belt Hyundai Accent 2008 Workshop Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Accent, Model: Hyundai Accent 2008Pages: 273, PDF Size: 9.36 MB

Page 177 of 273

3

WHAT TO DO IN AN EMERGENCY

5

!

!

4. Check to see if the water pump drive

belt is missing. If it is not missing,

check to see that it is tight. If the drive

belt seems to be satisfactory, check for

coolant leaking from the radiator, hoses

or under the car. (If the air conditioner

had been in use, it is normal for cold

water to be draining from it when you

stop).

WARNING:

While the engine is running, keep hands,

long hair and clothing away from mov-

ing parts such as the fan and drive belts

to prevent injury.

5. If the water pump drive belt is broken

or coolant is leaking out, stop the en-

gine immediately and call the nearest

Hyundai dealer for assistance.WARNING:

Do not remove the radiator cap when

the engine is hot. This may allow cool-

ant to be blown out of the opening and

cause serious burns.

!

6. If you cannot find the cause of the

overheating, wait until the engine tem-

perature has returned to normal. Then,

if coolant has been lost, carefully add

water to the reservoir (Page 6-7) to

bring the fluid level in the reservoir up

to the halfway mark.

7. Proceed with caution, keeping alert for

further signs of overheating. If over-

heating happens again, call a Hyundai

dealer for assistance.

CAUTION:

Serious loss of coolant indicates there

is a leak in the cooling system and this

should be checked as soon as possible

by a Hyundai dealer.

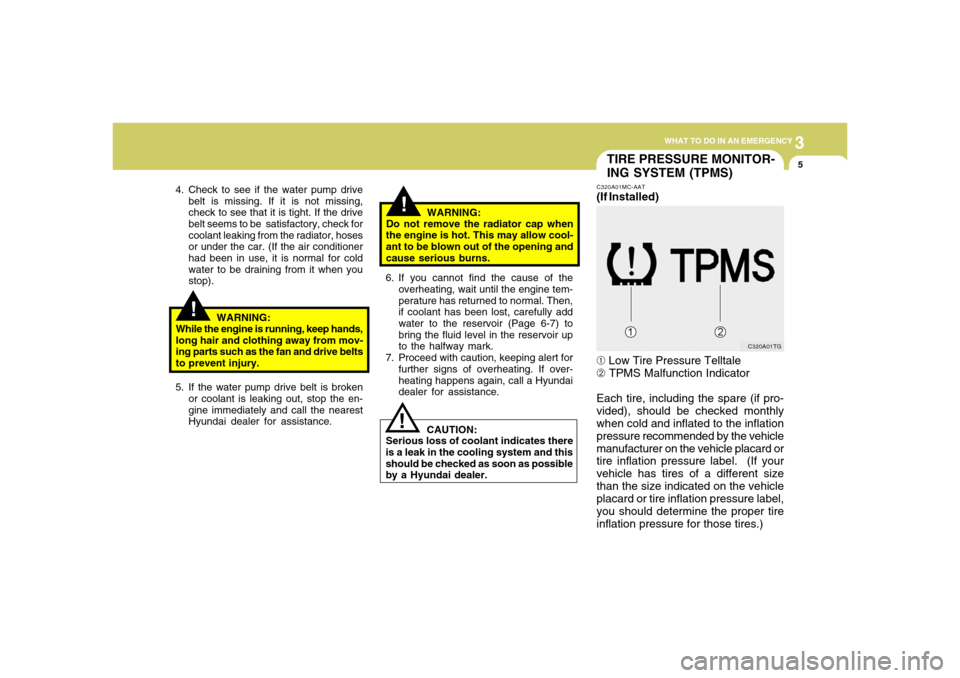

TIRE PRESSURE MONITOR-

ING SYSTEM (TPMS)

C320A01TG C320A01MC-AAT

(If Installed)

➀ Low Tire Pressure Telltale

➁ TPMS Malfunction Indicator

Each tire, including the spare (if pro-

vided), should be checked monthly

when cold and inflated to the inflation

pressure recommended by the vehicle

manufacturer on the vehicle placard or

tire inflation pressure label. (If your

vehicle has tires of a different size

than the size indicated on the vehicle

placard or tire inflation pressure label,

you should determine the proper tire

inflation pressure for those tires.)

