HONDA PASSPORT 2001 2.G Owners Manual

Manufacturer: HONDA, Model Year: 2001, Model line: PASSPORT, Model: HONDA PASSPORT 2001 2.GPages: 317, PDF Size: 4.85 MB

Page 221 of 317

Th

e engin e coolin g syste m is

designe d to maintai n th e engin e a t

th e prope r operatin g temperatures .

Th e coolin g syste m wa s fille d a t

th e factor y wit h a qualit y engin e

coolant . Th e engin e coolin g syste m

i s designe d to us e coolan t ( a

mixtur e o f wate r an d ethylen e

glyco l antifreeze ) rathe r tha n plai n

water . Th e engin e coolan t solutio n

shoul d b e use d year-round . I t ha s

man y advantage s suc h as : provide

s freezin g protectio n a s

lowas-33°F(-36°C ) provide

s boilin g protectio n u p

to262°F(128°C )

protect s agains t rus t an d

corrosio n in th e coolin g syste m maintain

s th e prope r engin e

temperatur e fo r efficien t

operatio n an d emissio n contro l allow

s prope r operatio n o f th e

engin e coolan t temperatur e gaug eSe

e th e Maintenanc e Schedul e in

thi s sectio n t o fin d ou t whe n th e

engin e coolan t mus t b e replaced .

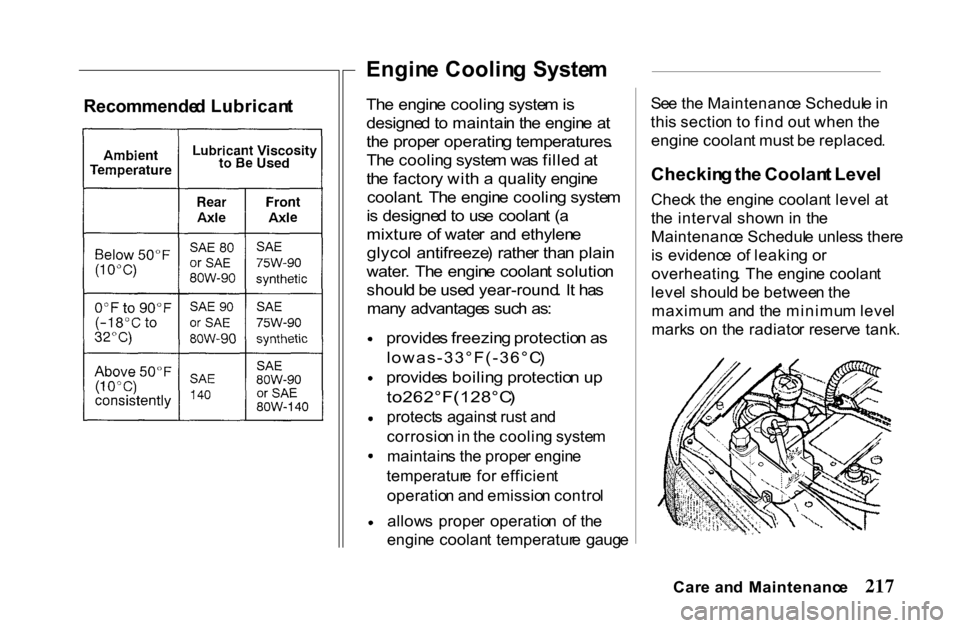

Checkin g th e Coolan t Leve l

Chec k th e engin e coolan t leve l a t

th e interva l show n in th e

Maintenanc e Schedul e unles s ther e

i s evidenc e o f leakin g o r

overheating . Th e engin e coolan t

leve l shoul d b e betwee n th e

maximu m an d th e minimu m leve l

mark s o n th e radiato r reserv e tank .

Car e an d Maintenanc e

Recommende

d Lubrican tEngin

e Coolin g Syste m

Page 222 of 317

Yo

u usuall y d o no t nee d t o remov e

th e radiato r ca p to chec k th e engin e

coolan t level .

