Hyundai Accent 2012 Owner's Manual - RHD (UK. Australia)

Manufacturer: HYUNDAI, Model Year: 2012, Model line: Accent, Model: Hyundai Accent 2012Pages: 367, PDF Size: 25.39 MB

Page 281 of 367

711

Maintenance

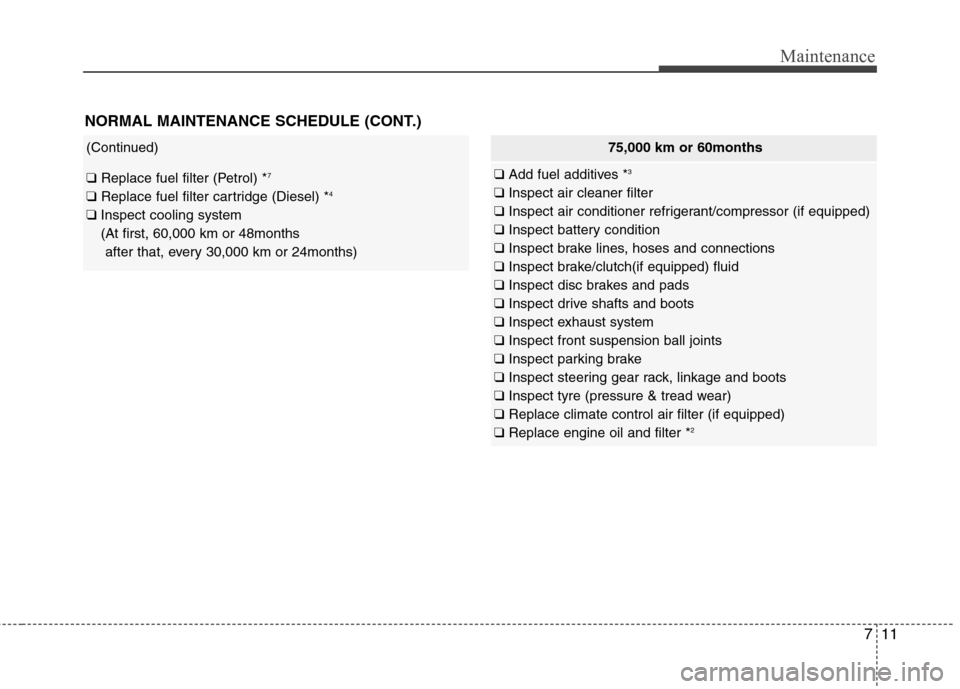

NORMAL MAINTENANCE SCHEDULE (CONT.)

(Continued)

