light HONDA S2000 2007 2.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2007, Model line: S2000, Model: HONDA S2000 2007 2.GPages: 228, PDF Size: 3.81 MB

Page 158 of 228

The low beam headlight bulbs are a

type of high voltage discharge tube.

High voltage can remain in the

circuit even with the light switch of f

and the key removed. Because of

this, you should not attempt to

examine or change a low beam

headlight bulb yourself . If a low

beam headlight bulb fails, take the

vehicle to your dealer to have it

replaced.Halogen bulbs are used f or the high

beam headlight bulbs. When

replacing a high beam headlight bulb,

handle it by its base, and protect the

glass from contact with your skin or

hard objects. If you touch the glass,

clean it with denatured alcohol and a

clean cloth.

Theheadlightswereproperlyaimed

when your vehicle was new. If you

regularly carry heavy items in the

trunk, readjustment may be required.

Adjustment should be done by your

dealer or other qualif ied mechanic.

CONT INUED

Headlight A iming

Replacing a Headlight Bulb

Lights

Maint enance

155

Halogen headlight bulbs get very hot

when lit. Oil, perspiration, or a scratch

on the glass can cause the bulb to

overheat and shatter.

Page 159 of 228

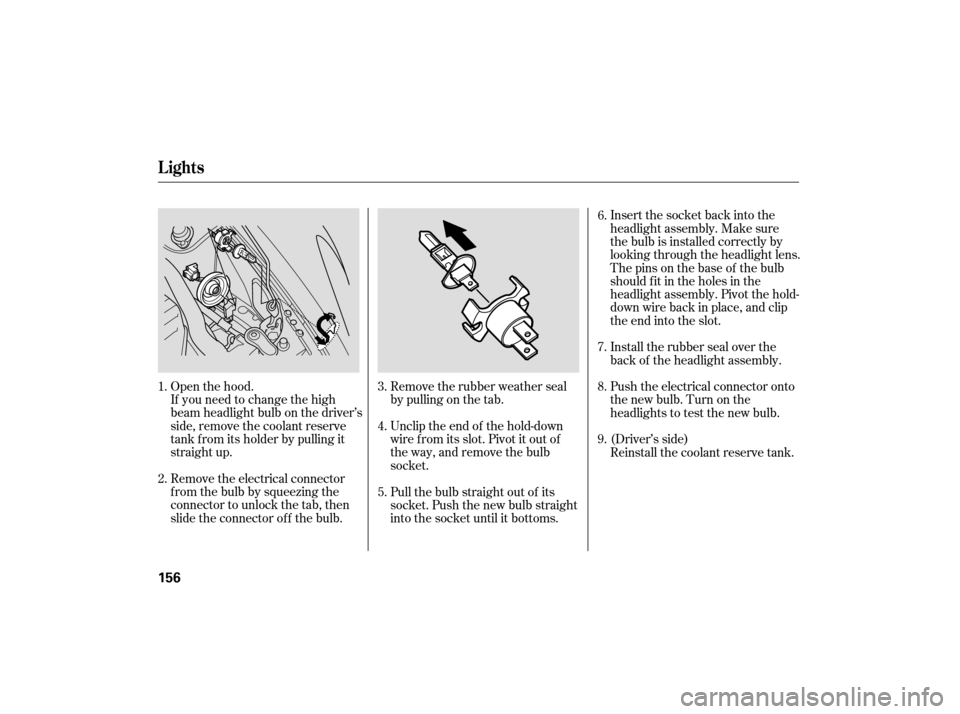

Open the hood.

If you need to change the high

beam headlight bulb on the driver’s

side, remove the coolant reserve

tank f rom its holder by pulling it

straight up.

Remove the electrical connector

f rom the bulb by squeezing the

connector to unlock the tab, then

slide the connector of f the bulb.Remove the rubber weather seal

by pulling on the tab.

Unclip the end of the hold-down

wire f rom its slot. Pivot it out of

the way, and remove the bulb

socket.Insert the socket back into the

headlight assembly. Make sure

the bulb is installed correctly by

looking through the headlight lens.

