Hyundai Atos 2002 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2002, Model line: Atos, Model: Hyundai Atos 2002Pages: 249, PDF Size: 3.11 MB

Page 231 of 249

DO-IT-YOURSELF MAINTENANCE 6-13

ZG150A1-A

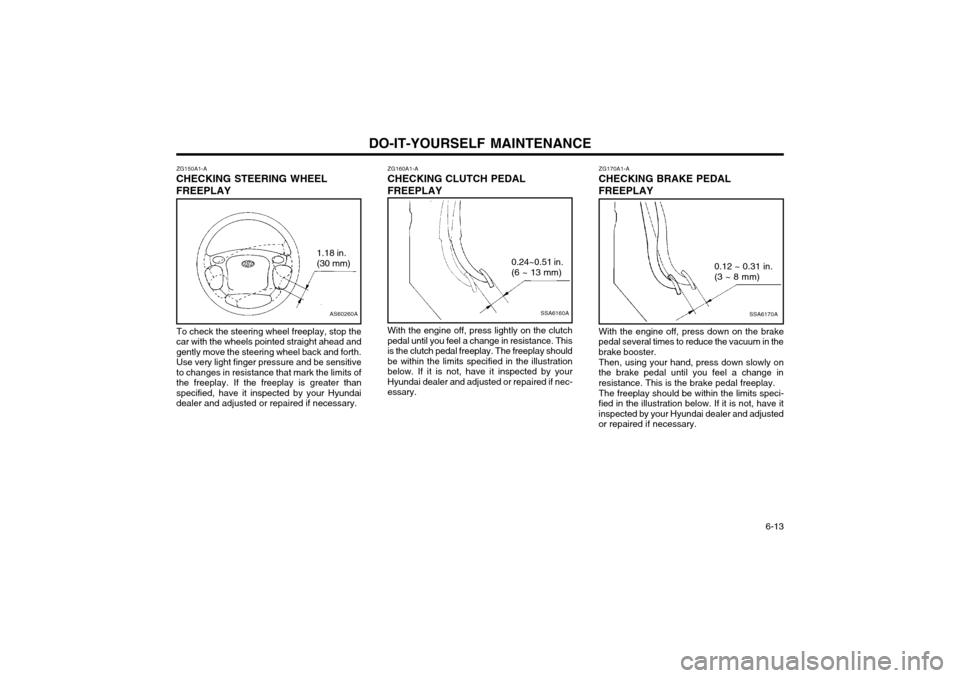

CHECKING STEERING WHEEL FREEPLAY

AS60260A

1.18 in. (30 mm)

To check the steering wheel freeplay, stop the

car with the wheels pointed straight ahead and gently move the steering wheel back and forth.Use very light finger pressure and be sensitiveto changes in resistance that mark the limits ofthe freeplay. If the freeplay is greater thanspecified, have it inspected by your Hyundaidealer and adjusted or repaired if necessary. ZG160A1-A CHECKING CLUTCH PEDAL FREEPLAY

SSA6160A

0.24~0.51 in. (6 ~ 13 mm)

With the engine off, press lightly on the clutch pedal until you feel a change in resistance. Thisis the clutch pedal freeplay. The freeplay shouldbe within the limits specified in the illustrationbelow. If it is not, have it inspected by yourHyundai dealer and adjusted or repaired if nec-essary.

SSA6170A

0.12 ~ 0.31 in. (3 ~ 8 mm)

ZG170A1-A

CHECKING BRAKE PEDAL FREEPLAY

With the engine off, press down on the brake

pedal several times to reduce the vacuum in the brake booster.

Then, using your hand, press down slowly on

the brake pedal until you feel a change inresistance. This is the brake pedal freeplay.

The freeplay should be within the limits speci-

fied in the illustration below. If it is not, have itinspected by your Hyundai dealer and adjustedor repaired if necessary.

