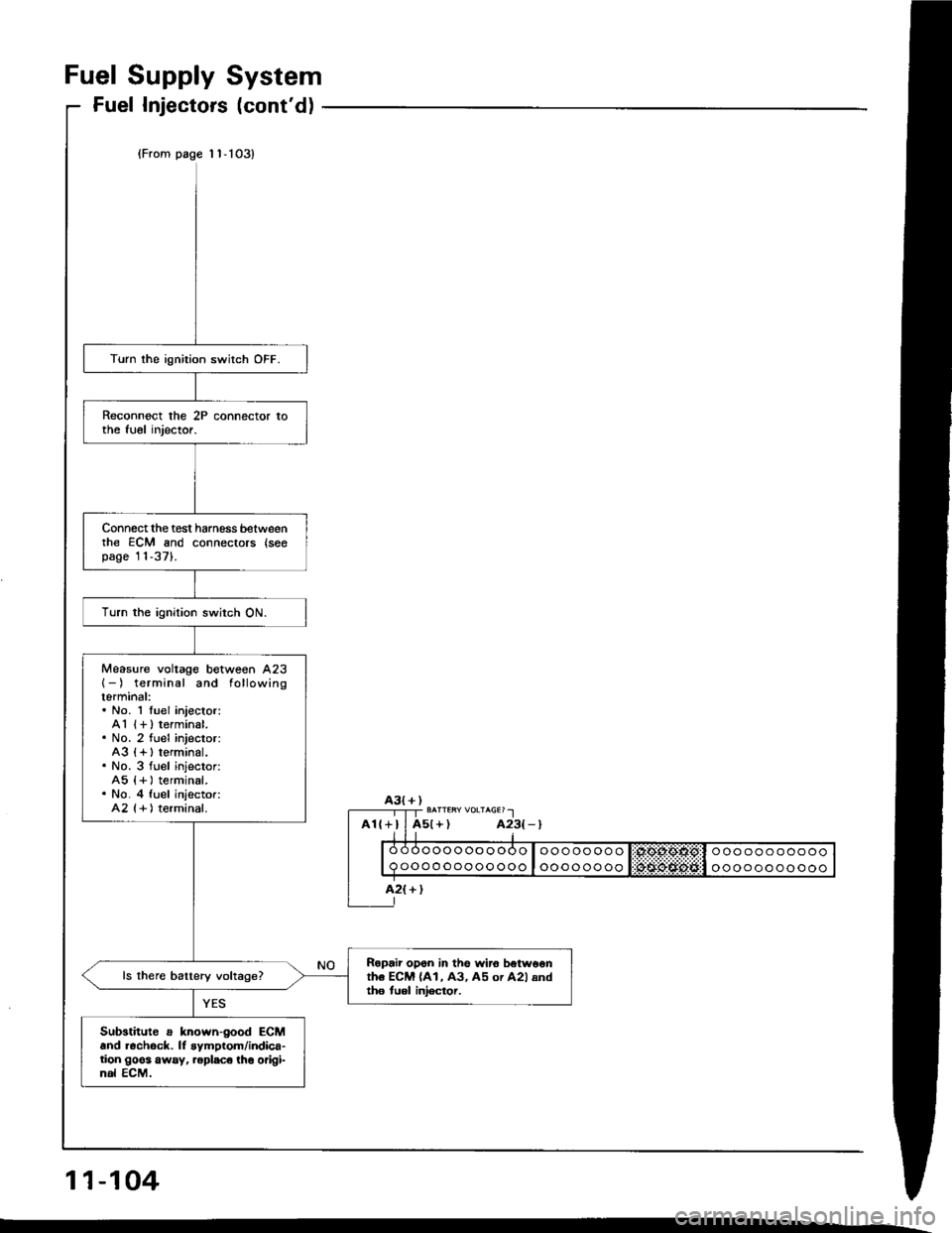

Fuel Supply System

Fuel Injectors (cont'd)

(From page 'l1-103)

Turn lhe ignition switch OFF.

Reconnect the 2P connector tothe tuel injector.