The pins on the base of the bulb

should f it in the holes in the

headlight assembly. Pivot the hold-

down wire back in place, and clip

the end into the slot.

Install the rubber seal over the

back of the headlight assembly.

Push the electrical connector onto

the new bulb. Turn on the

headlights to test the new bulb.

Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms. Reinstall the coolant reserve tank. (Driver’s side)

1.

2. 3.

4.

5.6.

7.

8.

9.

Lights

156

Page 160 of 228

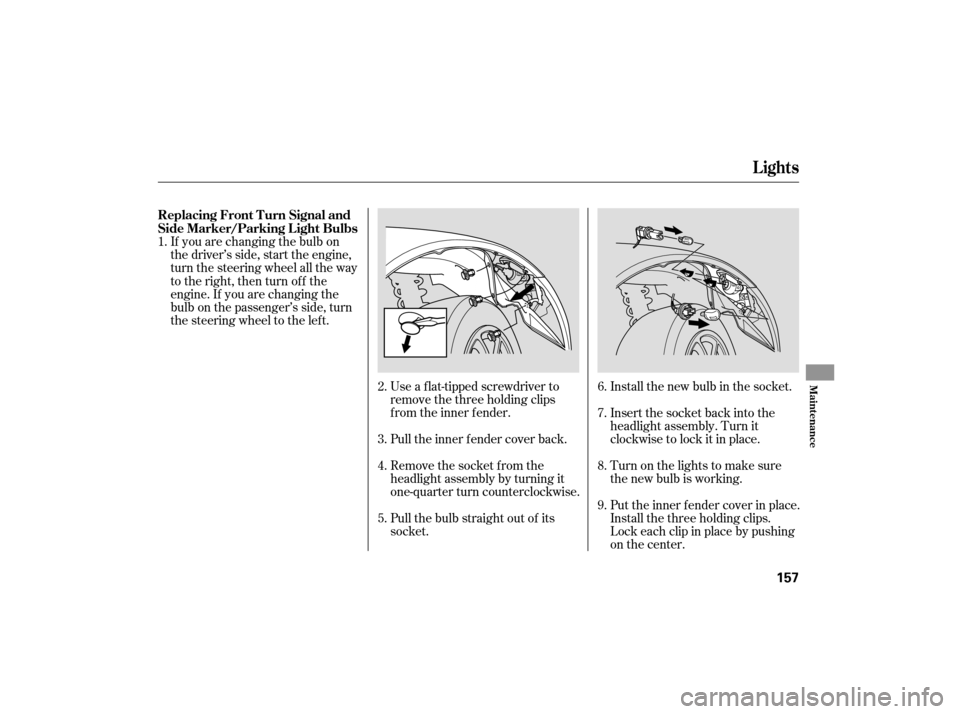

If you are changing the bulb on

the driver’s side, start the engine,

turn the steering wheel all the way

to the right, then turn off the

engine. If you are changing the

bulb on the passenger’s side, turn

the steering wheel to the left.Use a f lat-tipped screwdriver to

remove the three holding clips

f rom the inner f ender.

Pull the inner f ender cover back.

Remove the socket from the

headlight assembly by turning it

one-quarter turn counterclockwise.

Pull the bulb straight out of its

socket.Insert the socket back into the

headlight assembly. Turn it

clockwise to lock it in place. Install the new bulb in the socket.

Put the inner f ender cover in place.

Install the three holding clips.

Lock each clip in place by pushing

on the center. Turn on the lights to make sure

the new bulb is working.

1.

2.

3.

4.

5.6.

7.

8.

9.

