system connectors HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 11 of 1413

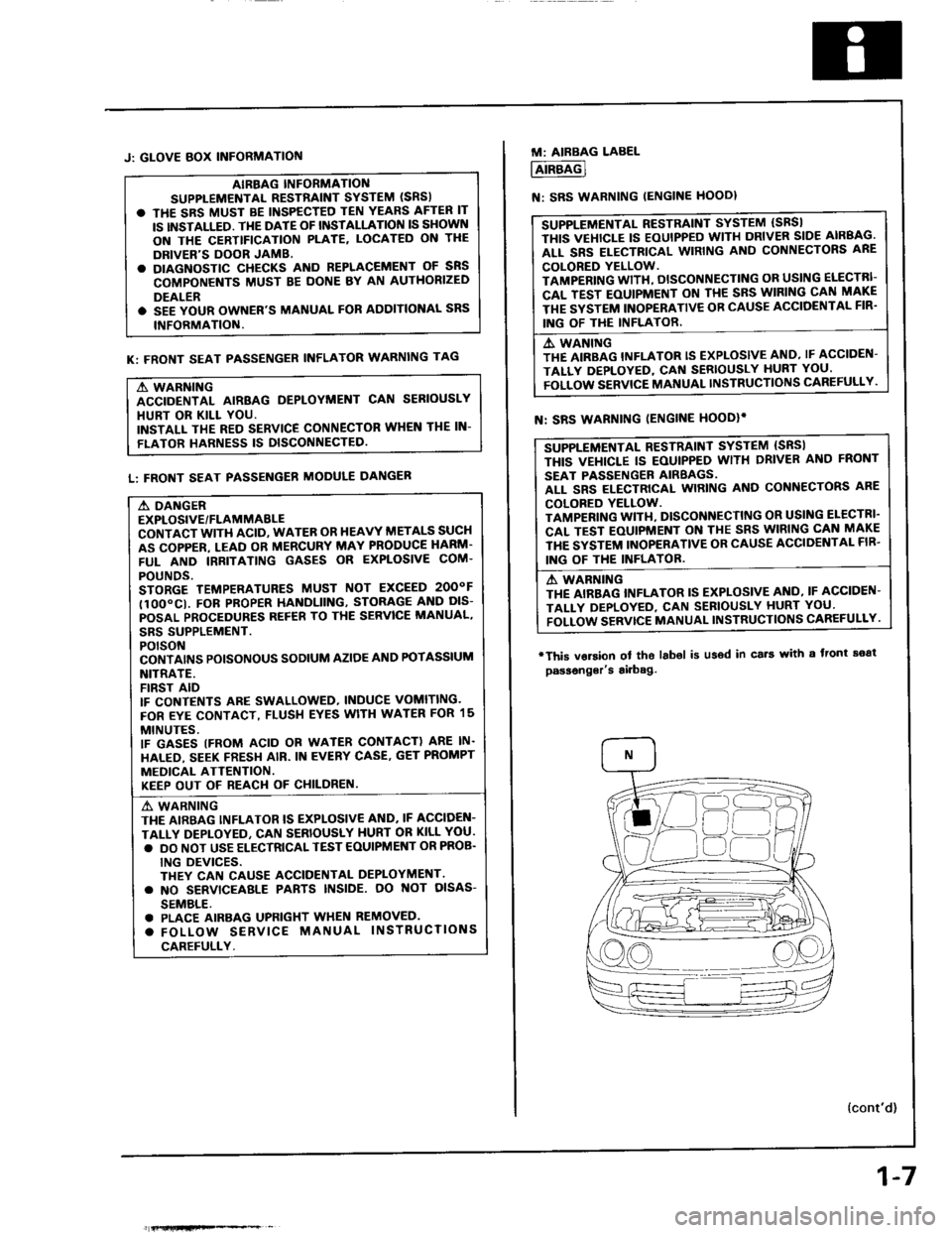

J: GLOVE BOX INFORMATIOf{

AIBBAG INFORMANO

SUPPLEMENTAL RESTiAINT SYSTEM (SRS)

. THE SRS MUST BE INSPECTED TEN YEARS AFTER IT

IS INSTALLED. TI{E DATE OF INSTALLATION IS SHOWN

ON THE CERTTFICATION PLATE, LOCATED ON THE

DRIVER'S DOOR JAMB.

. DIAGNOSTIC CHECKS AND REPLACEMENT OF SNS

COMPONENTS MUST BE DONE BY AN AUTHORIZED

DEALER

. SEE YOUR OWNER'S MANUAL FOR AODITIONAL SRS

INFORMATION.

