oil change HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 420 of 1681

Description

\J

t{

{

14-3

The automatic transmission is a combination of a 3-element torque converter and triple-shalt electronically controlled

automatic transmission which provides 4 speeds forward and 1 speed reverse. The entire unit is positioned in line with

the engrne.

Torque Converter, Gears, and Clutches

The torque converter consists of a pump, turbine, and stator, assembled in sigle unit. The torque converter is connected to

the engine crankshaft so they turn torether as a unit as the engine turns. Around the outside of the torque convener is a

ring gear which meshes with the starter pinion when the engine is being started. The entire torque converter assembly

serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts; the mainshaft. the countershaft, and the sub shaft. The mainshaft is in-line with

the engine crankshaft.

The mainshaft includes the 1st, and 2ndl4th clutches,and gear for 3rd, 2nd, 4th, reverse, and 1st. (3rd gear is integral with

the mainshaft, while reverse gear is integral with the 4th gear.)

The countershaft includes the 3rd clutch and gears for 3rd,2nd, 4th, reverse, 1st, and parking. Reverse and 4th gears can

be loched to the countershaft at its center,providing 4th gear or reverse, depending on which way the selector is moved.

The sub-shaft includes the 1st-hold clutch and gears fo 1st and 4th.

The gears on the mainshaft are in constant mesh with those on the countersahft and sub-shaft.When certain combinations

of gears in the transmission are engaged by clutches. power in transmitted from the mainshaft to the countershaft via the

sub-shaft to orovude oil, lo'1. E, E. and E.

Electronic Control

The electronic control svstem consists of the Transmission Control Module (TCM), sensors, and four solenoid valves.

Shilting and lock-up are electronically controlled for comfortable driving under all conditions.

The TCM is located below the dashboard, behind the lelt side kick panel on the driver's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the serbvo body, and

the lock-up valve body, through the respective separator plates, They are bolted to the torque converter housing,

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shitt valve, the Clutch Pressure Control

lCPC) valve, the 4th exhaust valve, the reliel valve, and the ATF pump gears.

The secondary valve body contains the 4-3 kick-down valve, the 3-2 kick-down valve, the 2-3 orifice control valve, the

3-4 shift valve, the orilice control valve, the modulator valve, and the servo control valve.

The regulator valve body contains the pressure regulator valve, the lock-up control valve, the torque converter check

valve, and the cooler check valve.

The servo body contains the servo valve, which is integrated with shift fork shaft, the throttle valve B, and the accumula-

tors.

The lock-up valve body contains the lock-up shift valve and the lock-up timing B valve, and is bolted to the regulator valve

ooqy.

Fluid from the regulator passes through the manual valve to the various control valves.

Shift Control Mechanism

Input to the TCM from various sensors located throughout the car determines which shift control solenoid valve should

be activated. Activating a shitt control solenoid valve changes modulator pressure, causing a shift valve to move. This

pressurizes a line to one ol the clutches, engaging that clutch and its corresponding gear.

Lock-uD Mechanism

In @ position, in 2nd, 3rd and 4th, and @ position in 3rd, pressurized fluid can be drained lrom the back oI the tor-

que converter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this

takes place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the TCM

optimizes the timing of the lock-up mechanism.

The lock-up valves controlthe range of lock-up according to lock-up control solenoid valves A and B, and throttle valve B.

When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid valves

A and B are mounted on the torque converter housing, and are controlled by the TCM.

(cont'd)