Connect the test harness betweenrhe ECM and connectors {seopage'11-371.

Turn the ignition switch ON.

Measure voltage between A23{-) terminal and followingterminal:. No. 1 tuel injector:A1 (+ ) terminal.. No. 2 fuel injector:A3 {+ I terminal.. No. 3 fuel injector:A5 {+ ) terminal.. No. 4 fuel injector:A2 {+ ) terminal.

Ropair opon in the wi.o betw6onth6 ECM (A1, A3, A5 or A2l andth6 tuel iniector.

Sub3titute a known-good ECMand r6chock. lf symptom/indica-tion goes away, .eplsco tho origi-nal ECM.

oooooooooo

oooooooooooooooooooo

oooooooo

ooooooooooo

ooooooooooo

A3{+)

A2{+}

11-104

Page 300 of 1413

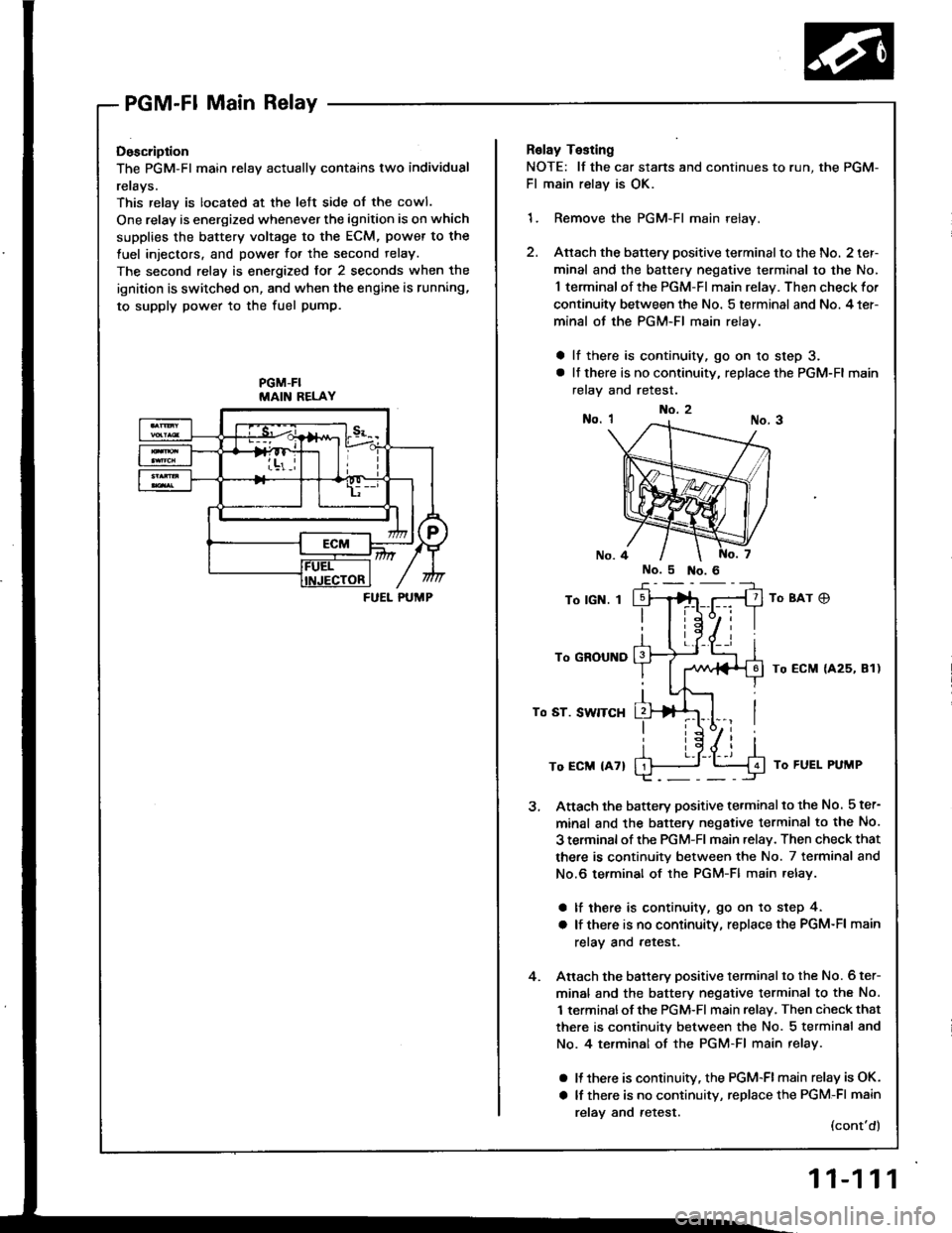

PGM-Fl Main Relay

Doscription

The PGM-Fl main relav actuallv contains two individual

rerays.

This relay is located at the lett side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM, power to the

fuel injectors, and power for the second relay.

The second relay is energized for 2 seconds when the

ignition is switched on, and when the engine is running,

to supply power to the fuel pump.

PGM-FIMAIN RELAY

FUEL PUMP

Relay Testing

NOTE: lf the car stans and continues to r

Fl main relay is OK.

1. Remove the PGM-Fl main relay.

2. Attach the battery positive terminalto

minal and the battery negative termir

1 terminal of the PGM-FI main relay. T

continuity between the No. 5 terminal

minal of the PGM-FI main relay.

a lf there is continuity, go on 10 ste

a lt there is no continuity, replace the

relay and retest.

To lGN. I

To GROUND

To ST. SWITCH

To ECM {47}

Attach the battery positive terminalto

minal and the battery negative termil

3 terminal of rhe PGM-Fl main .elav. Tl

there is continuity between the No. ;

No.6 terminal of the PGM-Fl main re

a lf there is continuity, go on to st€

a lf there is no continuity, replace th€

relay and retest.

Anach the battery positive terminalto

minal and the battery negative termil

1 terminalof the PGM-Fl main relay, Tl