K: FRONT SEAT PASSENGER INFLATOR WARNING TAG

A WARNING

ACCIDENTAL AIRBAG DEPLOYMENT CAN SERIOUSLY

HURT OR KILL YOU.

INSTALL THE RED SERVICE CONNECTOR WHEN THE IN-

FLATOR HARNESS IS DISCONNECTED

L: FRONT SEAT PASSENGER MODULE DANGER

A DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS SUCH

AS COPPER. LEAD OR MERCURY MAY PRODUCE HARM'

FUL AND IRRITATING GASES OR EXPLOSIVE COM.

POUNDS.

STORGE TEMPERATURES MUST NOT EXCEED 2OOOF

tlOO"CI. FOB PROPER HANDLIING, STORAG€ AND DIS-

POSAL PROCEDURES REF€B TO THE SERVICE MANUAL,

SBS SUPPLEMENT.

POTSON

CONTAI'\'S POISONOUS SODIUM AZIOE AND POTASSIUM

NITRATE.

FIRST AID

IF CONTENTS ARE SWALLOWED, INDUCE VOMITING.

FOR EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES.

IF GASES (FROM ACID OR WATER CONTACT) ARE IN.

HALED, SEEK FRESH AIR. IN EVERY CASE. GET PROMPT

MEDICAL ATTENTION.

KEEP OUT OF REACI.I OF CHILDREN.

A' WARNING

THE AIRBAG INFLATOR IS EXPLOSIVE AND. IF ACCIDEN-

TALLY DEPLOYEO, CAN SERIOUSLY HURT OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR PROB.

ING DEVICES.

THEY CAN CAUSE ACCIOENTAL DEPLOYMENT.

. NO SERVICEAALE PABTS INSIDE. OO NOT OISAS-

SEMBLE.

. PLACE AIRBAG UPFIGHT WHEN REMOVED.

. FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

fi{lHfiFe*% _

1-7

M: AIRBAG LABEL

AIRBAG

N: SRS WARNING IENGINE HOODI

SUPPLEMENTAL RESTRAINT SYSTEM (SBSI

THIS VEHICLE IS EOUIPPED WITH DRIVER SIDE AIRBAG.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPERING WITH, DISCONNECTING OR USING ELECTRI-

CAL TEST EOUIPMENT ON TI{E SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OB CAUSE ACCIOENTAL FIR'

ING OF THE INFLATOR.

A. WANING

THE AIRBAG INFLATOR IS EXPLOSIVE AND, IF ACCIDEN-

TALLY DEPLOYED, CAf{ SERIOUSLY HURT YOU'

FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

SUPPLEMENTAL RESTRAINT SYSTEM {SRSI

THIS VEI{ICLE IS EOUIPPED WITH DRIVER ANO FRONT

SEAT PASSENGER AIRBAGS.

ALL SRS ELECTRICAL WIRING AND CONNECTORS ARE

COLORED YELLOW.

TAMPENING WITI{, DISCONNECTING OR USI G ELECTRI'

CAL TEST EOUIPMENT ON THE SRS WIRING CAN MAKE

THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTAL FIB'

ING OF THE INFLATOB.

A WABNING

THE AIRBAG INFLATOR IS EXPLOSIVE AI{O, IF ACCIDEN-

TALI-Y DEPLOYED, CAN SEBIOUSLY HURT YOU'

FOLLOW SERVTCE MANUAL INSTRUCTIONS CAREFULLY.

N: SRS WARNING IENGINE HOODIi

'This vorsion

passonger's

ol tho labol is u36d in cs.t with a front soat

airbag.

{cont'd)