Addin g Engin e Coolan t

T o ad d engin e coolant , remov e th e

ca p o n th e radiato r reserv e tan k

an d fil l th e tan k u p t o th e

maximu m leve l mark . Ad d a

50/5 0 mixtur e o f wate r an d a goo d

qualit y ethylen e glyco l antifreeze .I

f yo u nee d t o ad d engin e coolan t

frequently , se e you r Hond a deale r

fo r a coolin g syste m check .

I f th e prope r qualit y antifreez e

i s used , ther e is n o nee d t o ad d

extr a inhibitor s o r additives . The y

ma y b e harmfu l t o th e prope r

operatio n o f th e system .

Coolin g Syste m Servic e

Th e coolin g syste m shoul d b e

service d a t th e interval s specifie d

i n th e Maintenanc e Schedul e a s

follows :

Was

h th e radiato r ca p an d fille r

nec k wit h clea n water .

Chec

k th e engin e coolan t leve l

i n th e radiato r an d hav e i t teste d

fo r freez e protection . Ad d

ethylen e glyco l antifreeze , i f

needed , t o maintai n freez e

protectio n a t -33° F (-36°C) . Hav

e th e coolin g syste m an d

radiato r ca p teste d fo r a

pressur e capacit y of 15 ps i (10 5

kPa) . I f a replacemen t ca p i s

needed , us e a ca p specifie d fo r

you r model . Tighte

n al l radiato r an d heate r

hos e clamp s an d inspec t al l

hoses . Replac e th e hose s i f the y

ar e swollen , "checked, " o r

otherwis e worn . Carefull y

tighte n th e hos e clamp s a t th e

radiator . Overtightenin g coul d

ben d o r collaps e th e radiato r

fittings .

Clean

the fron t o f the radiato r

core and ai r conditionin g

condenser.

I t i s th e owner' s responsibilit y to : Maintai

n th e coolin g syste m

freez e protectio n a t -33° F

Car e an d Maintenanc e

Removin

g th e radiato r ca p

whil e th e engin e i s ho t ca n

caus e th e coolan t t o spra y

out , seriousl y scaldin g you .

Alway s le t th e engin e an d

radiato r coo l dow n befor e

removin g th e radiato r cap .

Page 223 of 317

(-36°C

) t o ensur e protectio n

agains t corrosio n an d los s o f

engin e coolan t fro m boiling .

Thi s shoul d b e don e eve n i f

freezin g temperature s ar e no t

expected .

Ad d ethylen e glycol-base d

antifreez e whe n antifreez e ha s

t o b e adde d becaus e o f engin e

coolan t los s o r i f mor e

protectio n agains t freezin g a t

temperature s lowe r tha n -33° F

(-36°C ) i s needed . D o no t us e

a n alcohol-base d o r

methanol-base d antifreeze , o r

plai n water . The y boi l a t a

lowe r point , an d d o no t provid e

corrosio n protection .

Thermosta

t

Th e engin e coolan t temperatur e i s

controlle d b y a thermostat , whic h

stop s engin e coolan t flo w throug h

th e radiato r unti l a prese t

temperatur e is reached . Thi s

thermosta t i s installe d i n th e

engin e coolan t inle t o n th e fron t

o f th e engin e block . Th e sam e

thermosta t i s use d i n bot h winte r

an d summer . Othe

r Require d

Maintenanc e

Brak e Maste r Cylinde r

Chec k th e maste r cylinde r flui d

leve l i n th e reservoi r ever y tim e

yo u chec k th e engin e oi l level .

Th e leve l shoul d b e betwee n th e

MA X an d AD D leve l line . I f th e

leve l i s lowe r tha n th e AD D leve l

line , fil l t o th e MA X leve l lin e

wit h DOT- 3 o r DOT- 4 fluid .