Page 232 of 249

DO-IT-YOURSELF MAINTENANCE

6-14 AG200A1-A

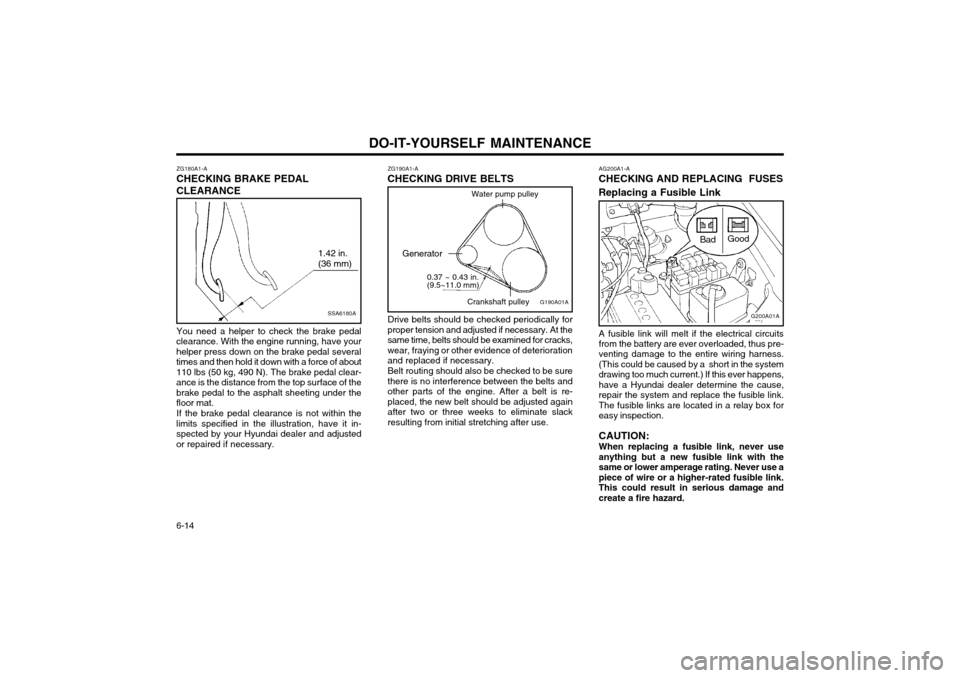

CHECKING AND REPLACING FUSES Replacing a Fusible Link

G200A01A

Bad

Good

A fusible link will melt if the electrical circuits from the battery are ever overloaded, thus pre- venting damage to the entire wiring harness.(This could be caused by a short in the systemdrawing too much current.) If this ever happens,have a Hyundai dealer determine the cause,repair the system and replace the fusible link.The fusible links are located in a relay box foreasy inspection. CAUTION: When replacing a fusible link, never use anything but a new fusible link with thesame or lower amperage rating. Never use apiece of wire or a higher-rated fusible link.This could result in serious damage andcreate a fire hazard.

ZG190A1-A

CHECKING DRIVE BELTS

G190A01A

Water pump pulley

Generator 0.37 ~ 0.43 in. (9.5~11.0 mm) Crankshaft pulley

Drive belts should be checked periodically for proper tension and adjusted if necessary. At thesame time, belts should be examined for cracks,wear, fraying or other evidence of deteriorationand replaced if necessary. Belt routing should also be checked to be sure there is no interference between the belts andother parts of the engine. After a belt is re-placed, the new belt should be adjusted againafter two or three weeks to eliminate slackresulting from initial stretching after use.

ZG180A1-A

CHECKING BRAKE PEDAL CLEARANCE

SSA6180A

1.42 in. (36 mm)

You need a helper to check the brake pedal

clearance. With the engine running, have your helper press down on the brake pedal severaltimes and then hold it down with a force of about110 lbs (50 kg, 490 N). The brake pedal clear-ance is the distance from the top surface of thebrake pedal to the asphalt sheeting under thefloor mat.

If the brake pedal clearance is not within the

limits specified in the illustration, have it in-spected by your Hyundai dealer and adjustedor repaired if necessary.