there is continuity between the No. :

No. 4 te.minal of the PGM-Fl main r

a It there is continuitv, the PGM-FI mi

a lf there is no continuity, replace th(

relav and retest.

No.2

run, the PGM-

nalto the No. 2 ter-

terminal to the No.

lay. Then check for

minal and No. 4 ter-

to step 3.

ce the PGM-Fl main

8Ar C)

ECM {425, 81)

J To FUEL PUMP

inalto the No. 5 ter-

terminsl to the No.

ay. Then check that

No. 7 terminal and

ain relay.

to step 4.

ce the PGM-Fl main

inal to the No. 6 ter-

terminal to the No.

ay, Then check that

No. 5 terminal and

nain relay.

-Flmain relay is OK.

ce the PGM-Fl main

(cont'd)

11-111

Page 301 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng HONDA INTEGRA 1994 4.G Repair Manual Fuel Supply System

PGM-Fl Main Relay (contdl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Eng](/img/13/6067/w960_6067-300.png)

Fuel Supply System

PGM-Fl Main Relay (cont'dl

BLU

BLU/wHt

Bt-xNOTE:. M/T: Clutch pedal mustbe depressed.. A/T: Transmission in

N or E] position.

BLK/ YEL/YEL BLK

Tloubloshooting

{To page 11 113}

- Engino will not sran.- Inspection oI PGM-FI main re-lay and rolay ha.n6!a.

Check lor continuitv between BLKterminal @ and body ground.

Rapair open in BLK wire botwoonPGM-FI main.el6y and GIO'l llo-catod at thormostot housingl.

Measure the voltage betweenYELMHT terminal @ and bodyground.- Roplaco th. ECU IECMI(15 Allus6 in tho under-hood fu!o/r6-lay box.- Ropair opan or short in theYEL/WHT wil6 botwosn thePGM-FI main rolay and the ECU

{EcMl 115 A} luso.

ls there battery voltage?

Turn the ignition switch ON.

Measure the voltage betweenBLK/YEL terminal @ and bodyground.- Reolac. ths No. 24 ACG {ALT}{lcl {15 A:81881 6ngino, 20A: Bl8Cl engin6) tuse in thoundor-dash fuso/rolaY box.- Ropaii op6n or rhon in thoBLK/YEL wiro botwoen thoPGM-FI main ielay and th€ No.24 ACG {ALT) flG} {'�15 A:818Bi ongine, 20 A: 818Cionginol fuso.Turn the ignition switch to theSTART position.