Car e an d Maintenanc e

Page 224 of 317

I

f th e diaphrag m insid e th e

reservoi r ca p i s deformed , retur n

i t t o th e origina l (collapsed )

condition , the n tighte n th e cap .

I t i s norma l fo r th e brak e flui d

leve l t o g o dow n slightl y a s th e

fron t brak e pad s wear . S o b e sur e

t o kee p th e reservoi r flui d a t th e

prope r level .

I f th e reservoi r need s frequen t

refilling , i t ma y indicat e a seriou s

mechanica l problem .

Brak e flui d absorb s wate r fro m

th e air . Neve r us e brak e flui d tha t

ha s bee n ope n t o th e ai r fo r a n

extende d period . Thro w it awa y

an d us e ne w brak e flui d fro m a

seale d container .

Brake fluid can damage your

vehicle's paint. Thoroughly clean

up any brake fluid spills.

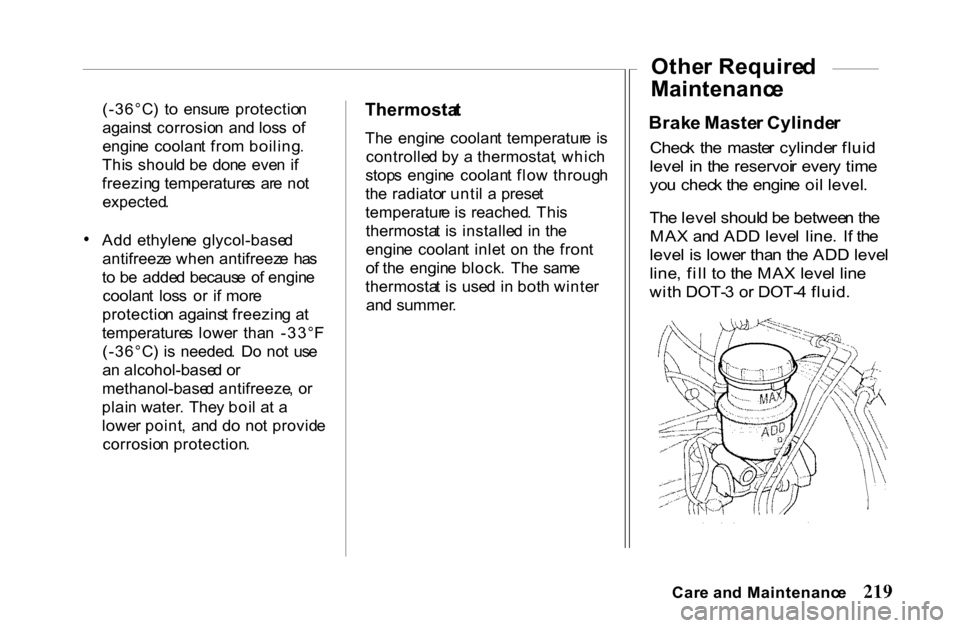

Shift-on-the-Fl

y Syste m

Th e flui d leve l i n th e syste m shoul d

b e checke d a t th e interval s show n

i n th e Maintenanc e Schedule .

FILLE R

PLU G

Remov e th e fille r plu g an d mak e

sur e th e flui d leve l i s u p t o th e

edge o f th e hole . I f i t i s not , ad d

GL- 5 gea r oi l t o brin g t o tha t

level . Us e th e sam e GL- 5 gea r oi l

specifie d fo r th e fron t axl e (see

pag e 216 ). Fron

t Whee l Bearing s

Clea n an d repac k th e fron t whee l

bearing s wheneve r th e fron t brak e

pad s ar e replaced . Du e t o th e

weigh t o f th e tir e an d whee l

assembl y i t i s recommende d tha t

the y b e remove d fro m th e hu b

befor e lubricatin g th e bearing s t o

preven t damag e t o th e oi l seal .

