valve Hyundai Accent 2012 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2012, Model line: Accent, Model: Hyundai Accent 2012Pages: 370

Page 256 of 370

What to do in an emergency

10

6

Changing a tire with TPMS

If you have a flat tire, the Low Tire

Pressure will come on. Have the flat

tire repaired by an authorized

HYUNDAI dealer as soon as possi-

ble or replace the flat tire with the

spare tire. Each wheel is equipped with a tire

pressure sensor mounted inside the

tire behind the valve stem. You must

use TPMS specific wheels. It is rec-

ommended that you always have

your tires serviced by an authorized

HYUNDAI dealer.

Even if you replace the low pressure

tire with the spare tire, the Low Tire

Pressure Telltale will blink or remain

on until the low pressure tire is

repaired and placed on the vehicle.

After you replace the low pressure

tire with the spare tire, the Low Tire

Pressure Telltale may blink or illumi-

nate after a few minutes because the

TPMS sensor mounted on the spare

wheel is not initiated.

Once the low pressure tire is reinflat-

ed to the recommended pressure

and installed on the vehicle or the

TPMS sensor mounted on the

replaced spare wheel is initiated by

an authorized HYUNDAI dealer, the

TPMS malfunction indicator and the

low tire pressure telltale will extin-

guish within a few minutes of driving.

If the indicator is not extinguished

after a few minutes of driving, please

visit an authorized HYUNDAI dealer.CAUTION

If original mounted tire is

replaced with the spare tire, theTPMS sensor on the replacedspare wheel should be initiatedand the TPMS sensor on theoriginal mounted wheel shouldbe deactivated by a HYUNDAIdealer. If the TPMS sensor on theoriginal mounted wheel locatedin the spare tire carrier still acti-vates, the tire pressure monitor-ing system may not operateproperly. Have the tire with TPMSserviced or replaced by anauthorized HYUNDAI dealer.

CAUTION

Never use a puncture-repairingagent not approved by HYUNDAIto repair and/or inflate a lowpressure tire. The tire sealant notapproved by HYUNDAI may dam-age the tire pressure sensor.

The sealant on the tire pressuresensor and wheel shall be elim-inated when you replace the tirewith a new one.