Measure the voltage betweenBLUMHT terminsl @ and bodyground.

- Replaco the l\lo. 18 STARTERSIGNAL {7.5 A} fuso in thoundor-dash fuaa/rolay box.- R6pai. open or short in thoBLU/WHT wire botweon thsPGM-FI main relay and tho No.1A STARTER SIGNAL I7.5 AIluse.

11-112

Page 302 of 1413

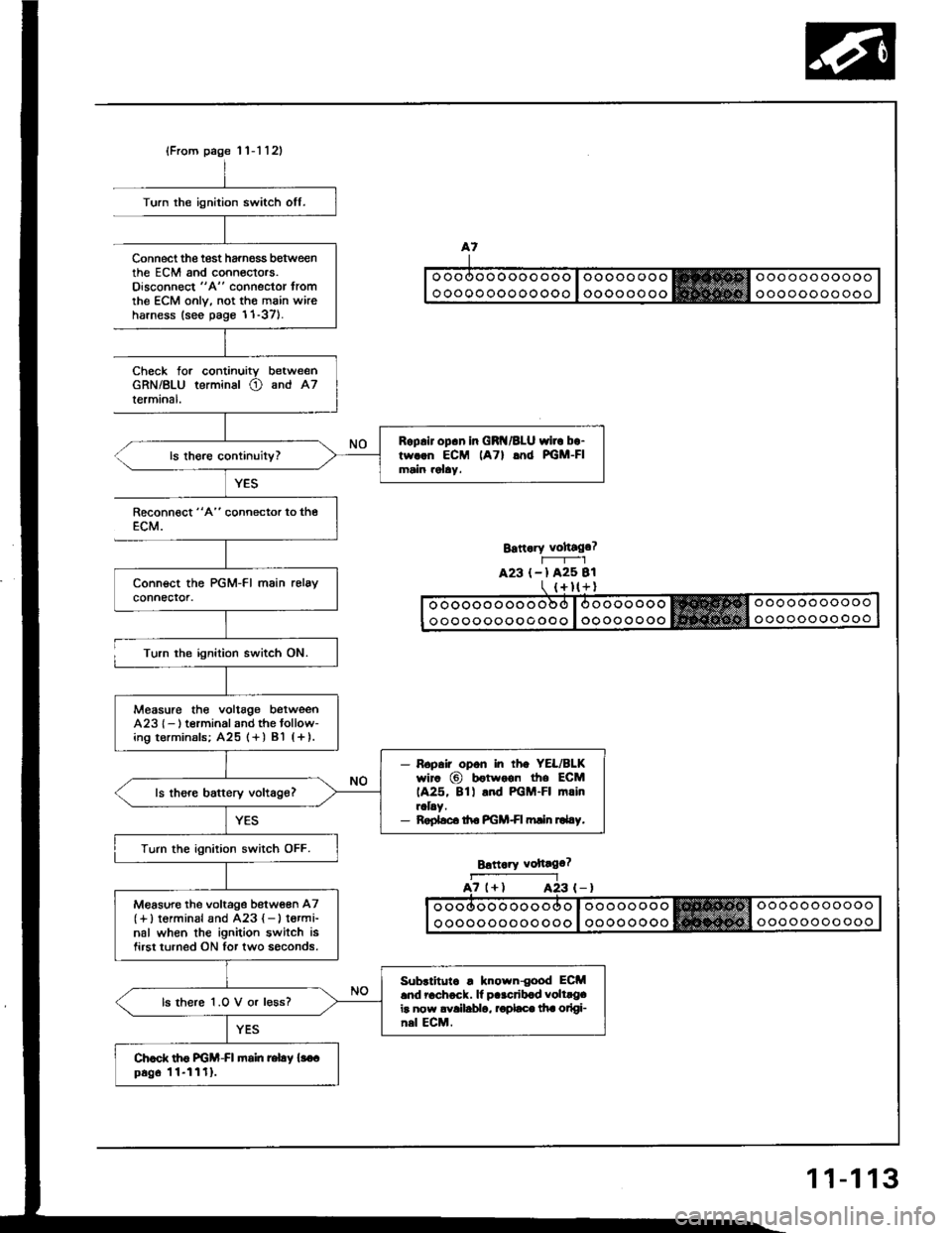

(From page 'l'l-1121

Roplir op.n in GRI{/BLU wirc bo-tw..n ECM lATl lnd PGM-FImain rolay.