Page 233 of 249

DO-IT-YOURSELF MAINTENANCE 6-15

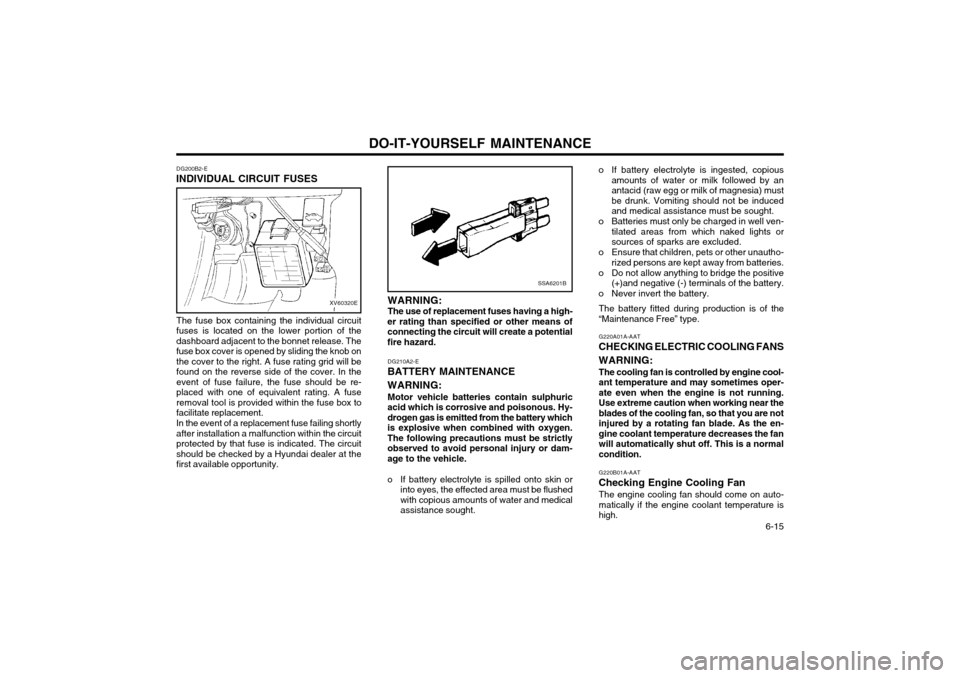

DG200B2-E

INDIVIDUAL CIRCUIT FUSES

XV60320E

The fuse box containing the individual circuit fuses is located on the lower portion of thedashboard adjacent to the bonnet release. Thefuse box cover is opened by sliding the knob onthe cover to the right. A fuse rating grid will befound on the reverse side of the cover. In theevent of fuse failure, the fuse should be re-placed with one of equivalent rating. A fuseremoval tool is provided within the fuse box tofacilitate replacement. In the event of a replacement fuse failing shortly after installation a malfunction within the circuitprotected by that fuse is indicated. The circuitshould be checked by a Hyundai dealer at thefirst available opportunity.

SSA6201B

WARNING: The use of replacement fuses having a high-

er rating than specified or other means of connecting the circuit will create a potentialfire hazard.

DG210A2-E

BATTERY MAINTENANCE WARNING:

Motor vehicle batteries contain sulphuric

acid which is corrosive and poisonous. Hy- drogen gas is emitted from the battery whichis explosive when combined with oxygen.The following precautions must be strictlyobserved to avoid personal injury or dam-age to the vehicle.

o If battery electrolyte is spilled onto skin or into eyes, the effected area must be flushed with copious amounts of water and medicalassistance sought. o If battery electrolyte is ingested, copious

amounts of water or milk followed by anantacid (raw egg or milk of magnesia) mustbe drunk. Vomiting should not be inducedand medical assistance must be sought.

o Batteries must only be charged in well ven- tilated areas from which naked lights orsources of sparks are excluded.

o Ensure that children, pets or other unautho- rized persons are kept away from batteries.

o Do not allow anything to bridge the positive (+)and negative (-) terminals of the battery.

o Never invert the battery.

The battery fitted during production is of the“Maintenance Free” type. G220A01A-AAT

CHECKING ELECTRIC COOLING FANS WARNING:

The cooling fan is controlled by engine cool- ant temperature and may sometimes oper-ate even when the engine is not running.