Page 194 of 1413

Fuel and Emissions

Spocial Tools ................ 1 1-2

Compon€nt Location

lndex ................. ...... 11-3

System Description

Vacuum Connectiona .......,.................... 1 1 -8

Efectrical Connections ....,.,.,......,...,,.....,'11-12

Syst€m Connectors ...,...,.................-.--. 11-2O

T.oubloshooting

Troubleshooting Guido .......................... 1 1-32

Self -diagnostic Procedures .,..,............... 1 1 -34

How to Road Flowcharts ...................,... 11-39

PGM-Fl System

Systom Description .............................. 1 l-4O

Troubleshooting Flowcharts

Engine Control Moduls ............... ........... 1 1 -42

Heated Oxygon Sensor ......,.................. 1 1-46

Heated Oxyg€n Sonsol Heatel .....,......... 1 1 -47

Fuel Supply System ..............-............... 1 1-50

Manitold Absolute Pressure

Ssnsor ............................................ 1 1-52

Top D6ad Cente./Crankshatr

Position/Cylindor Position sonsor ........ 1 1 -56

Engine Coolant Tempsrature Sonsor ....... 11-58

Throttlo Position Sonsor ........,..,,........... 1 1-60

Intake Air Temperaturs Sensor ............... 11-62

Baromet c Prsssuro Sensor ......,...,...,..,. 11-64

lgnition Output Signal ........................... 1 1 -66

Vehicle Spe€d Sensor ........................... 1 1 -68

Electdcal Load Dotector ....,...,..........,.... 1 1 -7O

Knock Sensor [818C1 engine] ............... 11-74

A/T Fl Signal A/B ................................. 1 1-76

ldle Contlol System

System Troubleshooting Guide .................. 1 1 -78

Systom Description ........ 11-79

Troubloshooting Flowchans

ldl€ Ail Control Valve ........................... 1 1 -82

Ail Conditioning Signal ......................... 1 1 -84

Altemator FR Signal ............................. 1 1 -86

Automatic Transaxle (A/T) Gear

Position Signal ......... 11-88

Brake Switch Signal ............................. 1 1 -9O

Startel Switch Signal ............................ 11-92

Power Steering Pressure Switch Signal ... 11-93

Fast ldle Thermo Valve ...................,......... 1 1 -94

ldls Speed S€tting .................................... 1 1 -95

Fuel Supply System

Systam Tloubloshooting Guid. .................. 1 1 -97

Fuol Linos ...................... 1'l -98

System Description ........ 11-100

Fuol Prassure ................. 11-100

Fu6l Ini6ctors ................. 11-102

Fuel Pressure Ragulato. .,. 11-106

Fuel Filter ...................... 11-108