Replacing Front Turn Signal and

Side Marker/Parking L ight Bulbs

Lights

Maint enance

157

Page 161 of 228

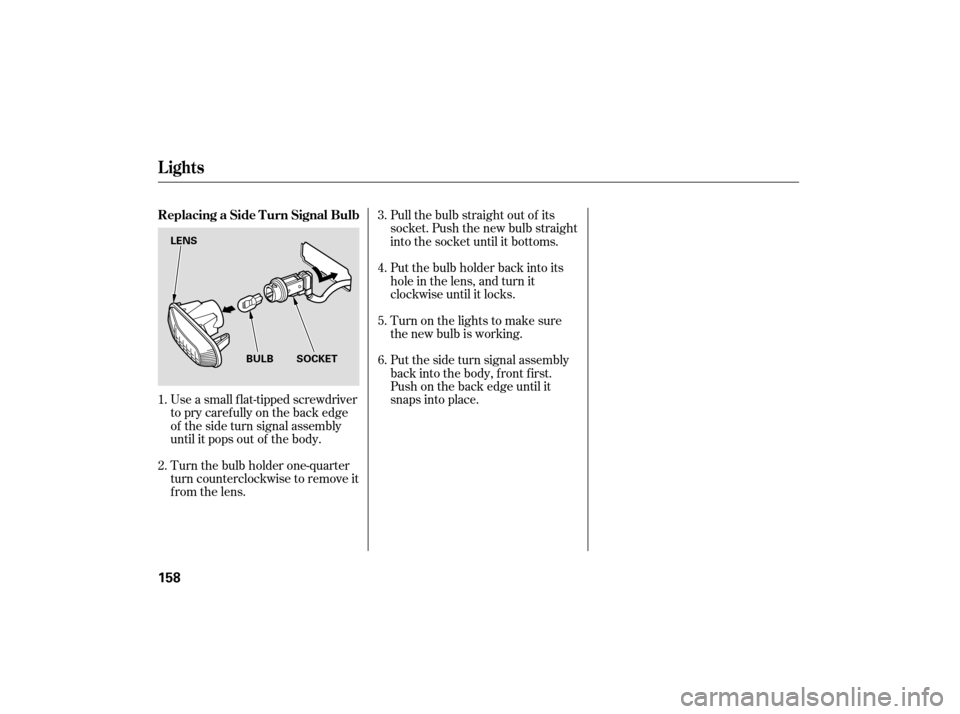

Use a small flat-tipped screwdriver

to pry caref ully on the back edge

of the side turn signal assembly

until it pops out of the body.

Turn the bulb holder one-quarter

turn counterclockwise to remove it

from the lens.Pull the bulb straight out of its

socket. Push the new bulb straight

into the socket until it bottoms.

Put the bulb holder back into its

hole in the lens, and turn it

clockwise until it locks.

Turn on the lights to make sure

the new bulb is working.

Put the side turn signal assembly

back into the body, front first.

Push on the back edge until it

snaps into place.

1.

2. 3.

4.

5.

6.