❑ Replace fuel filter (Petrol) * 7

❑ Replace fuel filter cartridge (Diesel) * 4

❑ Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

75,000 km or 60months

❑ Add fuel additives * 3

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 2

Page 282 of 367

Maintenance

12

7

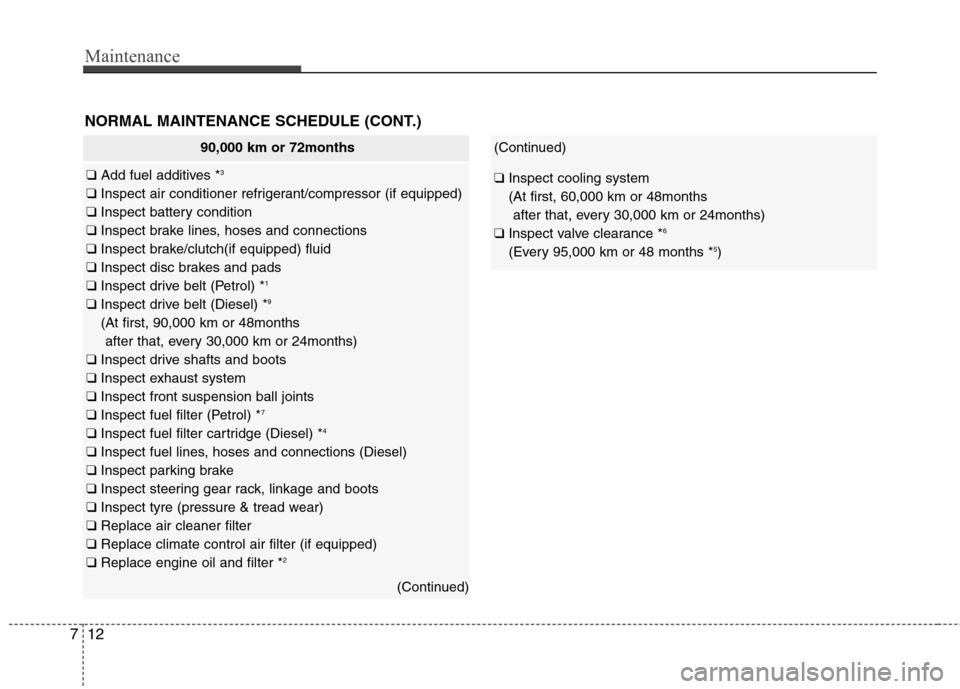

NORMAL MAINTENANCE SCHEDULE (CONT.)

90,000 km or 72months

❑ Add fuel additives * 3

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 1

❑ Inspect drive belt (Diesel) * 9

(At first, 90,000 km or 48months after that, every 30,000 km or 24months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Petrol) * 7

❑ Inspect fuel filter cartridge (Diesel) * 4

❑ Inspect fuel lines, hoses and connections (Diesel)

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace air cleaner filter

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 2

(Continued)

(Continued)

❑

Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

❑ Inspect valve clearance * 6

(Every 95,000 km or 48 months * 5

)

Page 283 of 367

713

Maintenance

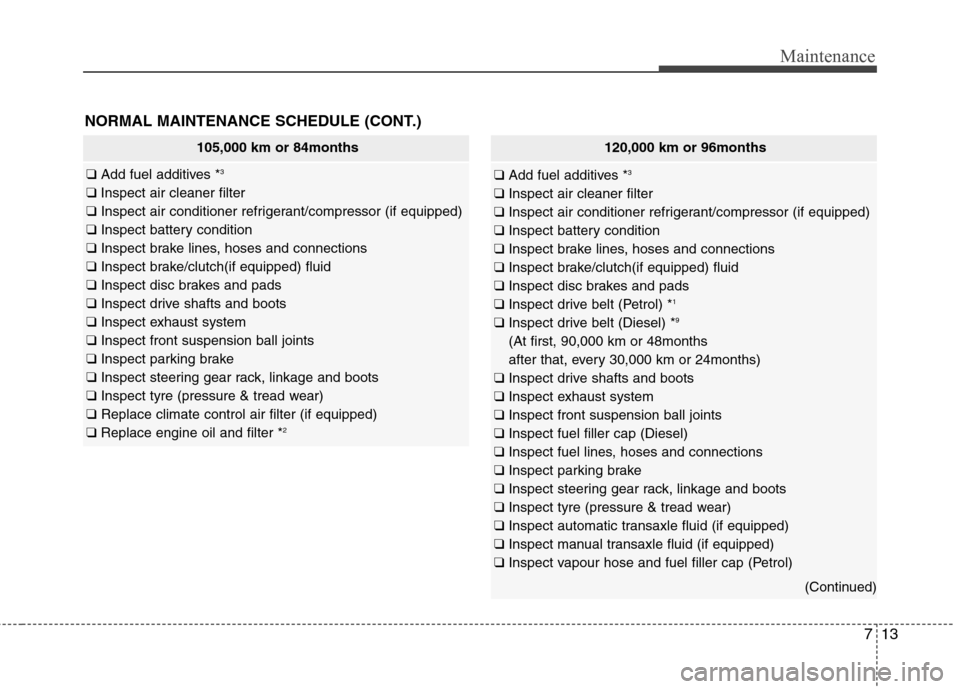

NORMAL MAINTENANCE SCHEDULE (CONT.)