Page 731 of 1681

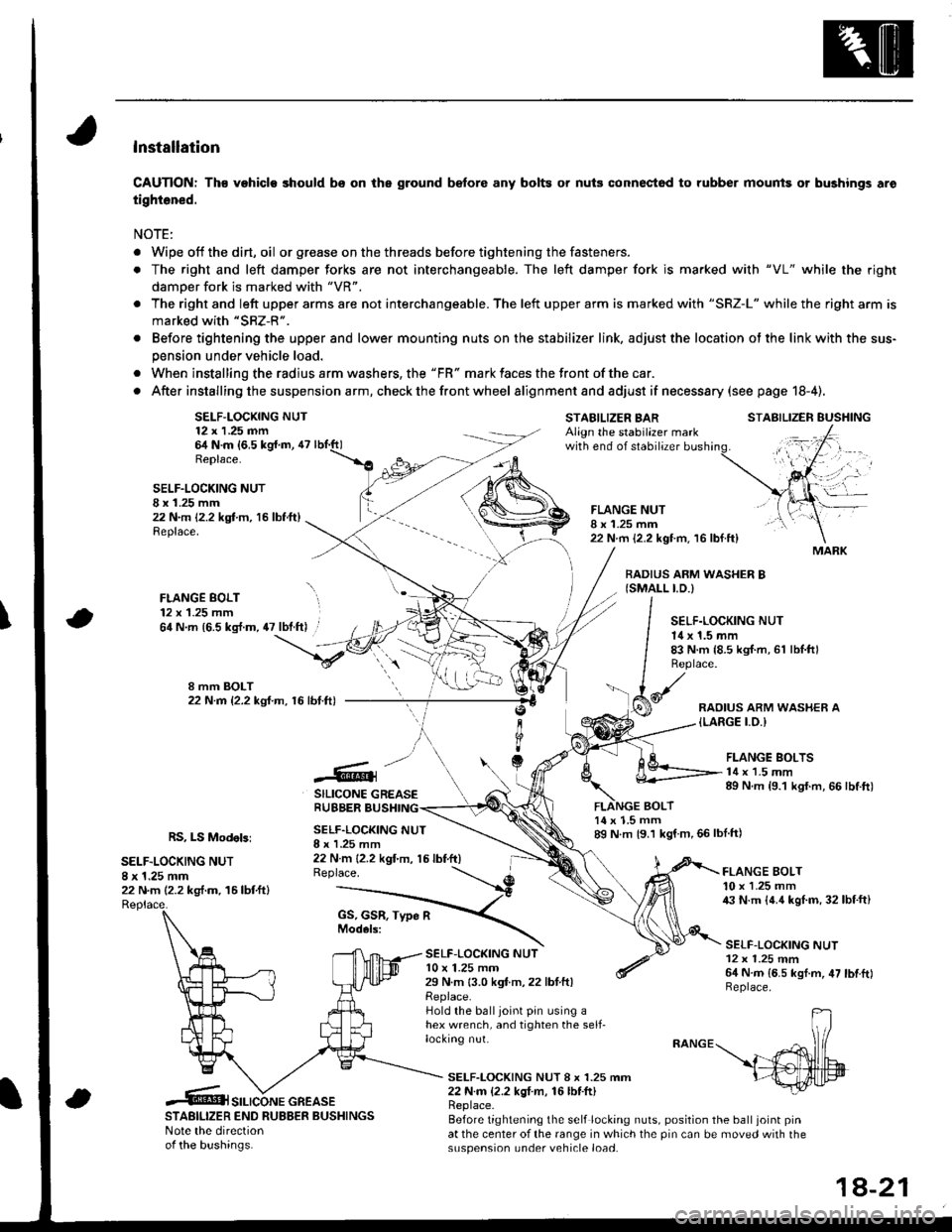

lnstallation

CAUTION: Th€ vehiclo should bs on the ground b€fore any bolts or nuis connectod to rubber mounis or bushings aro

tightened.

NOTE:

. Wipe off thedirt,oil or gr€ase on the threads before tightening the fasteners.

. The right and left damper forks are not interchangeable. The left damper fork is ma.ked with "VL" while the righr

damoer fork is marked with "VR".

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SRZ-L" while the right arm is

marked with "SRZ-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adjust the location ot the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front ofthe car.

. After installing the suspension a rm, check the front wheel alignmentand adjust if necesssry (see page 18-4).

SELF-LOCKING NUT12 x 1.25 nn64 N.m {6,5 kg{.m, 47Replace.

STABILIZER BARAlign the stabilazer markwith end of stabilizer

BOLT

STABILIZER EUSHING

SELF.LOCKING NUTI x 1.25 mm22 N.m 12.2 kgt m, 16 lbf.ft)Replace.

FLANGE BOLT12 x 1.25 mm

FLANGE NUTI x 1.25 mm22 N.m {2.2 kgt m. 16 lbf.ft}

BADIUS ARM WASHER B{SMALL I.D.)

\64 N.m {6.5 kg{.m, 47 lbt.ft) .SELF.LOCKING NUT14 x 1.5 mm83 N.m {8.5 kgI.m, 61 lbl.ftlReplace.

RAOIUS ARM WASHER A{LARGE I.O.I

.@]

SILICONE GREASERUBBER BUSHING

FLANGE BOLTS14 x 1.5 mm89 N.m {9.1 kgf.m, 66 lbtft)

RS, LS Modebi

SELF.LOCKING NUT8 x 1.25 mm22 N.m (2.2 kg,f.m. 16lbtftl

SELF.LOCKING NUTI x I .25 mm22 N m {2.2 kgt'm, 15 lbf.ft)Replace.

14 x 1.5 mm89 N m {9.1 kgf m,66lblft)

SELF-LOC(ING NUTl0 x 1.25 mm29 N.m 13.0 kgf.m,22 lbtftlReplace.Hold the balljoint pin using ahex wrench, and tighten the self-locking nut.

FLANGE BOLT10 x 1.25 mm43 N.m {4.4 kgl.m, 32lbf.ft}

SELF-LOCKING NUT12 x 1.25 mm64 N.m {6.5 kgf.m, 47 lbtftlReplace.

SELF-LOCKING NUT 8 x 1.25 mm22 N.m {2.2 kgI m, 16lbf.ft)

STABILIZER END RUBBER BUSHINGSNote the directionof the bushinas.

Replace.Before tightening the self locking nuts, position the ball joint pinat the center of the range in which the pin can be moved with thesuspension under vehicle load.

