coolant temperature Hyundai Coupe 2008 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Coupe, Model: Hyundai Coupe 2008Pages: 407, PDF Size: 11.03 MB

Page 226 of 407

6

DO-IT-YOURSELF MAINTENANCE

25

G220B01A-AAT

Checking Engine Cooling Fan

The engine coolant fan should come on automatically if the engine coolant temperature is high. G220C01A-AAT

Checking Condenser Cooling Fan

The condenser coolant fan should come on automatically whenever the air conditioning is in operation. G230A01GK-GAT

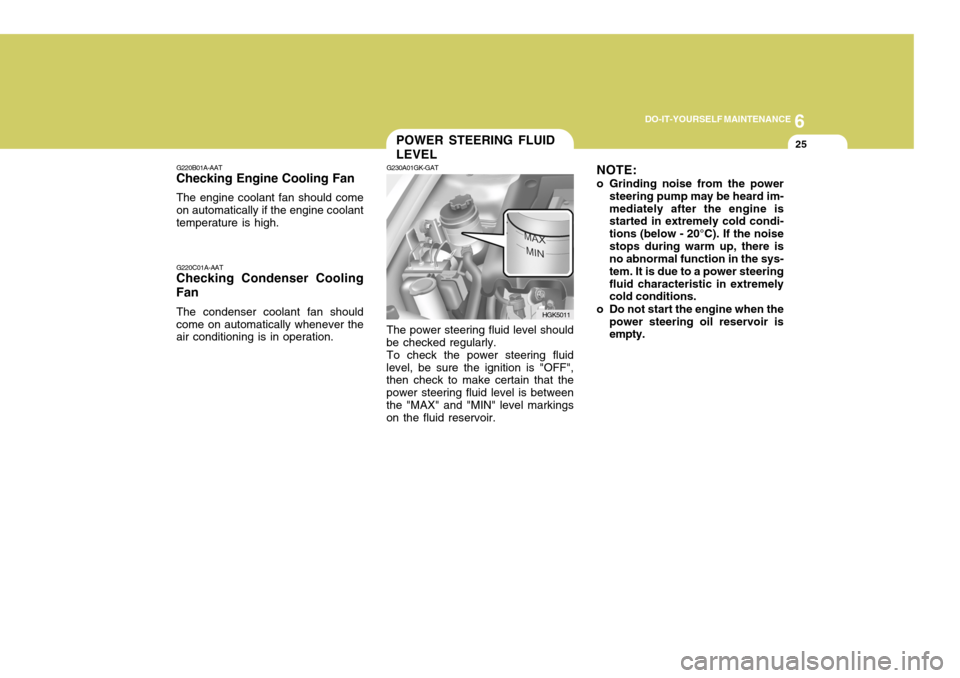

POWER STEERING FLUID LEVEL

The power steering fluid level should

be checked regularly.

To check the power steering fluid

level, be sure the ignition is "OFF", then check to make certain that the power steering fluid level is betweenthe "MAX" and "MIN" level markings on the fluid reservoir. NOTE:

o Grinding noise from the power

steering pump may be heard im- mediately after the engine is started in extremely cold condi- tions (below - 20°C). If the noisestops during warm up, there is no abnormal function in the sys- tem. It is due to a power steeringfluid characteristic in extremely cold conditions.

o Do not start the engine when the power steering oil reservoir isempty.

HGK5011

Page 243 of 407

7EMISSION CONTROL SYSTEMS

2

H010A01A-GAT (If Installed) Your Hyundai is equipped with an emission control system to meet all requirements of the Emission prohibi- tion rules of your province.There are three emission control sys-tems which are as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys-

tem

(3) Exhaust emission control systemIn order to assure the proper function of the emission control systems, it isrecommended that you have your car inspected and maintained by an au- thorized Hyundai dealer in accordancewith the maintenance schedule in this manual. EMISSION CONTROL SYSTEMS

H010B01F-GAT 1. Crankcase Emission ControlSystem

The positive crankcase ventilation system is employed to prevent air pollution caused by blow-by gases being emitted from the crankcase.This system supplies fresh air to the crankcase through the air cleaner. Inside the crankcase, the fresh airmixes with blow-by gases, then passes through the PCV valve into the induction system.