Replacing a Side Turn Signal Bulb

Lights

158

LENS

BULB SOCKET

Page 162 of 228

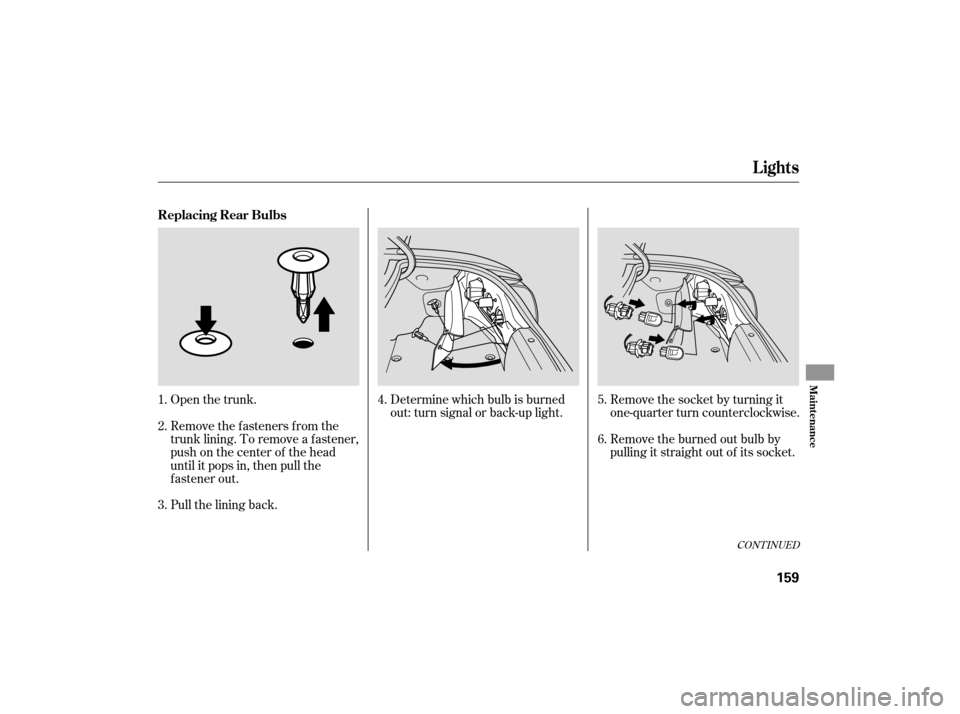

Open the trunk.

Remove the fasteners from the

trunk lining. To remove a f astener,

push on the center of the head

until it pops in, then pull the

f astener out.

Pull the lining back.Remove the socket by turning it

one-quarter turn counterclockwise.

Remove the burned out bulb by

pulling it straight out of its socket.

Determine which bulb is burned

out: turn signal or back-up light.

1.

2.

3. 4.

5.

6.

CONT INUED

Replacing Rear Bulbs

Lights

Maint enance

159

Page 163 of 228

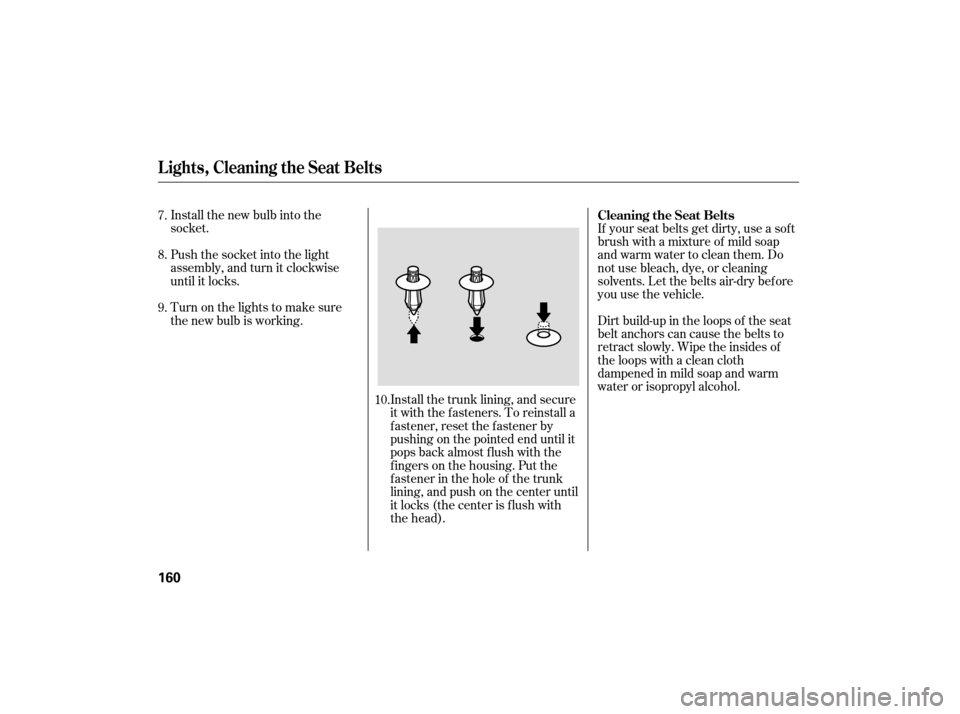

Install the new bulb into the

socket.

Push the socket into the light

assembly, and turn it clockwise

until it locks.Install the trunk lining, and secure

it with the fasteners. To reinstall a

f astener, reset the f astener by

pushing on the pointed end until it

pops back almost f lush with the

f ingers on the housing. Put the

f astener in the hole of the trunk

lining, and push on the center until

it locks (the center is flush with

the head).

