wheel size HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 152 of 1681

/

li

l

Main Bearings

Clearance

2.

3.

1.

4.

To check main bearing-to-iournal oil clearance,

remove the main caps and bearing halves.

Clean each main iournal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main iour-

na l-

NOTE: lf the engine is still in the car when you bolt

the main cap down to check clearance, the weight

of the crankshaft and flywheel will flatten the plasti'

gage further than just the torque on the cap bolt,

and give you an incorrect reading. For an accurate

reading, support the crank with a jack under the

counterweights and check only one bearing at a

trme.

Reinstall the bearing caps and cap bridge (B18C1,

B18C5 engines only)then torque the bolts.

Bl8Bl engine: 77 N'm (7.8 kgt.m.56lbf.ft)

B18Cl,818C5 engines:

No. 1,5 cap bolts 73 N.m (7.4 kgf.m,56lbnftl

No. 2. 3, 4 cap bolts 64 N.m {6.5 kgf m. 49 lbf ftl

NOTE: Do not rotate the crankshaft during inspec-

tro n.

Remove the cap bridge (818C1, 818C5 engines

only), caps and bearings again, and measure the

widest part of the plastigage.

Main Bearing-to-Journal Oil Clearance:

Standard lNew):

No. 1, 2, 4, 5: 0.024 - 0.042 mm

10.0009 -0.0017 in)

Service Limit:0.050 mm (0.0020 in)

No.3:0.030 - 0.048 mm

10.0012 - 0.0019 inl

Service Limit:0.060 mm {0.0024 inl

PLASTIGAGE STRIP

lf the plastigage measures too wide or too narrow,

{remove the engine if it's still in the car), remove the

crankshaft, and remove the upper half of the bear-

ing. lnstall a new, complete bearing with the same

color code (select the color as shown in the right

column), and recheck the clearance.

CAUTION: Do not file, shim. or scrape the bearings

or the caps to adiust clearance.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again.

NOTE: lf the oroDer clearance cannot be obtained

by using the appropriate larger or smaller bearings.

reolace the crankshaft and start over.