MARK

SILICONE GREASE

1A-21

Page 781 of 1681

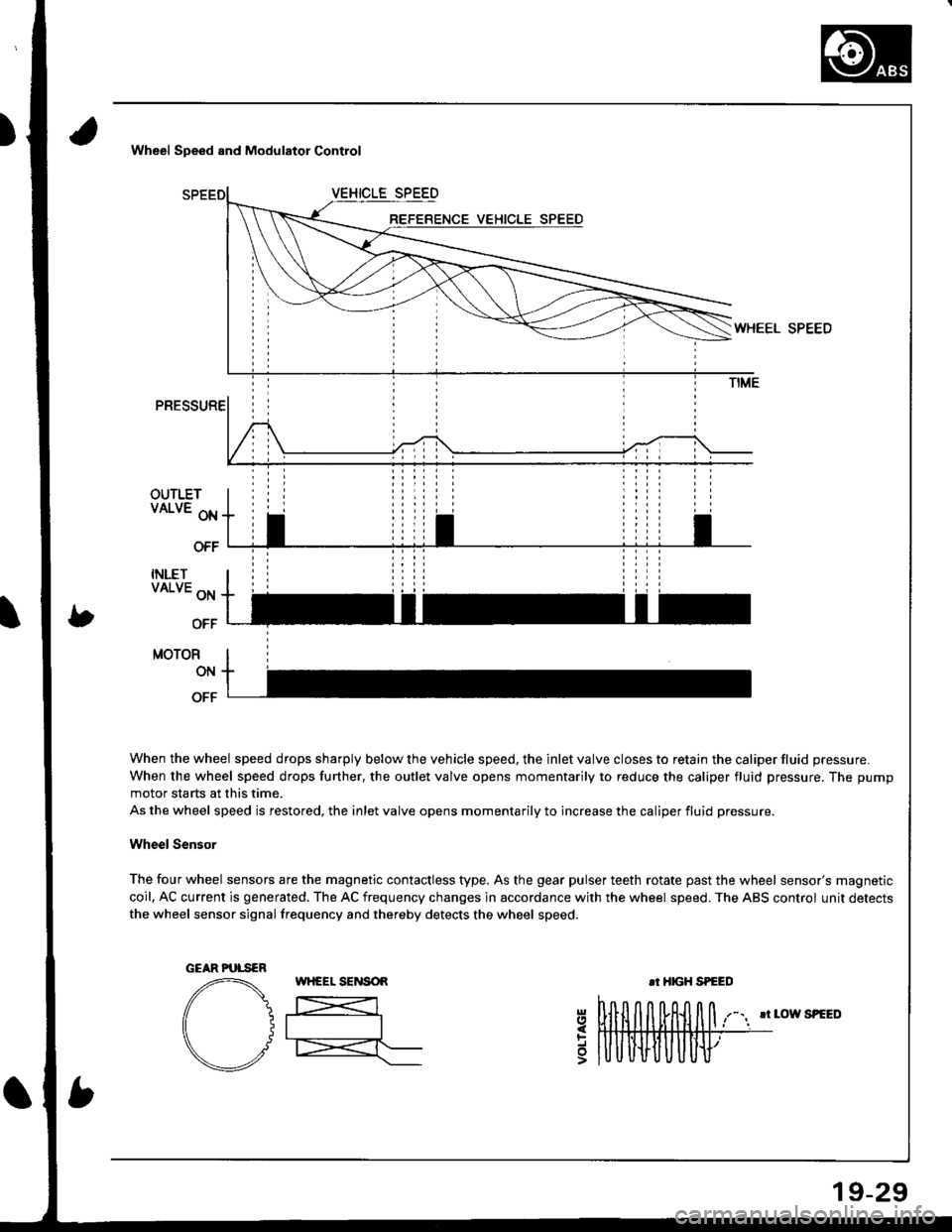

Wheel Speed and Modulator Control

OUTLETVALVE oN

OFF

INLETVALVE ON

OFF

MOTOR

ON

OFF

When the wheel speed drops sharply below the vehicle speed, the inlet valve closes to retain the caliper fluid pressure.

When the wheel speed drops further, the outlet valve opens momentarily to reduce the caliper fluid pressure. The pump

motor starts at this time.

As the wheel speed is restored, the inlet valve opens momentarily to increase the caliper fluid pressure.

Wheel Sensor

The four wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit detects

the wheel sensor signalfrequency and thereby detects the wheel speed.

rr LOW SPEED

5

GEAR PUTSER

19-29

Page 1024 of 1681

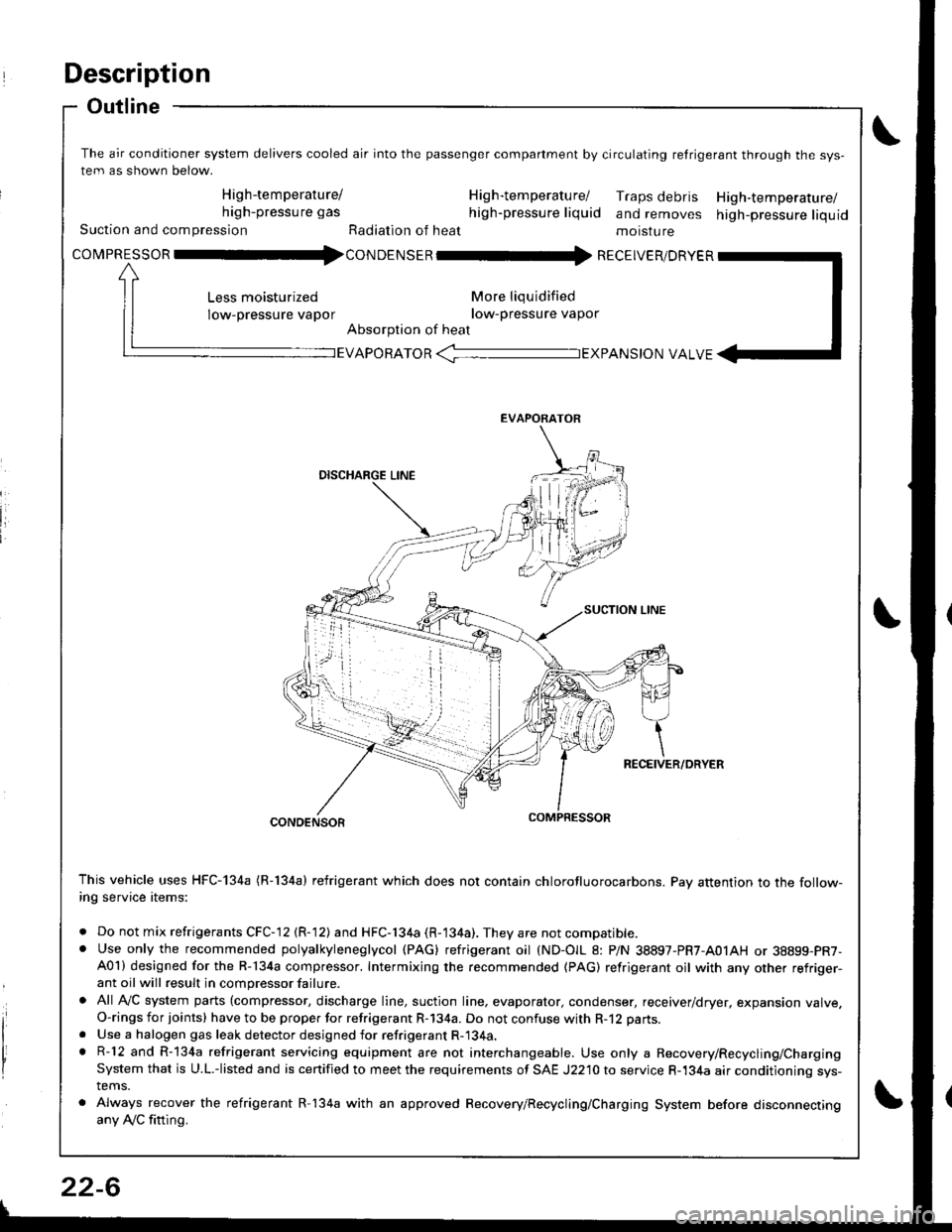

Description

Outline

The air conditioner system delivers cooled air into the passenger companment by circulating retrigerant through the sys-

tem as shown below.

High-temperature/ H ig h-tem peratu rel Traps debris High-temperature/high-pressure gas high-pressure liquid and removes high-pressure liquidSuction and compression Radiation of heat moisture

covpnEsson -tl4con oetsen -rr{ REcEIvER/DRvER

More liqu idified

low-pressure vapor

Absorption of heat

Less moisturized

low-pressure vapor

EVAPORATOR -TEXPANS|ON VALVE

EVAPORATOR

CONDENSOR

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01) designed for the R-134a compressor. Intermixing the recommended (PAG) refrigerant oil with any other refriger-ant oil will result in compressor failure.