Fual Pump ..................... 11-109

PGM-Fl Main F6lay ................................... 1 1"1 1 1

Fuel Tank ...................... t 1-114

Intake Air System

System Troubloshooting Guido .................. 1 1 -1 1 5

Systom Dascription ........ 11-116

Air Clean€r .................... 11-117

Throttls Cable ................'11-118

Throttl8 Body ................ 11-120

lntake Air Bypass Cont.ol Systsm

[B18Cl enginal .,......... 11-123

Intake Manilold [B1881 onginol ................. 11-128

Emission Control System

Systsm Troubleshooting Guido .................. 1 1 -1 29

Systam Doscription ........ 11-130

Tailpips Emission ........... 11-130

Thrae Way Catalytic Convortor ...,...,........., 11-131

Positiva CrankcaEo V6ntilation Systcm .,....., 11-134

Evaporativo Emission Contro|,..,..,.,.,,.,,..,.., 1 1-135

Page 212 of 1413

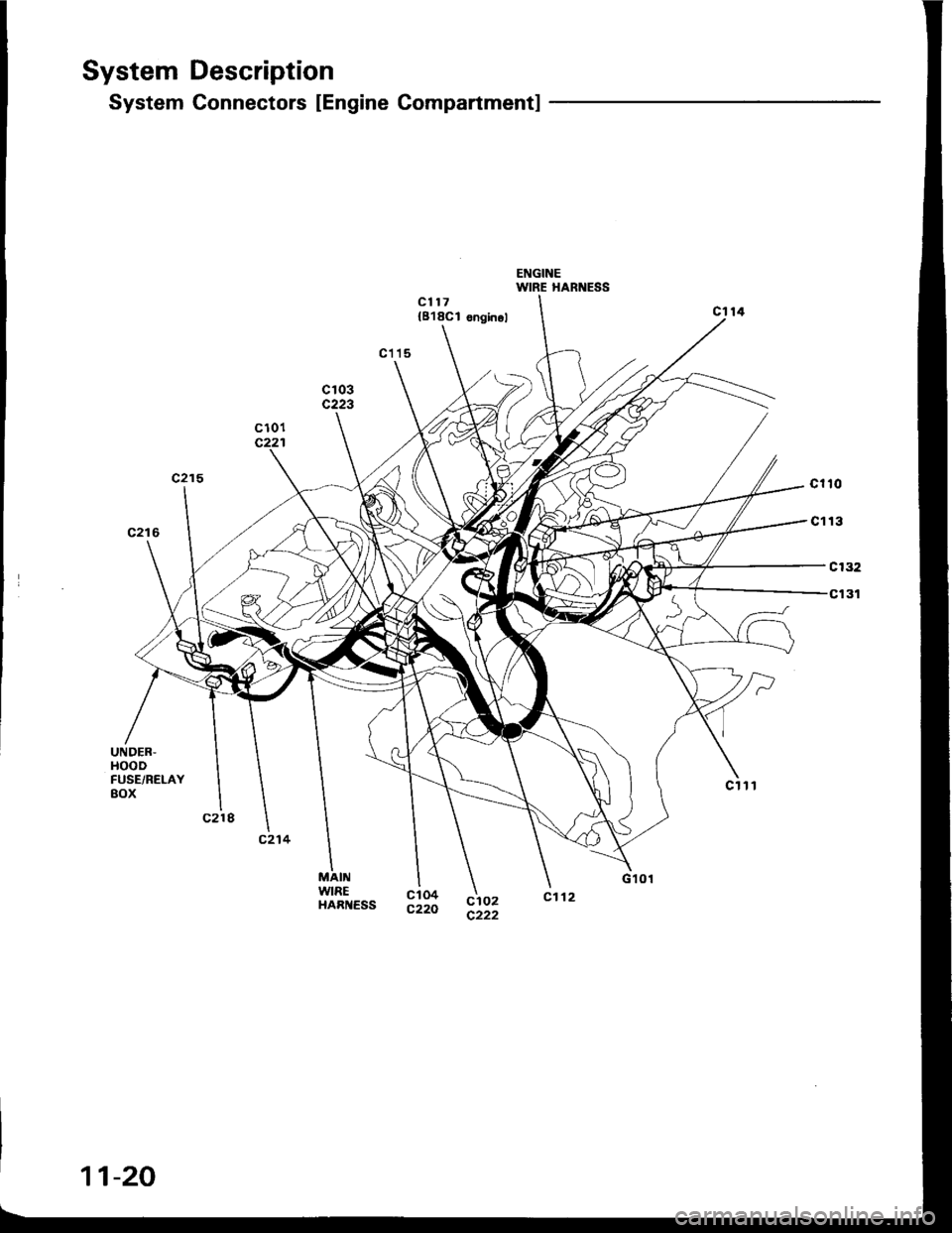

System Description

System Connectors IEngine Compartmentl

{818C1 onginol

ENGINEWIRE HARNESS

t3

c132

c131

UNDER,HOOOFUSE/RELAYaox

c102c222

ct 04c220

MAllrlWIREHARI{ESS

o

11-20

Page 214 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Engine Compartment] (contd)

c 120{81881 sngino}

(B18Cl onginol

11-22 HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Engine Compartment] (contd)

c 120{81881 sngino}

(B18Cl onginol

11-22](/img/13/6067/w960_6067-213.png)

System Description

System Connectors [Engine Compartment] (cont'd)

c 120{81881 sngino}

(B18Cl onginol

11-22

Page 216 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Dash and Floor]

PGM-FI MAINRELAY

C1I44 UNDEN-OASHFUSE/REALYBOX

ENGINECOMPARTMENTWIRE

DASHBOARO WIREHARNESS

MAINWIREHARI{ESS

REARWIREHARNESS

11-24 HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Dash and Floor]

PGM-FI MAINRELAY

C1I44 UNDEN-OASHFUSE/REALYBOX

ENGINECOMPARTMENTWIRE

DASHBOARO WIREHARNESS

MAINWIREHARI{ESS

REARWIREHARNESS

11-24](/img/13/6067/w960_6067-215.png)

System Description

System Connectors [Dash and Floor]

PGM-FI MAINRELAY

C1I44 UNDEN-OASHFUSE/REALYBOX

ENGINECOMPARTMENTWIRE

DASHBOARO WIREHARNESS

MAINWIREHARI{ESS

REARWIREHARNESS

11-24

Page 218 of 1413

![HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Dash and Floor] {contd}

UNDER-DASHFUSE/RELAYBOX

DASHBOARDHARNESS

MAINWIREHARNESS

11-26 HONDA INTEGRA 1994 4.G Workshop Manual System Description

System Connectors [Dash and Floor] {contd}

UNDER-DASHFUSE/RELAYBOX

DASHBOARDHARNESS

MAINWIREHARNESS

11-26](/img/13/6067/w960_6067-217.png)

