ECU Hyundai Accent 2007 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Accent, Model: Hyundai Accent 2007Pages: 282, PDF Size: 10.55 MB

Page 194 of 282

3

WHAT TO DO IN AN EMERGENCY

5

!!

SPARE TIRE

WARNING (Diesel Only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. High pressure pump, rail, injectors andhigh pressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced byfuel leaks may cause serious in- jury, if it touch the body. People using pacemakers should not movethan 30cm closer to the ECU or wiring harness within the engine room while engine is running, sincethe high currents in the Common Rail system produce considerable magnetic fields. WARNING:

Do not remove the radiator cap whenthe engine is hot. This can allowcoolant to be blown out of the open- ing and cause serious burns.

6. If you cannot find the cause of the overheating, wait until the engine temperature has returned to nor-mal. Then, if the engine coolant has been lost, carefully add coolant to the reservoir (Page 6-11) to bring thefluid level in the reservoir up to the halfway mark.

7. Proceed with caution, keeping alert

for further signs of overheating. Ifoverheating happens again, call a Hyundai dealer for assistance.

!

5. If the water pump drive belt is broken

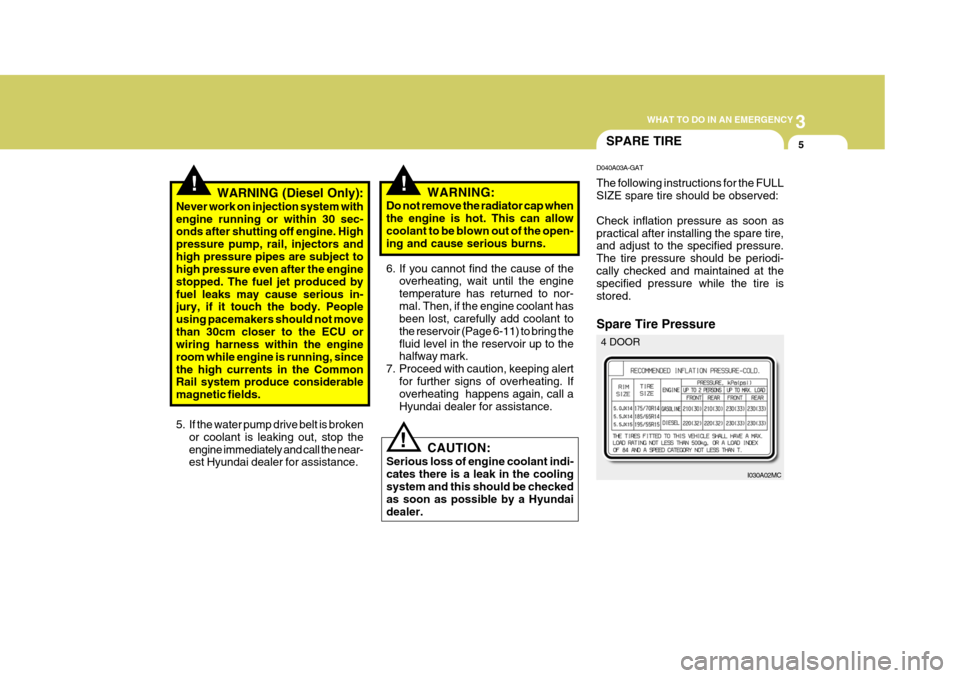

or coolant is leaking out, stop the engine immediately and call the near- est Hyundai dealer for assistance. D040A03A-GAT The following instructions for the FULL SIZE spare tire should be observed: Check inflation pressure as soon as practical after installing the spare tire, and adjust to the specified pressure. The tire pressure should be periodi-cally checked and maintained at the specified pressure while the tire is stored.