. All AVC system parts (compressor, discharge line, suction line. evaporator, condenser, receiver/dryer, expansion valve.O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/ChargingSystem that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning sys-tems.

. Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnectingany Ay'C fitting.

22-6

Page 1050 of 1681

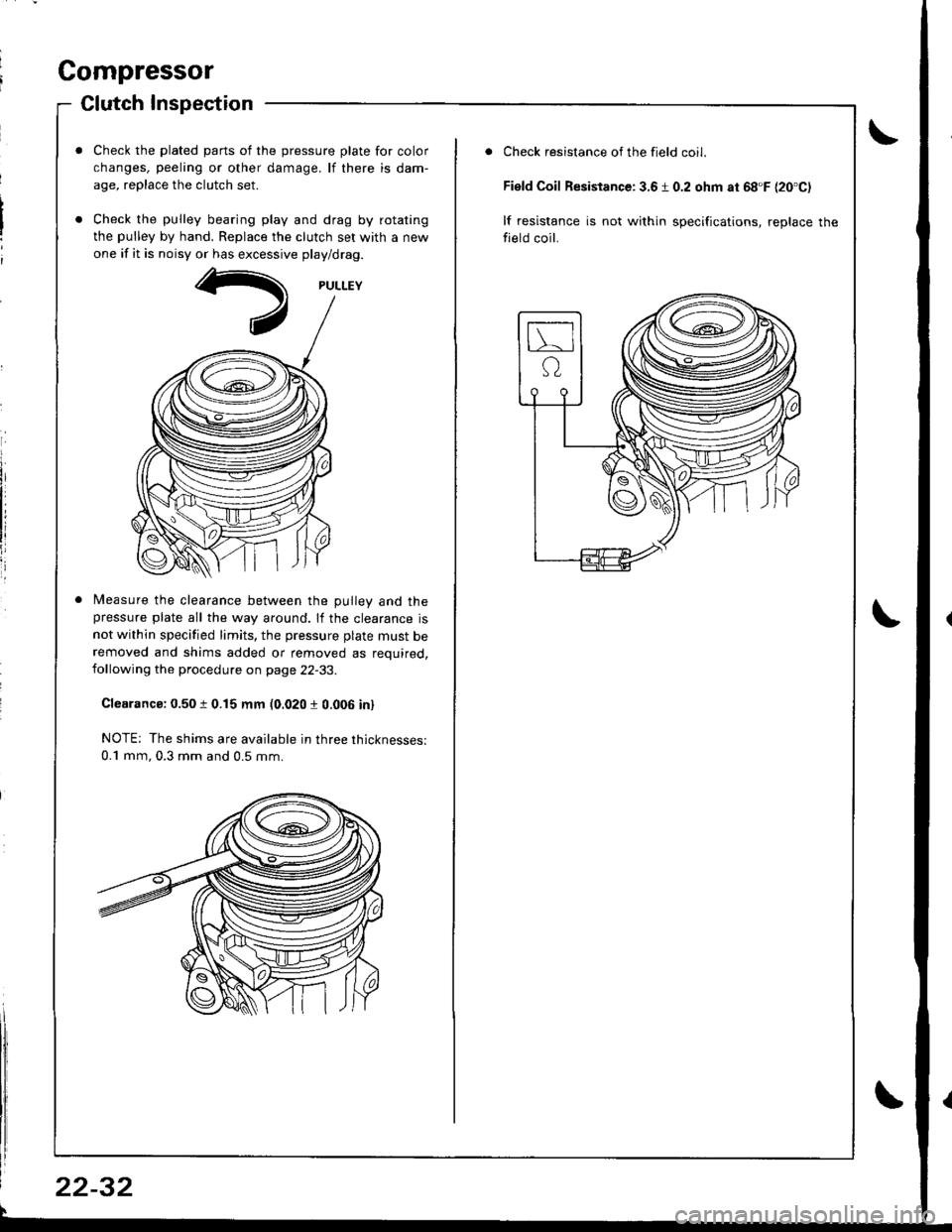

Compressor

Clutch Inspection

Check the plated parts of the pressure plate for color

changes, peeling or other damage. lf there is dam-

age, replace the clutch set.

Check the pulley bearing play and drag by rotating

the pulley by hand. Replace the clutch set with a new

one if it is noisy or has excessive play/drag.

Measure the clearance between the Dullev and thepressure plate all the way around. lf the clearance is

not within specified limits, the pressure plate must beremoved and shims added or removed as required,following the procedure on page 22-33.

Clearanca: 0.50 t 0.15 mm (0.020 r 0.006 in)

NOTE; The shims are available in three thicknesses:

0.1 mm, 0.3 mm and 0.5 mm.

22-32

Check resistance of the field coil.

Field Coil Resistance: 3.6 1 0.2 ohm at 68'F {20'C)

lf resistance is not within specifications, replace the

field coil.

Page 1500 of 1681

Gauges (cont'd)

- How the Circuit Works

When the ignition switch is in ON (ll) or START (lll),

battery voltage is supplied through fuse 25 to the

gauges in the gauge assembly.

Speedometer and Odometer

The odometer and speedometer drive circuits

receive pulses lrom the vehicle speed sensor

(VSS). The pulse rate increases as the car

accelerates. The frequency and duration of these

input pulses are measured and displayed by the

speedometer, odometer and tripmeter.

Tachometer ('98-'99 Models)

The tachometer drive circuit receives oulses from

the ignition control module (lCM) in the distributor

assembly. The solid-state tachometer then displays

these pulses as engine speed. For each 200 pulses

per minute from the ignition control module (lCM),

the tachometer displays 100 RPM.

Tachometer ('00 Model)

The tachometer drive circuit receives pulses f rom

the PCM or ECM. The solid-state tachometer then

displays these pulses as engine speed. For each

200 oulses oer minute trom the PCM or ECM the

tachometer displays 1 00 RPM.

