Wheel HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 640 of 1413

7.

Connect the ignition switch wire connectors to the

under-dash fuse/relav box.

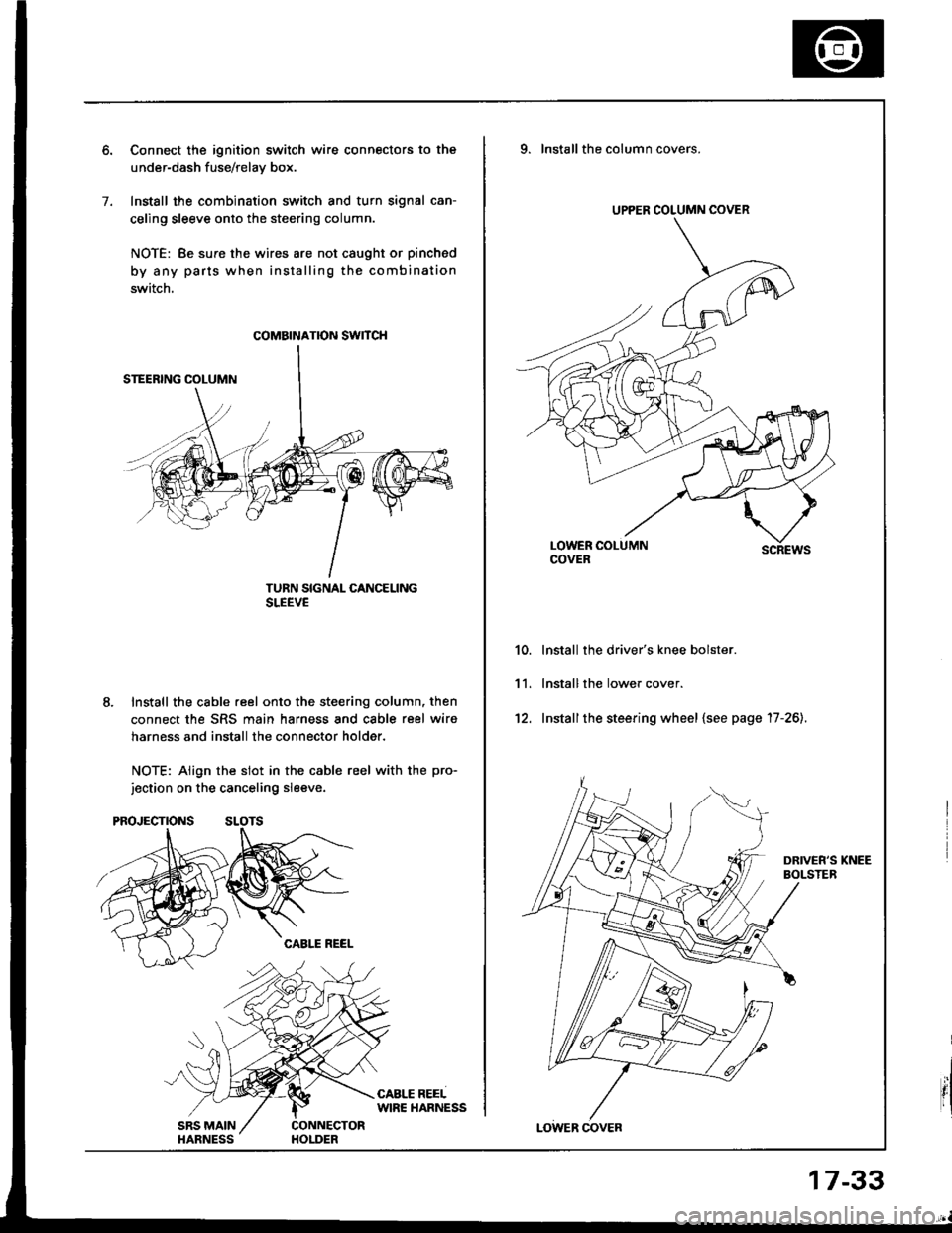

Install the combination switch and turn signal can-

celing sleeve onto the steering column.

NOTE: Be sure the wires are not caught or pinched

by any parts when installing the combination

switch.

TURN SIGNAL CANCELINGSLEEVE

Install the cable reel onto the steering column, then

connect the SRS main harness and cable reel wiro

harness and install the connector holder.

NOTE: Align the slot in the cable reel with the pro-

jection on the canceling sleeve.

coMatNATroN swncH

UPPER COLUMN COVER

9. Installthe column covers.

scREws

lnstall the driver's knee bolster.

lnstall the lower cover.

Installthe steering wheel {see page '17-26).

10.

11.

't2.