Use extreme caution when working near theblades of the cooling fan, so that you are notinjured by a rotating fan blade. As the en-

gine coolant temperature decreases the fanwill automatically shut off. This is a normalcondition. G220B01A-AAT

Checking Engine Cooling Fan The engine cooling fan should come on auto- matically if the engine coolant temperature ishigh.

Page 234 of 249

DO-IT-YOURSELF MAINTENANCE

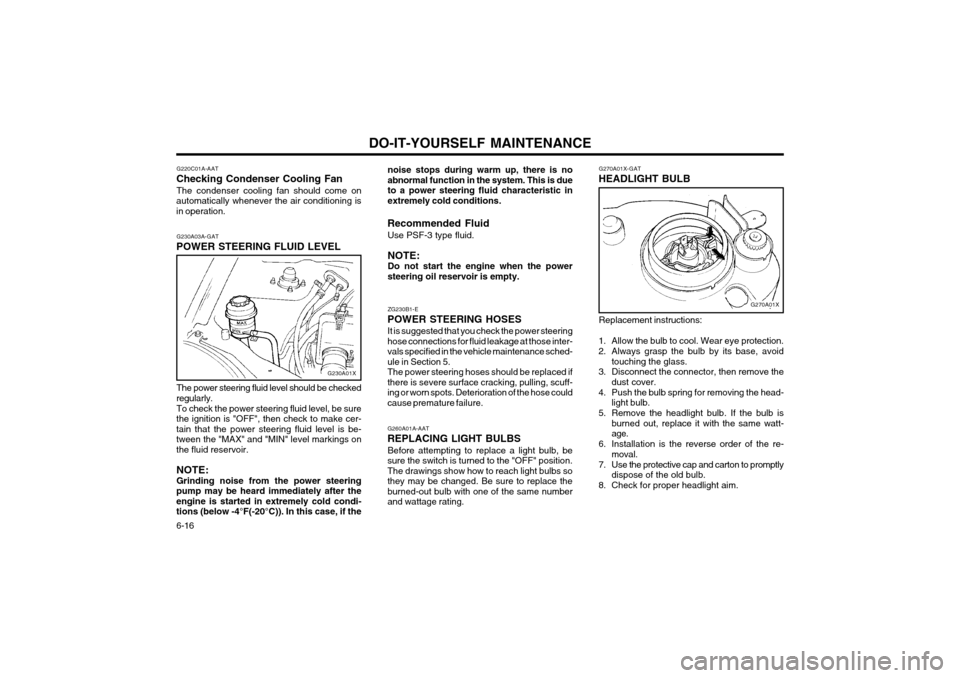

6-16 G270A01X-GAT

HEADLIGHT BULB

G270A01X

Replacement instructions:

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its base, avoid touching the glass.

3. Disconnect the connector, then remove the dust cover.

4. Push the bulb spring for removing the head- light bulb.

5. Remove the headlight bulb. If the bulb is burned out, replace it with the same watt- age.

6. Installation is the reverse order of the re- moval.

7. Use the protective cap and carton to promptly dispose of the old bulb.

8. Check for proper headlight aim.

noise stops during warm up, there is no

abnormal function in the system. This is dueto a power steering fluid characteristic inextremely cold conditions.

Recommended Fluid Use PSF-3 type fluid. NOTE: Do not start the engine when the power

steering oil reservoir is empty. ZG230B1-E

POWER STEERING HOSES It is suggested that you check the power steering hose connections for fluid leakage at those inter-vals specified in the vehicle maintenance sched-ule in Section 5.The power steering hoses should be replaced ifthere is severe surface cracking, pulling, scuff-ing or worn spots. Deterioration of the hose couldcause premature failure.

G260A01A-AAT

REPLACING LIGHT BULBS Before attempting to replace a light bulb, be

sure the switch is turned to the "OFF" position.

The drawings show how to reach light bulbs sothey may be changed. Be sure to replace the

burned-out bulb with one of the same numberand wattage rating.

G220C01A-AAT

Checking Condenser Cooling Fan

The condenser cooling fan should come on

automatically whenever the air conditioning is in operation.