"Lon g Fiber " greas e shoul d no t b e

use d t o lubricat e th e whee l bearings .

I t ca n caus e damage . Clea n th e ol d

greas e ou t o f th e bearing s an d hub s

befor e repacking .

Car e an d Maintenanc e

NOTIC

E

Page 225 of 317

Hoo

d Latc h an d Hinge s

Lubricat e th e hoo d latc h assembl y

an d hoo d hing e assembl y a s

follows :

1 . Wip e of f an y accumulatio n o f

dir t o r contaminatio n o n th e

latc h parts .

2 . Appl y multipurpose-typ e

grease (NLG I No . 1 or 2 ) t o

th e hoo d latc h pi n cam .

3 . Appl y ligh t engin e oi l t o al l

pivo t point s in th e releas e

mechanism .

4 . Lubricat e hoo d hinge s wit h

multipurpose-typ e grease

(NLG I No . 1 or 2) .

5 . Chec k th e hoo d hinge s an d

latc h mechanis m to assur e

the y ar e workin g correctly .

Ai

r Conditionin g

Periodicall y hav e you r Hond a

deale r chec k you r ai r conditionin g

syste m to b e sur e ther e ha s bee n

n o los s in coolin g output . Se e

you r Hond a deale r i f yo u suspec t

tha t th e syste m is no t performin g

a s it should .

Bod y Lubricatio n

Norma l us e o f a vehicl e cause s

metal-to-meta l movemen t a t certai n

point s i n th e body . Noise , wea r an d

imprope r operatio n a t thes e point s

wil l resul t whe n a protectiv e fil m

o f lubrican t i s no t provided .

Fo r expose d surface s suc h a s doo r

checks , doo r loc k bolts , loc k

strike r plates , etc. , appl y a thi n

fil m o f ligh t engin e oil .

An y lubrican t shoul d b e use d

sparingly . Afte r application , al l exces

s lubrican t shoul d b e

carefull y wipe d off .

Th e sea t adjuster s an d sea t trac k

shoul d b e lubricate d wit h water -

resistan t E P chassi s lubricant .

Ther e ar e othe r point s o n th e

vehicl e bod y whic h ma y

occasionall y requir e lubrication .

Windo w regulator s an d control s

ar e confine d in th e spac e betwee n

th e upholster y an d th e outsid e

doo r panel . Eas y acces s t o th e

workin g part s ma y b e mad e b y

removin g th e trim . Doo r

weatherstrip s an d rubbe r hoo d

bumper s shoul d b e lightl y coate d

wit h a rubbe r lubricant .

Car e an d Maintenanc e

Page 226 of 317

Fron

t (4W D Only ) an d Rea r

Propelle r Shaf t

Lubricat e th e slidin g yok e wit h

E P chassi s grease. Lubricat e

universa l joint s wit h grease

containin g MoS 2 (molybdenu m

disulfide-typ e grease ) a t th e

interval s show n in th e

Maintenanc e Schedule . Als o

chec k th e propelle r shaf t

flange-to-pinio n bolt s fo r prope r

torqu e o f 6 4 N. m (46. 3 Ib-ft) .

Mos t lubricatio n recommendation s

an d procedure s fo r four-whee l drive -

equippe d vehicle s ar e th e same

fo r th e correspondin g component s

i n conventiona l driv e vehicles .

Exhaus t Syste m

Chec k th e complet e exhaust

syste m an d nearb y bod y areas fo r

damaged , missing , o r

mispositione d parts , ope n seams ,

holes

, loos e connections , o r othe r

deterioratio n tha t coul d allo w

exhaus t fume s t o see p int o th e

passenger compartmen t o r cause

hea t build-u p in th e floo r pan . An y

necessary correction s shoul d b e

mad e immediately . Fo r continued

safety , exhaus t syste m pipe s an d

resonator s rearwar d o f th e muffle r

mus t b e replace d wheneve r a ne w

muffle r i s installed .