CAUTION:

Serious loss of engine coolant indi-cates there is a leak in the coolingsystem and this should be checked as soon as possible by a Hyundai dealer. Spare Tire Pressure

I030A02MC

4 DOOR

Page 200 of 282

3

WHAT TO DO IN AN EMERGENCY

11

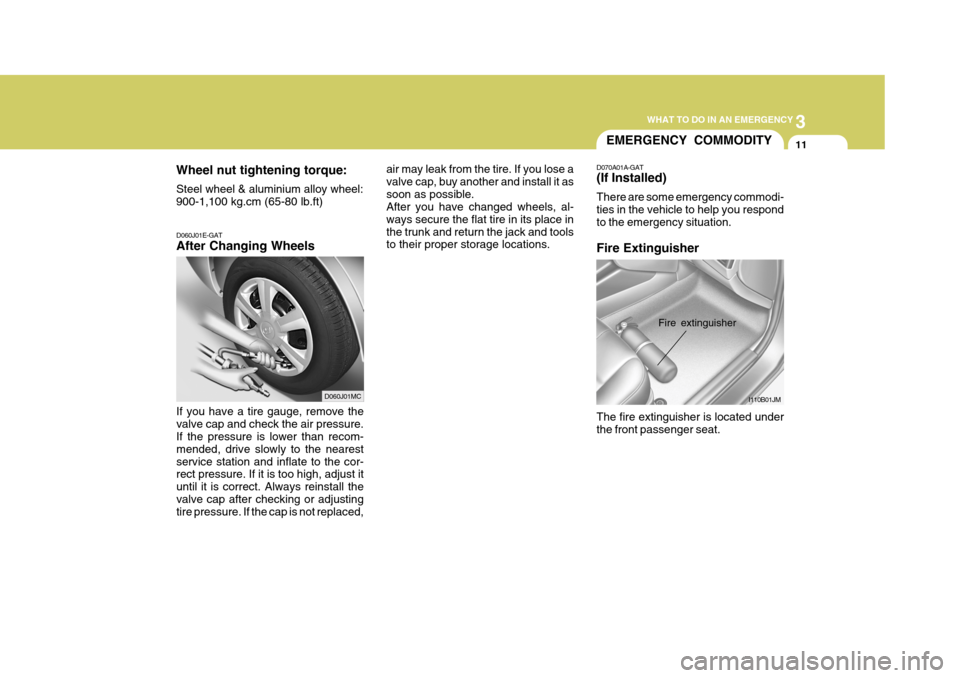

D060J01E-GAT After Changing Wheels If you have a tire gauge, remove the valve cap and check the air pressure. If the pressure is lower than recom- mended, drive slowly to the nearestservice station and inflate to the cor- rect pressure. If it is too high, adjust it until it is correct. Always reinstall thevalve cap after checking or adjusting tire pressure. If the cap is not replaced,

Wheel nut tightening torque: Steel wheel & aluminium alloy wheel: 900-1,100 kg.cm (65-80 lb.ft)

air may leak from the tire. If you lose avalve cap, buy another and install it assoon as possible. After you have changed wheels, al- ways secure the flat tire in its place inthe trunk and return the jack and tools to their proper storage locations.

D060J01MC

EMERGENCY COMMODITY

D070A01A-GAT (If Installed) There are some emergency commodi- ties in the vehicle to help you respond to the emergency situation. Fire Extinguisher The fire extinguisher is located under the front passenger seat. I110B01JM

Fire extinguisher

Page 220 of 282

5VEHICLE MAINTENANCE REQUIREMENTS

8

!

EXPLANATION OF SCHED- ULED MAINTENANCE ITEMS

F060M01A-AAT

o Engine Oil and Filter The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. F060B01A-AAT

o Drive Belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked period-ically for proper tension and adjusted as necessary. F060C01A-AAT

o Fuel Filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam-age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians. F060D01TB-GAT

o Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immedi-ately.

WARNING (Diesel only):

Never work on injection system with

engine running or within 30 sec-onds after shutting off engine. High pressure pump, rail, injectors and high pressure pipes are subjectedto high pressure even after the en- gine has been switched off. The fuel jet produced by fuel leaks maycause serious injury, if it contacts with the body. People using pace- makers should not move closerthan 30cm to the ECU or wiring harness within the engine room with the engine running, since the highcurrents in the Common Rail sys- tem produce considerable magnetic fields.