Page 263 of 370

617

What to do in an emergency

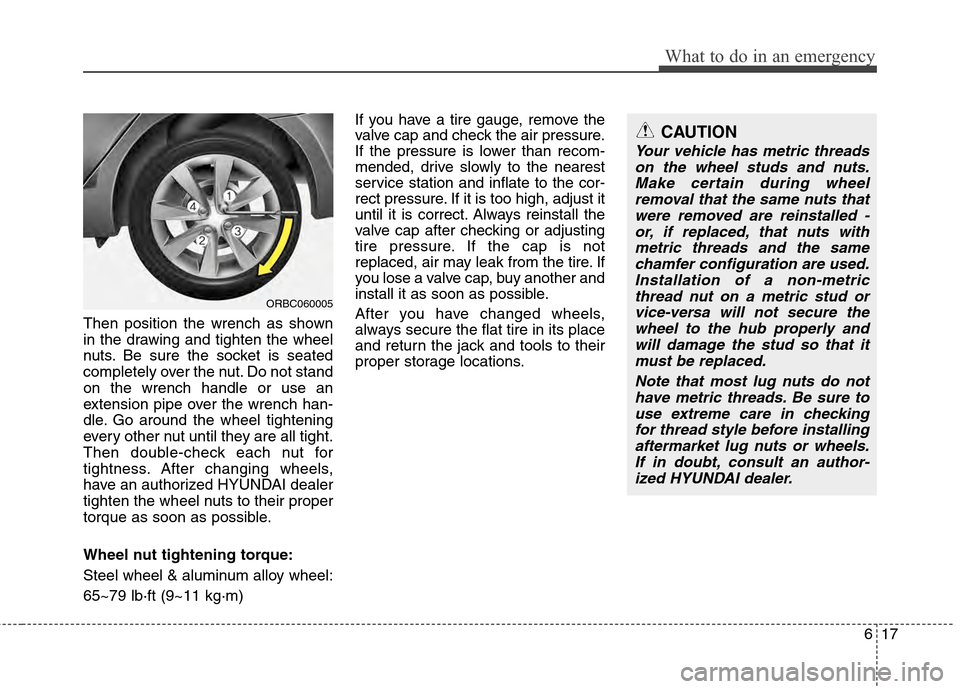

Then position the wrench as shown

in the drawing and tighten the wheel

nuts. Be sure the socket is seated

completely over the nut. Do not stand

on the wrench handle or use an

extension pipe over the wrench han-

dle. Go around the wheel tightening

every other nut until they are all tight.

Then double-check each nut for

tightness. After changing wheels,

have an authorized HYUNDAI dealer

tighten the wheel nuts to their proper

torque as soon as possible.

Wheel nut tightening torque:

Steel wheel & aluminum alloy wheel:

65~79 lb·ft (9~11 kg·m)If you have a tire gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust it

until it is correct. Always reinstall the

valve cap after checking or adjusting

tire pressure. If the cap is not

replaced, air may leak from the tire. If

you lose a valve cap, buy another and

install it as soon as possible.

After you have changed wheels,

always secure the flat tire in its place

and return the jack and tools to their

proper storage locations.

CAUTION

Your vehicle has metric threads

on the wheel studs and nuts.Make certain during wheelremoval that the same nuts thatwere removed are reinstalled -or, if replaced, that nuts withmetric threads and the samechamfer configuration are used.Installation of a non-metricthread nut on a metric stud orvice-versa will not secure thewheel to the hub properly andwill damage the stud so that itmust be replaced.

Note that most lug nuts do nothave metric threads. Be sure touse extreme care in checkingfor thread style before installingaftermarket lug nuts or wheels.If in doubt, consult an author-ized HYUNDAI dealer.