Measure the voltag€ betweenA23l- ) t€rminal and the tollow-ing t€rminals; A25 (+ ) Bl (+ ).

- Ropair opon in rh. YEL/BLKwir. @ b€twoon the ECM1A25, 8tl .nd PGM-FI mrinraLy.- Roplsc. ttro PGM+I min ru4.y.

Turn the ignition switch OFF.

M€asure the voltage betw€en A7(+)torminal and A23 { - } t€rmi-nal when the ignition switch isfirst turned ON for two soconds.

Subrlitutc . known{ood ECM.nd 6chock. lf p..crib.d volt.g.ir now avallablo, rodaco lha otlgi-nsl ECM.

ls there 1.O V or l€ss?

Chod. th6 FGM-FI fioin relay {3o.p6g6 11-1111.

Turn the ignition switch off.

Connect the test harnoss b€tweenthe EcM and conneclors.Oisconnect "A" connector tromthe ECM onlv. not the main wireharness (see page 1'1-37).

Check forGRN/BLUlermrnal.

continuity betweenterminal O and A7

YES

Reconn€ct "4" connector to theECM.

Turn the ignition switch ON.

Bstt.ry vohago?r-----r_-lA23 (-l A25 Bl

Brttaiy voftago?

a7 (+l A23A23 (-)