Fue l Lin e an d Fue l Tank/Ca p

Inspec t th e fue l tank , ca p an d line s

fo r damag e tha t coul d caus e

leakage . Inspec t th e fue l ca p an d

gaske t fo r correc t sealin g abilit y

an d indication s o f physica l

damage . Replac e an y damage d o r

malfunctionin g parts .

Driv

e Bel t

Chec k th e bel t drivin g th e

alternator , powe r steerin g pump ,

an d ai r conditionin g compressor .

Loo k fo r cracks , fraying , an d

wear . Replac e a s necessary .

Timin g Bel t

Th e timin g bel t shoul d normall y

b e replace d a t th e interval s show n

i n th e Maintenanc e Schedule .

Valv e Clearanc e

Incorrec t valv e clearanc e wil l

resul t i n increase d engin e nois e

an d lowe r engin e output , thereb y

adversel y affectin g engin e

performance .

Car e an d Maintenanc e

Page 227 of 317

Spar

k Plug s

Replac e th e spar k plug s wit h th e

typ e specifie d in th e "Technica l

Data " section .

Clutc h

Chec k th e clutc h pla y a t th e pedal .

Lubricat e th e clutc h peda l bushin g

an d clevi s pin , a t th e interval s

show n in th e Maintenanc e

Schedule , wit h water-resistan t

chassi s lubricant . I f yo u hea r a

squeakin g nois e comin g fro m th e

are a o f th e bushin g o r clevi s pi n a t

th e clutc h peda l ar m whe n th e

clutc h peda l i s depressed ,

lubricat e it wit h water-resistan t E P

chassi s grease .

Chec k th e flui d leve l i n th e clutc h

reservoi r a t th e interva l show n in

th e Maintenanc e Schedule . I f th e

flui d i s lo w in th e reservoir , i t

shoul

d b e fille d to th e maximum

leve l lin e wit h DOT-3 or DOT-4

fluid .

Flui d o r Lubrican t Level s

Chec k th e flui d o r lubrican t leve l

i n th e brak e maste r cylinder ,

clutc h maste r cylinder , powe r

steerin g reservoir , rea r axle ,

engin e an d transmission ,

windshiel d washe r reservoi r an d

engin e coolan t a t specifie d

intervals .