Page 198 of 273

44

CORROSION PREVENTION AND APPEARANCE CARE6

E040D01A-AATCleaning the Seat BeltsTo clean the seat belts, use a cloth or

sponge with mild soap or detergent and

warm water. Do not use strong deter-

gents, dye, bleach or abrasive materials

on the seat belts as this may weaken the

fabric.

While cleaning the belts, inspect them for

excessive wear, cuts, fraying or other

signs of damage and replace them if

necessary.E040E01A-AATCleaning the WindowsYou may use any household window

cleaner on the windows. However, when

cleaning the inside of the rear window be

careful not to damage the rear window

defroster wiring.

E040A01A-AATTo Clean the Vinyl UpholsteryTo clean the vinyl upholstery, first remove

loose dirt and dust with a vacuum cleaner.

Then apply a solution of mild soap or

detergent and water using a clean sponge

or soft cloth. Allow this to stay on the

surface to loosen the dirt, then wipe with

a clean damp sponge or cloth. If all the

dirt stains are not removed, repeat this

procedure until the upholstery is clean.

Do not use gasoline, solvent, paint thin-

ner or other strong cleaners.

E040C01A-AATCleaning the CarpetsUse a foam-type carpet cleaner. Clean-

ers of this type are available in aerosol

cans in liquid form or powder. Read the

instructions and follow them exactly. Us-

ing a vacuum cleaner with the appropri-

ate attachment, remove as much dirt from

the carpets as possible. Apply the foam

following the manufacturer's directions,

then rub in overlapping circles. Do not

add water. These cleaners work best

when the carpet is kept as dry as pos-

sible.