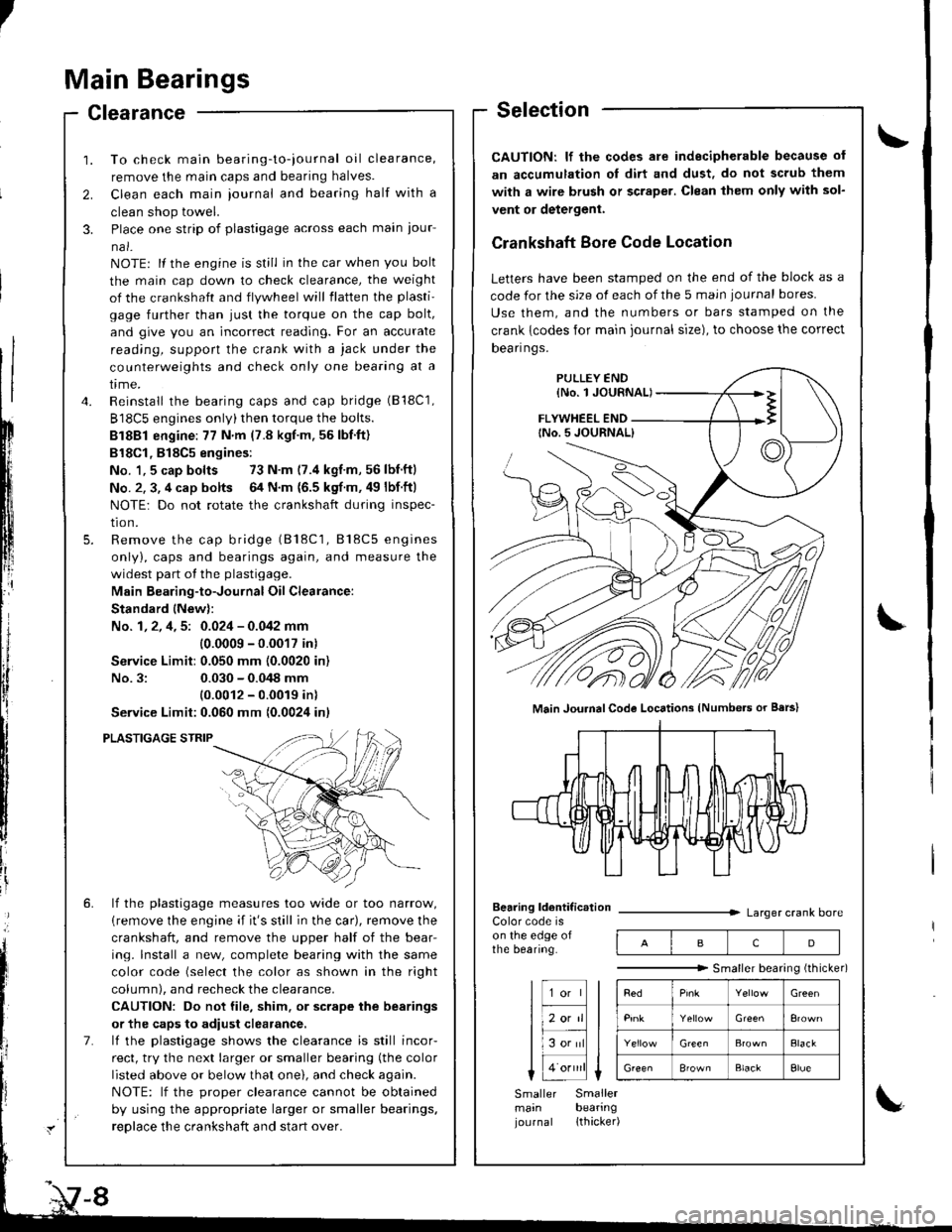

Selection

CAUTION: lf the codes ale indecipherable because of

an accumulation oI dirt and dust, do not scrub them

with a wire bru6h or scraper. Clean lhem only with sol-

vent or detergent.

Crankshaft Bore Code Location

Letters have been stamped on the end of the block as a

code for the size of each of the 5 main iournal bores

Use them, and the numbers or bars stamped on the

crank {codes for main journal size), to choose the correct

Dean nqs,

FLYWHEEL END

Main JouhalCode Locations (Numbe.s or Bars)

Bearing ldentif ic.tionColor code ison the edge ofthe bearing.

Larger crank bore

acD

"""""""" Smallerbearingithicker)

Green

Elack

B'ownBlackElue

Smaller Smallermain bearingjournal lthacker)