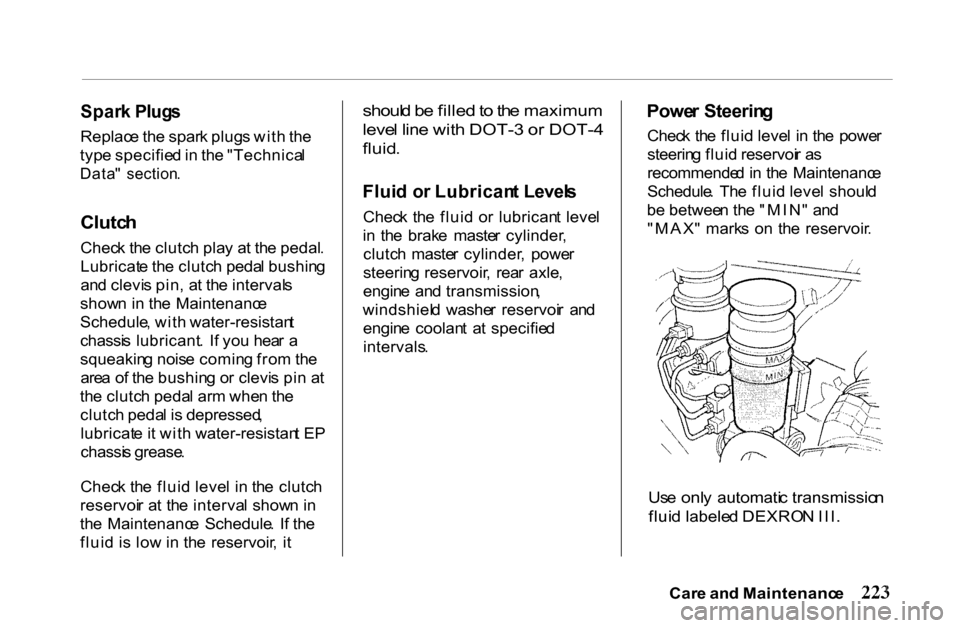

Powe

r Steerin g

Chec k th e flui d leve l i n th e powe r

steerin g flui d reservoi r a s

recommende d in th e Maintenanc e

Schedule . Th e flui d leve l shoul d

b e betwee n th e "MIN " an d

"MAX " mark s o n th e reservoir .

Us e onl y automati c transmissio n

flui d labele d DEXRO N III .

Car e an d Maintenanc e

Page 228 of 317

Whee

l Alignmen t

Prope r whee l alignmen t improve s

tir e mileage . You r vehicle' s

suspensio n part s shoul d b e

inspecte d ofte n an d aligne d whe n

neede d (see th e "Technica l Data "

section) . Imprope r alignmen t wil l

caus e th e fron t tire s t o rol l a t a n

angl e tha t wil l resul t i n faste r tir e

wear .

Prope r tir e balancin g provide s th e

bes t ridin g comfor t an d help s

reduc e tir e trea d wear .

Out-of-balanc e tire s ca n cause

annoyin g vibratio n an d uneve n

tir e wea r suc h a s cuppin g an d fla t

spots.

Exterio

r

Washin g You r Vehicl e

Th e bes t wa y t o preserv e you r

vehicle' s finis h is t o kee p it clea n b y

frequen t washings . Was h th e vehicl e

wit h lukewar m o r col d water .

D o no t us e ho t wate r o r was h in

direc t sunlight . D o no t us e stron g

soa p o r chemica l detergents . Al l

cleanin g agent s shoul d b e promptl y

flushe d fro m th e surfac e an d no t

allowe d t o dr y o n th e finish .

Polishin g an d Waxin g

You r Vehicl e

Polishin g is recommende d to

remov e accumulate d residu e an d

eliminat e an y "weathered "

appearance .

You r Hond a deale r offer s severa l

polishe s an d cleaner s tha t hav e

prove n to maintai n th e origina l

finis h appearanc e an d durability .

Protectio

n o f Exterio r

Brigh t Meta l Part s

Brigh t meta l part s shoul d b e cleane d

regularl y t o kee p thei r luster .

Washin g wit h wate r i s al l tha t i s

usuall y needed . However , chrom e

polis h ma y b e use d o n chrom e o r

stainles s stee l trim , i f necessary . A

coatin g o f wax , rubbe d t o a hig h

polish , i s recommende d fo r al l brigh t

meta l parts .

Car e o f Aluminu m Wheel s

Aluminu m wheel s hav e a

clear-coa t finis h simila r t o paint .

Us e a chamoi s skin , spong e o r

othe r sof t materia l whe n washin g

th e wheels .

Foreig n Materia l Deposit s

Calciu m chlorid e an d othe r salts ,

ic e meltin g agents , roa d oi l an d

tar , tre e sap , bir d droppings ,

Car e an d Maintenanc e

Page 229 of 317

chemical

s fro m industria l

chimneys , an d othe r foreig n

matte r ma y damag e you r vehicle' s

finis h if allowe d t o remai n o n

painte d surfaces .

Promp t washin g ma y no t

completel y remov e al l o f thes e

deposits . Additiona l cleaner s ma y

b e needed . Whe n usin g chemica l

cleaner s develope d fo r thi s

purpose , b e certai n the y ar e saf e

fo r us e o n painte d surfaces .