17-33

Page 651 of 1413

Power Steering Pump

lnstallation

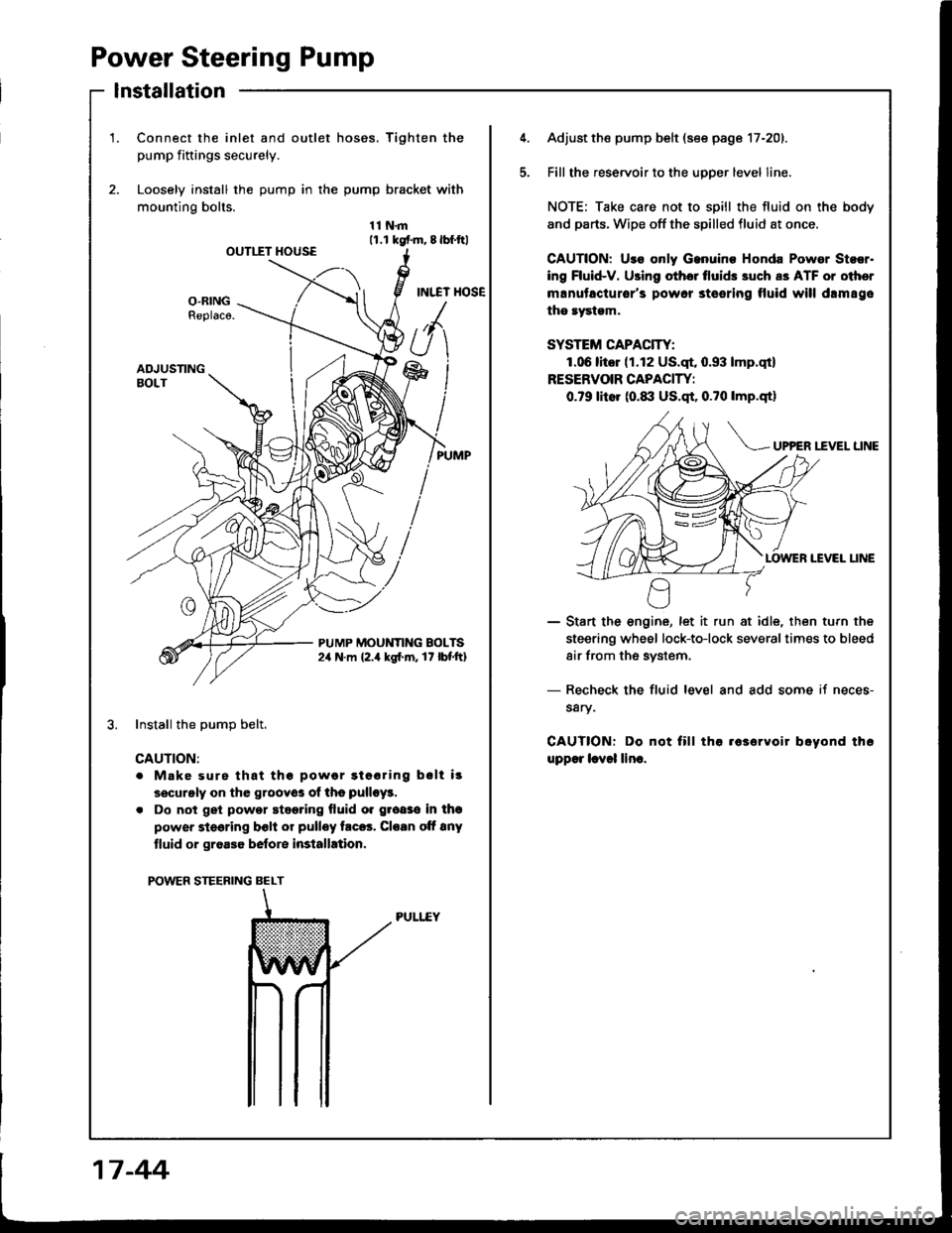

1.Connect the inlet and outlet hoses. Tighten the

pump fiftings securely.

Loosely install the pump in the pump bracket with

mounting bolts.

11N.m11.r kgf.m, 8lbf.ftlOUTIIT HOUSE

INI.TT HOSEO-RINGReplaco.

ADJUSTINGBOLT

PUMP MOUNTING BOLTS2,r N.m {2.4 kgl.m. 17 lbf'ft}

Install the DumD belt.

CAUTION:

. Make surs that thg powor gtooring bslt i!

securgly on the grooyos of ths pulloy!.

. Do not get powor stggring fluid o. groaso in thg

power steering bclt or pulley trc6. Cloan oft 8ny

tluid or groa36 belore installation.

POWER STEERING BELT

PULI..EY

5.

Adjust the pump belt (see page 17-201.

Fill the reservoir to the uoDer level line.

NOTE; Take care not to spill the fluid on the body

and parts. Wipe off the spilled fluid at once.

GAUTION: Uro only Ganuino Honda Powor Stsor.

ing Fluid-V. Using othor tlui& 3uch a3 ATF or oiher

manutacturor's powor steering tluid will drm89e

the rystgm.

SYSTEM CAPACITY:

1.06litor (1.12 US.qt, 0.93 lmp.qt)

RESERVOIR CAPACIW:

0.79 litor (0.1|:| US.qt, 0.?0 lmp.qtl

UP?ER I.fVEL LINE

IEVEI LINE

- Start the engine, let it run at idle, then turn the

steering wheel lock-to-lock severaltimes to bleed

air from the system.

- Recheck the fluid level and add some if neces-

s8ry.

CAUTIONT Do not fill tha .63ervoir boyond th6

upp€r lcvol lino.