ORBC060005

Page 269 of 370

623

What to do in an emergency

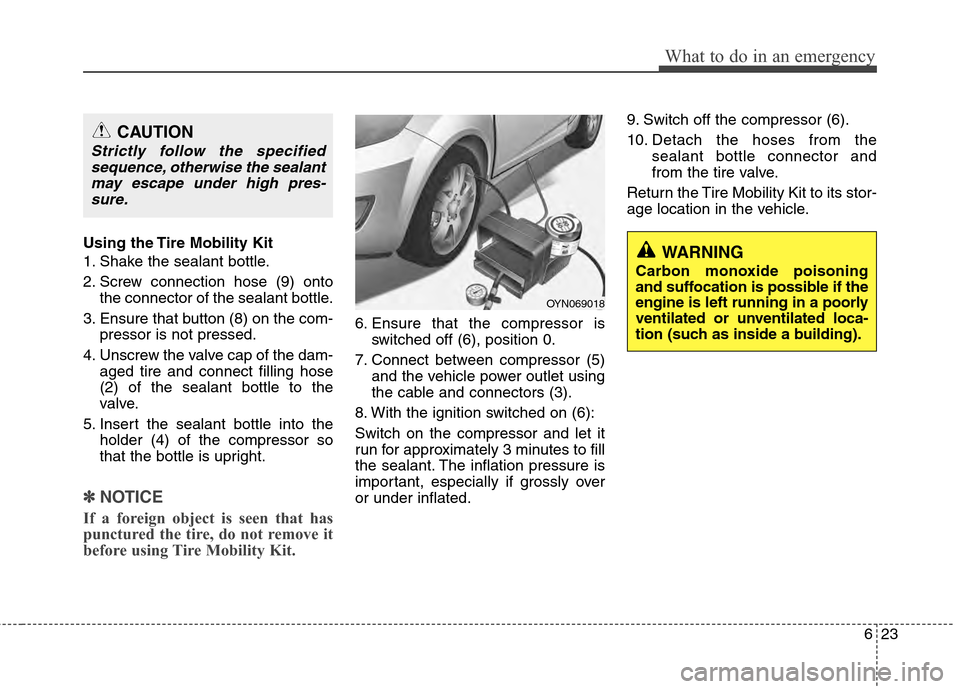

Using the Tire Mobility Kit

1. Shake the sealant bottle.

2. Screw connection hose (9) ontothe connector of the sealant bottle.

3. Ensure that button (8) on the com- pressor is not pressed.

4. Unscrew the valve cap of the dam- aged tire and connect filling hose

(2) of the sealant bottle to the

valve.

5. Insert the sealant bottle into the holder (4) of the compressor so

that the bottle is upright.

✽ ✽NOTICE

If a foreign object is seen that has

punctured the tire, do not remove it

before using Tire Mobility Kit.

6. Ensure that the compressor is

switched off (6), position 0.

7. Connect between compressor (5) and the vehicle power outlet using

the cable and connectors (3).

8. With the ignition switched on (6):

Switch on the compressor and let it

run for approximately 3 minutes to fill

the sealant. The inflation pressure is

important, especially if grossly over

or under inflated. 9. Switch off the compressor (6).

10. Detach the hoses from the

sealant bottle connector and

from the tire valve.

Return the Tire Mobility Kit to its stor-

age location in the vehicle.

WARNING

Carbon monoxide poisoning

and suffocation is possible if the

engine is left running in a poorly

ventilated or unventilated loca-

tion (such as inside a building).

OYN069018

CAUTION

Strictly follow the specified sequence, otherwise the sealantmay escape under high pres-sure.

Page 270 of 370

What to do in an emergency

24

6

Distributing the sealant

11. Immediately drive approximately

2 miles (3 km) to evenly distribute

the sealant in the tire. Setting the tire inflation pressure

12. After driving approximately 2

miles (3 km), stop at a suitable

location.

13. Connect connection hose (9) of the compressor directly to the tire

valve.

14. Connect between compressor (5) and the vehicle power outlet using

the cable and connectors (3).

15. Adjust the tire inflation pressure to 32 psi (220 kPa). With the igni-

tion switched on, proceed as fol-

lows.

- To increase the inflation pres- sure: Switch on the compressor

(6), position I. To check the cur-

rent inflation pressure setting,

briefly switch off the compressor. ✽ ✽

NOTE

The pressure gauge may show high-

er than actual reading when the

compressor is running. To get an

accurate tire reading, the compres-

sor needs to be turned off.

- To reduce the inflation pres- sure: Press the button (8) on the

compressor.

16. Remove the speed restriction label(0) from the sealant bottle(1)

and place it in a highly visible

place in the vehicle such as on

the steering wheel to remind you

not to drive too fast.

WARNING

Do not let the compressor run for

more than 10 minutes, otherwise

the device will overheat and may

be damaged.

CAUTION

Do not exceed a speed of 35mph (60 km/h). If possible, donot fall below a speed of 12 mph(20 km/h).

While driving, if you experienceany unusual vibration, ride dis-turbance or noise, reduce yourspeed and drive with cautionuntil you can safely pull off ofthe side of the road.

Call for road side service or tow-ing.

CAUTION

Be careful not to overinflate thetire and stay away from the tirewhen filling it.

Page 285 of 370

Maintenance

10

7

60,000 miles (96,000 km) or 48 months

❑ Rotate tire

❑Inspect battery condition

❑Inspect vacuum hose

❑Inspect air conditioning refrigerant

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers

❑Inspect rear brake disc/pads (if equipped)

❑Inspect rear brake drums/linings (if equipped)

❑Inspect steering gear box, linkage & boots/lower arm ball joint,

upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect brake/clutch (if equipped) fluid

❑Inspect fuel filter *1

❑Inspect fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *1

❑Inspect parking brake

❑Inspect vapor hose and fuel filler cap

❑Inspect drive belts *2

(First, 60,000 miles (96,000 km) or 72 months

after every 15,000 miles (24,000 km) or 24 months)

❑ Inspect valve clearance

(Continued)

67,500 miles (108,000 km) or 54 months

❑Rotate tire

❑Inspect battery condition

❑Inspect air cleaner filter

❑Inspect vacuum hose

❑Replace engine oil and filter

(67,500 miles (108,000 km) or 108 months)

❑Add Fuel Additive *3

NORMAL MAINTENANCE SCHEDULE (CONT.)