Page 221 of 282

5

VEHICLE MAINTENANCE REQUIREMENTS

9

F060H01A-AAT

o Air Cleaner Filter A Genuine Hyundai air cleaner filter is

recommended when the filter is re- placed. F060J01A-AAT

o Spark Plugs (For Gasoline Engine)

Make sure to install new spark plugs of the correct heat range. F070C01A-AAT o Coolant The coolant should be changed at the intervals specified in the mainte- nance schedule.

F060E01MC-AAT

o Timing Belt (Gasoline)

Inspect all parts related to the timing

belt for damage and deformation.Replace any damaged parts immedi- ately.

F060G01A-AAT

o Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap

should be inspected at those intervalsspecified in the maintenance sched-ule. Make sure that a new vapor hose or fuel filler cap is correctly replaced. F060F01A-AAT

o Vacuum, Crankcase Ventila-

tion Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ine those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure

that the hoses do not come in contactwith any heat source, sharp edges or moving component which might causeheat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make surethey are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidenceof deterioration or damage. F070B01A-GAT o Cooling System Check the cooling system part, such as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

Page 239 of 282

6 DO-IT-YOURSELF MAINTENANCE

16

!

!

3. If the transaxle fluid level is low, use

a funnel to add transaxle fluid through the dipstick tube until the levelreaches the "HOT" range. Do not overfill.

WARNING:

The cooling fan is controlled by en- gine coolant temperature and maysometimes operate even when the engine is not running. Use extreme caution when working near the bladesof the cooling fan, so that you are not injured by a rotating fan blade. As the engine coolant temperature decreas-es, the fan will automatically shut off. This is a normal condition. WARNING (

Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine. High pres- sure pump, rail, injectors and highpressure pipes are subjected to high pressure even after the engine has been switched off. The fuel jet pro-duced by fuel leaks may cause seri- ous injury, if it contacts with the body. People using pacemakersshould not move closer than 30cm to the ECU or wiring harness within the engine room with the engine run-ning, since the high currents in the Common Rail system produce con- siderable magnetic fields.

G110D03MC

Fluid level should be within "HOT" range

1. Open the hood, being careful to keep

hands, long hair and clothing clear of any moving parts.

2. Remove the transaxle dipstick, wipe it clean, reinsert the dipstick as faras it will go, then remove it again.Now check the fluid level on the dipstick. It should be in the "HOT" range on the dipstick. G110D02MC

Page 247 of 282

6 DO-IT-YOURSELF MAINTENANCE

24

o When lifting a plastic-cased bat-

tery, excessive pressure on the case may cause battery acid to leak, resulting in personal injury.Lift with a battery carrier or with your hands on opposite corners.

o Never attempt to charge the bat-

tery when the battery cables areconnected.

o The electrical ignition system

works with high voltage.Never touch these components with the engine running or the ignition switched on.

CHECKING ELECTRIC COOLING FANS

!

G220B01A-AAT Checking Engine Cooling Fan The engine cooling fan should come on automatically if the engine coolant tem-perature is high. G220C01TB-GAT Checking Condenser Cooling Fan When the air conditioning is in opera- tion, the condenser cooling fan comeson automatically to be controlled by ECU.G220A01A-AAT

WARNING:

The cooling fan is controlled by en- gine coolant temperature and may sometimes operate even when the engine is not running. Use extremecaution when working near the blades of the cooling fan, so that you are not injured by a rotating fanblade. As the engine coolant temper- ature decreases the fan will automat- ically shut off. This is a normal con-dition.