17 -44

Page 652 of 1413

Steering Gearbox

Removal

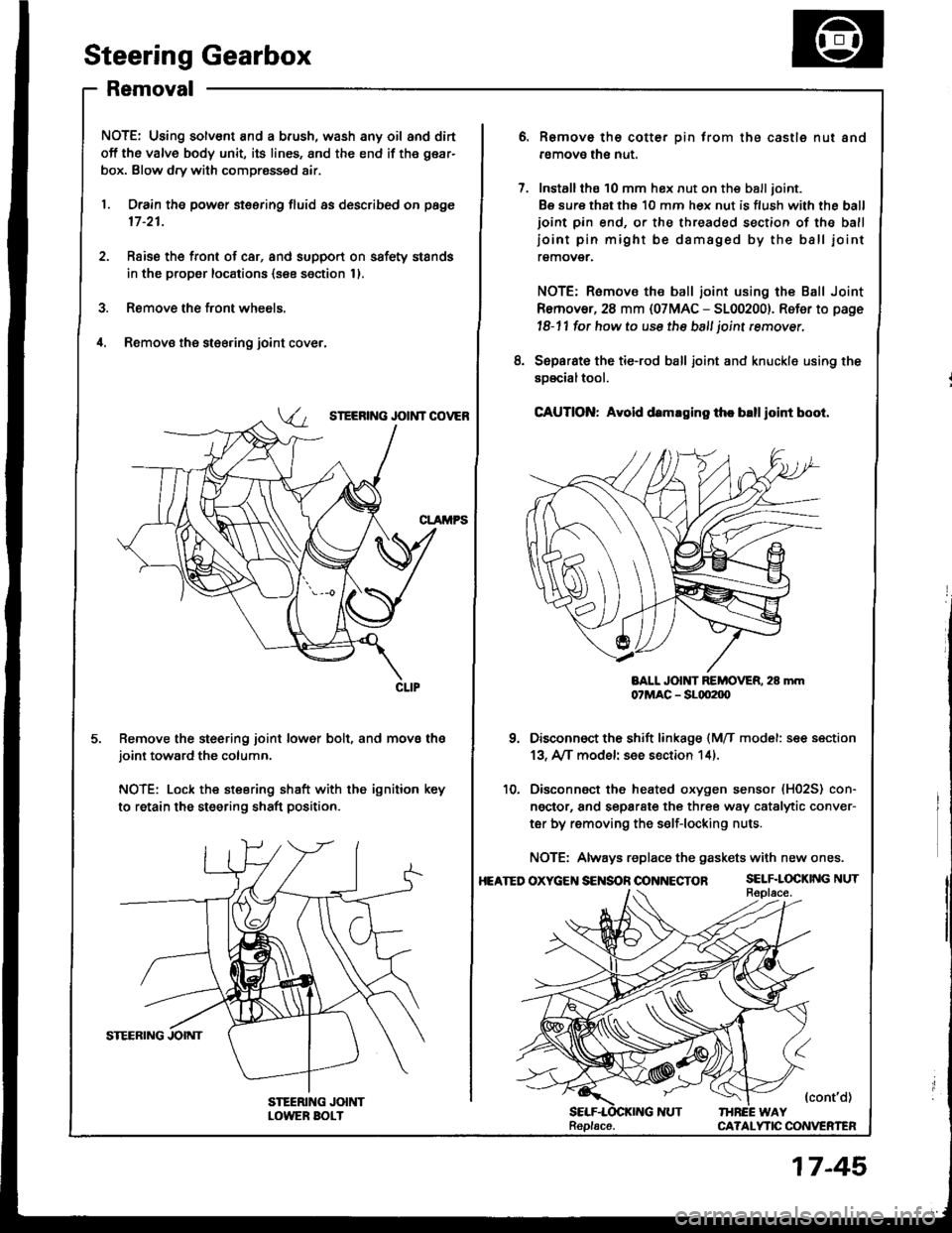

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

1. Drain the power steering fluid as described on page

17 -21.

2. Rsise the front of car, and support on safety stands

in the propsr locations (see section 1).

3. Remove the front wheels.

il. Removs the st€ering joint cove.,

SIEERING JOIi{T COVEB

Remove the steering joint lower bolt, and move thejoint toward the column.

NOTE: Lock the steering shaft with the ignition key

to retain the steering shaft position.

Remove the cotter pin trom the castle nut and

removo the nut.

Installthe 10 mm hex nut on the balljoint.

Be sure that ths 10 mm hex nut is flush with the ball

ioint pin end, or the threaded section of the ball

ioint pin might be damaged by the ball iointremover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm {07MAC - 5100200}. Refer to page

l8-11 fot how to use the ball joint rcmover,

Separat€ the tie-rod ball joint and knuckle using the

soscialtool.

CAUTION: Avold d.maging th. blllloint boot.

BALL JOlt{T REMOVER. 28 mm07MAC - SLqt2|X)

Disconnect the shift linkage {MfI model: see section

13, A/[ model see section 14).

Disconnect the heated oxygen sensor (H02S) con-

ngctor, and separate the three way catalytic conver-

ter by removing the s€lf-locking nuts.

NOTE: Always replace the gaskets with new ones.

OXycEt{S€NSOnOONNECTOR SELF.LOCKINGNUT

{cont'd)IHREE WAYCA?ALYTIC CONVERTEN

8.

10.

HEATED

Replacs.

17-45

Page 670 of 1413

lnstallation

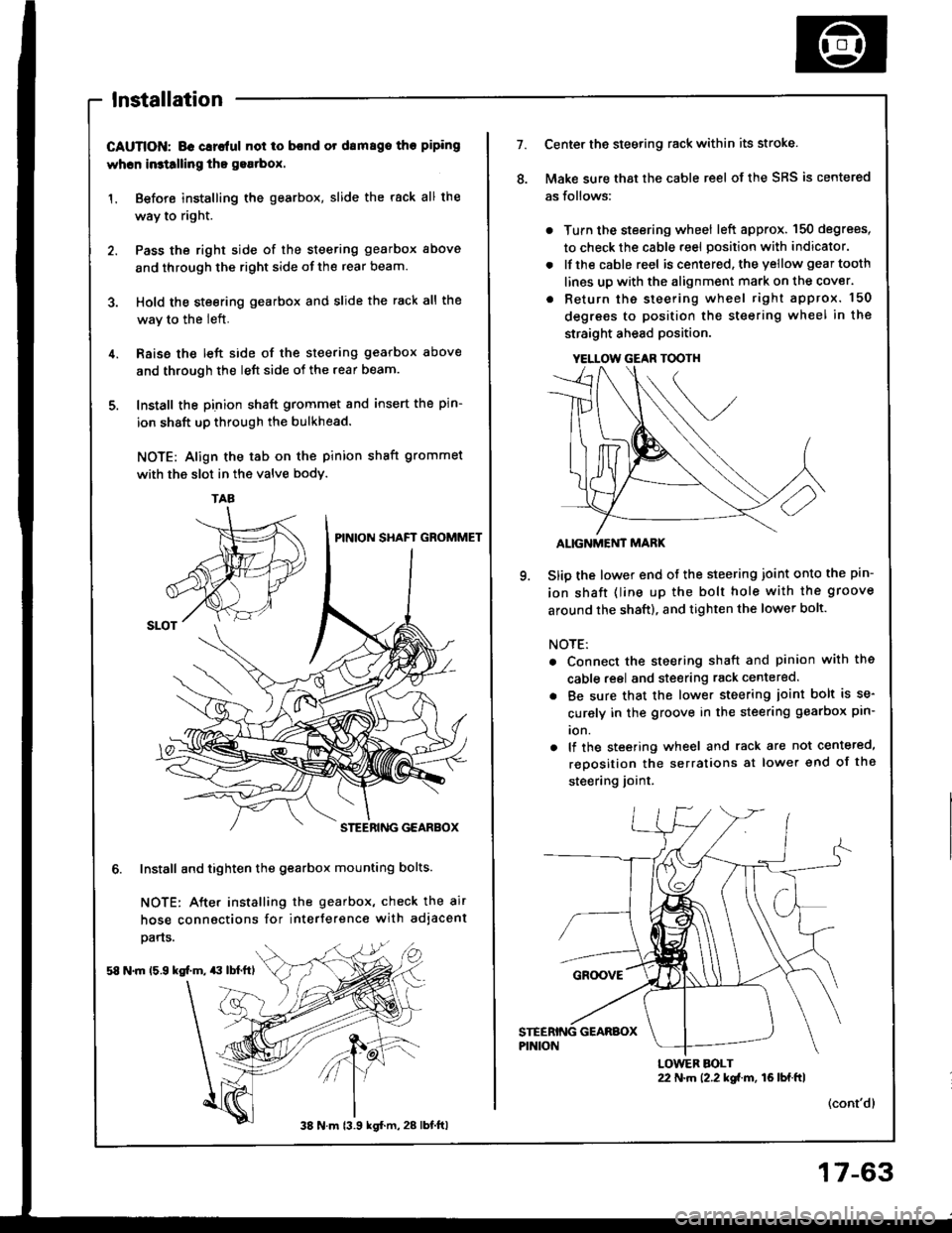

CAUTION; BG Glrc{ul not io bcnd or drm8go tho piping

whcn in3tllling tho gea.box.