H010C01F-GAT

2. Evaporative Emission Control

System (If Installed)

The evaporative emission control sys-

tem is designed to prevent fuel va-pors from escaping into the atmo-sphere. H010D01A-AAT

3. Exhaust Emission Control

System

The exhaust emission control system is a highly effective system which controls exhaust emissions while maintaining good vehicle performace.

Canister While the engine is inoperative, fuel vapors generated inside the fuel tank are absorbed and stored in the canis-ter. When the engine is running, the fuel vapors absorbed in the canister are drawn into the induction systemthrough the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled by the ECM; when the en- gine coolant temperature is low, and during idling, it closes, so that evapo- rated fuel is not taken into the engine. After engine warm-up, during ordi-nary driving, it opens so as to intro- duce evaporated fuel to the engine.

Page 257 of 407

10

INDEX

3

Driving Economical driving .................................................. 2-16

Smooth corneri ng ..................................................... 2-17

Winter driving ........................................................... 2-17

E Electronic Stability Program (ESP) ............................2-13

Emissions Control Systems ........................................ 7-2 Engine Before starting the engine ........................................ 2-3

Changing the oil and filter ......................................... 6-6Compartment (1.6L, 2.0L, 2.7L) ................................ 6-2

Coolant ..................................................................... 6-9

Coolant temperature gauge ......................................1-50

If the engine overheats ............................................. 3-4

Number ..................................................................... 8-2

Oil ............................................................................. 6-6Oil consumption ........................................................ 6-8

Starting ..................................................................... 2-5

Engine Exhaust Can Be Dangerous ............................ 2-2

FFog Light .................................................................... 1-62

Front Seats Adjustable front seats .............................................. 1-13

Adjustable headrests ............................................... 1-14

Adjusting seat forward and rearward ........................ 1-13

Adjusting seatback angle ........................................ 1-14

Lumbar support control ............................................ 1-16

Seat cushion height adjustment .............................. 1-16Seat warmer

............................................................ 1-16

Fuel Capacity ................................................................... 9-2

Gauge ...................................................................... 1-49

Recommendations .................................................... 1-2

Fuel Filler Lid Remote release ....................................................... 1-76

Fuse Panel Description .............................................. 6-37

Fuses ......................................................................... 6-21

G

General Everyday Checks ..... ...................................... 6-5

Glove box ................................................................... 1-71

H Hazard Warning System ............................................. 1-62

Headlight Leveling Device S ystem .............................1-66

Heating and Air Conditioning Control Rotary type .............................................................. 1-87

Automatic type ........................................................ 1-96

High-mounted rear stoplight .. ......................................1-74

Hood Release ............................................................. 1-75

Horn ............................................................................ 1-80

I Ignition Switch ............................................................. 2-4

Immobilizer System ..................................................... 1-4

Instrument Cluster and Indicator Lights ...................... 1-42

Instrument Panel Light Control (Rheostat) .................. 1-64

Intermittent Wiper ....................................................... 1-61

Page 314 of 407

2

DRIVING YOUR HYUNDAI

21

YC200C4-E Trailer Brakes If your trailer is equipped with a braking system, make sure it conforms to localregulations and that it is properly in- stalled and operating correctly. NOTE: If you tow a trailer or vehicle, your car will require more frequent main- tenance due to the additional load.See Maintenance Under Severe Us- age Conditions" on page 5-7.

YC200B2-E Trailer Towbars Select the proper towbar and ball com- bination, making sure that its location is compatible with that of the trailer or vehicle being towed.Use a quality non-equalizing towbar which distributes the nose weight uni- formly throughout the chassis. The towbar should be bolted securely to the car and installed by a qualifiedtechnician.

CAUTION:

o Never connect a trailer brake sys- tem directly to the vehicle brakesystem.

o When towing a trailer on steep grades (in excess of 6%) pay closeattention to the engine coolanttemperature gauge to ensure the engine does not overheat. If the needle of the coolant temperaturegauge moves across the dial to- wards "H" (HOT), pull over and stop as soon as it is safe to do so,and allow the engine to idle until it cools down. You may proceed once the engine has cooled suffi-ciently.

!

Page 322 of 407

3 IN CASE OF EMERGENCY

4

7. Switch "ON" the main beam

headlamps before carefully remov- ing the jumper cables have been removed, switch "OFF" the main beam headlamps. SD040A2-E If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as

it is safe to do so.

2. Place the gear selector lever in "P"

(automatic), or neutral (manual transaxle) and set the parking brake. If the air conditioning is on, turn it off.