105,000 km or 84months

❑ Add fuel additives * 3

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 2

120,000 km or 96months

❑

Add fuel additives * 3

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 1

❑ Inspect drive belt (Diesel) * 9

(At first, 90,000 km or 48months

after that, every 30,000 km or 24months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filler cap (Diesel)

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect automatic transaxle fluid (if equipped)

❑ Inspect manual transaxle fluid (if equipped)

❑ Inspect vapour hose and fuel filler cap (Petrol)

(Continued)

Page 284 of 367

Maintenance

14

7

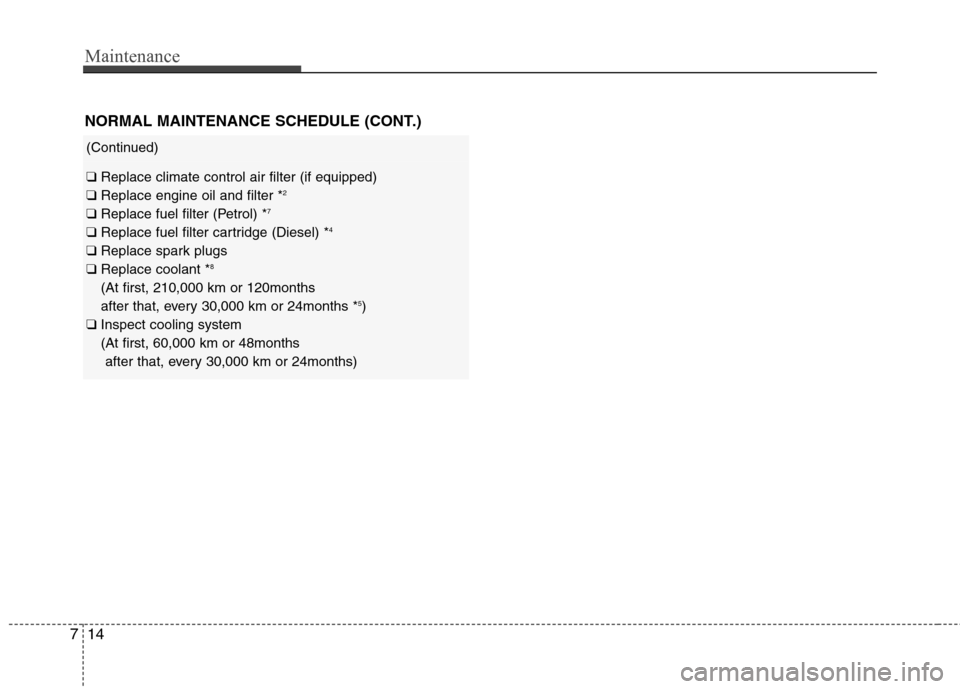

NORMAL MAINTENANCE SCHEDULE (CONT.)

(Continued)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 2

❑ Replace fuel filter (Petrol) * 7

❑ Replace fuel filter cartridge (Diesel) * 4

❑ Replace spark plugs

❑ Replace coolant * 8

(At first, 210,000 km or 120months

after that, every 30,000 km or 24months * 5

)

❑ Inspect cooling system

(At first, 60,000 km or 48months

after that, every 30,000 km or 24months)

