maintenance schedule Hyundai Coupe 2008 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Coupe, Model: Hyundai Coupe 2008Pages: 407, PDF Size: 11.03 MB

Page 342 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

4

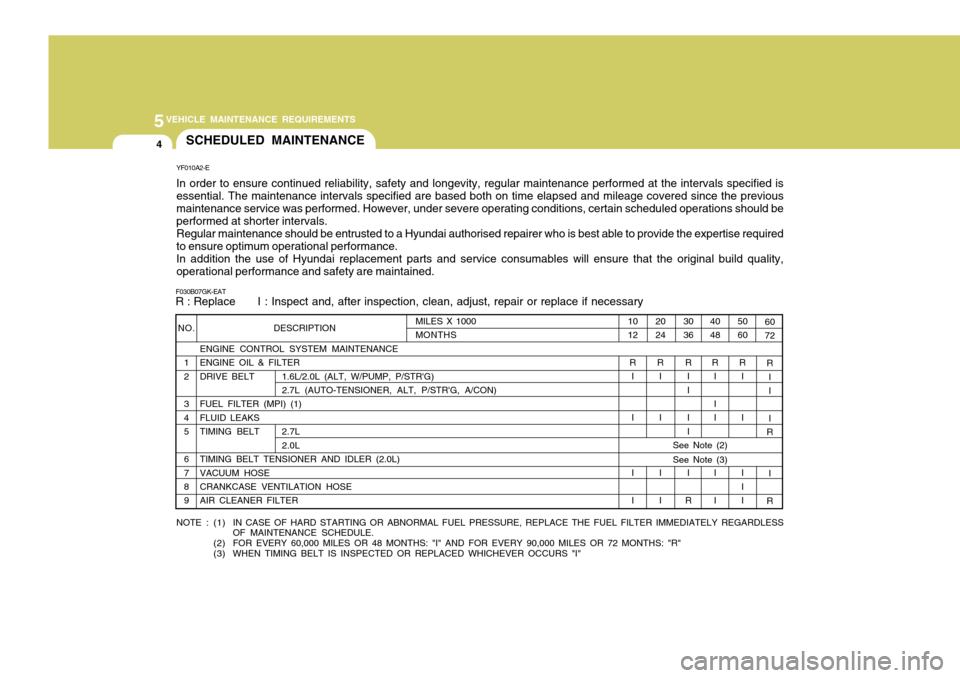

DESCRIPTION ENGINE CONTROL SYSTEM MAINTENANCE ENGINE OIL & FILTER

DRIVE BELT 1.6L/2.0L (ALT, W/PUMP, P/STR'G) 2.7L (AUTO-TENSIONER, ALT, P/STR'G, A/CON)

FUEL FILTER (MPI) (1)FLUID LEAKS

TIMING BELT 2.7L

2.0L

TIMING BELT TENSIONER AND IDLER (2.0L)VACUUM HOSE CRANKCASE VENTILATION HOSE AIR CLEANER FILTER 3036

R II I I I

R

NO.

1 2 3 45 6 7 8 9

YF010A2-E In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should beperformed at shorter intervals.Regular maintenance should be entrusted to a Hyundai authorised repairer who is best able to provide the expertise requiredto ensure optimum operational performance.In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality,operational performance and safety are maintained.

F030B07GK-EAT

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary50 60

R I I I I I 60 72

R I I I

R

I

R

40 48

R I I I I I

20 24

R I I I I

10 12

R I I I I

MILES X 1000 MONTHS

SCHEDULED MAINTENANCE

See Note (2) See Note (3)

NOTE : (1) IN CASE OF HARD STARTING OR ABNORMAL FUEL PRESSURE, REPLACE THE FUEL FILTER IMMEDIATELY REGARDLESS

OF MAINTENANCE SCHEDULE.