1. Before installing the gearbox, slide the rack all the

way to right.

2. Pass the right side of the steering gearbox above

and through the right side of the rear beam.

3. Hold the steering gearbox and slide the rack all the

wav to the left.

4. Raise the left side of the steering gearbox above

and through the left side of the rear beam.

5. Install the pinion shaft grommet and insert the pin-

ion shaft up through the bulkhead.

NOTE: Align the tab on the pinion shaft grommet

with the slot in the valve bodv.

6. Install and tighten the gearbox mounting bolts.

NOTE: After installing the gearbox, check the air

hose connactions for interference with adjacent

pans.

58 N.m 15.9 kg[.m, $ lbl.ftl

TAA

38 N m 13.9 kgl.m, 28 lbt.ftl

17-63

YELLOW GEAR TOOTH

7.Center the steering rack within its stroke.

Make sure that the cable reel of the SRS is centered

as follows:

. Turn the steering wheel left approx. 150 degrees,

to check the cable reel position with indicator.

. lfthe cable reel is centered. the yellow gear tooth

lines up with the alignment mark on the cover.

. Return the steering wheel right approx. 150

degrees to position the steering wheel in the

straight ahead position.

ALIGNMEi'IT MARK

Slip the lower end of the steering joint onto the pin-

ion shaft (line up the bolt hole with the groove

around the shaft), and tighten the lower bolt.

NOTE:

. Connect the steering shaft and pinion with the

cable reel and steering rack centered.

. Be sure that the lower steering ioint bolt is se-

curely in the groove in the steering gearbox pin-

ion.

. lf the steering wheel and rack are not centeted,

reposition the serralions at lower end of the

steering joint.

(cont'dl

22 N.m 12.2 kgi.m, 16lbf.ftlLOWER BOLT

Page 672 of 1413

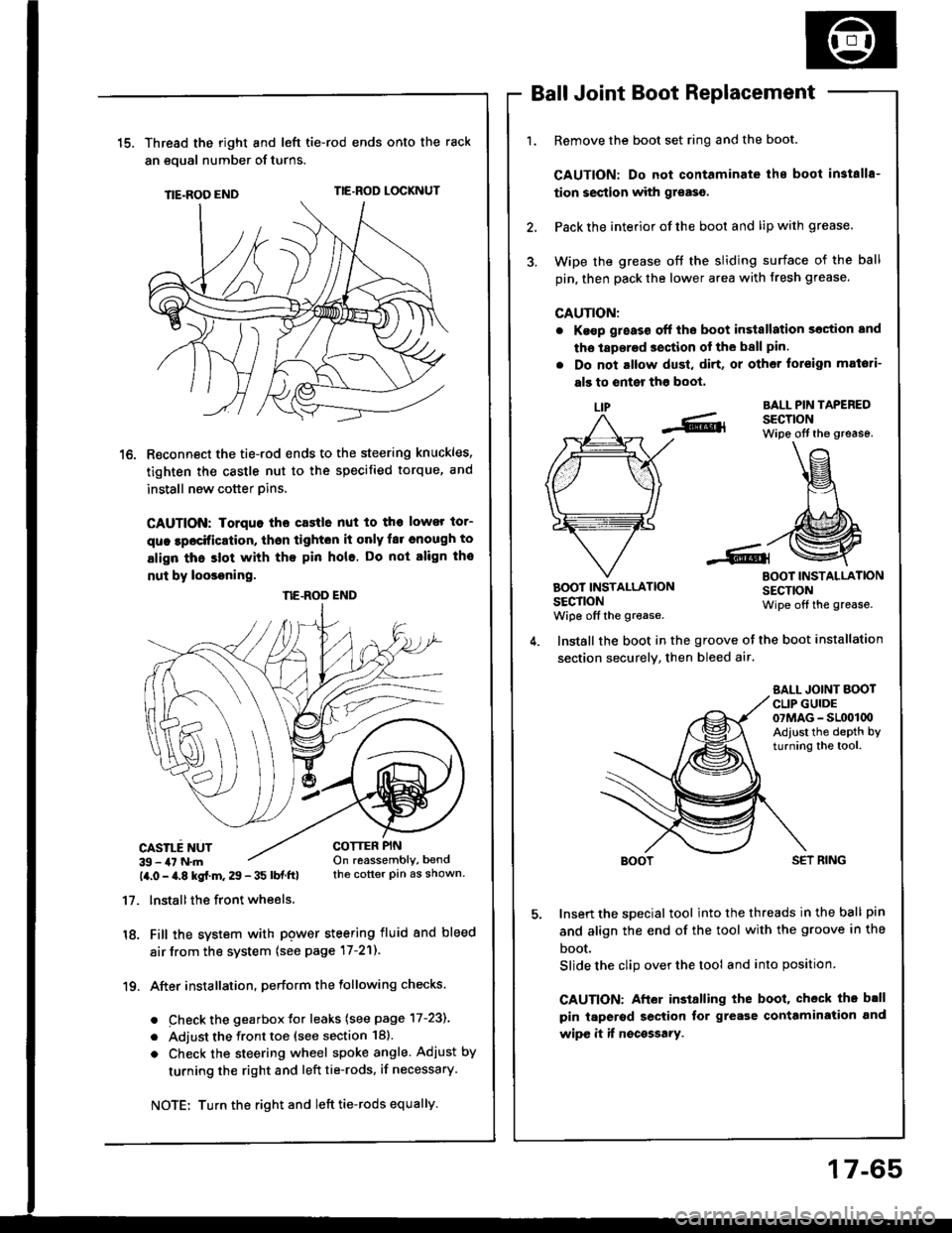

15.Thread the right and lefi tie-rod ends onto the rack

an eoual number of turns.