Engine Coolant Temperature Gauge and Fuel

Gauge

The engine coolant temperature gauge has two

intersecting coils wound around a permanent

magnet rotor. Voltage applied to the coils, through

fuse 25, generates a magnetic field. The magnetic

field, controlled by the engine coolant temperature

gauge sending unit, causes the rotor to rotate and

the gauge needle to move. As the resistance in the

sending unit varies, current through the gauge coils

changes. The gauge needle moves toward the coil

with the strongest magnetic tield. The fuel gauge

works the same way.

The engine coolant temperature gauge sending

unit's resistance varies from about 137 ohms at low

engine temperature to between 30-46 ohms at high

temperature (radiator fan running).

The fuel gauge sending unit's resistance varies from

about 2-5 ohms at full, to about 110 ohms at empty.

When you turn the ignition switch to LOCK (0), the

gauge remains at the last reading until you turn lhe

ignition switch to ON (ll) or START (lll) again.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

81'2

Page 1641 of 1681

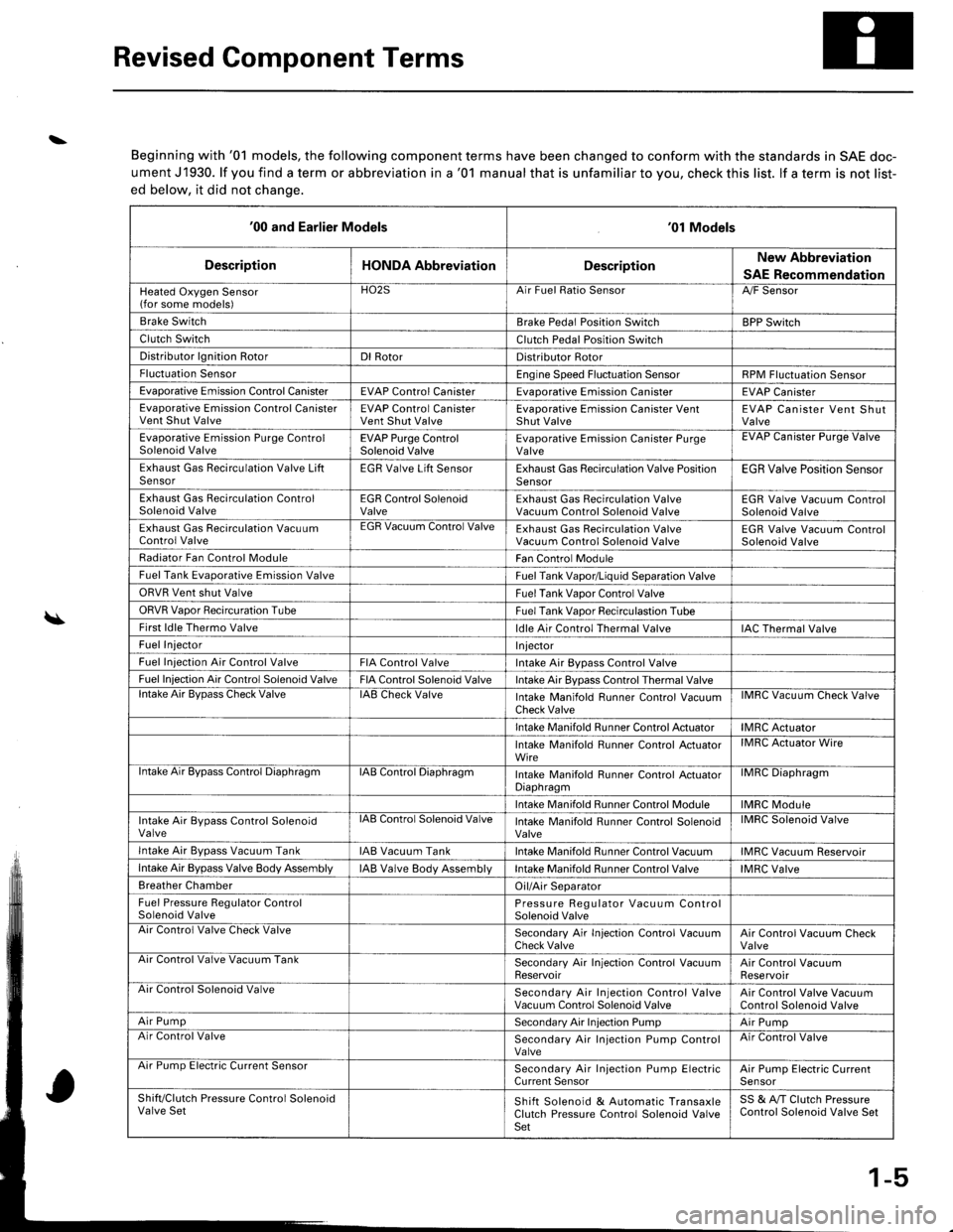

Revised Component Terms

\

\

Beginning with '01 models, the following component terms have been changed to conform with the standards in SAE doc-

ument J1930. lf you find a term or abbreviation in a '01 manual that is unfamiliar to you, check this list. lf a term is not list-

ed below, it did not chanqe.

'00 and Earlier Models'01 Models

DescriptionHONDA AbbreviationDescriptionNew Abbreviation

SAE Recommendation

Heated Oxygen Sensor(for some models)HO2SArr ruet llalto )ensorA,/F Sensor

Brake SwitchBrake Pedal Position SwitchBPP Switch

Clutch SwitchClutch Pedal Position Switch

Distributor lgnition RotorDl RotorDistributor Rotor

Fluctuation SensorEngine Speed Fluctuation SensorRPM Fluctuation Sensor

Evaporative Emission Control CanisterEVAP Control CanisterEvaDorative Emission CanisterEVAP Canister

Evaporative Emission Control CanisterVent Shut ValveEVAP Control CanisterVent Shut ValveEvaporative Emission Canister VentShut ValveEVAP Canister Vent ShutValve

Evaporative Emission Purge ControlSolenoid ValveEVAP Purge ControlSolenoid ValveEvaporative Emission Canister PurgeValveEVAP Uanister Purge Valve

Exhaust Gas Recirculation Valve LiftSensorEGR Valve Lift SensorExhaust Gas Recirculation Valve PositionSensorEGR Valve Position Sensor