CLEANING THE INTERIOR

Page 204 of 273

5

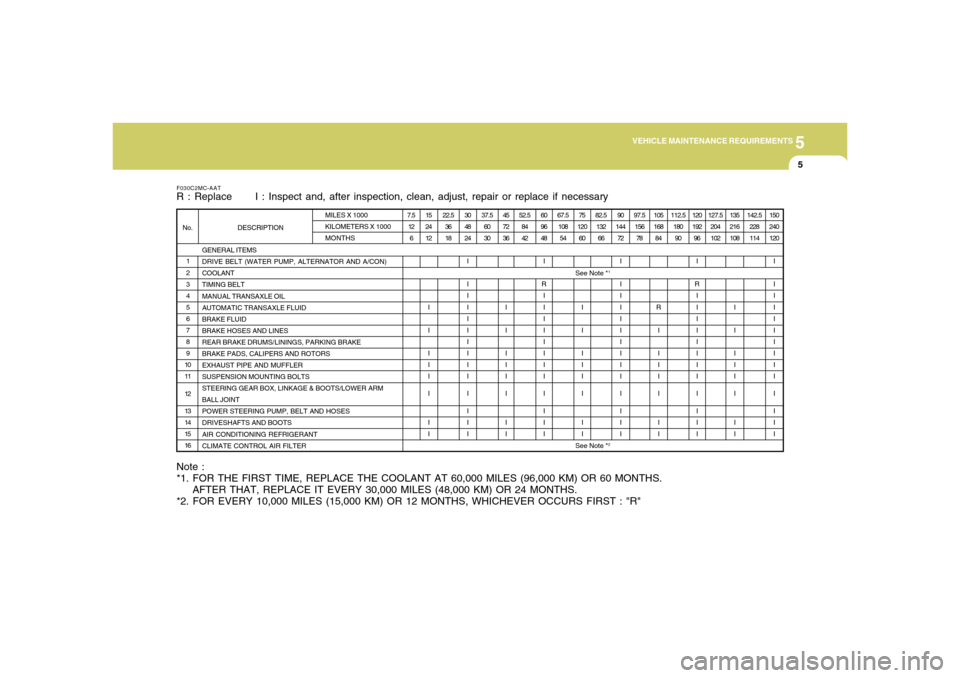

VEHICLE MAINTENANCE REQUIREMENTS

5

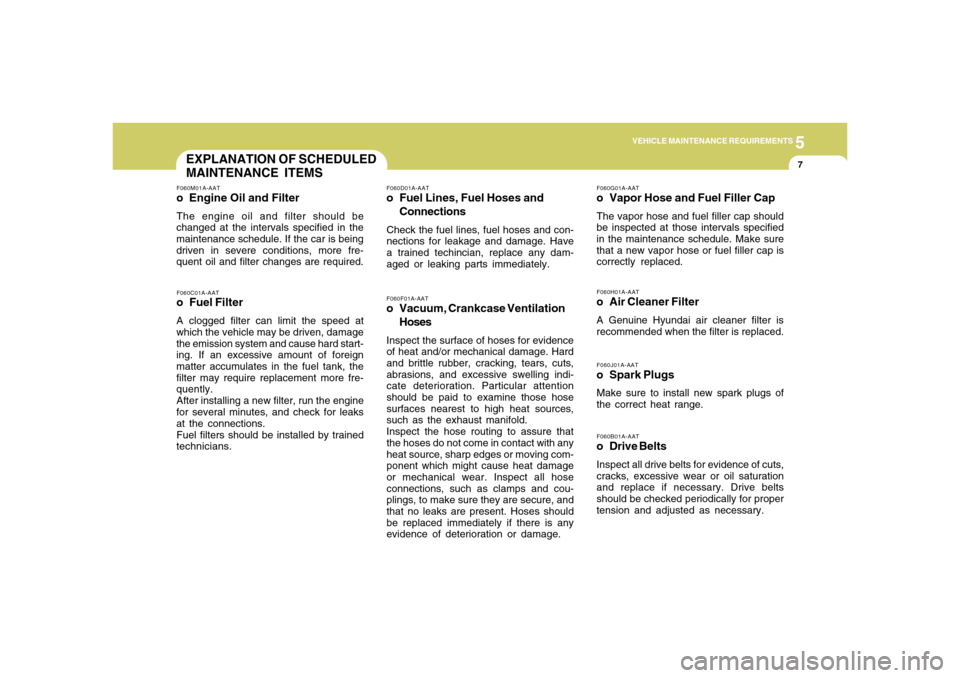

GENERAL ITEMS

DRIVE BELT (WATER PUMP, ALTERNATOR AND A/CON)

COOLANT

TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORS

EXHAUST PIPE AND MUFFLER

SUSPENSION MOUNTING BOLTS

STEERING GEAR BOX, LINKAGE & BOOTS/LOWER ARM

BALL JOINT

POWER STEERING PUMP, BELT AND HOSES

DRIVESHAFTS AND BOOTS

AIR CONDITIONING REFRIGERANT

CLIMATE CONTROL AIR FILTER 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 No.DESCRIPTIONMILES X 1000

KILOMETERS X 1000

MONTHS7.5

12

615

24

12

I

I

I

I

I

I

I

I22.5

36

1830

48

24

I

I

I

I

I

I

I

I

I

I

I

I

I

I37.5

60

3045

72

36

I

I

I

I

I

I

I

I52.5

84

4260

96

48

I

R

I

I

I

I

I

I

I

I

I

I

I

I67.5

108

5475

120

60

I

I

I

I

I

I

I

I82.5

132

6690

144

72

I

I

I

I

I

I

I

I

I

I

I

I

I

I97.5

156

78105

168

84

R

I

I

I

I

I

I

I112.5

180

90120

192

96

I

R

I

I

I

I

I

I

I

I

I

I

I

I127.5

204

102135

216

108

I

I

I

I

I

I

I

I142.5

228

114150

240

120

I

I

I

I

I

I

I

I

I

I

I

I

I

I

See Note *

2

Note :

*1. FOR THE FIRST TIME, REPLACE THE COOLANT AT 60,000 MILES (96,000 KM) OR 60 MONTHS.

AFTER THAT, REPLACE IT EVERY 30,000 MILES (48,000 KM) OR 24 MONTHS.