(2) FOR EVERY 60,000 MILES OR 48 MONTHS: "I" AND FOR EVERY 90,000 MILES OR 72 MONTHS: "R"

(3) WHEN TIMING BELT IS INSPECTED OR REPLACED WHICHEVER OCCURS "I"

Page 346 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

8EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked periodi- cally for proper tension and adjustedas necessary. 6ZF060D1-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately. 6ZF060E1-A

o Timing belt

Inspect all parts related to the timing

belt for damage and deformation. Replace any damaged parts immedi- ately.

6ZF060G1-E

o Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervalsspecified in the maintenance sched- ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

F060C01A-AAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians.

Page 347 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

9

6ZF060F2-A

o Crankcase ventilation hoses

Inspect the surface of hoses for evi- dence of heat and/or mechanical dam- age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examin- ing those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold. Inspect the hose routing to assure that the hoses do not come in contact with any heat source, sharp edges or mov-ing component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clampsand couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immedi-ately if there is any evidence of dete- rioration or damage. 6ZF060H1-A

o Air cleaner filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re-placed.

6ZF060J1-A

o Spark plugs

Make sure to install new spark plugs

of the correct heat range.

F060N02E-AAT

o Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces- sary. A qualified technician should perform the operation. 6ZF070B1-A

o Cooling system Check the cooling system part, such as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts. 6ZF070C1-A

o Coolant The coolant should be changed at the intervals specified in the mainte-nance schedule. 6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil ac- cording to the maintenance schedule. NOTE: If the oil level is low, check for possible leaks before adding oil. Do not overfill.

Page 358 of 407

6

OWNER MAINTENANCE

9

!

ENGINE COOLANT CHECKING AND REPLACING

SG050A1-E

WARNING:

Do not remove the radiator cap

when the engine is hot, since the system is pressurised and coolant may be ejected from the radiator resulting in scalding. NOTE: It is imperative that vehicles fitted with an air conditioning systemhave a coolant concentration of the recommended strength at all times. The use of the air condition-ing system when the cooling sys- tem is filled with water only will result in the heater matrix freezingand subsequently bursting.

SG050B1-E

Coolant recommendations

Only ethylene glycol based coolantwith a corrosion inhibitor suited to aluminium alloy engine components should be used in the cooling system.No further additives or inhibitors should be used. The coolant specific gravity should be checked as pre-scribed in the maintenance schedule to ensure adequate frost and corro- sion protection. In addition, the en-gine coolant must be replaced at the specified interval since the corrosion inhibitor properties deteriorate withtime.It is important to note that whilst anincrease in the concentration of anti freeze gives an increase in the level of frost protection, a solution which isin excess of 65% anti freeze will result in reduced frost protection and engine overheating. Therefore therecommended concentration of 50% should not be exceeded for general use. The use of methanol based anti freeze compounds may result in engine over- heating and will invalidate the vehiclewarranty.