TIE-ROO ENDTIE.ROD LOCKNUT

R€connect the tie-rod ends to the steering knuckles,

tighten the castle nut to the specified torque, and

install new cotter pins.

CAUTION: Iorquo tho castle nut to tho lower tor-

que lpocification, thsn tighton it only far cnough to

align thc slot with tho pin hole. Do not align tho

nut by loosoning.

CASILE NUT39 - 47 N.m14.0 - a.8 kgf.m. 29 - 35 lbf ftl

17. lnstallthe front wheels.

18. Fill the system with pgwer steering fluid and bleed

air from the system (see page 17-21).

19. After installation. perform the following checks.

. Check the gearbox Jor leaks (see page 17-231

. Adjust the front toe (see section 18).

o Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate ihe boot in3talls-

tion section with gr€aso.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ball

pin, then pack the lower area with fresh grease.

CAUTION:

. Ke€p g;eass off the boot in3tallation section and

tho laperad section of the ball pin.

. Do not altow dust, di.t, or other toreign mat6ti-

als to enter tho boot,

LIPBALL PIN TAPEREDSECTIONWipe off the grease.

BOOT INSTALLATIONSECTIONwiDe off the grease.

BOOT INSTALLATIONSECTIONWipe off the grease.

COTTER PINOn reassembly, bendthe cotter pin as shown.

Install the boot in the groove ot the boot installation

section securely, then bleed air.

SALL JOINT BOOTCLIP GUIDE07MAG - SL(x)l00Adiust the depth byturning the tool.

SET RING

Insert the special tool into the threads in the ball pin

and align the end of the tool with the groove in the

boot.

Slide the clip over the tool and into position

CAUTION: After installing the boot, check th. b.ll

pin taperod section tor grease contamiration and

wipe it if nocossary.

NE.ROD END

Turn the right and left tie-rods equally.

17-65

Page 1028 of 1413

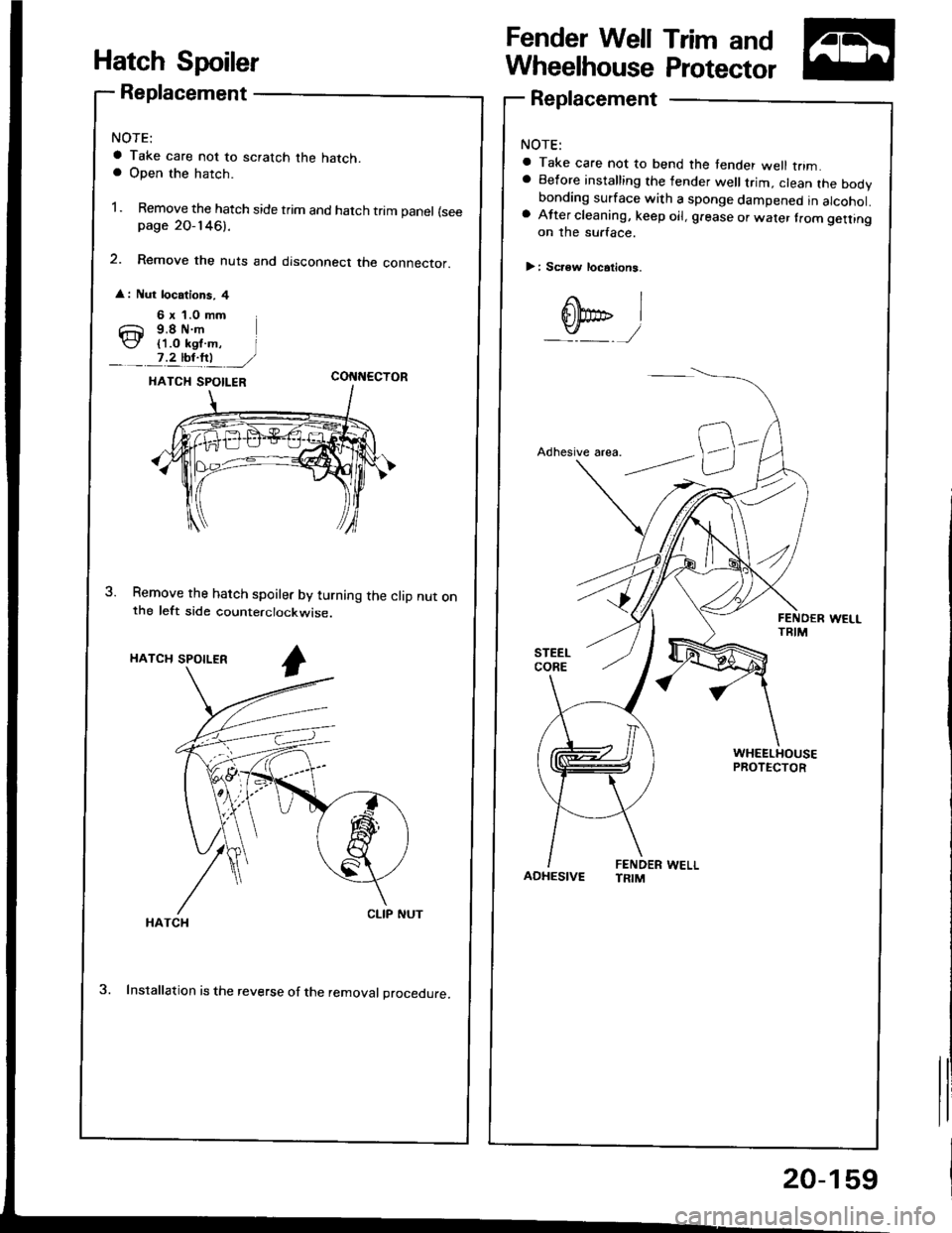

Hatch Spoiler

Replacement

a Take care not to scratch the hatch.a Open the hatch.

1. Remove the hatch side trim and hatch trim panel (seepage 2O-146).

2. Remove the nuts and disconnect the connector.

: Nut locations, 4

6 x 1.0 mm

Ch 9.8 N.m(J (1.0 ksl m, I__. 7,4b1!t ,/coI{t{EcroR

Remove the hatch spoiler by turning the clip nut onthe left side counterclockwise.