Page 285 of 367

715

Maintenance

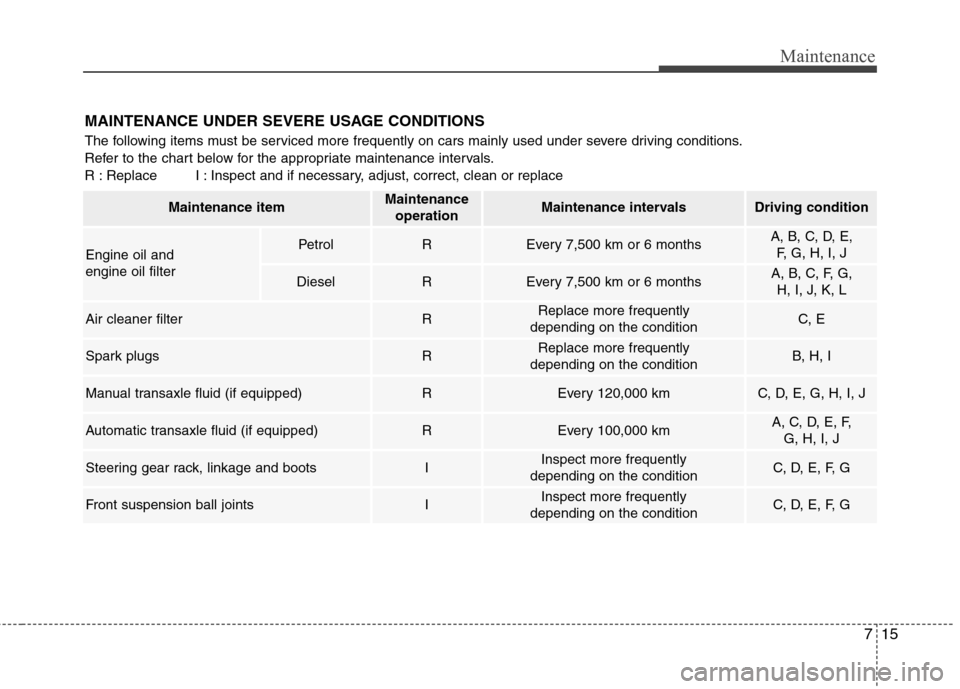

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenanceoperationMaintenance intervalsDriving condition

Engine oil and engine oil filterPetrolREvery 7,500 km or 6 monthsA, B, C, D, E, F, G, H, I, J

DieselREvery 7,500 km or 6 monthsA, B, C, F, G, H, I, J, K, L

Air cleaner filterRReplace more frequently

depending on the conditionC, E

Spark plugs RReplace more frequently

depending on the conditionB, H, I

Manual transaxle fluid (if equipped)REvery 120,000 kmC, D, E, G, H, I, J

Automatic transaxle fluid (if equipped)REvery 100,000 kmA, C, D, E, F, G, H, I, J