Page 658 of 1681

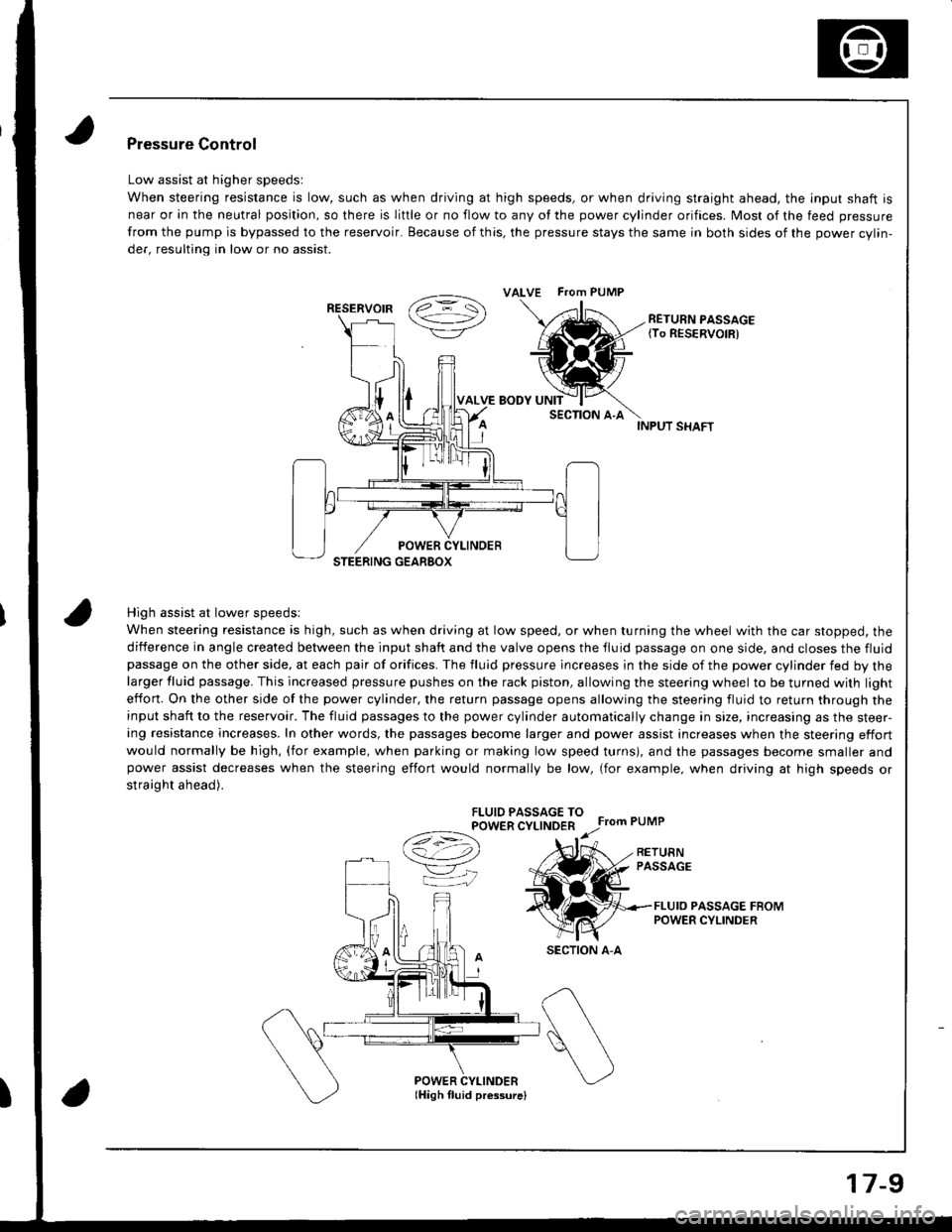

INPUT SHAFT

High assist at lower speedsl

When steering resistance is high, such as when driving at low speed, or when turning the wheel with the car stopped, the

diiference in angle created between the input shaft and the valve opens the tluid passage on one side, and closes the fluidpassage on the other side, at each pair of orifices. The fluid pressure lncreases in the side of the power cylinder fed by thelarger fluid passage. This increased pressure pushes on the rack piston, allowing the steering wheel to be turned with light

effon. On the other side of the power cylinder, the return passage opens allowing the steering fluid to return through theinput shaft to the reservoir. The fluid passages to the power cylinder automatically change in size, increasing as the steer-ing resistance increases. In other words, the passages become larger and power assist increases when the steering effort

would normally be high, (for example, when parking or making low speed turns), and the passages become smaller andpower assist decreases when the steering effort would normally be low, (for example, when driving at high speeds or

straight ahead).

FLUIO PASSAGE TOPOWER CYLINDER

Ce) r.r;

VK

Pressure Control

Low assist at higher speedsl

When steering resistance is low, such as when driving at high speeds, or when driving straight ahead. the lnput shaft is

near or in the neutral position, so there is liftle or no flow to any of the power cylinder orifices. Most of the feed pressure

from the pump is bypassed to the reservoir. Because of this, the pressure stays the same in both sides of the power cvlin-

der, resulting in low or no assist.