3. If coolant is running out under the car or steam is coming out fromunder the bonnet stop the engine. Do not open the bonnet until thecoolant has stopped running or the steaming has stopped. If there is no visible loss of coolant and no steam,leave the engine running and check to be sure the engine cooling fan is operating.If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is broken. If it is not missing,check to see that it is tight. If the drive belt seems to be satisfactory,check for coolant leaking from the radiator, hoses or under the car. (If the air conditioning had been in use,it is normal for cold water to be draining from it).

IF THE ENGINE OVERHEATS

1. Ensure that the booster battery is 12 volt type. If the booster battery is installed in another vehicle, ensure that the two vehicles are not touch- ing.

2. Turn off all unnecessary electrical equipment in both vehicles.

3. Ensure that the engine of the ve- hicle providing the jump start is run- ning prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the boosterbattery and the other end to thepositive (+) terminal of the dis- charged battery.

5. Attach the black jump cable to the negative (-) terminal of the boosterbattery, and the other end to a ground point within the engine compartmentof the vehicle with the flat battery. Do not connect to the negative battery terminal of the flat battery sincesparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flat battery. CAUTION:

If the jump cables are incorrectlyinstalled, damage to the vehicle elec-trical system may occur, in particu- lar the electronic components such as the Fuel Injection system com- puter and the Automatic Transaxle computer. The battery must neverbe disconnected whilst the engine is running.

!

Page 323 of 407

3

IN CASE OF EMERGENCY

5

!

!WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drive belts to prevent injury.

5. If the water pump drive belt is broken or coolant is leaking out, stop the engine immediately and call the near- est Hyundai authorised repairer forassistance.

WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

!

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, care- fully add coolant to the reservoir(page 6-10) to bring the fluid level in the reservoir up to the base of the radiator fill opening. Fill the coolantexpansion tank to the halfway mark. To ensure the correct water to cool- ant mix is obtained after top up,testing by an authorised repairer is required.

7. Proceed with caution until it is estab- lished that the engine is operatingnormally. If the engine overheats repeatedly, the advice of a Hyundaiauthorised repairer should be sought.

CAUTION:

Serious loss of coolant indicates there is a leak in the cooling system and this should be checked as soonas possible by a Hyundai authorised repairer.D040A01GK-EAT The following instructions for the tem- porary spare tyre should be observed:

1. Check inflation pressure as soon as practical after installing the spare tyre, and adjust to the specified pressure. The tyre pressure shouldbe periodically checked and main- tained at the specified pressure whilst the tyre is stored.

TEMPORARY SPARE TYRE

Tyre Size

Inflation Pressure T125/70 R16

420 kPa (60 psi)

Spare Tyre Pressure

2. The spare tyre should only be used temporarily and should be returned to the luggage compartment as soonas the original tyre can be repaired or replaced.