HATCH SPOILER

3. Installation is the reverse of the removal procedure.

Fender Well Trim and

Wheelhouse Protector

Replacement

a Take care not to bend the tender well trim.a Before installing the lender well trim, clean the bodvbonding surface with a sponge dampened in alcohol.a After cleaning, keep oil, g.ease or wafer lrom getlingon the surface.

> i Scr€w locations.

I

ADHESIVEFENDER WELLTRIM

20-159

Page 1037 of 1413

Heater and Air Conditioning

Heater ........ 21-1

Air Conditioning .......... ..22-1

SUPPLEMENTAL RESTRAINT SYSTEM {SRS}

The Integra SRS includes a driver's airbag, located in the steering wheel hub. In addition. all models except the

RS model for Canada have a front passenge.'s airbag located in the dashboard above the glovs box. Information

necessary to safely service the SRS is included in this Service Manual. ltems msrk€d with an asterisk (') on the

conlents page include, or are located near, SRS components. Servicing, disassembling or,eplacing thes€ items

will require special precautions and tools, and should therefore be done by an authorized Acura dealer.

a To avoid r6nd6dng tho SRS inoporativo. which could lead to personal injury or dealh in tho svont ot a sevele

frontal collision, all SRS servica work musl b€ portormed by an authorized Acura dealer.

a lmpropor sorvico procaduro3, including incorrect romoval and installatlon of tho SRS, could load to porsonal iniu-

ry causod by uninlonlional activation of tho ailbag8.

a All SRS eloctdcal widng harnossos are covored with yollow in3ulation. Relatsd compononts a.o locatod in tha

stsering column, flont console, daehboard, and dashboafd low6r pan6l, and in lhe dsshboa.d above lh€ glove

box. Do not uao electdcal tost equipmont on theae circuhs.

NOTE: The original radio has a coded theft protection circuit. Be sure to get the customer's code number beto.e

- disconnecting the battery.- removing the No. 32 (7.5 A) luse from the under-hood fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

Page 1126 of 1413

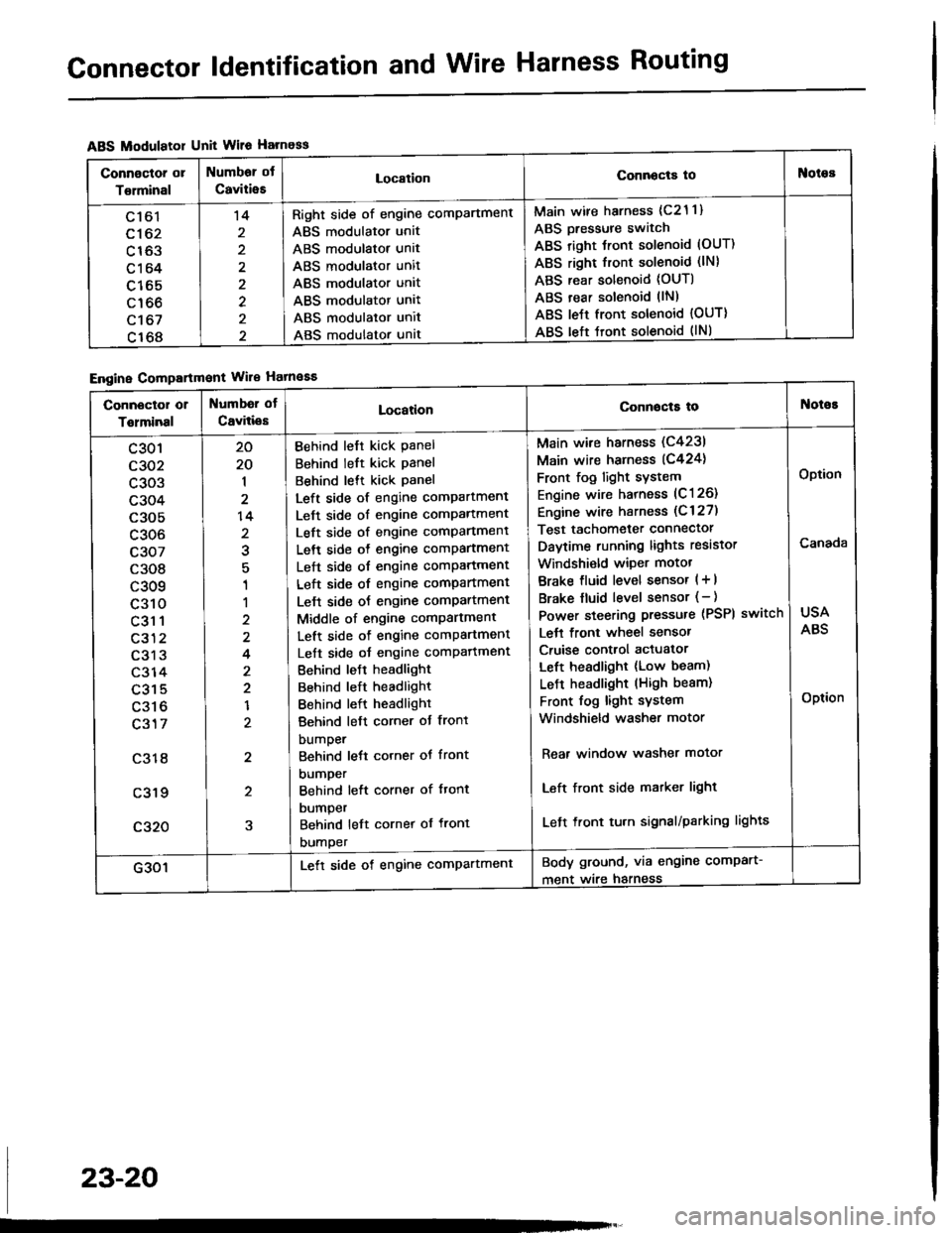

Connector ldentification and Wire Harness Routing

ABS Modulatol Unit Wile Harness

Engine Compartmont Wile Hatnaaa

Connoctor or

Torminal

Numbor ot

CaviiieELocationConnocta tooies

Ltol

c162

c163

c164

c165

c166

c't 67

c168

't4

2

2

Right side of engine comPartment

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unit

ABS modulator unat

Main wire harness (c21 1)