11-113

Page 314 of 1413

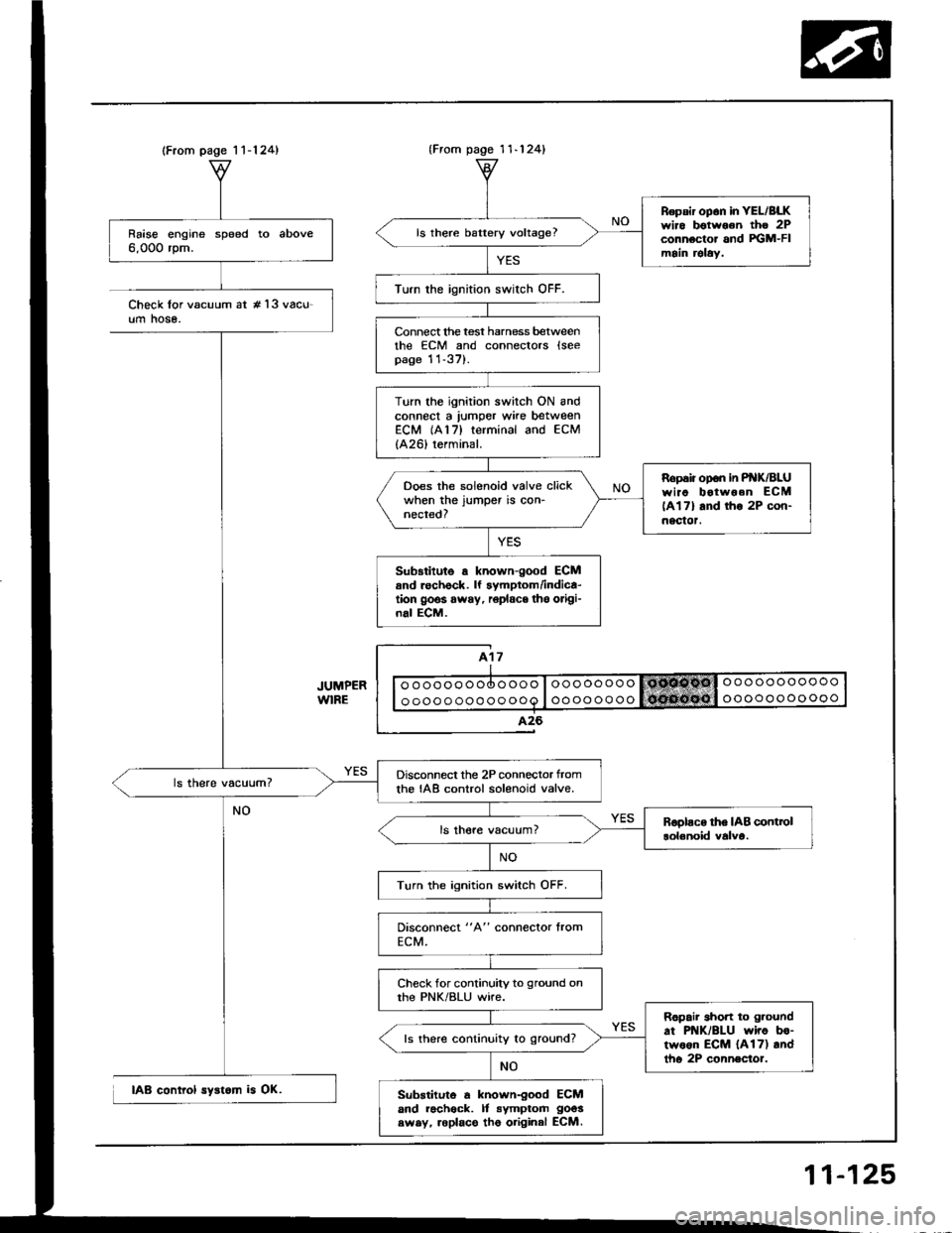

(From page 1 1-124)

Raise engine speed to above6,000 rpm.

Disconnect the 2P connector tromthe IAB control solenoid valve.

Turn the ignition switch OFF.

Check for continuity to ground onthe PNK/BLU wire.

Ropair short to g.ound

at PNK/BLU wiro bo-two6n ECM {A17) andtho 2P connector.

ls there continuity to ground?

Substituto a known-good ECMand racheck. It symptom goos

swsy, roplace tho original ECM.

{From pago 1 1-124}

Repsir op6n in YEL/BLKwiro botwoon tho 2Pconnector and FGM-FImain relaY.

ls there battery voltage?

Turn the ignition swirch OFF.

Connect lhe test harness betweenthe ECM and connectors lseepage 11-37).

Turn the ignition switch ON andconnect a lumper wke betweenECM (A17) terminal and ECM

{A26) terminal.

Ropaiiopon inP K/BLUwiao botwoen ECM

lAl7l and tho 2P con-nectot.

Ooes the solenoid valve clickwhen the jumper is con-nected?

Sub3titute a known-good ECMand rechock. lf symptom/indica-tion goos away, r6place tho origi-nal ECM.

Check lor vacuum at #'l3 vacu-um hose.

IAB control syst6m is OK.

