oil pressure Hyundai Accent 2016 - RHD (UK. Australia) User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: Accent, Model: Hyundai Accent 2016Pages: 425, PDF Size: 8.62 MB

Page 342 of 425

Maintenance

14 7

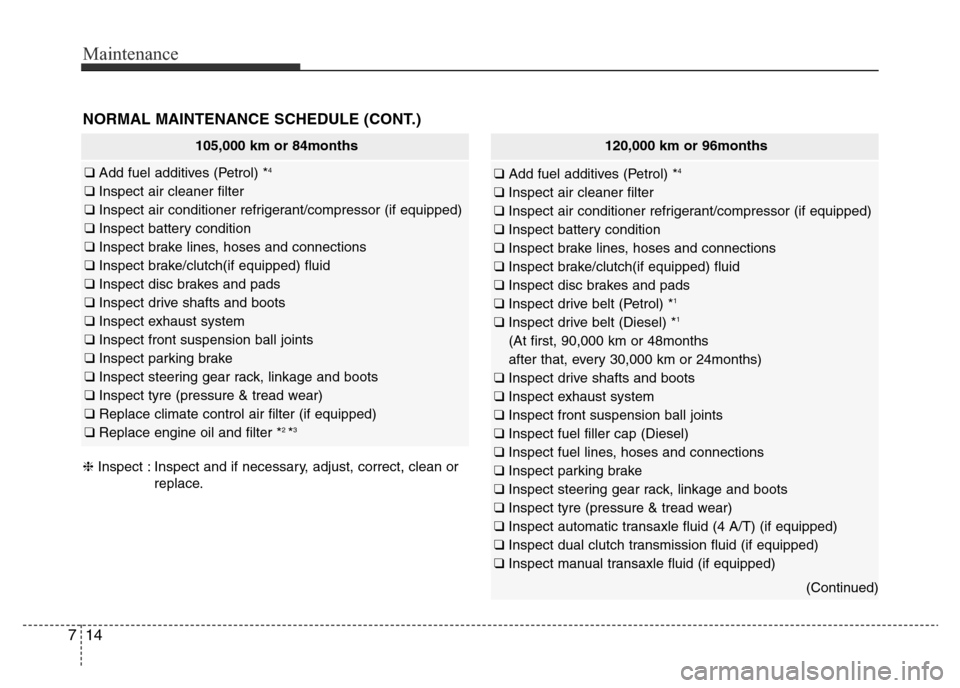

NORMAL MAINTENANCE SCHEDULE (CONT.)

105,000 km or 84months

❑ Add fuel additives (Petrol) *4

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter *

2 *3

120,000 km or 96months

❑ Add fuel additives (Petrol) *4

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) *

1

❑ Inspect drive belt (Diesel) *1

(At first, 90,000 km or 48months

after that, every 30,000 km or 24months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filler cap (Diesel)

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect automatic transaxle fluid (4 A/T) (if equipped)

❑ Inspect dual clutch transmission fluid (if equipped)

❑ Inspect manual transaxle fluid (if equipped)

(Continued)

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 346 of 425

Maintenance

18 7

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorised HYUNDAI

dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorised HYUNDAI dealer replace

any damaged or leaking parts immedi-

ately.

WARNING - Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectors

and high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move within 30 cm of the ECU

or wiring harness within the engine

room whilst engine is running, high

currents used in the Common Rail

system produce considerable mag-

netic fields.

CAUTION

When you are inspecting the belt,

place the ignition switch in the

LOCK/OFF or ACC position.