System Description

System Connectors [Dash and Floor] {cont'd}

UNDER-DASHFUSE/RELAYBOX

DASHBOARDHARNESS

MAINWIREHARNESS

11-26

Page 220 of 1413

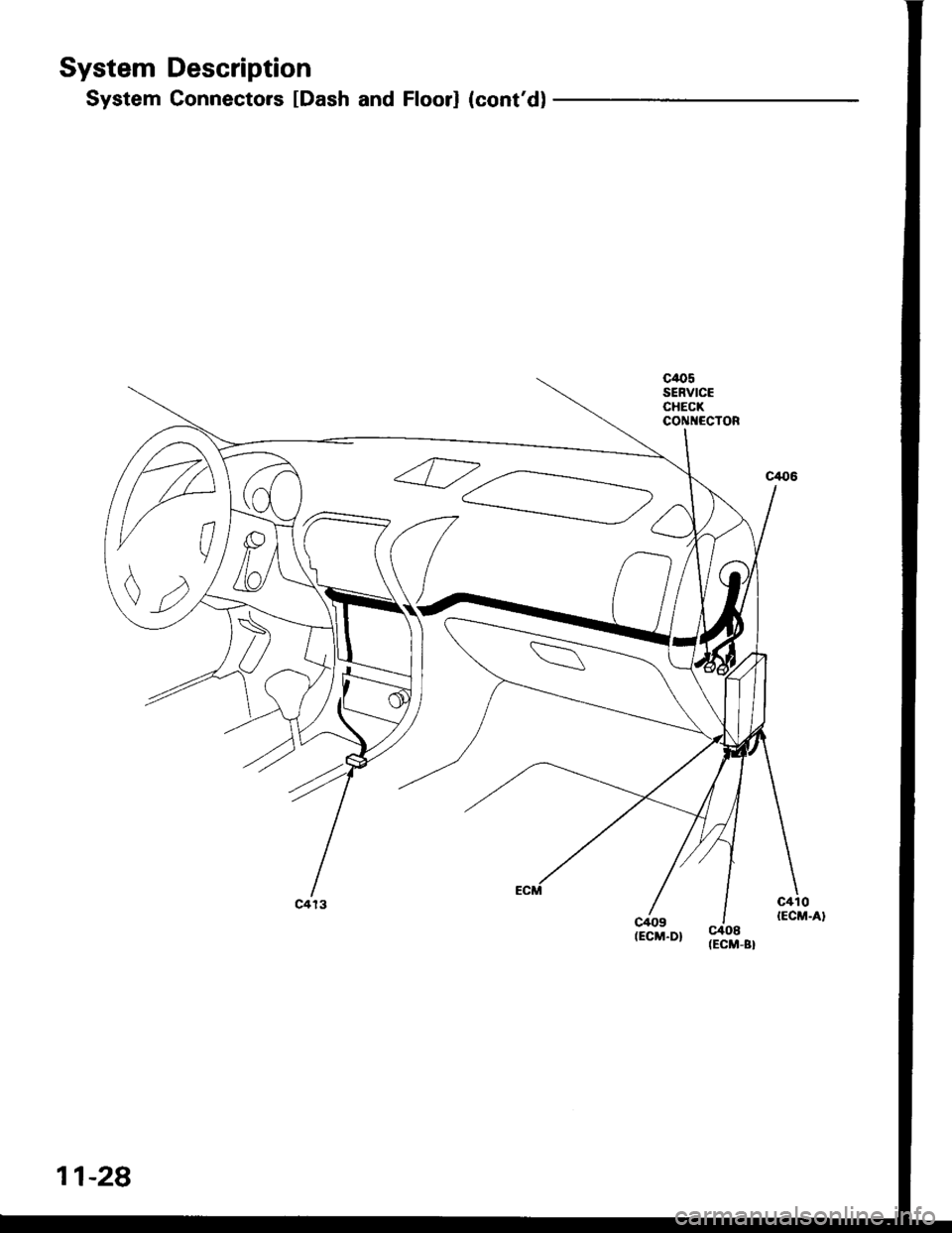

System Description

System Connectors [Dash and Floorl (cont'd)