RETURN PASSAGE{To RESERVOIR)

POWER CYLINDERlHigh fluid pressurelI

ALVE FTom PUMP

RESERVOIR

SECTION A-A

17-9

Page 659 of 1681

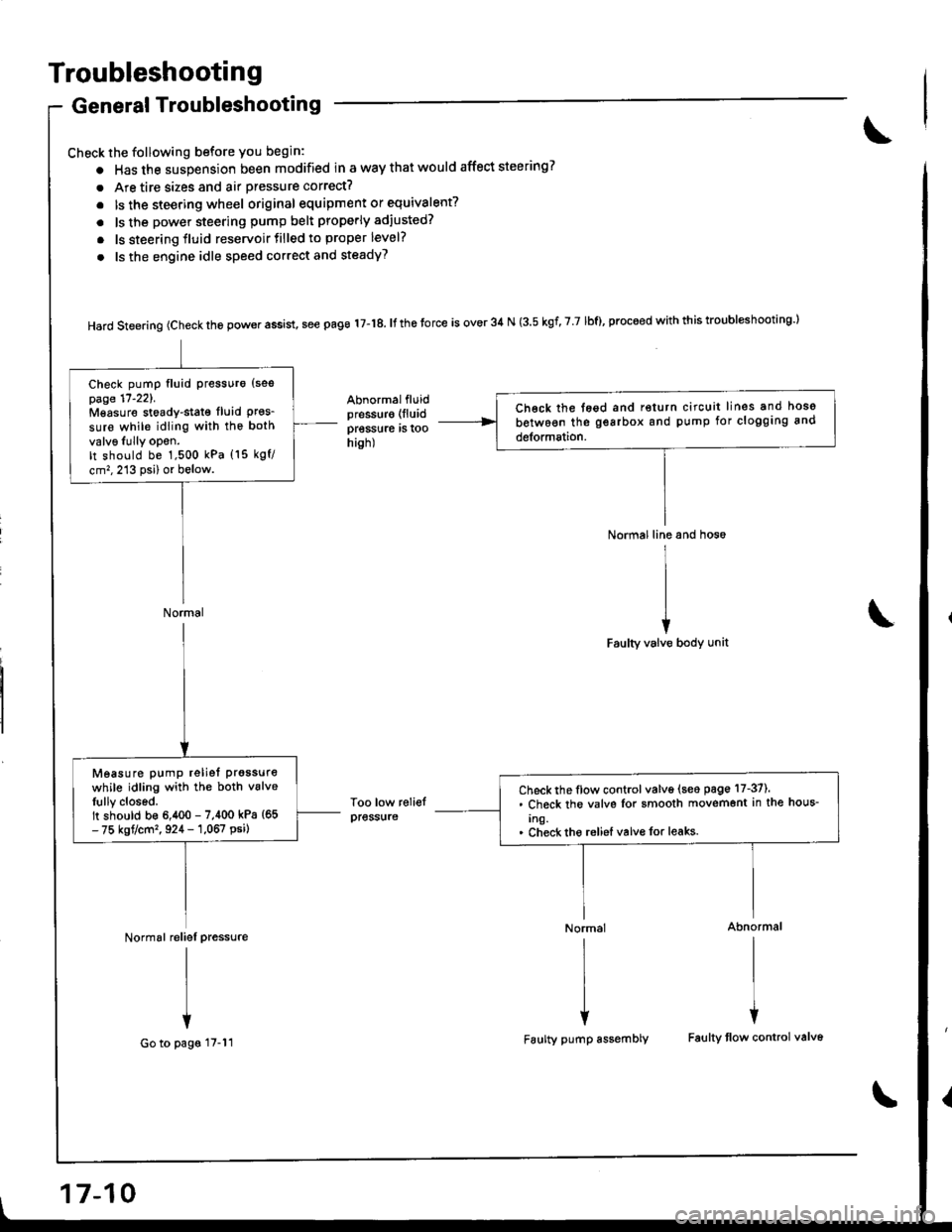

Troubleshooting

General Troubleshooting

Check the following before you begin:

o Has the suspension been modified in a way that would affect steering?

. Are tire sizes and air pressure correct?

. lsthe steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adiusted?

. ls steering fluid reservoirtilled to proper level?

. ls the engine idle speed correct and steadyT

Hard steering (check the power assist, see page 17-18. It the torce is over 34 N (3.5 kgf, 7 7 lbf), proceed with this troubl*hooting l

Abnormalfluidpressur€ (lluid

pressure rs roohish)

Too low reliefpress{ire

Normal line and hos6

I

II

iFaulty valve body unit

Normal Abnormal

rlrl

l{

Faulty pump assembly Faulty tlow control valv6

Ch€ck the tegd and return circuit lines and hoso

between the gearbox and pump for clogging and

detormation.