G230A03A-GAT

POWER STEERING FLUID LEVEL

G230A01X

The power steering fluid level should be checked

regularly.

To check the power steering fluid level, be sure

the ignition is "OFF", then check to make cer- tain that the power steering fluid level is be-

tween the "MAX" and "MIN" level markings onthe fluid reservoir.

NOTE: Grinding noise from the power steering

pump may be heard immediately after the engine is started in extremely cold condi-tions (below -4°F(-20°C)). In this case, if the

Page 235 of 249

DO-IT-YOURSELF MAINTENANCE 6-17

WARNING: The halogen bulb contains gas under pres-

sure and if impacted could shatter, and re- sulting in flying fragments. Always wear eye

protection when servicing the bulb. Protectthe bulb against abrasions or scratches andagainst liquids when lighted. Turn on thebulb only when installing in a headlight.Replace the headlight if damaged or cracked.Keep the bulb out of the reach of childrenand dispose of the used bulb with care.

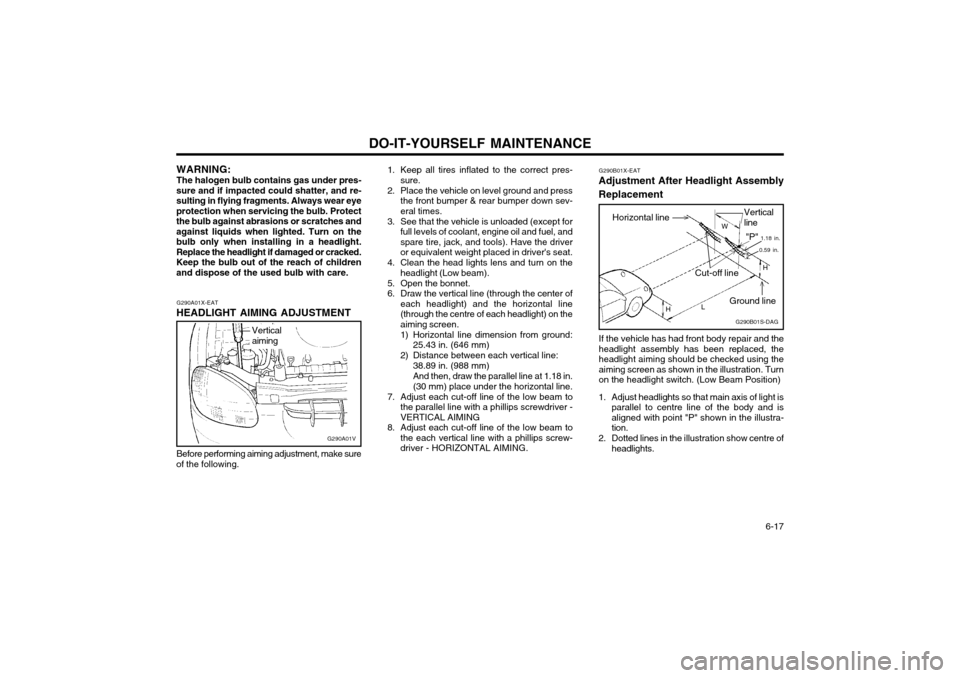

G290A01X-EAT

HEADLIGHT AIMING ADJUSTMENT

G290A01V

Before performing aiming adjustment, make sure

of the following.

Vertical aiming

1. Keep all tires inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down sev- eral times.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, andspare tire, jack, and tools). Have the driveror equivalent weight placed in driver's seat.

4. Clean the head lights lens and turn on the headlight (Low beam).

5. Open the bonnet.

6. Draw the vertical line (through the center of each headlight) and the horizontal line(through the centre of each headlight) on theaiming screen.