*2. FOR EVERY 10,000 MILES (15,000 KM) OR 12 MONTHS, WHICHEVER OCCURS FIRST : "R"F030C2MC-AATR : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

See Note *

1

Page 205 of 273

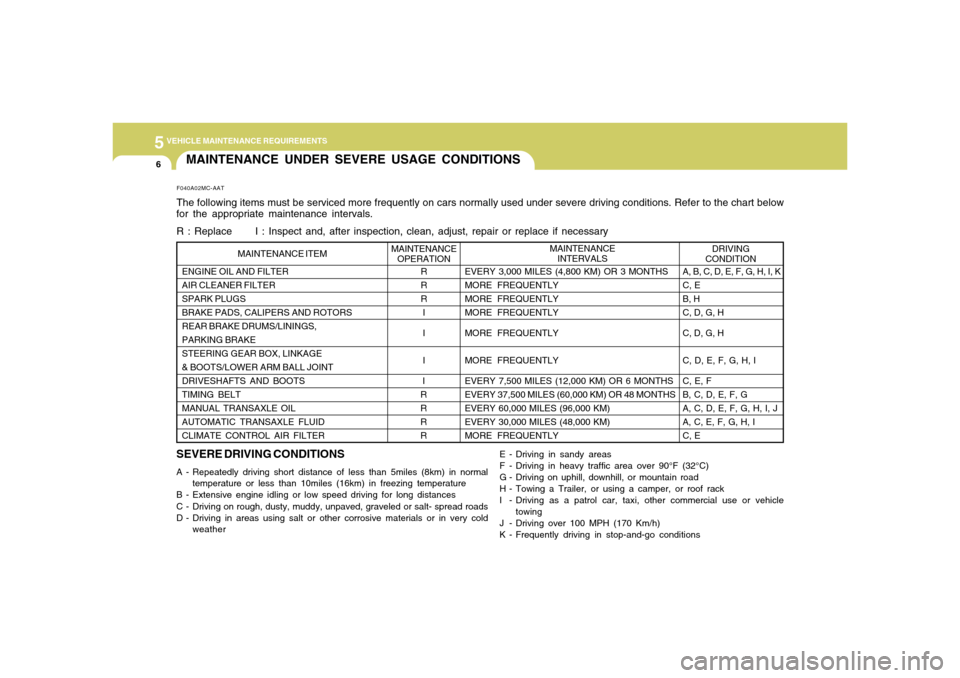

5

VEHICLE MAINTENANCE REQUIREMENTS6

DRIVING

CONDITION MAINTENANCE

INTERVALS

ENGINE OIL AND FILTER

AIR CLEANER FILTER

SPARK PLUGS

BRAKE PADS, CALIPERS AND ROTORS

REAR BRAKE DRUMS/LININGS,

PARKING BRAKE

STEERING GEAR BOX, LINKAGE

& BOOTS/LOWER ARM BALL JOINT

DRIVESHAFTS AND BOOTS

TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

CLIMATE CONTROL AIR FILTER

R

R

R

I

I

I

I

R

R

R

R MAINTENANCE

OPERATION MAINTENANCE ITEM

EVERY 3,000 MILES (4,800 KM) OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 7,500 MILES (12,000 KM) OR 6 MONTHS

EVERY 37,500 MILES (60,000 KM) OR 48 MONTHS

EVERY 60,000 MILES (96,000 KM)

EVERY 30,000 MILES (48,000 KM)

MORE FREQUENTLY

SEVERE DRIVING CONDITIONSA - Repeatedly driving short distance of less than 5miles (8km) in normal

temperature or less than 10miles (16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold

weatherE - Driving in sandy areas

F - Driving in heavy traffic area over 90°F (32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle

towing

J - Driving over 100 MPH (170 Km/h)

K - Frequently driving in stop-and-go conditionsA, B, C, D, E, F, G, H, I, K

C, E

B, H

C, D, G, H

C, D, G, H

C, D, E, F, G, H, I

C, E, F

B, C, D, E, F, G

A, C, D, E, F, G, H, I, J

A, C, E, F, G, H, I

C, EMAINTENANCE UNDER SEVERE USAGE CONDITIONSF040A02MC-AATThe following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below

for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 206 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS

7

EXPLANATION OF SCHEDULED

MAINTENANCE ITEMS

F060D01A-AATo Fuel Lines, Fuel Hoses and

ConnectionsCheck the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

a trained techincian, replace any dam-

aged or leaking parts immediately.