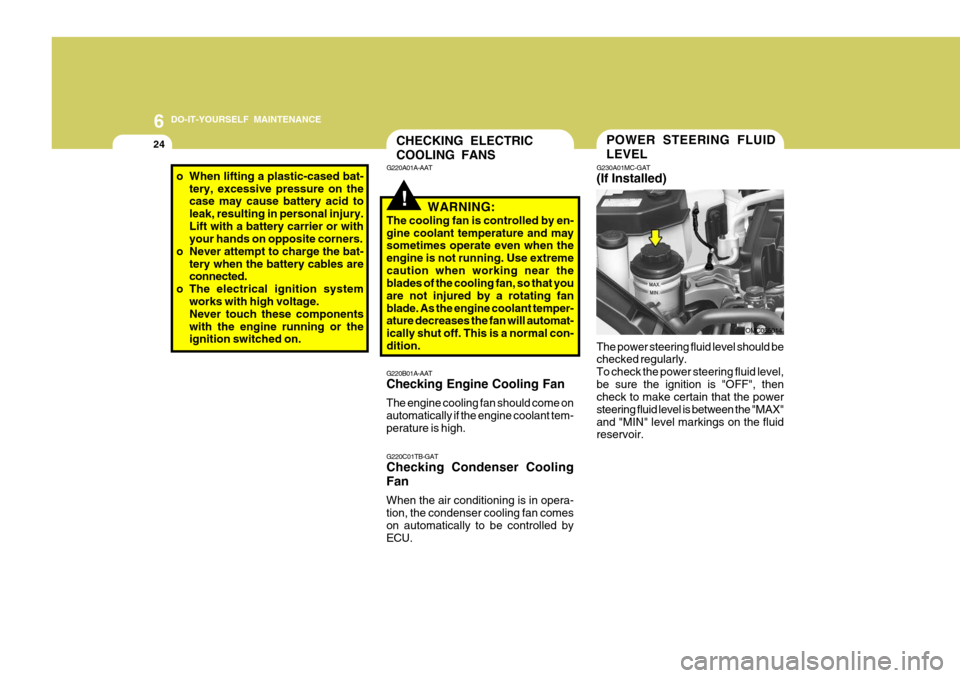

POWER STEERING FLUID LEVEL

G230A01MC-GAT (If Installed) The power steering fluid level should be checked regularly. To check the power steering fluid level,be sure the ignition is "OFF", then check to make certain that the power steering fluid level is between the "MAX"and "MIN" level markings on the fluid reservoir. OMC055014