Exhaust Gas Recirculation ControlSolenoid ValveEGR Control SolenoidValveExhaust Gas Recirculation ValveVacuum Control Solenoid ValveEGR Valve Vacuum ControlSolenoid Valve

Exhaust Gas Recirculation VacuumControl ValveEGR Vacuum Control ValveExhaust Gas Recirculation ValveVacuum Control Solenoid ValveEGR Valve Vacuum ControlSolenoid Valve

Radiator Fan Control ModuleFan Control Module

Fuel Tank Evaporative Emission ValveFuel Tank Vapor/Liquid Separation Valve

ORVR Vent shut ValveFuel Tank Vaoor Control Valve

ORVR Vaoor Recircuration TubeFuel Tank Vaoor Recirculastion Tube

First ldle Thermo Valveldle Air Control Thermal ValveIAC Thermal Valve

Fuel InjectorI njector

Fuel Iniection Air Control ValveFIA Control ValveIntake Air Bypass Control Valve

Fuel Injection Air Control Solenoid ValveFIA Control Solenoid ValveIntake Air Bypass Control Thermal Valvelntake Air BvDass Check ValveIAB Check ValveIntake Manifold Runner Control VacuumCheck ValveIMRC Vacuum Check Valve

Intake Manifold Runner Control ActuatorIMRC Actuator

Intake Manifold Runner Control ActuatorWireIMRC Actuator Wire

ntake Air Bypass Control DiaphragmIAB Control DiaphragmIntake Manifold Runner control ActuatorDiaphragmilvrr1u urapnragm

Intake Manifold Runner Control ModuleIMRC Module

Intake Air Bypass Control SolenoidValvelAts Control Solenoid ValveIntake Manifold Runner Control SolenoidValveIMRC Solenoid Valve

Intake Air Bvpass Vacuum TankIAB Vacuum TankIntake Manifold Runner Control VacuumIMRC Vacuum Reservoir

Intake Air Bypass Valve Body AssemblyIAB Valve Body AssemblVIntake Manifold Runner Control ValveIMRC Valve

Breather ChamberOil/Air Separator

Fuel Pressure Regulator ControlSolenoid ValvePressure Regulator Vacuum ControlSolenoid ValveAir Control Valve Check ValveSecondary Air In.jection Control VacuumCheck ValveAir Control Vacuum CheckValveArr Control Valve Vacuum TankSecondary Air Injection Control VacuumReservoirAir Control VacuumReservoirAir Control Solenoid ValveSecondary Air Injection Control ValveVacuum Control Solenoid ValveAir Control Valve VacuumControl Solenoid Valve

Air PumpSecondary Air Injection PumpAir PumpAir Control ValveSecondary Air Injection Pump ControlValveAir Control Valve

Arr rump tsreclnc uurrent bensorSecondary Air Injection Pump ElectricCurrent SensorAir Pump Electric CurrenlSensor

Shift/Clutch Pressure Control SolenoidValve SetShift Solenoid & Automatic TransaxleClutch Pressure Control Solenoid ValveSet