ABS Dressure switch

ABS right Jront solenoid (OUT)

ABS right front solenoid (lN)

ABS rear solenoid (OUT)

ABS rear solenoid llN)

ABS le{t front solenoid {OUT)

ABS left tront solenoid (lNl

Connector or

Tolminal

Numbd of

CaviliesLocationConnocta tot{oioE

c301

c302

c303

c304

c305

c306

c307

c308

c309

c310

c31 1

c312

c313

c314

c315

c316

c317

c318

c319

c320

20

20

1

2

14

2

1

1

2

4

2

2

1

2

2

5

Behind left kick Panel

Behind left kick panel

Behind lett kick Panel

Left side of engine compartment

Left side of engine comPartment

Left side of engine comPartment

Left side o{ engine comPartment

Left side of engine comPartment

Left side of engine compartment

Lelt side oJ engine comPartment

Middle of engine comPartment

Left side of engine comPartment

Left side oJ engine comPafiment

Behind leJt headlight

Behind left headlight

Behind left headlight

Behind left corner ot front

bumper

Behind lett corner ot front

DUmper

Behind left corner of ftont

DUmper

Behind left cornet of front

DUmper

Main wire harness (C4231

Main wire harness (C424)

Front fog light sYstem

Engine wire harness (C126)

Engine wire harness (C 127)

Test tachometer connector

Daytime running lights resistor

Windshi€ld wiper motot

Brake fluid level sensor ( + |

Brake fluid level sensor (- )

Power steering pressure (PSPI

Lett front wheel sensor

Cruise control actuator

Left headlight (Low beam)

LeJ-t headlight (High beam)

Front fog light system

Windshield washer motor

switch

Rear window washer motor

Left front side matker light

Left front tu.n signal/parking lights

USA

ABS

Option

Canada

Option

G301Lett side of engine comPartmentBody ground, via engine comPart-

ment wire harness

23-20

Page 1128 of 1413

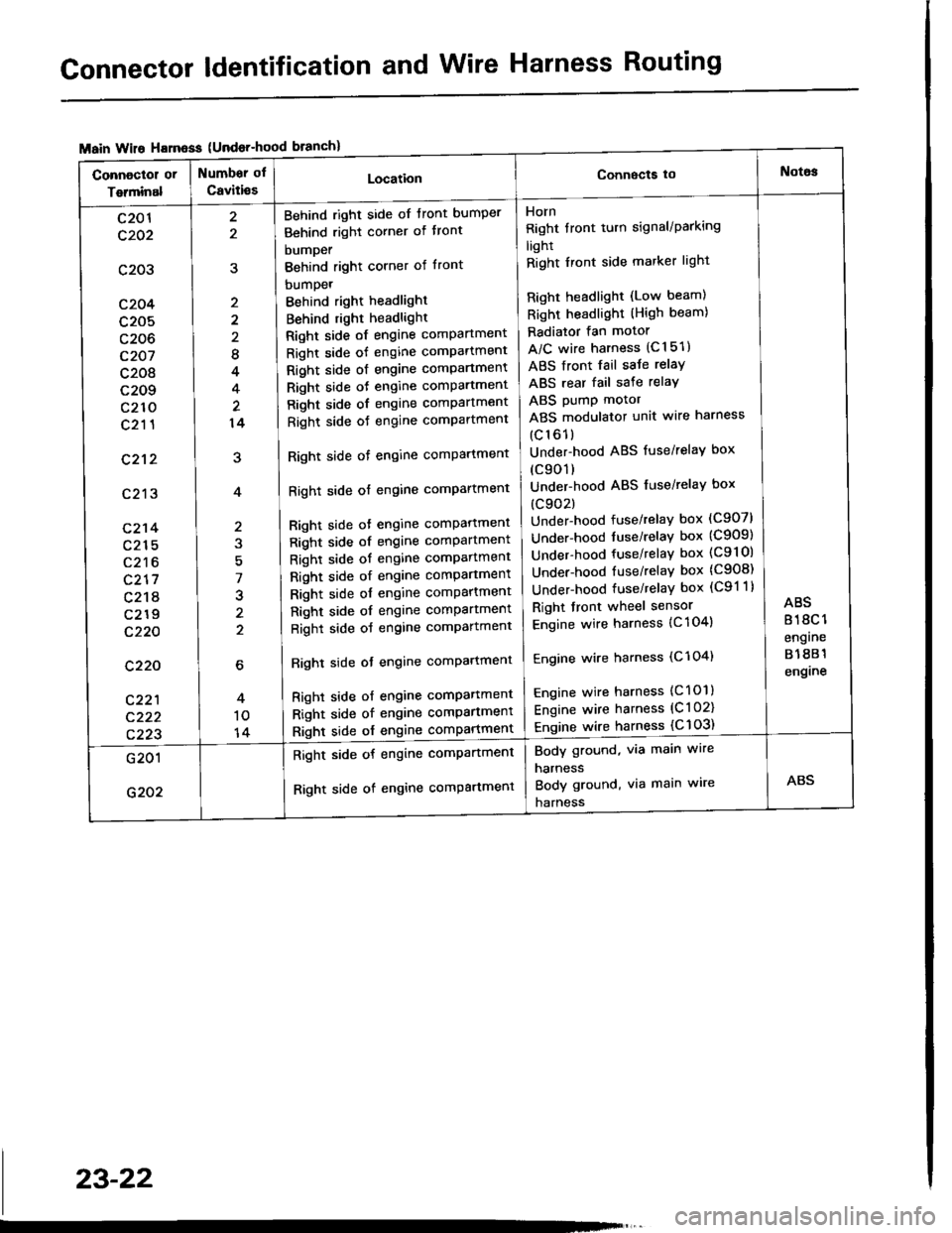

Connector ldentification and Wire Harness Routing

{Undor-hood

Horn

Right tront turn signal/Parking

light

Right Iront side marker light

Right headlight (Low beam)

Right headlight (High beam)

Radiator fan motor

A/C wire harness (C151)

ABS front fail saJe relay

ABS rear fail sate relay

ABS pump motor

ABS modulator unit wire harness

(c161)