Finis h Damag e

An y ston e chips , fracture s o r dee p

scratche s in th e finis h shoul d b e

repaire d promptly . Expose d meta l

wil l corrod e quickl y an d ma y

develo p int o a majo r repai r

expense . Mino r chip s an d scratche s

ca n b e repaire d usin g touch-u p

material s availabl e fro m you r

Hond a dealer .

Corrosio

n Protectio n

You r vehicl e ha s bee n designe d

an d buil t t o resis t corrosion .

Specia l material s an d protectiv e

finishe s wer e applie d t o mos t

part s o f you r vehicl e whe n i t wa s

buil t t o hel p maintai n it s goo d

looks , strengt h an d reliabl e

operation . However , som e part s

tha t ar e normall y no t visibl e (suc h

a s certai n part s unde r th e vehicl e

an d unde r th e hood ) ar e stron g

enoug h s o tha t surfac e rus t wil l

no t affec t thei r reliability . S o

corrosio n protectio n is no t neede d

o r use d o n thes e parts . B y

omittin g unneede d rus t protectio n

o n suc h part s an d applyin g extr a

protectio n wher e i t i s neede d

most , th e bes t valu e is assure d fo r

th e vehicl e buyer .

Shee

t Meta l Damag e

I f you r vehicl e i s damage d an d

require s sheet meta l repai r o r

replacement , mak e sur e th e bod y

repai r sho p applie s anti-corrosio n

materia l t o th e part s repaire d o r

replace d s o tha t corrosio n

protectio n is restored . (Als o see

"Finis h Damage." )

Underbod y Maintenanc e

Corrosiv e material s use d fo r ic e

an d sno w remova l an d dus t

contro l ca n collec t o n th e

underbody . I f thes e material s ar e

no t removed , accelerate d

corrosio n (rust ) ca n occu r o n

underbod y part s suc h a s fue l lines ,

frame , floo r pan , an d exhaus t

syste m eve n thoug h the y hav e

Car e an d Maintenanc e

Page 230 of 317

bee

n coate d wit h corrosio n

protectants .

A t leas t ever y spring , flus h thes e

material s fro m th e underbod y

wit h plai n water . Tak e car e t o

thoroughl y clea n an y area s wher e

mu d an d othe r debri s ca n collect .

Sedimen t packe d in close d area s

o f th e fram e shoul d b e loosene d

befor e bein g flushed .

Wit

h th e us e o f moder n tri m

material s i t i s ver y importan t tha t

prope r cleanin g technique s an d

cleaner s b e used . Failur e to d o

thi s o n th e firs t cleanin g ma y

resul t i n wate r spots , spo t ring s o r

settin g o f stains , al l o f whic h

mak e it mor e difficul t t o remov e

o n a secon d cleaning .

Th e portio n o f th e followin g

cleanin g instruction s tha t ar e in

AL L CAPITA L LETTER S ar e

especiall y importan t an d MUS T

b e followed .

Dus t an d loos e dir t tha t

accumulat e o n interio r fabric s

shoul d b e remove d ofte n wit h a

vacuu m cleane r o r sof t brush .

Viny l o r leathe r tri m shoul d b e

wipe d regularl y wit h a clea n

dam p cloth . Norma l tri m soil ,

spot s o r stain s ca n b e cleane d wit h

conventiona l cleaners .

Remembe

r Thes e Basi c Step s

Befor e Cleanin g

1 . Remov e stain s a s quickl y a s

possibl e befor e the y becom e

"set. "

2 . Us e a clea n clot h o r spong e

an d chang e t o a clea n are a

often . ( A SOF T brus h ma y b e

use d i f stain s persist. )

3 . Us e solvent-typ e cleaner s onl y

i n a wel l ventilate d area ; also ,

d o no t saturat e th e staine d

area .

4 . I f a rin g form s afte r spo t

cleaning , clea n th e entir e are a

IMMEDIATELY .

5 . Follo w specifi c instruction s o n

th e cleanin g products ' labels .

Car e an d Maintenanc e

Interio

r