SS & A,/T Clutch PressureControl Solenoid Valve Set

1-5

Page 1647 of 1681

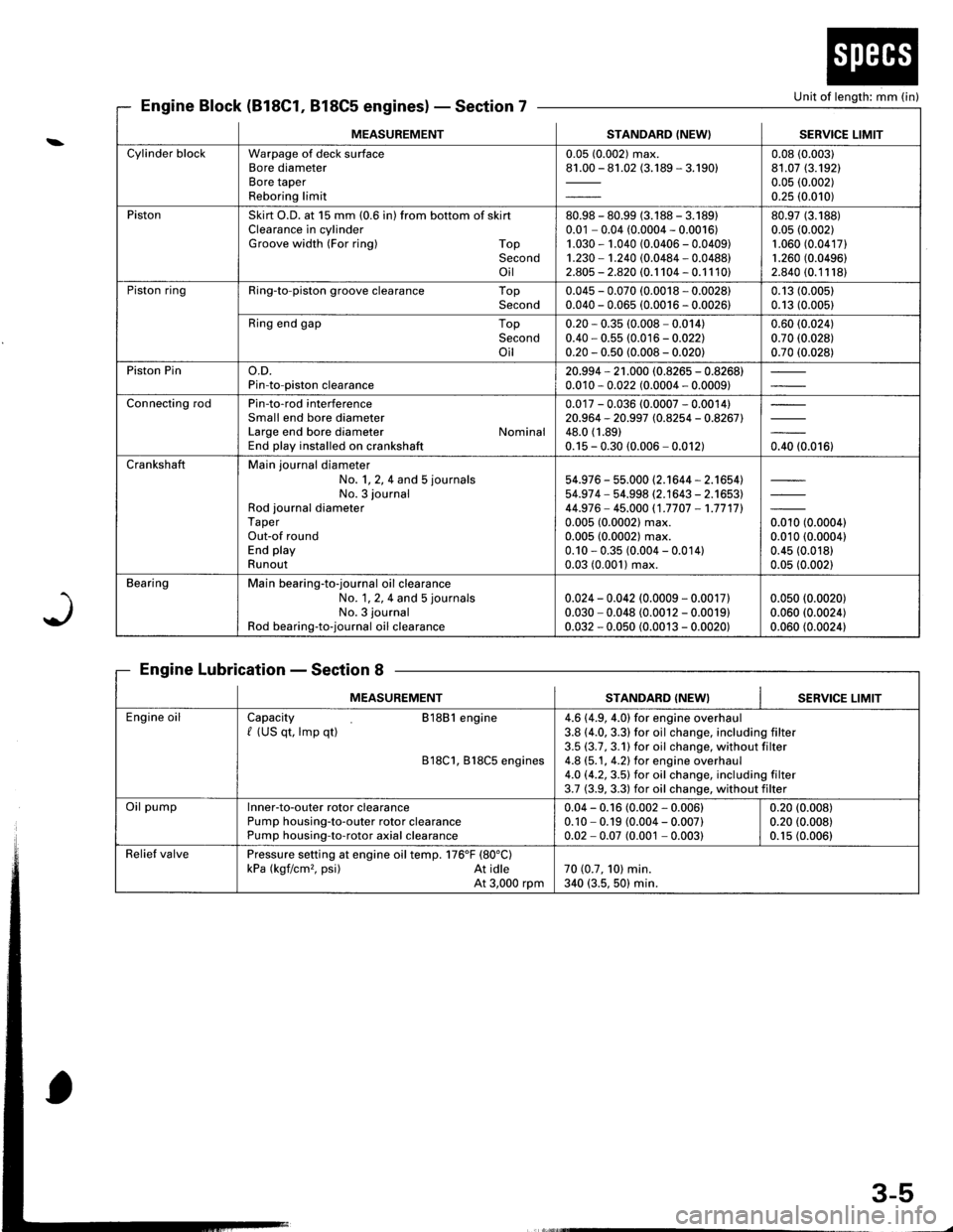

Unit of length: mm (in}

J

Engine Block (818C1, 818C5 engines)Section 7

Engine LubricationSection 8

MEASUREMENTSTANDARD (NEW} I SERVICE LIMIT

Cylinder blockWarpage of deck surfaceBore diameterBore taperReboring limit

0.05 (0.002) max.81.00 - 81.02 (3.189 - 3.190)0.08 (0.003)

81.07 (3.192)

0.05 (0.002)

0.25 (0.010)

PistonSkirt O.D. at 15 mm (0.6 in) from bottom of skirtClearance in cylinderGroove width (For ring) TopSecondoil

80.98 - 80.99 (3.188 - 3.18910.01 - 0.04 (0.0004 - 0.0016)1.030 - 1.040 (0.0406 - 0.0409)1.230 - 1.240 (0.0484 - 0.0488)2.805 - 2.820 (0.1 104 - 0.1 1 10)

80.97 (3.188)

0.05 (0.002)

1.060 (0.04171

1.260 (0.0496)

2.840 (0.11181

Piston ringRing-to-piston groove clearance TopSecond0.045 - 0.070 (0.0018 - 0.0028)0.040 - 0.065 (0.0016 - 0.0026)0.13 (0.005)

0.13 (0.005)

Ring end gap TopSecondoil

0.20 * 0.35 (0.008 - 0.014)0.40 - 0.55 (0.016 - 0.022)0.20 - 0.50 (0.008 - 0.020)

0.60 (0.024)

0.70 (0.028)

0.70 (0.028)

Piston Pino.D.Pin-to-piston clearance20.994 - 21 .000 (0.8265 - 0.8268)0.010 - 0.022 (0.0004 - 0.0009)

Connecting rodPin-to-rod interferenceSmall end bore diameterLarge end bore diameter NominalEnd play installed on crankshaft

0.017 - 0.036 (0.0007 - 0.0014)20.964 - 20.997 (0.8254 - 0.8267)48.0 (1.89)

0.15 - 0.30 (0.006 - 0.012)0.40 (0.016)

CrankshaftMain journal diameterNo. 1, 2, 4 and 5 journals

No. 3 journalRod journal diameterTaperOut-of roundEnd playRunout

54.976 - 55.000 (2.1644 - 2.1654)54.97 4 - 54.998 (2.1643 - 2.1653)44.976- 45.000 (1.7707 -1.7717l.

0.005 (0.0002) max.0.005 (0.0002) max.0.10 - 0.35 (0.004 - 0.014)0.03 (0.001) max.

orro to.ooool0.010 (0.0004)

0.45 (0.018)

0.05 (0.002)

BearingMain bearing-to-journal oil clearanceNo. 1, 2, 4 and 5 journals

No. 3 journal

Rod bearing-to-journal oil clearance

0.024 - 0.042 (0.0009 - 0.0017)0.030 - 0.048 (0.0012 - 0.0019)0.032 - 0.050 (0.0013 - 0.0020)

0.050 (0.0020)

0.060 (0.0024)

0.060 (0.0024)

MEASUREMENTSTANDARD (NEW}SERVICE LIMIT

Engine oilCapacity 81881 engine/ (US qt, lmp qt)

818C1, B18C5 engines

4.6 (4.9, 4.0) for engine overhaul3.8 (4.0, 3.3) for oil change, including filter3.5 (3.7,3.1)for oil change, without filter4.8 (5.1, 4.2) for engine overhaul4.O (4.2,3.5) for oil change. including filter3.7 (3.9, 3.3) for oil change, without filter

Oil pumplnner-to-outer rotor clearancePump housing-to-outer rotor clearancePump housing-to-rotor axial clearance

0.04 - 0.16 (0.002 - 0.006)0.10 - 0.19 (0.004 - 0.007)0.02 - 0.07 (0.001 - 0.003)

0.20 (0.008)

0.20 (0.008)

0.1s (0.006)

Relief valvePressure setting at engine oil temp. 176'F (80"C)

kPa (kgf/cm,. psi) At idleAt 3,000 rpm70 (0.7, 101 min.340 (3.5, 50) min.