*1: Fuel filter & Fuel tank air filter are considered to be maintenance free\

but

periodic inspection is recommended for this maintenance schedule depends

on fuel quality. If there are some important safety matters like fuel flow

restriction, surging, loss of power, hard starting problem etc, replace the fuel

filter immediately regardless of maintenance schedule and consult an

authorized HYUNDAI dealer for details.

*

2: The drive belt should be replaced when cracks occur or tension is reduced excessively.

*

3: If TOP TIER Detergent Gasoline is not available, one bottle of additive is rec- ommended. Additives are available from your authorized HYUNDAI dealer

along with information on how to use them. Do not mix other additives.

(Continued)

❑ Replace climate control air filter (for evaporator and blower unit)

❑Replace air cleaner filter

❑Replace engine oil and filter

(60,000 miles (96,000 km) or 96 months)

❑Add Fuel Additive *3

Page 289 of 370

Maintenance

14

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

120,000 miles (192,000 km) or 96 months

❑ Rotate tire

❑Inspect battery condition

❑Inspect vacuum hose

❑Inspect air conditioning refrigerant

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers

❑Inspect rear brake disc/pads (if equipped)

❑Inspect rear brake drums/linings (if equipped)

❑Inspect steering gear box, linkage & boots/lower arm ball joint,

upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect brake/clutch (if equipped) fluid

❑Inspect fuel filter *1

❑Inspect fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *1

❑Inspect parking brake

❑Inspect vapor hose and fuel filler cap

❑Inspect drive belts *2

(First, 60,000 miles (96,000 km) or 72 months

after every 15,000 miles (24,000 km) or 24 months)

❑ Inspect valve clearance

❑Replace climate control air filter (for evaporator and blower unit)

(Continued)

*1: Fuel filter & Fuel tank air filter are considered to be maintenance free\

but

periodic inspection is recommended for this maintenance schedule depends

on fuel quality. If there are some important safety matters like fuel flow

restriction, surging, loss of power, hard starting problem etc, replace the fuel

filter immediately regardless of maintenance schedule and consult an

authorized HYUNDAI dealer for details.

*

2: The drive belt should be replaced when cracks occur or tension is reduced excessively.

*

3: If TOP TIER Detergent Gasoline is not available, one bottle of additive is rec- ommended. Additives are available from your authorized HYUNDAI dealer

along with information on how to use them. Do not mix other additives.

127,500 miles (204,000 km) or 102 months

❑ Rotate tire

❑Inspect battery condition

❑Inspect air cleaner filter

❑Inspect vacuum hose

❑Replace engine oil and filter

(127,500 miles (204,000 km) or 204 months)

❑Add Fuel Additive *3

(Continued)

❑ Replace air cleaner filter

❑Replace engine oil and filter

(120,000 miles (192,000 km) or 192 months)

❑Replace coolant (First, 120,000 miles (192,000 km) or 120 months

after every 30,000 miles (48,000 km) or 24 months)

❑Add Fuel Additive *3

Page 294 of 370

719

Maintenance

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is

recommended when the filter is

replaced.

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Automatic transaxle fluid

(if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, the fluid should

be changed at an authorized HYUNDAI

dealer in accordance to the scheduled

maintenance at the beginning of this

chapter.

✽ ✽NOTICE

Automatic transaxle fluid color is basi-

cally red.

As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.

It is normal condition and you should

not judge the need to replace the fluid

based upon the changed color.

Manual transaxle fluid

(if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake/clutch fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4

specification.

Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized HYUNDAI dealer should

perform the operation.

CAUTION

The use of a non-specified fluid

could result in transaxle malfunc-tion and failure.

Use only specified automatictransaxle fluid. (Refer to“Recommended lubricants andcapacities” in section 8.)

Page 313 of 370

Maintenance

38

7

Checking tire inflation pressure

Check your tires once a month or

more.

Also, check the tire pressure of the

spare tire.

How to check

Use a good quality gage to check tire

pressure. You can not tell if your tires

are properly inflated simply by look-

ing at them. Radial tires may look

properly inflated even when they're

underinflated.

Check the tire's inflation pressure

when the tires are cold. - "Cold"

means your vehicle has been sitting

for at least three hours or driven no

more than 1 mile (1.6 km).

WARNING - Tire Inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

CAUTION - Tire pressure

Always observe the following:

Check tire pressure when the tires are cold. (After vehiclehas been parked for at leastthree hours or hasn't beendriven more than one mile (1.6km) since startup.)

Check the pressure of your spare tire each time you checkthe pressure of other tires.

Never overload your vehicle. Be careful not to overload avehicle luggage rack if yourvehicle is equipped with one.

Worn, old tires can cause acci- dents. If your tread is badlyworn, or if your tires havebeen damaged, replace them.

CAUTION

Warm tires normally exceed recommended cold tire pres-sures by 4 to 6 psi (28 to 41kPa). Do not release air fromwarm tires to adjust the pres-sure or the tires will be under-inflated.

Be sure to reinstall the tire inflation valve caps. Withoutthe valve cap, dirt or moisturecould get into the valve coreand cause air leakage. If avalve cap is missing, install anew one as soon as possible.

Page 314 of 370

739

Maintenance

Remove the valve cap from the tire

valve stem. Press the tire gage firm-

ly onto the valve to get a pressure

measurement. If the cold tire inflation

pressure matches the recommended

pressure on the tire and loading

information label, no further adjust-

ment is necessary. If the pressure is

low, add air until you reach the rec-

ommended amount.

If you overfill the tire, release air by

pushing on the metal stem in the

center of the tire valve. Recheck the

tire pressure with the tire gage. Be

sure to put the valve caps back on

the valve stems. They help prevent

leaks by keeping out dirt and mois-

ture.Tire rotation

To equalize tread wear, it is recom-

mended that the tires be rotated

every 7,500 miles (12,000 km) or

sooner if irregular wear develops.

During rotation, check the tires for

correct balance.

When rotating tires, check for uneven

wear and damage. Abnormal wear is

usually caused by incorrect tire pres-

sure, improper wheel alignment, out-

of-balance wheels, severe braking or

severe cornering. Look for bumps or

bulges in the tread or side of tire.

Replace the tire if you find either of

these conditions. Replace the tire if

fabric or cord is visible. After rotation,

be sure to bring the front and rear tire

pressures to specification and check

lug nut tightness.

WARNING

Inspect your tires frequently

for proper inflation as well as

wear and damage. Always use

a tire pressure gauge.

Tires with too much or too little pressure wear unevenly caus-

ing poor handling, loss of vehi-

cle control, and sudden tire

failure leading to accidents,

injuries, and even death. The

recommended cold tire pres-

sure for your vehicle can be

found in this manual and on

the tire label located on the dri-

ver's side center pillar.

Worn tires can cause acci- dents. Replace tires that are

worn, show uneven wear, or

are damaged.

Remember to check the pres- sure of your spare tire.

HYUNDAI recommends that

you check the spare every

time you check the pressure

of the other tires on your vehi-

cle.