Page 258 of 282

6

DO-IT-YOURSELF MAINTENANCE

35

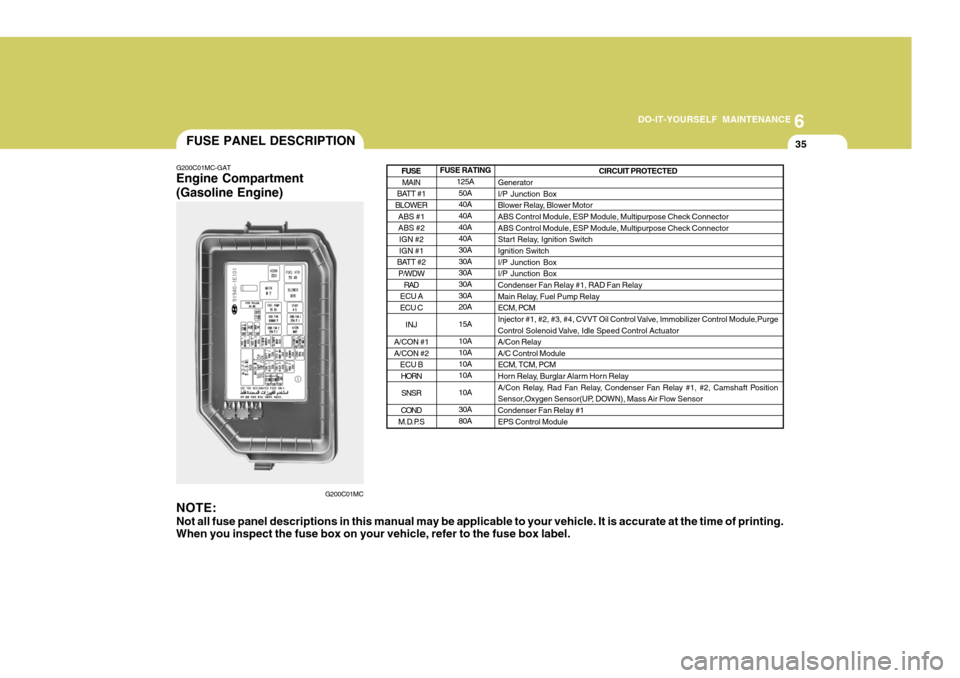

FUSE RATING 125A50A 40A 40A 40A40A 30A 30A30A 30A 30A20A 15A10A 10A 10A10A 10A30A 80A

G200C01MC-GAT Engine Compartment (Gasoline Engine)

G200C01MC

NOTE:

Not all fuse panel descriptions in this manual may be applicable to your vehicle. It is accurate at the time of printing.

When you inspect the fuse box on your vehicle, refer to the fuse box label. CIRCUIT PROTECTED

Generator I/P Junction Box

Blower Relay, Blower MotorABS Control Module, ESP Module, Multipurpose Check Connector ABS Control Module, ESP Module, Multipurpose Check Connector

Start Relay, Ignition SwitchIgnition Switch I/P Junction Box I/P Junction BoxCondenser Fan Relay #1, RAD Fan Relay

Main Relay, Fuel Pump Relay ECM, PCM

Injector #1, #2, #3, #4, CVVT Oil Control Valve, Immobilizer Control Module,Purge

Control Solenoid Valve, Idle Speed Control Actuator A/Con RelayA/C Control ModuleECM, TCM, PCM

Horn Relay, Burglar Alarm Horn Relay

A/Con Relay, Rad Fan Relay, Condenser Fan Relay #1, #2, Camshaft Position

Sensor,Oxygen Sensor(UP, DOWN), Mass Air Flow Sensor Condenser Fan Relay #1 EPS Control Module