Check pump fluid Pressuro {sespage 17'221.Mgasure stoady-stat€ fluid Pres_sure while idling with the both

valv6Iully opon.It should be 1,500 kPa (15 kgf/

cm,,213 psi) or below.

Normal

Check the flow control valve (seo page 17-37).. Check the valvs Ior smooth movemont in the hous-

Ing.. Check tho reliel valvo for leaks.

Measure pump reliet prgssure

while idling with the both vslveIully closed.It should b€ 6,400 - 7,400 kPa {65- 75 kgt/cm'�, 924 - 1,067 psi)

Normal reliel pressure

I

I

+

Go to pags 17-11

17-10

Page 714 of 1681

Wheel Alignment

Caster

NOTE: For proper inspection/adjustment of the wheel

alignment check and adjust the following before check-

ing the alignment.

. Check that the susoension is not modified.

. Check the tire size and tire pressure.

. Check the runout of the wheels and tires.

. Check the suspension ball joints. (Hold a wheel with

your hands and move it up and down and right and

left to check tor wobbling.)

Inspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment {caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the caster angle.

Casler angle: 1'10't 1"

2. lf out of specification. check for bent or damaged

suspension compohents.

Camber

Inspection

NOTE: Use commercially available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the eouioment manufacturer's instructions.

1. Check the camber angle.

Camb€r angle:

Front:

Type R Modal:-0"30' r 1'

All exc6pi Type R Model: -0'10'1 1"

Rear: -0'45' ll['a8l

2. lf out of specification, check for bent or damaged

susoension comDonents.