F060C01A-AATo Fuel FilterA clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause hard start-

ing. If an excessive amount of foreign

matter accumulates in the fuel tank, the

filter may require replacement more fre-

quently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections.

Fuel filters should be installed by trained

technicians.F060M01A-AATo Engine Oil and FilterThe engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.

F060H01A-AATo Air Cleaner FilterA Genuine Hyundai air cleaner filter is

recommended when the filter is replaced.F060G01A-AATo Vapor Hose and Fuel Filler CapThe vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

F060F01A-AATo Vacuum, Crankcase Ventilation

HosesInspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with any

heat source, sharp edges or moving com-

ponent which might cause heat damage

or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

F060B01A-AATo Drive BeltsInspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation

and replace if necessary. Drive belts

should be checked periodically for proper

tension and adjusted as necessary.F060J01A-AATo Spark PlugsMake sure to install new spark plugs of

the correct heat range.

Page 207 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS8

F070H01A-AATo Rear Brake Drums/Linings,

Parking BrakeCheck the rear brake drums and linings

for scoring, burning, leaking fluid, broken

parts, and excessive wear. Inspect the

parking brake system including the park-

ing brake lever and cables. For detailed

service procedures, refer to the Shop

Manual.F070F01A-AATo Brake Hoses and LinesVisually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

F070G02A-AATo Brake FluidCheck brake fluid level in the brake fluid

reservoir. The level should be between

"MIN" and "MAX" marks on the side of the

reservoir. Use only hydraulic brake fluid

conforming to DOT 3 or DOT 4.F070E06A-AATo Automatic Transaxle FluidThe fluid level should be in the “HOT”

range of the dipstick, after the engine and

transaxle are at normal operating tem-

perature. Check the automatic transaxle

fluid level with the engine running and

the transaxle in neutral, with the parking

brake properly applied. Use HYUNDAI

GENUINE ATF SP III, DIAMOND ATF SP

III, SK ATF SP III or other brands meeting

the SP III specification approved by

Hyundai Motor Co. when adding or chang-

ing fluid. Using the wrong ATF may result

in damage to the ATM.

F070D01A-AATo Manual Transaxle OilInspect the manual transaxle oil accord-

ing to the maintenance schedule.

NOTE:

If the oil level is low, check for possible

leaks before adding oil. Do not overfill.F060E01A-AATo Timing BeltInspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.F070C01A-AATo CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 208 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS

9

F070M01A-AATo Steering Gear Box, Linkage &

Boots/Lower Arm Ball JointWith the vehicle stopped and engine off,

check for excessive free-play in the steer-

ing wheel. Check the linkage for bends or

damage. Check the dust boots and ball

joints for deterioration, cracks, or dam-

age. Replace any damaged parts.

F070L01A-AATo Suspension Mounting BoltsCheck the suspension connections for

looseness or damage. Retighten to the

specified torque.F070K01A-AATo Exhaust Pipe and MufflerVisually inspect the exhaust pipes, muf-

fler and hangers for cracks, deterioration,

or damage. Start the engine and listen

carefully for any exhaust gas leakage.

Tighten connections or replace parts as

necessary.F070J01A-AATo Brake Pads, Calipers and RotorsCheck the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.

F070Q01A-AATo Air Conditioning RefrigerantCheck the air conditioning lines and con-

nections for leakage and damage. Check

air conditioning performance according

to the relevant shop manual if necessary.F070P01A-AATo Driveshafts and BootsCheck the drive shafts, boots and clamps

for cracks, deterioration, or damage. Re-

place any damaged parts and, if neces-

sary, repack the grease.

F070N01A-AATo Power Steering Pump, Belt and

HosesCheck the power steering pump and

hoses for leakage and damage. Replace

any damaged or leaking parts immedi-

ately. Inspect the power steering belt for

evidence of cuts, cracks, excessive wear,

oiliness and proper tension. Replace or

adjust it if necessary.

Page 209 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS

10

CALIFORNIA PERCHLORATE

NOTICEF080A01NF-AATPerchlorate Material-special handling

may apply, See www.dtsc.ca.gov/

hazardouswaste/perchlorate.