1) Horizontal line dimension from ground:25.43 in. (646 mm)

2) Distance between each vertical line: 38.89 in. (988 mm)And then, draw the parallel line at 1.18 in. (30 mm) place under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver -VERTICAL AIMING

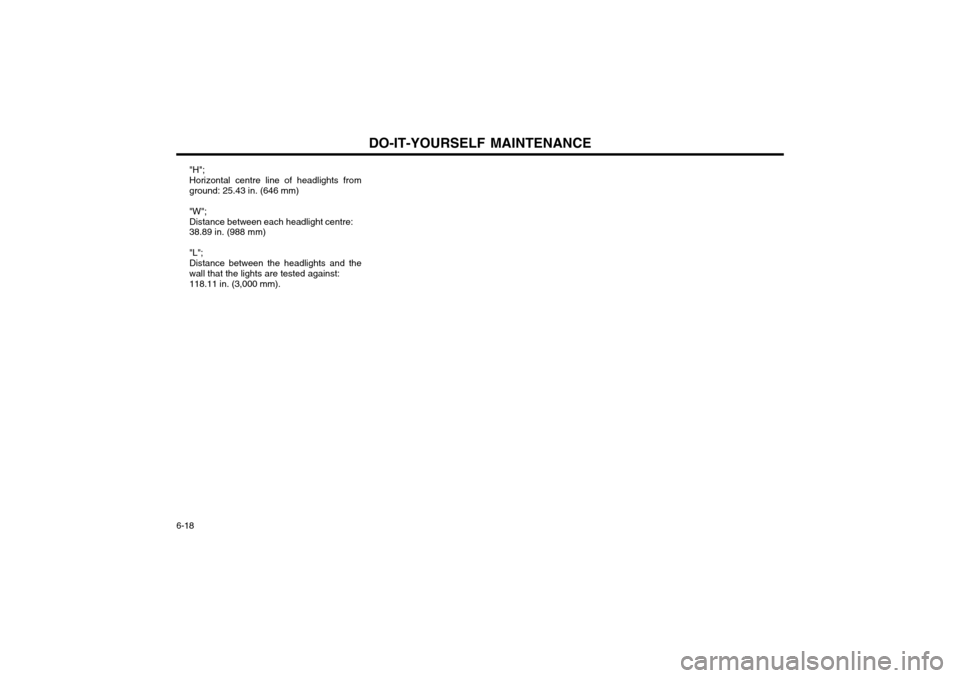

8. Adjust each cut-off line of the low beam to the each vertical line with a phillips screw-driver - HORIZONTAL AIMING. G290B01X-EAT

Adjustment After Headlight Assembly Replacement

If the vehicle has had front body repair and the headlight assembly has been replaced, theheadlight aiming should be checked using theaiming screen as shown in the illustration. Turnon the headlight switch. (Low Beam Position)

1. Adjust headlights so that main axis of light is parallel to centre line of the body and isaligned with point "P" shown in the illustra-tion.

2. Dotted lines in the illustration show centre of headlights. G290B01S-DAG

Horizontal lineVertical line

W

0.59 in.

"P" 1.18 in.

Cut-off line

Ground line H

H L

Page 236 of 249

DO-IT-YOURSELF MAINTENANCE

6-18 "H"; Horizontal centre line of headlights from ground: 25.43 in. (646 mm) "W"; Distance between each headlight centre: 38.89 in. (988 mm) "L"; Distance between the headlights and the wall that the lights are tested against: 118.11 in. (3,000 mm).

Page 237 of 249

DO-IT-YOURSELF MAINTENANCE 6-19

No.