3. Continuous use at speeds of over 50 mph (80 km/h) is not recom-mended.

4. As the temporary spare tyre is spe- cifically designed for your car, itshould not be used on any other vehicle.

Page 359 of 407

6OWNER MAINTENANCE

10

HGK4006

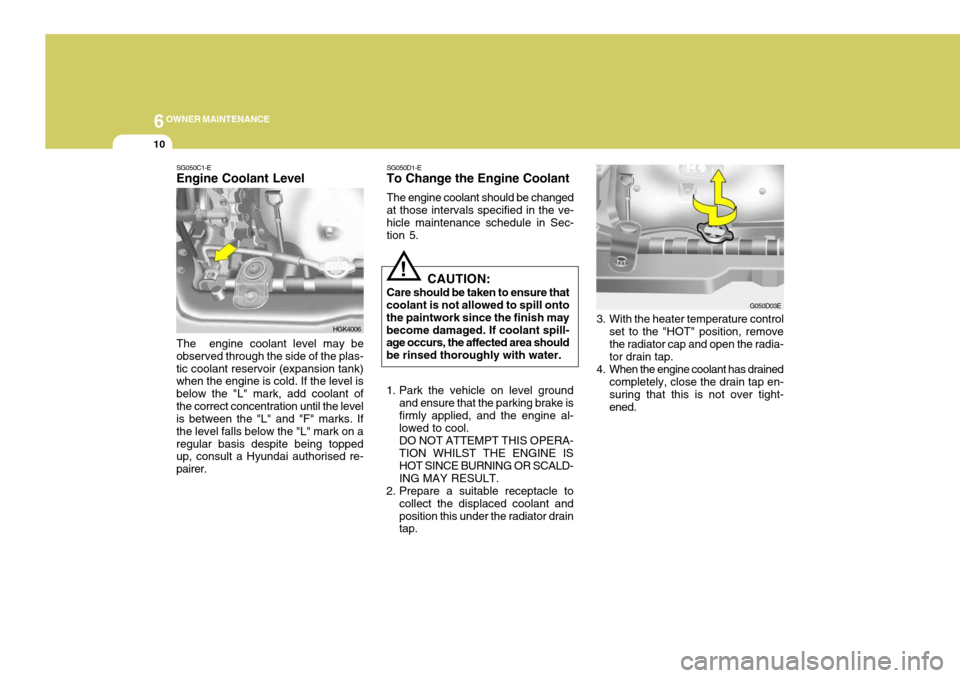

SG050C1-E Engine Coolant Level

The engine coolant level may be

observed through the side of the plas- tic coolant reservoir (expansion tank) when the engine is cold. If the level is below the "L" mark, add coolant ofthe correct concentration until the level is between the "L" and "F" marks. If the level falls below the "L" mark on aregular basis despite being topped up, consult a Hyundai authorised re- pairer. SG050D1-E To Change the Engine Coolant The engine coolant should be changed at those intervals specified in the ve- hicle maintenance schedule in Sec- tion 5.

3. With the heater temperature controlset to the "HOT" position, removethe radiator cap and open the radia- tor drain tap.

4. When the engine coolant has drained completely, close the drain tap en- suring that this is not over tight-ened. G050D03E

CAUTION:

Care should be taken to ensure that

coolant is not allowed to spill ontothe paintwork since the finish maybecome damaged. If coolant spill- age occurs, the affected area should be rinsed thoroughly with water.

!

1. Park the vehicle on level ground and ensure that the parking brake is firmly applied, and the engine al- lowed to cool. DO NOT ATTEMPT THIS OPERA- TION WHILST THE ENGINE IS HOT SINCE BURNING OR SCALD-ING MAY RESULT.

2. Prepare a suitable receptacle to

collect the displaced coolant andposition this under the radiator drain tap.

Page 360 of 407

6

OWNER MAINTENANCE

11CHANGING THE AIR CLEANER FILTER

G070A01E-AAT To change the filter, unsnap the clips around the cover. When this is done, the cover can be lifted off, the oldfilter removed and the new filter put in its place. Genuine Hyundai Replace- ment Parts are recommended.

HGK5010

! CAUTION:

o Operating your vehicle without a proper air cleaner filter in place can result in excessive engine wear.

o When removing the air cleaner filter, be careful that dust or dirtdoes not enter the air intake. These may result in damage tothe air cleaner filter.

G050D04E

!WARNING:

The cooling fan is controlled by engine coolant temperature and may sometimes operate even when theengine is not running. Use extreme caution when working near the blades of the cooling fan so thatyou are not injured by a rotating fan blade. As the engine coolant tem- perature decreases, the fan will au-tomatically shut off. This is a nor- mal condition.

5. Prepare a suitable quantity of new

engine coolant (refer to section 9) and pour this into the radiator.

6. Start the engine with the radiator

cap still removed and continue toadd coolant as the level decreases as air is expelled from the system. When the level remains constant,replace the radiator cap and re- plenish the coolant reservoir.

7. When the engine is hot, check to ensure that no coolant leaks arepresent.

Page 372 of 407

6

OWNER MAINTENANCE

23POWER STEERING FLUID LEVELELECTRIC COOLING FANS

!