1A-4

Page 1659 of 1681

:/

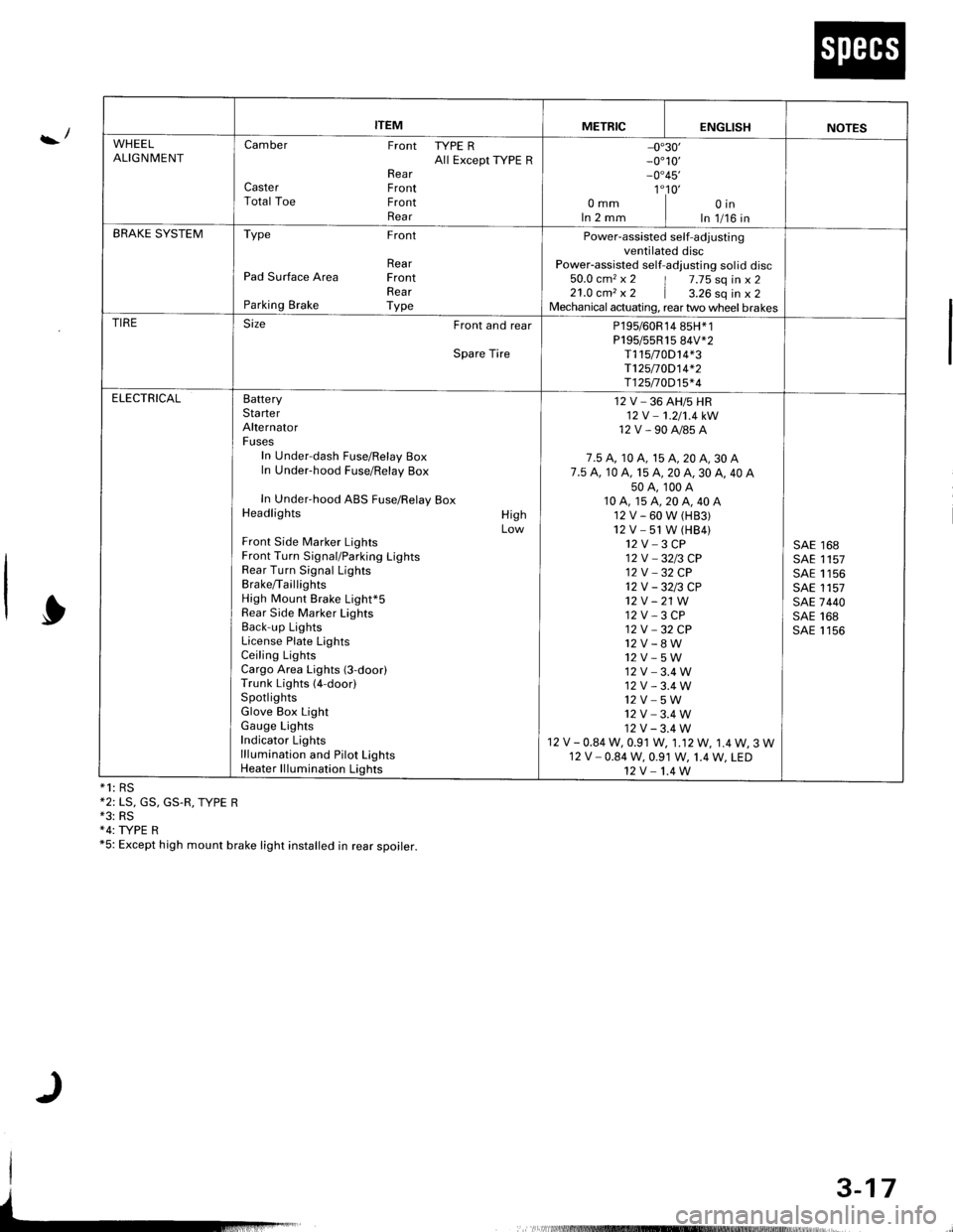

*1: RS*2: LS, GS, GS.R, TYPE R*3: RS+4: TYPE R*5: Except high mount brake light installed in rear spoirer.

ITEMMETRICENGLISHNOTES

WHEELALIGNMENTCamber Front TYPE RAll Except ryPE RRearCaster FrontTotal Toe FrontRear

-0"30'_0"10,_0"45'

1"10'omm I oinIn 2 mm I In 1/16 inBRAKE SYSTEMType Front

RearPad Surface Area FrontRearParking Brake Type

Power-assisted self-adjustingventilated discPower-assisted self-adlusting sol id disc50.0 cm2 x 2 | 7.75 sq in x 221.0 cm, x 2 | a.ZO sq in x 2Mechanical actuating, rear two wheel brakesTIRESize Front and rear

Spare Tire

P195/60R14 85H*1P195/55R15 84V*2T115t0D14*3T125/70D14*2T125n0D15*4

ELECTRICALBatteryStarterAlternatorFusesIn Under-dash Fuse/Relay BoxIn Under-hood Fuse/Relay Box

In Under-hood ABS Fuse/Relay BoxHeadlights

Front Side Marker LightsFront Turn Signal/Parking LightsRear Turn Signal LightsBrake/TaillightsHigh Mount Brake Light*5Rear Side Marker LightsBack-up LightsLicense Plate LightsCeiling LightsCargo Area Lights (3-door)Trunk Lights (4-door)SpotlightsGlove Box LightGauge LightsIndicator Lightslllumination and Pilot LightsHeater lllumination Lights

HighLow

12 V _ 36 AH/5 HR12V -1.2/'t.4kW

12V-90A/85A

7.5 A, 10 A, 15 A, 20 A, 30 A7.5 A. 10 A, 15 A, 20 A, 30 A, 40 A50A,100A10A,15A,20A,40A12V-60W(H83)12V -51 W (HB4)12V-3CP12V _3213 CP12V _32 CP12V-3213CP't2v -21 W12 V - 3 CP12V -32CP

12V_8W12V-5W12V-3.4W12V-3.4W12V_5W12V-3.4W12V-3.4W12 V - 0.84 W, 0.91 W, 1.12W, 1.4W, 3 W12 V - 0.84 W, 0.91 W, 1.4 W, LED12V-1.4W

SAE 168SAE 1157SAE 1156SAE 1157SAE 7440SAE 168SAE 1156

3-17