1 23456 7

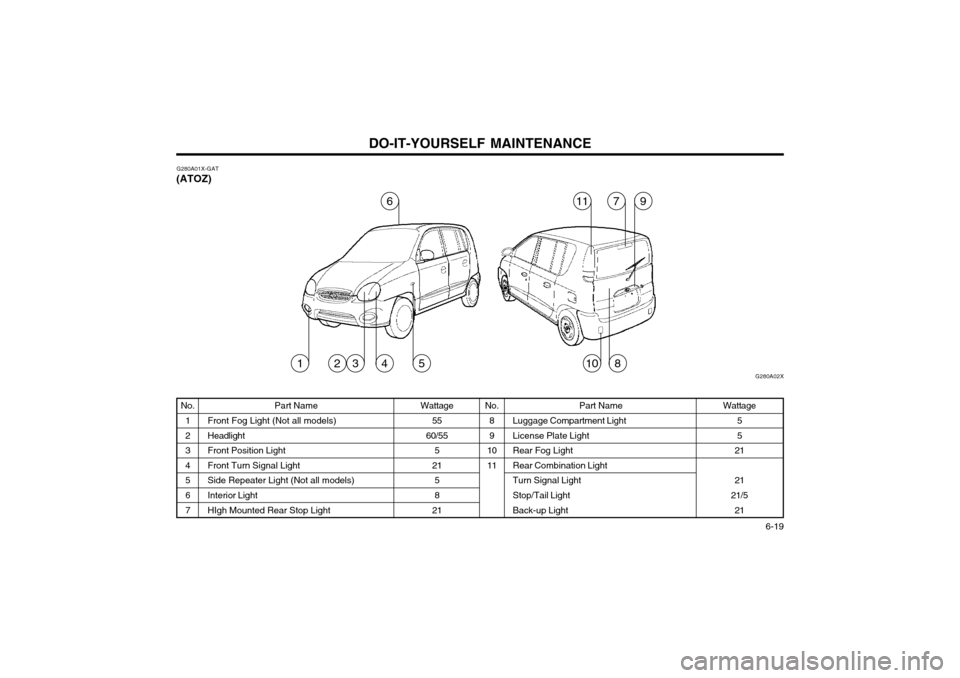

G280A01X-GAT

(ATOZ)

Part Name

Front Fog Light (Not all models) HeadlightFront Position LightFront Turn Signal LightSide Repeater Light (Not all models)Interior Light HIgh Mounted Rear Stop Light Wattage

55

60/55 5

21

5 8

21 No.

89

1011 Wattage

55

21 21

21/5

21Part Name

Luggage Compartment Light License Plate LightRear Fog LightRear Combination LightTurn Signal LightStop/Tail Light Back-up Light

G280A02X

61179

14325108

Page 238 of 249

DO-IT-YOURSELF MAINTENANCE

6-20 No.

1 2 3 4567

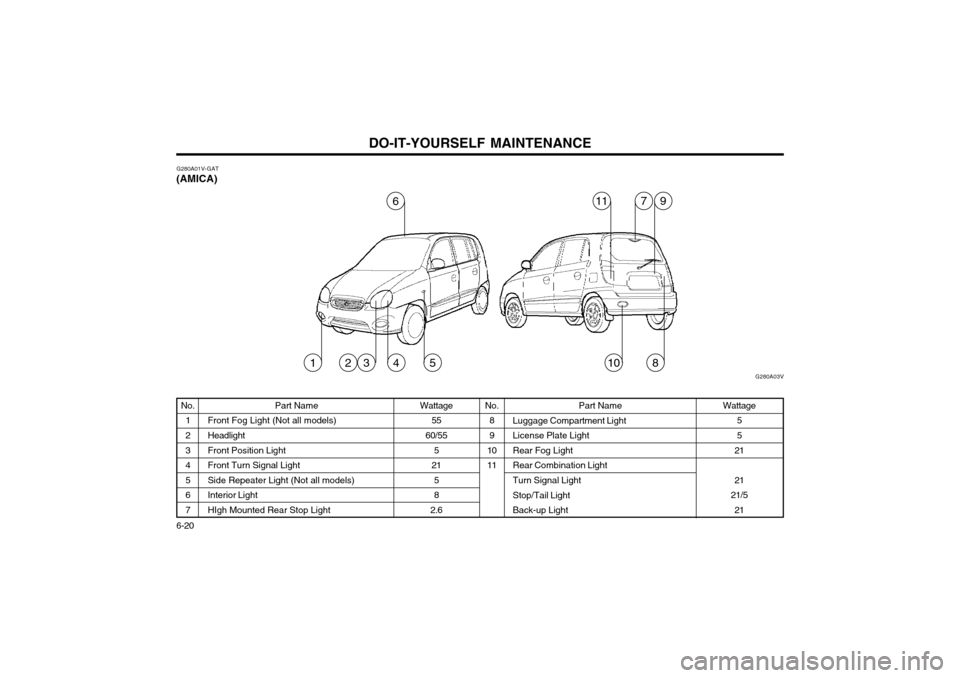

G280A01V-GAT

(AMICA)