c/ro5SERVICECHECKCONI{ECTOR

11-28

Page 222 of 1413

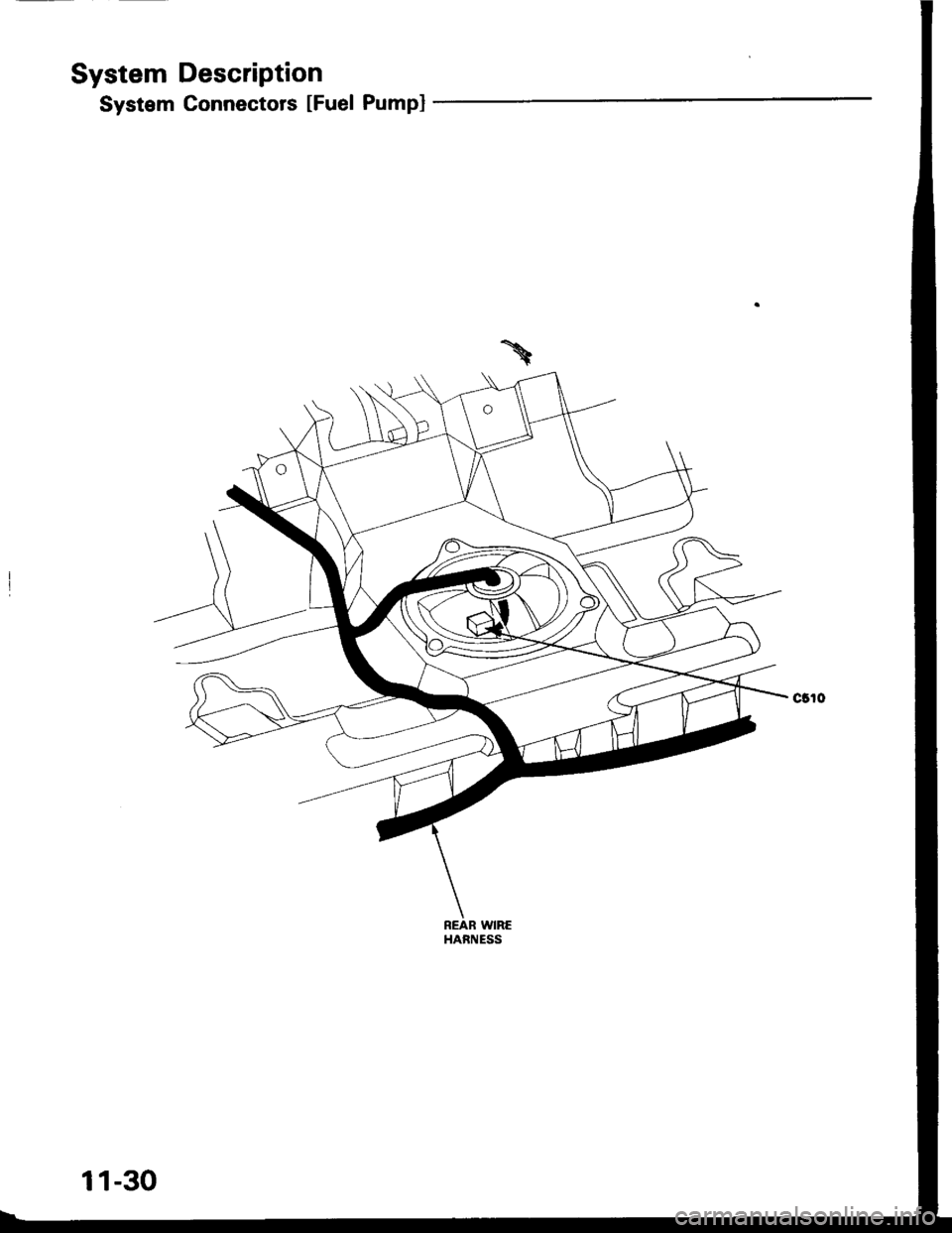

System Description

System Connectors [Fuel Pumpl

REAR WIREHAFNESS

11-30

Page 231 of 1413

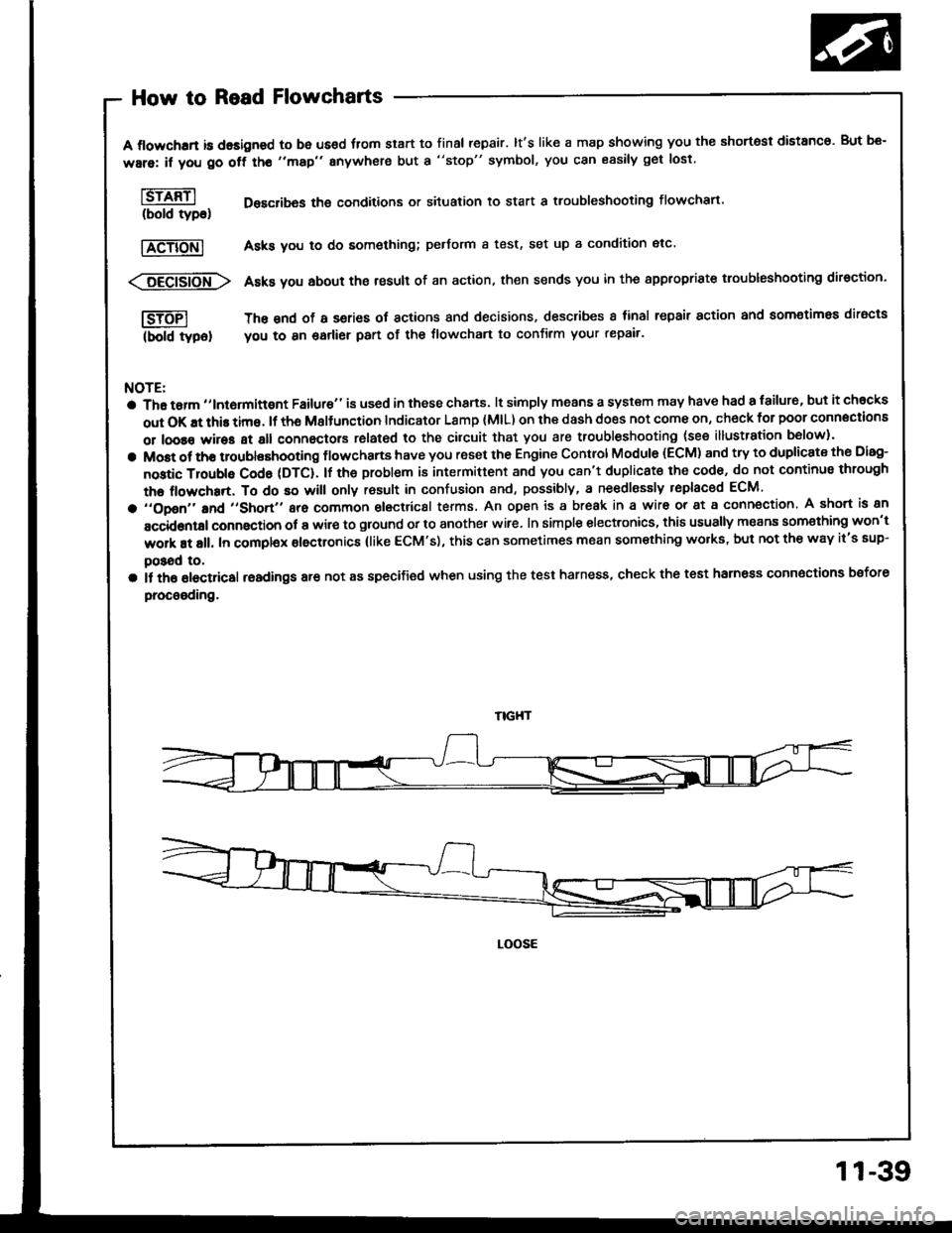

How to Read Flowcharts

A flowchrrt is dasigned to be us€d fiom start to final repair. lt's like a map showing you the shortest distanco. But be-

ware: if you go off tho "map" anywhere but a "stop" symbol, you can easily get lost

l6rffil Desclibas the conditions or situation to start a troubleshooting flowchart.(bold tyDo)

|TeTiONl Asks you to do something; pedorm a test, set up a condition etc'

<:6Eei6io-fr\> Asks you about the result of an action, then sends you in the appropriste troubleshooting direction.

I-SJTFI The snd of a series ot actions and decisions, describes I tinal repair action and aomotimea diracts

(bold typel you to 8n garlier part of the tlowchart to confirm your repair'

NOTE:

a Tha tarm ,,lntormittgnt Failure" is used in these chans. lt simply means a system may have had a failur6, but it chocks

out OK !t this time. lf th6 Msltunction Indicator Lamp (MlL) on ihe dash does not come on, check for poor connections

or loose wires at all connectors rolated to the cilcuit that you are troubleshooting (see illustration b6low).

a Most ot tho troublashooting flowchans have you reset the Engine Control Module (ECM) and try to duplicate the Disg-

nostic Troubls Cod6 (DTC). lf the problem is intermittent and you c8n't duplicat€ the cod6, do not continus through

the flowchart, To do so will only rosult in confusion and, possibly, a ne€dlessly replaced ECM

a ,,opon,'and ,,short,, are common electrical terms. An open is a break in a wir6 or at a conn€ction. A short is an

accidontal connaction ot a wir€ to ground or to another wire. In simple electronics, this usually means som€thing won't

work at all. In complex electronics (like ECM's), this can sometimes mean something wolks, but not the way it's sup-

poSad to,

a il th6 olectricsl readings are not as specified when using the test harness, check the test harness connoctions bsfore

procooding.