Steering gear rack, linkage and bootsIInspect more frequently

depending on the conditionC, D, E, F, G

Front suspension ball jointsIInspect more frequently

depending on the conditionC, D, E, F, G

Page 286 of 367

Maintenance

16

7

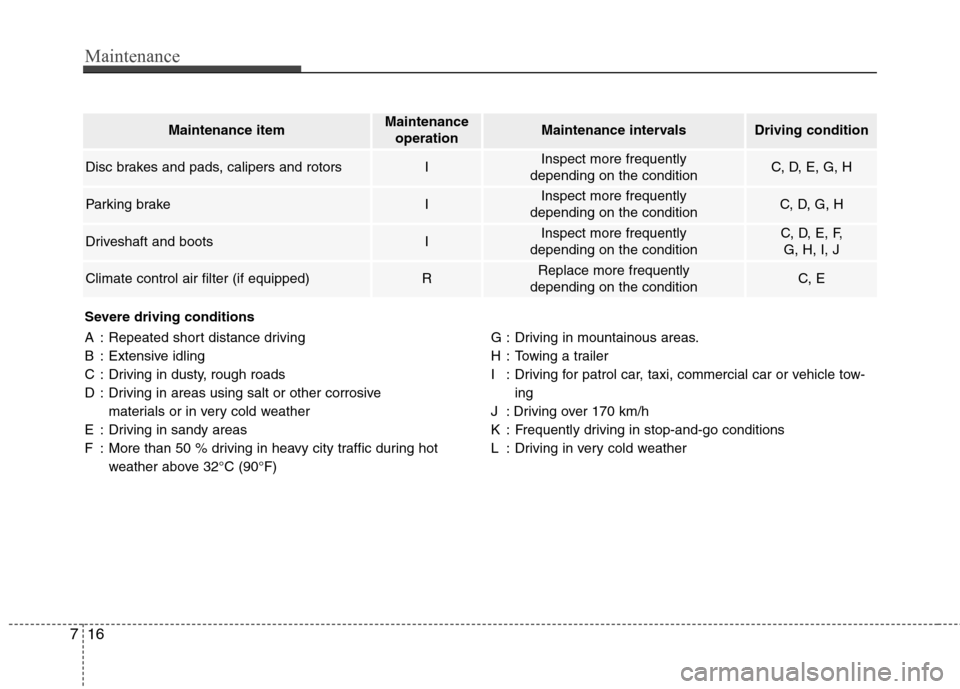

Severe driving conditions

A : Repeated short distance driving

B : Extensive idling

C : Driving in dusty, rough roads

D : Driving in areas using salt or other corrosive

materials or in very cold weather

E : Driving in sandy areas

F : More than 50 % driving in heavy city traffic during hot weather above 32°C (90°F) G : Driving in mountainous areas.

H : Towing a trailer

I : Driving for patrol car, taxi, commercial car or vehicle tow-

ing

J : Driving over 170 km/h

K : Frequently driving in stop-and-go conditions

L : Driving in very cold weather

Maintenance itemMaintenance operationMaintenance intervalsDriving condition

Disc brakes and pads, calipers and rotorsIInspect more frequently

depending on the conditionC, D, E, G, H

Parking brakeIInspect more frequently

depending on the conditionC, D, G, H

Driveshaft and bootsIInspect more frequently

depending on the conditionC, D, E, F, G, H, I, J

Climate control air filter (if equipped)RReplace more frequently

depending on the conditionC, E

Page 287 of 367

717

Maintenance

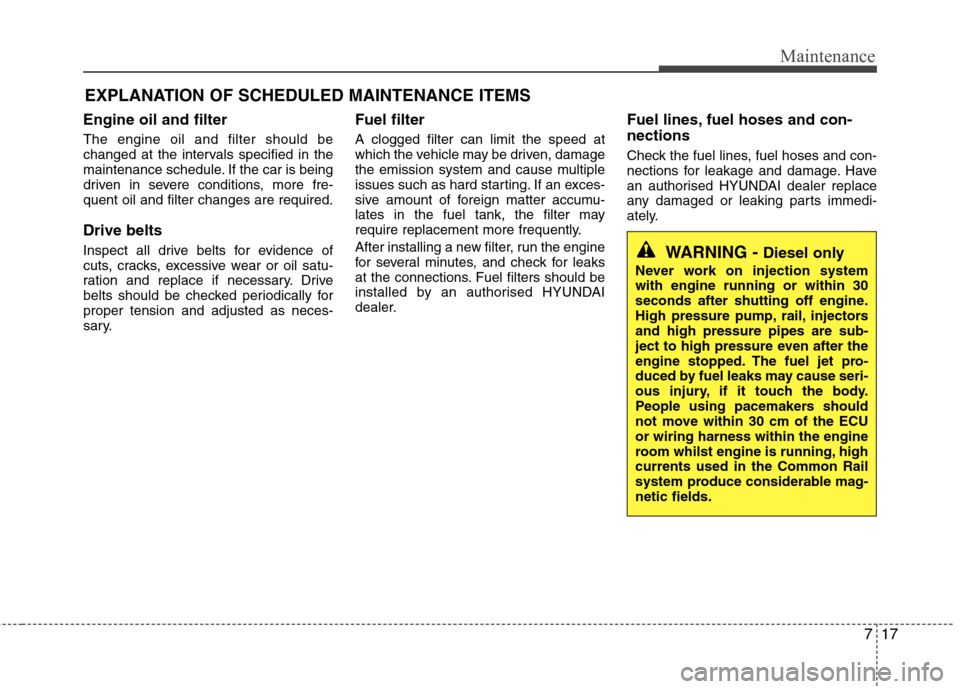

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically forproper tension and adjusted as neces-

sary. Fuel filter A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorised HYUNDAI

dealer.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorised HYUNDAI dealer replace

any damaged or leaking parts immedi-

ately.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move within 30 cm of the ECUor wiring harness within the engine

room whilst engine is running, highcurrents used in the Common Rail

system produce considerable mag-netic fields.