Page 332 of 370

757

Maintenance

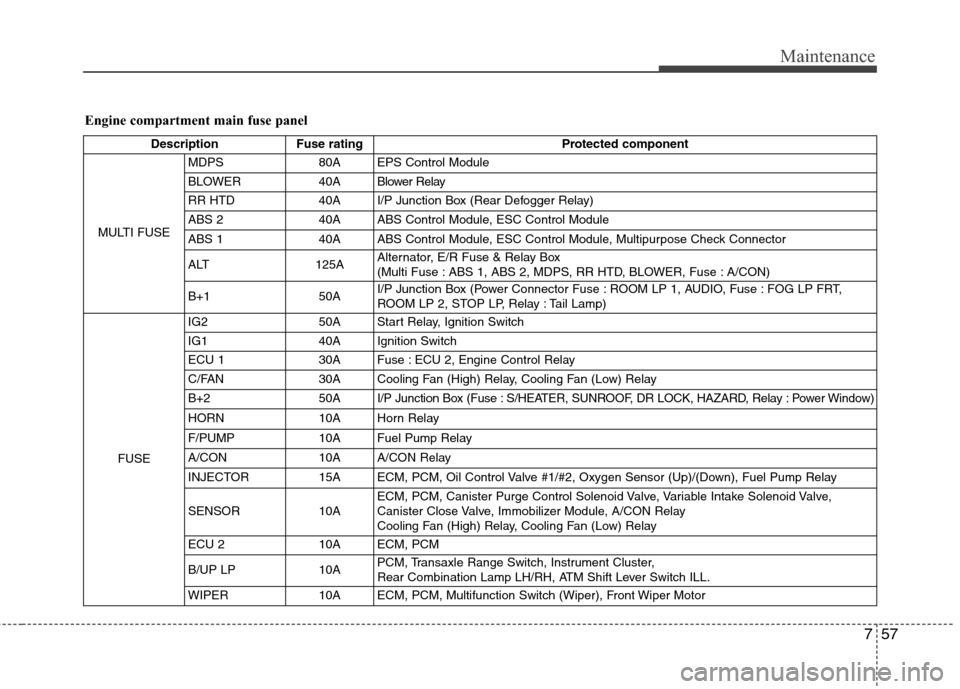

Engine compartment main fuse panel

DescriptionFuse rating Protected component

MULTI FUSE MDPS

80A EPS Control Module

BLOWER 40A Blower Relay

RR HTD 40A I/P Junction Box (Rear Defogger Relay)

ABS 2 40A ABS Control Module, ESC Control Module

ABS 1 40A ABS Control Module, ESC Control Module, Multipurpose Check Connector

ALT 125AAlternator, E/R Fuse & Relay Box

(Multi Fuse : ABS 1, ABS 2, MDPS, RR HTD, BLOWER, Fuse : A/CON)

B+1 50AI/P Junction Box (Power Connector Fuse : ROOM LP 1, AUDIO, Fuse : FOG LP FRT,

ROOM LP 2, STOP LP, Relay : Tail Lamp)

FUSE

IG250AStart Relay, Ignition Switch

IG140AIgnition Switch

ECU 1 30A Fuse : ECU 2, Engine Control Relay

C/FAN 30A Cooling Fan (High) Relay, Cooling Fan (Low) Relay

B+2 50A I/P Junction Box (Fuse : S/HEATER, SUNROOF, DR LOCK, HAZARD, Relay : Power Window)

HORN 10A Horn Relay

F/PUMP 10A Fuel Pump Relay

A/CON 10A A/CON Relay

INJECTOR 15A ECM, PCM, Oil Control Valve #1/#2, Oxygen Sensor (Up)/(Down), Fuel Pump Relay

SENSOR 10A ECM, PCM, Canister Purge Control Solenoid Valve, Variable Intake Solenoid Valve,

Canister Close Valve, Immobilizer Module, A/CON Relay

Cooling Fan (High) Relay, Cooling Fan (Low) Relay

ECU 2 10A ECM, PCM

B/UP LP 10A PCM, Transaxle Range Switch, Instrument Cluster,

Rear Combination Lamp LH/RH, ATM Shift Lever Switch ILL.

WIPER 10A ECM, PCM, Multifunction Switch (Wiper), Front Wiper Motor