Part Name

Front Fog Light (Not all models) Headlight Front Position Light Front Turn Signal LightSide Repeater Light (Not all models)Interior LightHIgh Mounted Rear Stop Light Wattage

55

60/55

5

21 58

2.6 No.

89

1011 Wattage

55

21 21

21/5 21Part Name

Luggage Compartment Light License Plate LightRear Fog LightRear Combination LightTurn Signal Light Stop/Tail Light Back-up Light

G280A03V

6119

14325108

7

Page 239 of 249

EMISSION CONTROL SYSTEMS 7-1

H010A01A-GAT EMISSION CONTROL SYSTEM (Not all models) Your Hyundai is equipped with an emission

control system to meet all requirements of the Emission prohibition rules of your province.

There are three emission control systems which

are as follows.

1) Crankcase emission control system

2) Evaporative emission control system

3) Exhaust emission control system In order to assure the proper function of the

emission control systems, it is recommended that you have your car inspected and main-tained by an authorized Hyundai dealer in ac-

cordance with the maintenance schedule in thismanual. ZH000A1-A

7. EMISSION

CONTROL SYSTEMS

H010B01A-AAT

1. Crankcase Emission Control Sys-

tem

The Positive Crankcase Ventilation System is

employed to prevent air pollution caused by blow-by gases being emitted from the crank- case. This system supplies fresh filtered air to

the crankcase through the air intake hose.Inside the crankcase, the fresh air mixes with

blow-by gases, which then pass through thePCV valve and into the induction system.

H010D01A-AAT

3. Exhaust Emission Control SystemThe Exhaust Emission Control System is a

highly effective system which controls exhaust

emission while maintaining good vehicle perfor-mance.

H010C02A-GAT

2. Evaporative Emission

Control System (Not all models)

The Evaporative Emission Control System is

designed to prevent fuel vapors from escapinginto the atmosphere.

Canister While the engine is inoperative, fuel vapours

generated inside the fuel tank are absorbed and stored in the onboard canister. When the en-gine is running, the fuel vapors absorbed in thecanister are drawn into the induction systemthrough the purge control solenoid valve.

Purge Control Solenoid Valve The purge control solenoid valve is controlled

by the ECM; when the engine coolant temper- ature is low, and during idling, it closes, so that

evaporated fuel is not taken into the engine.

After engine warm-up, during ordinary driving, itopens so as to introduce evaporated fuel to theengine.

H020A01ACatalytic Converter

H020A01A-GAT CATALYTIC CONVERTER (Not all models) The catalytic converter is part of the exhaust

emission control system. Its purpose is to re- move certain engine emission products from

the engine’s exhaust. It looks something like amuffler and is located underneath the car in theexhaust system.

7

Page 240 of 249

7-2EMISSION CONTROL SYSTEMS

H020B01A-GAT About the Catalytic ConverterExhaust gases passing through the catalytic

converter cause it to operate at very high tem- peratures. As a result, the introduction of large

amounts of unburned gasoline may cause it to

overheat and create a fire hazard. This can beavoided by observing the following:

o Use unleaded fuel only.

o Maintain your engine in good condition. Ex- tremely high converter temperatures can result from improper operation of the electri-cal, ignition or fuel injection systems.

o If your engine stalls, pings, knocks, or is hard to start, take your car to your Hyundaidealer as soon as possible and have thedifficulty corrected.

o Avoid driving with a very low fuel level. If your run out of gasoline, it could cause theengine to misfire and result in excessive

loading of the catalytic converter.

o Avoid idling the engine for periods longer than 10 minutes.

o Your Hyundai should not be either pushed or pulled to get it started. This can cause thecatalytic converter to overload.

o Take care not to stop your Hyundai over any combustible material such as grass, paper,leaves or rags. As these materials could

come in contact with the catalytic converterand could cause a fire. o Do not touch the catalytic converter or any

other part of the exhaust system while theengine is running as it is very hot and couldresult in burns.

o Remember that your Hyundai dealer is your best source of assistance.