Turn on the lights to make sure

the new bulb is working.

If your seat belts get dirty, use a sof t

brush with a mixture of mild soap

and warm water to clean them. Do

not use bleach, dye, or cleaning

solvents. Let the belts air-dry bef ore

you use the vehicle.

Dirt build-up in the loops of the seat

belt anchors can cause the belts to

retract slowly. Wipe the insides of

the loops with a clean cloth

dampened in mild soap and warm

water or isopropyl alcohol.

7.

8.

9.

10. Cleaning the Seat Belts

Lights, Cleaning the Seat Belts

160

Page 174 of 228

If you need to park your vehicle f or

an extended period (more than 1

month), there are several things you

should do to prepare it f or storage.

Proper preparation helps prevent

deterioration and makes it easier to

get your vehicle back on the road. If

possible, store your vehicle indoors.Fill the f uel tank.

Change the engine oil and f ilter.

Wash and dry the exterior

completely.

Cleantheinterior.Makesurethe

carpeting, floor mats, etc., are

completely dry.

Raise the convertible top cover.

Leave the parking brake off. Put

the transmission in reverse. Block the rear wheels.

If the vehicle is to be stored f or a

longer period, it should be

supported on jackstands so the

tires are of f the ground.

Leave one window open slightly (if

the vehicle is being stored

indoors).

Disconnect the battery.

Cover the vehicle with a

‘‘breathable’’ cover, one made

f rom a porous material such as

cotton. Non-porous materials, such

as plastic sheeting, trap moisture,

which can damage the paint.

Support the f ront wiper blade

arms with a f olded towel or rag so

they do not touch the windshield.

To minimize sticking, apply a

silicone spray lubricant to all door

and trunk seals. Also, apply a

vehiclebodywaxtothepainted

surfaces that mate with the door

and trunk seals. If possible, periodically run the

engine until it reaches f ull

operating temperature (the

cooling f an cycles on and of f

twice). Pref erably, do this once a

month.