YG210A1-E

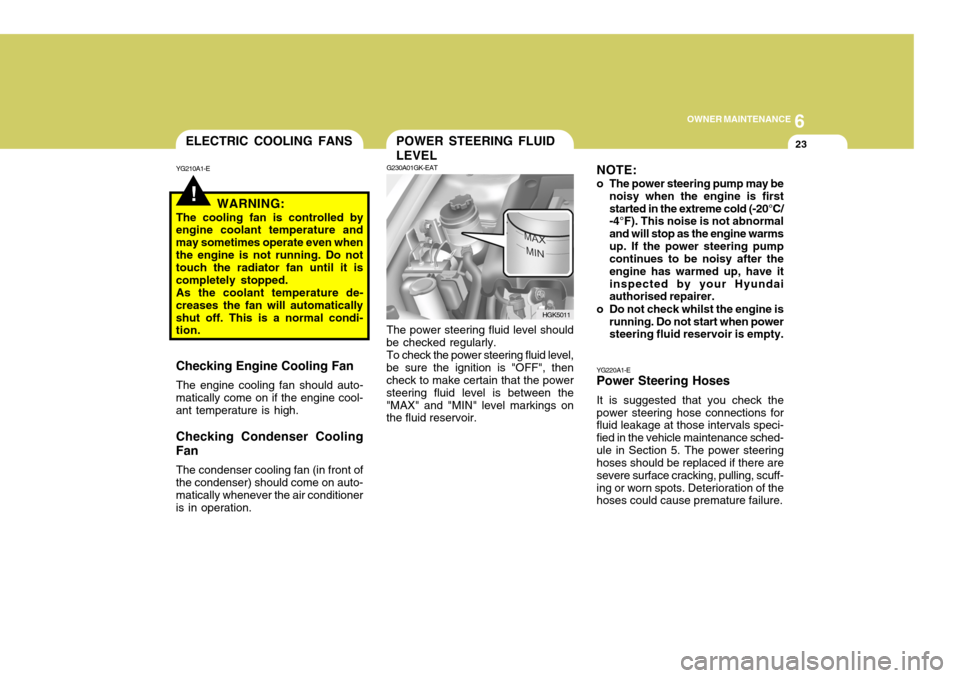

WARNING:

The cooling fan is controlled by

engine coolant temperature and may sometimes operate even whenthe engine is not running. Do not touch the radiator fan until it is completely stopped.

As the coolant temperature de-

creases the fan will automaticallyshut off. This is a normal condi- tion. Checking Engine Cooling Fan

The engine cooling fan should auto-

matically come on if the engine cool- ant temperature is high. Checking Condenser Cooling Fan

The condenser cooling fan (in front of

the condenser) should come on auto- matically whenever the air conditioneris in operation. YG220A1-E Power Steering Hoses It is suggested that you check the power steering hose connections for fluid leakage at those intervals speci- fied in the vehicle maintenance sched-ule in Section 5. The power steering hoses should be replaced if there are severe surface cracking, pulling, scuff-ing or worn spots. Deterioration of the hoses could cause premature failure.

HGK5011

G230A01GK-EAT The power steering fluid level should

be checked regularly.

To check the power steering fluid level,

be sure the ignition is "OFF", then check to make certain that the power steering fluid level is between the"MAX" and "MIN" level markings on the fluid reservoir. NOTE:

o The power steering pump may be

noisy when the engine is first started in the extreme cold (-20°C/ -4°F). This noise is not abnormal and will stop as the engine warmsup. If the power steering pump continues to be noisy after the engine has warmed up, have itinspected by your Hyundai authorised repairer.

o Do not check whilst the engine is running. Do not start when powersteering fluid reservoir is empty.

Page 388 of 407

7EMISSION CONTROL SYSTEMS

2

SH010A1-E (Not all models) Depending upon the market for which the vehicle is destined, the emission control system will comprise one or more of the following emission controldevices.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. EMISSION CONTROL SYS- TEMS

DH010B1-E

1. Crankcase Emission Control

System

The positive crankcase ventilation (PCV) system is employed to prevent air pollution caused by blow-by gases being emitted from the crankcase. This system supplies fresh air to the crankcase through the air cleaner. In- side the crankcase, the fresh air mixeswith blow-by gases, then passes through the PCV valve into the intake system. When the engine is running, the fuelvapors absorbed in the canister aredrawn into the induction system through the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled by the ECU (Engine Control Unit); when the engine coolant tem- perature is low, and during idling, itcloses, so that evaporated fuel is not taken into the surge tank. After engine warm-up, during ordinary driving, itopens to introduce evaporated fuel to the surge tank.

JH010D1-E

3. Exhaust Emission Control

System

This system helps control oxides of

nitrogen by recirculating a portion of the exhaust gases into the intake manifold, thereby reducing cylinder combustion temperatures.

ZH010C1-E

2. Evaporative Emission

Control System

The Evaporative Emission Control System is designed to prevent fuelvapors from escaping into the atmo- sphere. Canister Whilst the engine is inoperative, fuel vapors generated inside the fuel tank are absorbed and stored in the canis- ter.