3-5

Page 1649 of 1681

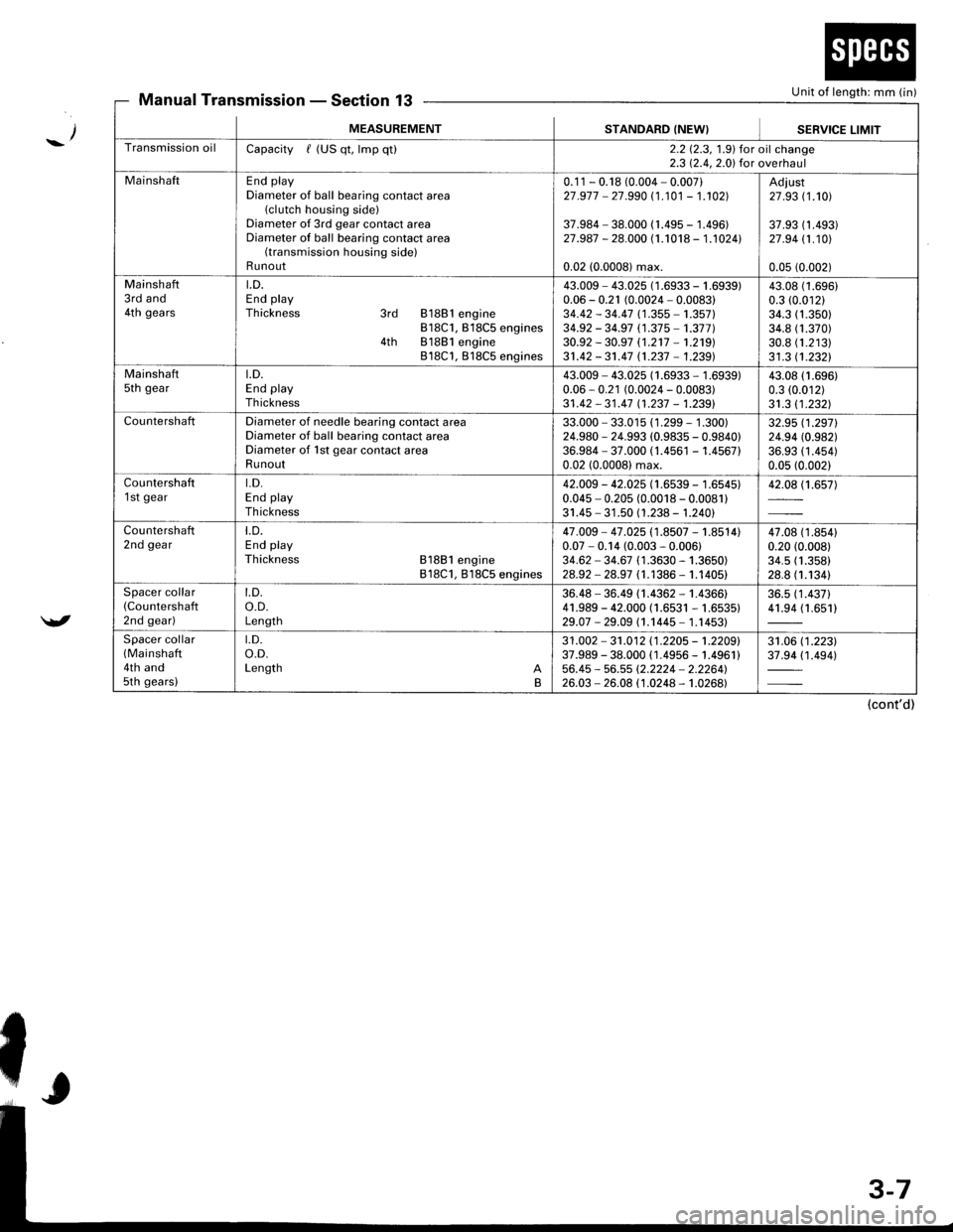

Unit of length: mm (in)Manual TransmissionSection 13

_/

/

MEASUREMENTSTANDARD (NEW}SEBVICE LIMIT

Transmission oilCapacity / (US qt, lmp qt)2.2 12.3, 1.9) for oil change2.3 12.4,2.0) for overhaul

MainshaftEnd playDiameter of ball bearing contact area(clutch housing side)Diameter of 3rd gear contact areaDiameter of ball bearing contact area(transmission housing side)Runout

0.1 1 - 0.18 (0.004 - 0.007)27 .977 - 27.990 (1 .101 - 1.102]|

37.984 - 38.000 (1.495 - 1.496)27.987 - 28.000 (1.1018 - 1.1024l.

0.02 (0.0008) max.

Adiust27 .93 (1.101

37.93 (1 .493)27 .94 11.101

0.05 (0.002)

Mainshaft3rd and4th gears

LD.End playThickness 3rd 81881 engine818C1, B18C5 engines4th 81881 engine818C1, 818C5 engines

43.009 - 43.025 (1 .6933 - 1 .(0.06 - 0.21 (0.0024 - 0.0083)34.42 - 34.47 (1 .355 - 1.357)34.92 - 34.97 (1.37 5 -'�t.377 )30.92 - 30.97 (1.2't7 -'�t.219)

31.42 - 31.47 n.237 - 1.239)

i939)43.0t0.3 ((

34.334.830.831 .3

(1.696)

.01211.350)1.370)1.21311.2321

Mainshaftsth geart.D.End playTh ickness

43.009 - 43.025 (1.6933 - 1.6939)0.06 - 0.21 (0.0024 - 0.0083)31 .42 - 31 .47 11 .237 - 1.2391

43.08 (1.696)

0.3 (0.012)

31.3 11.2321

CountershaftDiameter of needle bearing contact areaDiameter of ball bearing contact areaDiameter of 1st gear contact areaRunout

33.000 - 33.015 (1 .299 - 1 .300)24.980 - 24.993 (0.9835 - 0.9840)36.984 - 37.000 (1.4561 - 1.456710.02 (0.0008) max.

32.95 (1.2971

24.94 (0.982)

36.93 (1 .454)0.05 (0.002)

Countershaft1 st geart.D.End playTh ickness

42.009 - 42.025 (1.6539 - 1.6545)0.045 - 0.205 (0.0018 - 0.0081)31.45 - 31 .50 (1.238 - 1.240)

42.08 (1.657)

Countershaft2nd geart.D.End playThickness 81881 engine818C1, 818C5 engines

47.009 - 47 .025 (1.8507 - 1.8514)0.07 - 0.14 (0.003 - 0.006)34.62 - 34.67 (1 .3630 - 1.3650)28.92 - 28.97 (1.1386 - 1.1405)

47.08 (1 .8s410.20 (0.008)

34.5 (1.358)

28.8 (1.1341

Spacer collar(Countershafl

2nd gear)

t.D.o.D.Length

36.48 - 36.49 (1.4362 - 1.4366)41.989 - 42.000 (1.6531 - 1.6535)29.07 -29.09 (1.1445- 1.14531

36.5 (1 .437)41.94 (1.651)

Spacer collar(Mainshaft

4th and5th gears)

t.D.o.D.Length AB

31 .002 - 31 .012 11 .2205 - 't .2209'37.989 - 38.000 ( 1.4956 - 1.4961 )56.45 - 56.55 (2.2224 - 2.2264'�)26.03 - 26.08 (1.0248 - 1.0268)

31.06 (1 .223)37.94 (1 .494)

(cont'd)