Page 393 of 425

765

Maintenance

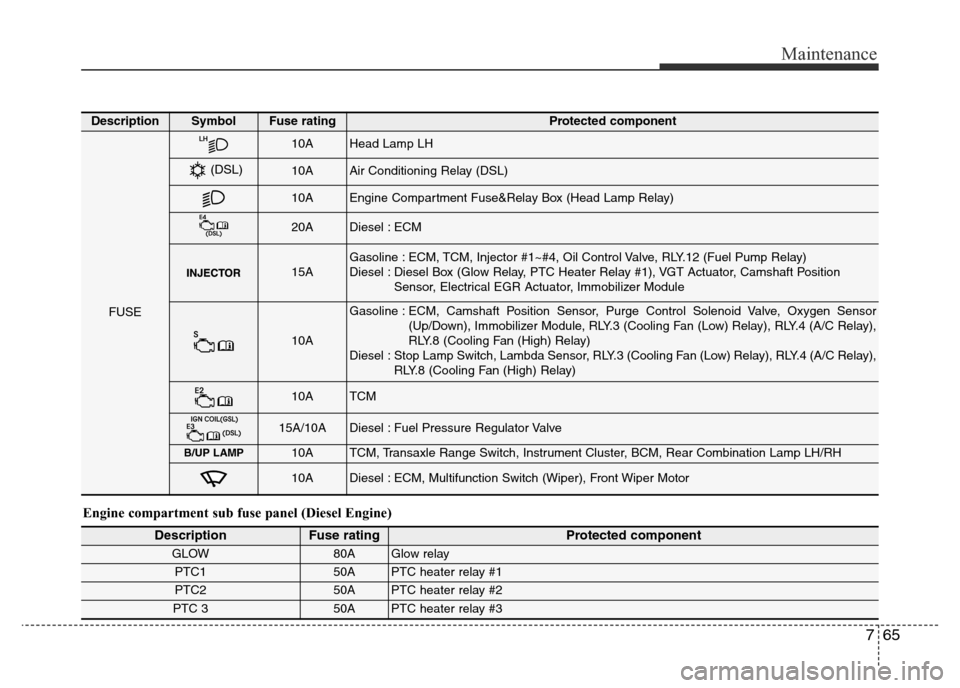

Engine compartment sub fuse panel (Diesel Engine)

DescriptionFuse ratingProtected component

GLOW80A Glow relay

PTC150A PTC heater relay #1

PTC250A PTC heater relay #2

PTC 350A PTC heater relay #3

DescriptionSymbolFuse ratingProtected component

FUSE

10AHead Lamp LH

10AAir Conditioning Relay (DSL)

10AEngine Compartment Fuse&Relay Box (Head Lamp Relay)

20ADiesel : ECM

15AGasoline : ECM, TCM, Injector #1~#4, Oil Control Valve, RLY.12 (Fuel Pump Relay)

Diesel : Diesel Box (Glow Relay, PTC Heater Relay #1), VGT Actuator, Camshaft Position

Sensor, Electrical EGR Actuator, Immobilizer Module

10A

Gasoline : ECM, Camshaft Position Sensor, Purge Control Solenoid Valve, Oxygen Sensor

(Up/Down), Immobilizer Module, RLY.3 (Cooling Fan (Low) Relay), RLY.4 (A/C Relay),

RLY.8 (Cooling Fan (High) Relay)

Diesel : Stop Lamp Switch, Lambda Sensor, RLY.3 (Cooling Fan (Low) Relay), RLY.4 (A/C Relay),

RLY.8 (Cooling Fan (High) Relay)

10ATCM

15A/10ADiesel : Fuel Pressure Regulator Valve

B/UP LAMP10ATCM, Transaxle Range Switch, Instrument Cluster, BCM, Rear Combination Lamp LH/RH

10ADiesel : ECM, Multifunction Switch (Wiper), Front Wiper Motor

(DSL)

Page 409 of 425

781

Maintenance

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

CAUTION

• Wiping dust or dirt off the body

with a dry cloth will scratch the

finish.

• Do not use steel wool, abrasive

cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated

or anodized aluminum parts. This

may result in damage to the pro-

tective coating and cause discol-

oration or paint deterioration.

CAUTION

• Water washing in the engine com-

partment including high pressure

water washing may cause the fail-

ure of electrical circuits or engine

and related part located in the

engine compartment.

• Never allow water or other liquids

to come in contact with electri-

cal/electronic components and

air duct inside the vehicle as this

may damage them.

OJB037800