Notice to California Vehicle Dismantlers:

Perchlorate containing materials, such

as airbag inflators, seatbelt pretensioners

and keyless remote entry batteries, must

be disposed of according to Title 22 Cali-

fornia Code of Regulations Section

67384.10 (a).

Page 212 of 273

6

DO-IT-YOURSELF MAINTENANCE

3

GENERAL CHECKS

G020C01A-AATVehicle InteriorThe following should be checked each

time when the vehicle is driven:

o Light operation

o Windshield wiper operation

o Horn operation

o Defroster, heater system operation (and

air conditioning, if installed)

o Steering operation and condition

o Mirror condition and operation

o Turn signal operation

o Accelerator pedal operation

o Brake operation, including parking

brake

o Manual transaxle operation, including

clutchoperation

o Automatic transaxle operation, includ-

ing "Park" mechanism operation

o Seat control condition and operation

o Seat belt condition and operation

o Sun visor operation

If you notice anything that does not oper-

ate correctly or appear to be functioning

correctly, inspect it carefully and seek

assistance from your Hyundai dealer if

service is needed.

G020A01A-AATEngine Compartment

The following should be checked regu-

larly:

o Engine oil level and condition

o Transaxle fluid level and condition

o Brake fluid level

o Clutch fluid level

o Engine coolant level

o Windshield washer fluid level

o Accessory drive belt condition

o Engine coolant hose condition

o Fluid leaks (on or below components)

o Power steering fluid level and condi-

tion

o Battery condition

o Air cleaner filter condition

G020B01A-AATVehicle ExteriorThe following should be checked monthly:

o Overall appearance and condition

o Wheel condition and wheel nut tight-

ness

o Exhaust system condition

o Light condition and operation

o Windshield glass condition

o Wiper blade condition

o Paint condition and body corrosion

o Fluid leaks

o Door and hood lock condition

o Tire pressure and condition

(including spare tire)

Page 250 of 273

8

CONSUMER INFORMATION, REPORTING SAFETY DEFECTS & BINDING ARBITRATION OF WARRANTY CLAIMS

7

1. Manufacturer or Brand name

o Manufacturer or Brand name is

shown.

2. Tire size (example: P175/70R14)

o The "P" indicates the tire is de-

signed for passenger vehicles. A

"T" is the designation for a tempo-

rary spare tire.

o Three-digit number (175): This

number gives the width in millime-

ters of the tire from sidewall edge

to sidewall edge.

o Two-digit number (70): This num-

ber, known as the aspect ratio,

gives the tire's ratio of height to

width.

o R: The "R" stands for radial.

o Two-digit number (14): This num-

ber is the wheel or rim diameter in

inches.

o Two (or three) digit number (84):

This number is the tire's load in-

dex. It is a measurement of how

much weight each tire can sup-

port.o T: Speed Rating. The speed rat-

ing denotes the speed at which a

tire is designed to be driven for

extended periods of time. The

ratings range from "A" to "Z" (98

to 186 MPH).

3. TIN (Tire Identification Number) for

new tire (example: DOT XX XX

XXX XXXX)

o DOT: Abbreviation for the "De-

partment of Transportation". The

symbol can be placed above, be-

low or to the left or right of the Tire

Identification Number. Indicates

tire is in compliance with the U.S.

Department of Transportation

Motor Vehicle Safety Standards.

o 1st two-digit code: Manufacturer's

identification mark

o 2nd two-digit code: Tire size

o 3rd three-digit code: Tire type code

(Optional)

o 4th four-digit code: Date of Manu-

factureo Four numbers represent the week

and year the tire was built. For

example, the numbers 3105

means the 31st week of 2005.

4. Tire ply composition and mate-

rial

The number of layers or plies of

rubbercoated fabric in the tire. Tire

manufacturers also must indicate

the materials in the tire, which in-

clude steel, nylon, polyester, and

others. The letter "R" means radial

ply construction; the letter "D" means

diagonal or bias ply construction;

and the letter "B" means belted-bias

ply construction.

5. Maximum permissible inflation

pressure

This number is the greatest amount

of air pressure that should be put in

the tire. Do not exceed the maxi-

mum permissible inflation pressure.

Refer to the Tire and Loading Infor-

mation label for recommended infla-

tion pressure.