Page 288 of 367

Maintenance

18

7

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage. Air cleaner filter

A Genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range.

Valve clearance

(for petrol engine)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorised HYUNDAI dealer should

perform the operation. Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.

Page 289 of 367

719

Maintenance

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately. Brake fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4specification.

Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables.

Brake discs, pads, calipers and

rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts. Drive shafts and boots

Check the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.

Air conditioning refrigerant (if equipped)

Check the air conditioning lines and con-

nections for leakage and damage.

Page 290 of 367

Maintenance

20

7

ENGINE OIL

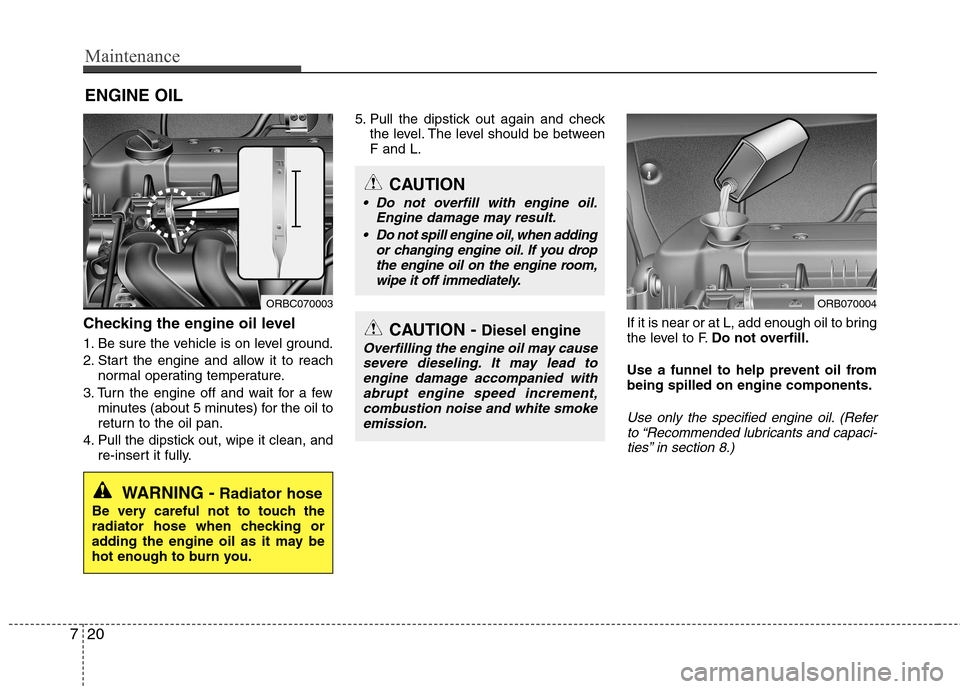

Checking the engine oil level

1. Be sure the vehicle is on level ground.

2. Start the engine and allow it to reach normal operating temperature.

3. Turn the engine off and wait for a few minutes (about 5 minutes) for the oil to

return to the oil pan.

4. Pull the dipstick out, wipe it clean, and re-insert it fully. 5. Pull the dipstick out again and check

the level. The level should be betweenF and L.

If it is near or at L, add enough oil to bring

the level to F.Do not overfill.

Use a funnel to help prevent oil frombeing spilled on engine components.

Use only the specified engine oil. (Refer to “Recommended lubricants and capaci- ties” in section 8.)

WARNING - Radiator hose

Be very careful not to touch the

radiator hose when checking or

adding the engine oil as it may be

hot enough to burn you.

ORBC070003

CAUTION

Do not overfill with engine oil. Engine damage may result.

Do not spill engine oil, when adding or changing engine oil. If you dropthe engine oil on the engine room,wipe it off immediately.

ORB070004

CAUTION - Diesel engine

Overfilling the engine oil may cause

severe dieseling. It may lead toengine damage accompanied with

abrupt engine speed increment,combustion noise and white smoke emission.