11-125

Page 327 of 1413

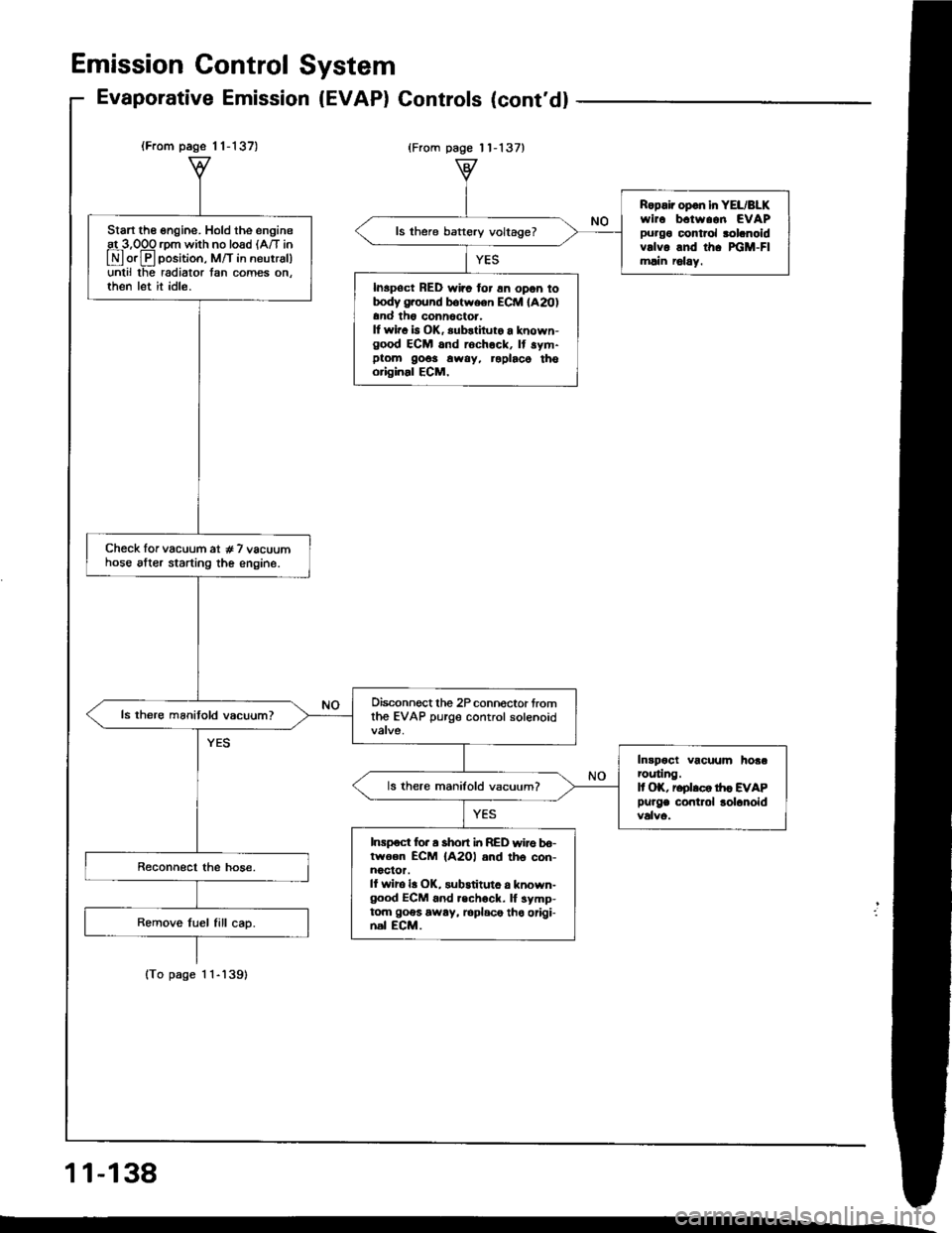

(From page 1 1-137)

lTo page 1 1-'l39)

Start the engine. Hold the engineat 3,OOO rom with no load lA/T in

E orE position, M/T in neutrsl)unlil lhe radiator tan comes on.then let it idle.

Check lor vacuum at # 7 vacuumhose alter starting the engine.

Oisconnect the 2P connoctor fromthe EVAP purge control solenoid

Intpoct vacuum hoaarcuting.It OK, reolrco tr|c EVAP

Purge contlol lolanoid

ls there manifold vacuum?

Inrpoct for a short i|t RED wire bo-lwoen ECM {A2Ol and th6 con-noclor.ll wiro la OK, substituto a known-good ECM 6nd .echock. lf symp-tom goes away, loplace tho origi-nal ECM.

Ropair opon in YEL/BLKwirc b.tw..n EVAPpurgo control rolanoidvrlvo and th. xiM-Flmlin r6lay.

ls there baftery voltage?

Inspoct RED wirc for 6n opon totrody g.ound botween ECM lA20)and th6 conn6ctor.It wir. b OK, substiluto a known-good ECM and rochock, It sym-ptom 9o6s away, roplaco thooriginal ECM,

Emission Gontrol System

Evaporative Emission (EVAP) Gontrols (cont'd)

{From page 11-137}

11-138