MAIN

BATT #1

BLOWER

ABS #1 ABS #2IGN #2 IGN #1

BATT #2 P/WDW

RAD

ECU A ECU C

INJ

A/CON #1 A/CON #2 ECU BHORN

SNSR

COND

M.D.P.S

FUSE

FUSE PANEL DESCRIPTION

Page 259 of 282

6 DO-IT-YOURSELF MAINTENANCE

36

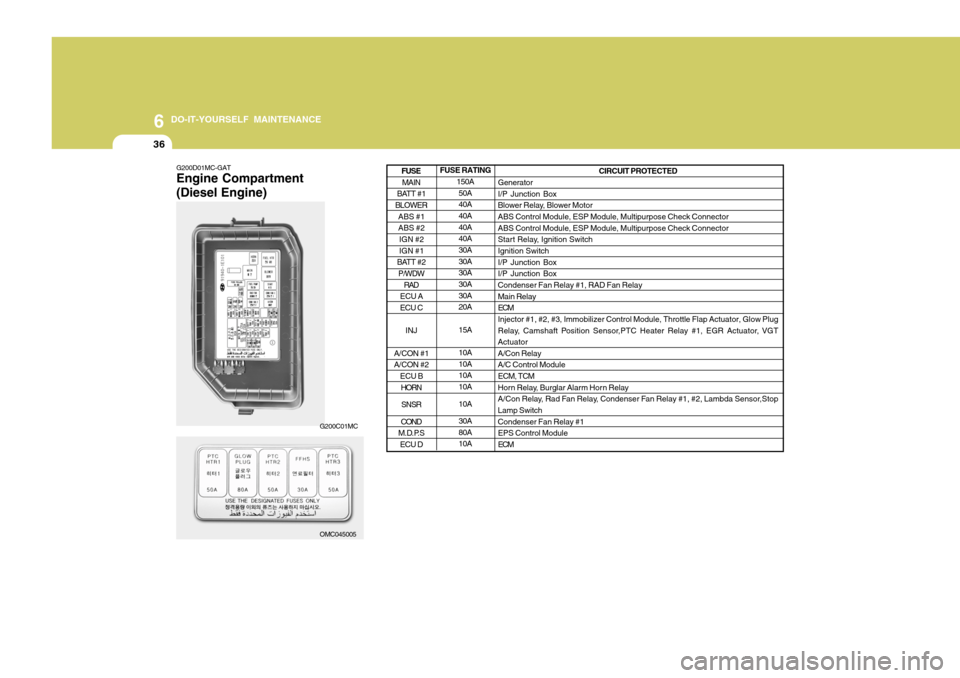

G200D01MC-GAT Engine Compartment (Diesel Engine) FUSE RATING

150A50A 40A 40A 40A40A 30A 30A30A 30A 30A20A 15A10A 10A10A 10A 10A30A 80A10A CIRCUIT PROTECTED

Generator I/P Junction Box

Blower Relay, Blower MotorABS Control Module, ESP Module, Multipurpose Check Connector ABS Control Module, ESP Module, Multipurpose Check Connector

Start Relay, Ignition SwitchIgnition Switch I/P Junction Box I/P Junction BoxCondenser Fan Relay #1, RAD Fan Relay Main Relay ECMInjector #1, #2, #3, Immobilizer Control Module, Throttle Flap Actuator, Glow Plug

Relay, Camshaft Position Sensor,PTC Heater Relay #1, EGR Actuator, VGT ActuatorA/Con RelayA/C Control Module ECM, TCM

Horn Relay, Burglar Alarm Horn Relay

A/Con Relay, Rad Fan Relay, Condenser Fan Relay #1, #2, Lambda Sensor,Stop Lamp Switch Condenser Fan Relay #1EPS Control Module ECM

MAIN

BATT #1

BLOWER

ABS #1 ABS #2IGN #2 IGN #1

BATT #2 P/WDW

RAD

ECU A ECU C

INJ

A/CON #1A/CON #2 ECU B

HORN

SNSR

COND

M.D.P.S ECU D

FUSE

OMC045005

G200C01MC

Page 261 of 282

6 DO-IT-YOURSELF MAINTENANCE

38

FUSE RATING10A 20A10A 10A 15A 10A10A 20A 10A 15A 10A 15A 10A10A 10A 10A 10A CIRCUIT PROTECTED

Front Fog Lamp Switch, Front Fog Lamp LH, Front Fog Lamp RH,BCM Sunroof Motor Hazard SwitchOver Driver Switch, TCM(Diesel), Pulse Generator 'A'(Diesel),Pulse Generator

'B'(Diesel), Vehicle Speed Sensor

Data Link Connector, Stop Lamp Switch, P/WDW Relay,Multipurpose CheckConnector Instrument Cluster ECM, PCM, EPS Control Module, Mass Air Flow Sensor(Diesel), Fuel FilterWarning Switch(Diesel) Driver Door Lock Actuator, Assist Door Lock Actuator, BCM,Rear Door Lock

Actuator LH, Rear Door Lock Actuator RH,Driver Power Window Switch, TailGate Lock Actuator Start Relay BCM, Instrument Cluster, Generator, DRL Control ModuleIgnition Coil #1, #2, #3, #4, CondenserAudio

Luggage Lamp, Room Lamp, Vanity Lamp Switch, Digital Clock,Overhead Consol Lamp, A/C Control Module, Instrument Cluster,Back Warning Buzzer, Door Warning Switch, BCM ESP Switch, Steering Angle Sensor, ABS Control Module,ESP Module,Multipurpose Check Connector

Back-up Lamp Switch, Transaxle Range Switch DRL Control ModulePower Outside Mirror & Mirror Folding Switch

FR FOG LP S/ROOF

T/SIG LP

TCU

STOP LP

A/BAG IND ECU

C/DR LOCK START

CLUSTER IGN COIL AUDIO

(Power Connector)

MULT B/UP

(Power Connector)

ABS

B/UP LP DRL

FOLD'G

FUSE