LOOSE

11-39

Page 234 of 1413

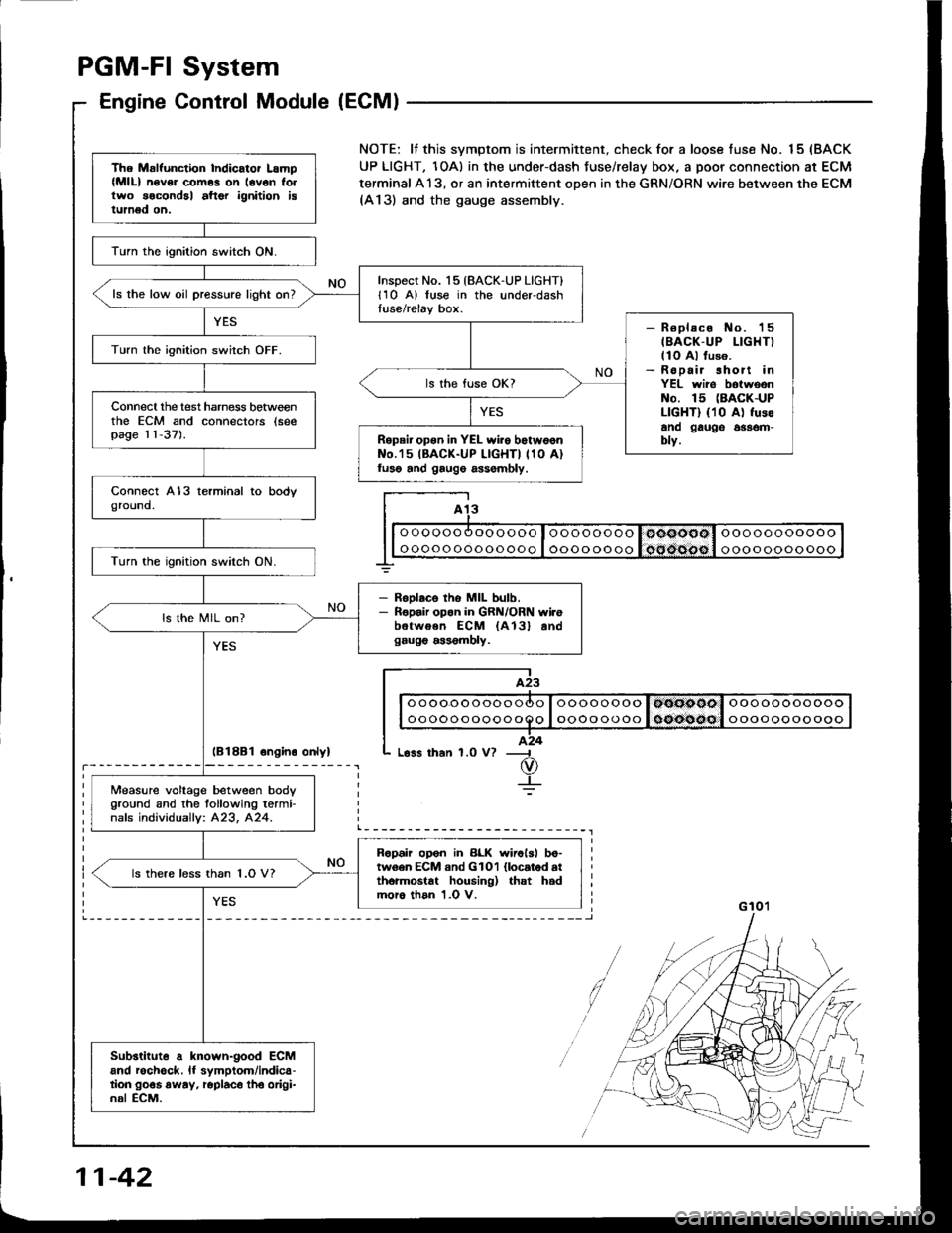

PGM-FI System

Engine Control Module (ECM)

lB18B1 ongino onlyl

The Malfunction Indicator Lamp(MlL) n6v6. com6s on lovon follwo socondal aftor ignition istumed on.

lurn the ignition switch ON.

Inspect No. 15 {BACK-UP LIGHT}l1O A) luse in the underdashtuse/relay box.ls the low oil pressure light on?

- R€placo No. 'l5

IBACK-UP LIGHT)llo Al fuso.- Ropair short inYEL wiro botwoonNo. 15 (BACK-UP

LIGHT) {10 A) fusoano gauge 6$om-blv.

Turn lhe ignition switch OFF.

ls the fuse OK?

Connecl the test harness betweenthe ECM and connectors (seepag€ 11-37).Repair opon in YEL wiio botw6onNo.'15 IBACK-UP LIGHTI 110 A)luso and gaug6 assombly.

Turn the ignition switch ON.

- RsDlaco tho MIL bulb.- Ropair opon in GRN/ORN wi.ebetwoen ECM {A13} andgaug€ a$6mbly.

ls the MIL on?

Measure voltage between body

Oround and the tollowing termi-nafs individuallv: 423, 424.

Ropah op6n in BLK wirolsl bo-tw6en ECM and GlOl llocatod atthormostat housing) that hadmoro than 1.0 V.

ls there less than 1.O V?

Substituto a known-good ECMand rochgck, lf symptom/indica-tion go€s away, roplaco tho origi-nal ECM.

NOTE: lf this svmptom is intermittent. check for a loose fuse No. 15 (BACK

UP LIGHT, 1OA) in the under-dash Juse/relay box, a poor connection at ECM

terminal A13, or an intermittent open in the GRN/ORN wire between the ECM(A13) and the gauge assembly.

I A13

I| | o oooo oooooooo I oooo oooo I ooooool ooooooooooo I

G 10'�l

11-42