Vehicle Storage

Maint enance

171

Page 178 of 228

Thesizedifferencemayalsocause

damage to the rear dif f erential, so do

not mount the compact spare on the

rear. If either rear tire goes f lat,

remove the f ront tire on that same

side, mount the compact spare tire

on the f ront, then mount the f ront

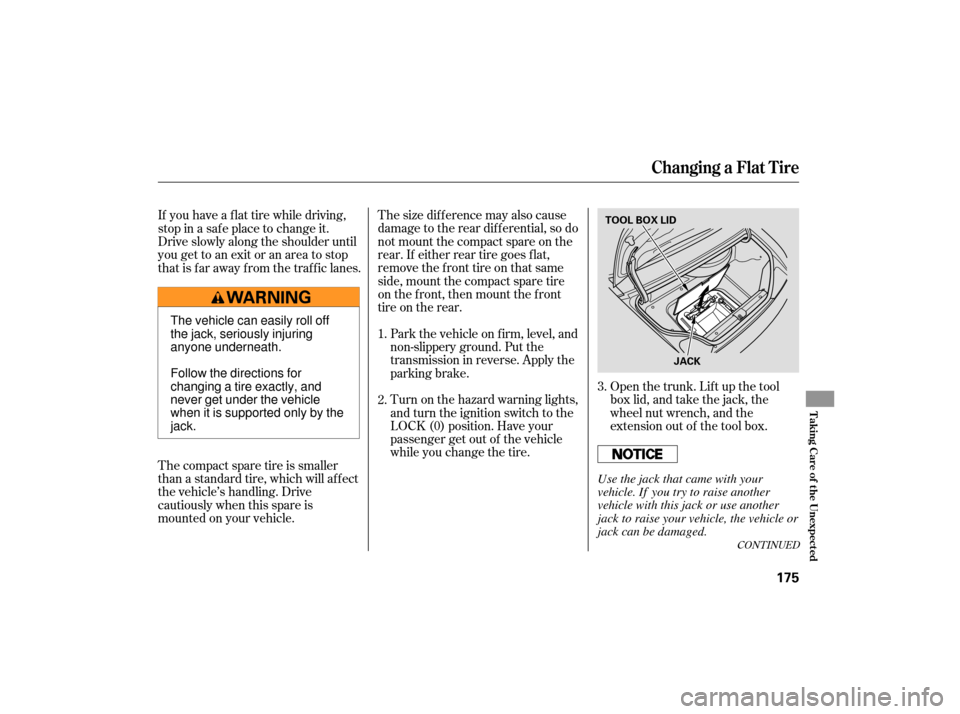

tire on the rear.Park the vehicle on f irm, level, and

non-slippery ground. Put the

transmission in reverse. Apply the

parking brake.

Turn on the hazard warning lights,

and turn the ignition switch to the

LOCK (0) position. Have your

passenger get out of the vehicle

while you change the tire. Open the trunk. Lift up the tool

box lid, and take the jack, the

wheel nut wrench, and the

extension out of the tool box.

Thecompactsparetireissmaller

than a standard tire, which will affect

the vehicle’s handling. Drive

cautiously when this spare is

mounted on your vehicle. If you have a f lat tire while driving,

stop in a saf e place to change it.

Drive slowly along the shoulder until

you get to an exit or an area to stop

that is far away from the traffic lanes.

3.

1.

2.

CONT INUED

Changing a Flat Tire

T aking Care of t he Unexpect ed

175

TOOL BOX LID

JACK

The vehicle can easily roll off

the jack, seriously injuring

anyone underneath.

Follow the directions for

changing a tire exactly, and

never get under the vehicle

when it is supported only by the

jack. Use the jack that came with your

vehicle. If you try to raise another

vehicle with this jack or use another

jack to raise your vehicle, the vehicle or

jack can be damaged.

Page 183 of 228

Diagnosing why the engine won’t

start falls into two areas, depending

on what you hear when you press

the ENGINE START button.

You hear nothing, or almost

nothing. The engine’s starter

motor does not operate at all, or

operates very slowly.

You can hear the starter motor

operating normally, or the starter

motor sounds like it is spinning

faster than normal, but the engine

does not start up and run. When

you press the ENGINE

START button, you do not hear the

norm al noise of the engine trying to

start. You may hear a clicking sound

or series of clicks, or nothing at all.

Check these things:

Check the transmission interlock.

The clutch pedal must be pushed

all the way to the floor or the

starter will not operate.

Turn the ignition switch to the ON

(II) position. Turn on the

headlights, and check their

brightness. If the headlights are

very dim or do not come on at all,

the battery is discharged. See

on page . Press

the ENGI NE START button,

then release it. If the headlights do

not dim, check the condition of the

fuses.IfthefusesareOK,thereis

probably something wrong with

the electrical circuit for the

ignition switch or starter motor.

You will need a qualified mechanic

to determine the problem. (See

on page .)

182 196

Nothing Happens or the Starter

Motor Operates Very Slowly

Jump Starting Emergency T owing

If theEngineWon’tStart

180

Page 184 of 228

If the headlights dim noticeably or

go out when you try to start the

engine, either the battery is

discharged or the connections are

co rroded. Check the condition of the

battery and terminal connections

(see page ). You can then try

jump starting the vehicle from a

booster battery (see page ). In

this case, the starter motor’s

speed sounds normal, or even faster

than normal, when you press the

ENGI NE START button, but the

engine does not run. There

may be an electrical

problem, such as no power to the

fuel pump. Check all the fuses

(see page ).

Are you using a properly coded

key? An improperly coded key will

cause the immobilizer system

indicator in the instrument panel

to blink rapidly (see page ).

Are you using the proper starting

procedure? Refer to

on page .

Do you have fuel? Check the fuel

gauge; the low fuel indicator may

not be working. Ifyoufindnothingwrong,youwill

need

a qualified mechanic to find the

problem. See

on page .

61

169

182

124 190

196

T he Starter Operates Normally

Starting the

Engine Emergency T owing

If theEngineWon’tStart

T aking Care of t he Unexpect ed

181