Under-hood ABS fuse/relaY box

(c901)

Under-hood ABS fuse/relaY box

(c902)

Under-hood fuse/relay box (C907)

Under-hood tuse/relaY box (C909)

Under-hood fuse/relay box (C9l Ol

Under-hood fuse/relaY box (C908)

Under-hood fuse/relaY box (C91 1)

Right front wheel sensor

Engine wire harness {C 104)

Engine wire harness (C'l 04)

Engine wire harness (C101)

Engine wire harness (C l 02)

Engine wire harness {C 103)

Behind right side of tront bumper

Behind right corner of tront

bumper

Behind right corner of front

bumpet

Behind right headlight

Behind right headlight

Right side of engine comPartment

Right side of engine comPartment

Right side ot engine comPartment

Right side oJ engine comPartment

Right side of engine comPartment

Right side oJ engine comPartment

Right side of engine comPartment

Right side of engine comPartment

Bight side ot engine comPattment

Right side of engine comPartment

Right side of engine comPartment

Right side of engine comPartment

Right side of engine comPartment

Right side of engine comPartment

Right side of engine comPartment

Righl side ot engine comPartmenl

Right side of engine compartmenl

Right side of engine comPartmen'

Right side of engine comPartment

8

4

14

7

J

2

c201

c202

c203

c204

c205

c206

c207

c208

c209

c210

c211

c212

c213

c214

c215

c216

c217

c218

c219

c220

c220

c221

c222

c223

Body ground, via main wire

harness

Body ground, via main wire

harness

Right side of engine compartment

Right side of engine comPartment

23-22

Page 1148 of 1413

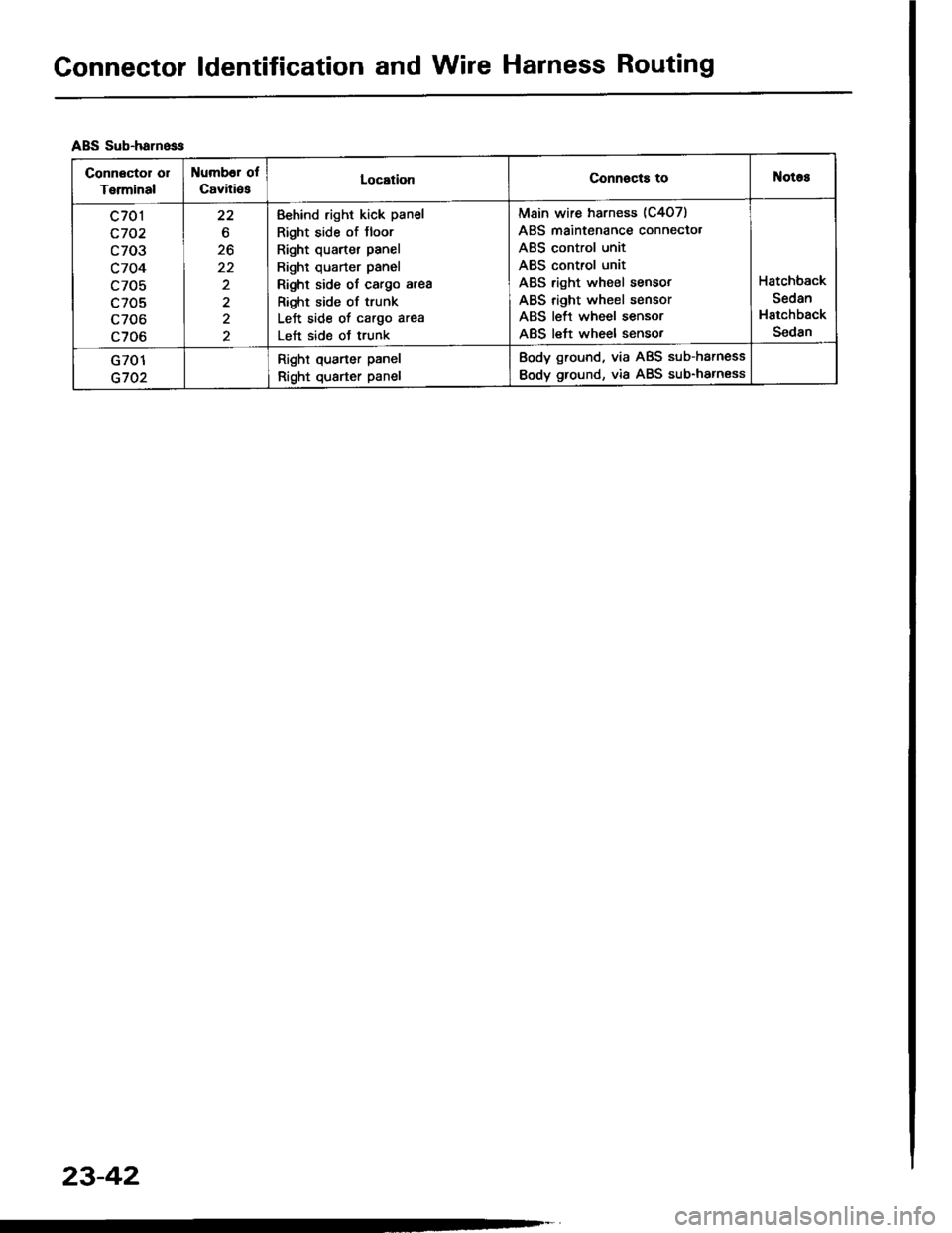

Gonnector ldentification and Wire Harness Routing

ABS Sub-harn6ss

Connactor ol

Terminal

Number of

CavitiesLocationConn€cts toNotas

c701

c702

c703

c704

c705

c705

c706

c706

22

20

22

2

2

Behind right kick panel

Right side of Jloor

Right quarter panel

Bighl quarter panel

Right side of cargo area

Right side of trunk

LeJt side of cargo area

Left side ot trunk

Main wire harness (C407)

ABS maintenance connecto.

ABS control unit

ABS control unit

ABS right wheel sensor

ABS right wheel sensor

ABS left wheel sensor

ABS left wheel sensor

Hatchback

Sedan

Hatchback

Sedan

G701

G702

Right quarter panel

Right quarter panel

Body ground, via ABS sub-harness

Body ground, via ABS sub-harness

23-42