Page 359 of 407

6OWNER MAINTENANCE

10

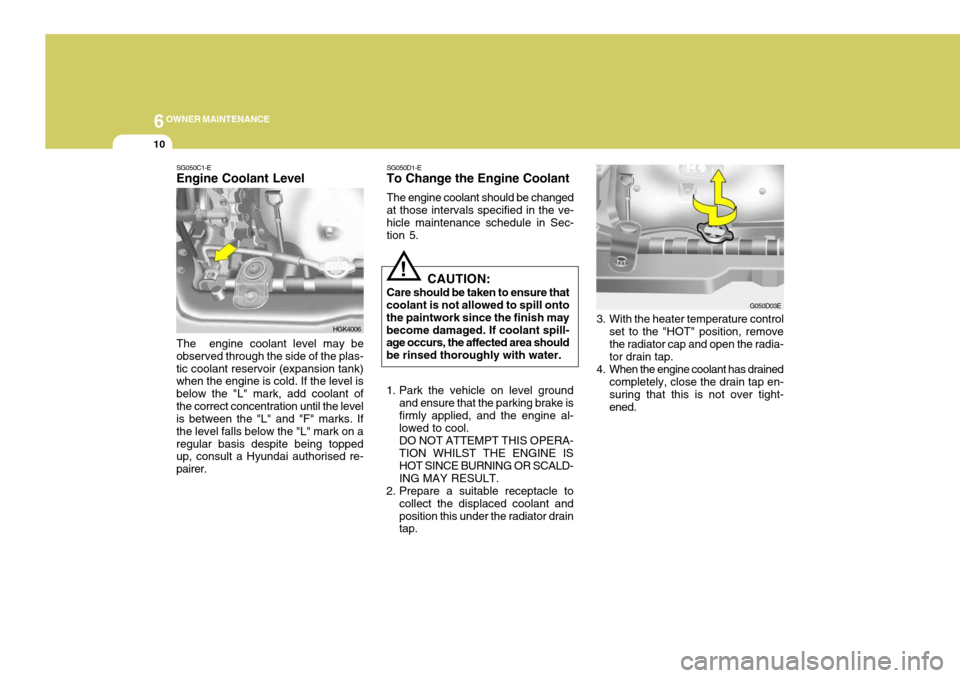

HGK4006

SG050C1-E Engine Coolant Level

The engine coolant level may be

observed through the side of the plas- tic coolant reservoir (expansion tank) when the engine is cold. If the level is below the "L" mark, add coolant ofthe correct concentration until the level is between the "L" and "F" marks. If the level falls below the "L" mark on aregular basis despite being topped up, consult a Hyundai authorised re- pairer. SG050D1-E To Change the Engine Coolant The engine coolant should be changed at those intervals specified in the ve- hicle maintenance schedule in Sec- tion 5.

3. With the heater temperature controlset to the "HOT" position, removethe radiator cap and open the radia- tor drain tap.

4. When the engine coolant has drained completely, close the drain tap en- suring that this is not over tight-ened. G050D03E

CAUTION:

Care should be taken to ensure that

coolant is not allowed to spill ontothe paintwork since the finish maybecome damaged. If coolant spill- age occurs, the affected area should be rinsed thoroughly with water.

!

1. Park the vehicle on level ground and ensure that the parking brake is firmly applied, and the engine al- lowed to cool. DO NOT ATTEMPT THIS OPERA- TION WHILST THE ENGINE IS HOT SINCE BURNING OR SCALD-ING MAY RESULT.

2. Prepare a suitable receptacle to

collect the displaced coolant andposition this under the radiator drain tap.

Page 363 of 407

6OWNER MAINTENANCE

14

!WARNING:

o Windscreen washer fluid agents contain some amounts of alcohol and can be flammable under cer- tain circumstances. Do not allow sparks or flame to contact thewasher fluid or the washer fluid reservoir. Damage to the vehicle or its occupants could occur.

o Windscreen washer fluid is poi- sonous to humans and animals.Do not drink windscreen washer fluid. Serious injury or death could occur.

AUTOMATIC TRANSAXLE FLUIDCHECKING THE TRANSAXLE OIL (MANUAL)

G100A01MC-EAT

Transaxle lubricant in the manual transaxle should be checked at those intervals specified in the vehicle main-tenance schedule in Section 5.

!WARNING:

It is always better to check the

transaxle oil level when the engine is cool or cold. If the engine is hot, you should exercise great caution to avoid burning yourself on hotengine or exhaust parts.

NOTE: It is recommended that the manual

transaxle fluid should be checked by a Hyundai authorised repairer. G110A01MC-EAT The automatic transaxle fluid level should be checked and changed at those intervals prescribed in the main-tenance schedule. It is of paramount importance that only the specified fluid is used when replenishing or changingthe fluid. The use of other fluids may irreparably damage the transaxle and invalidate the manufacturers warranty.In addition the ingress of dirt or lint may prevent correct functioning of the transaxle and care must be exercisedto prevent the ingress of such matter.

Page 364 of 407

6

OWNER MAINTENANCE

15

!

NOTE: Automatic transaxle fluid is red in colour. As driving distance in-creases, the fluid colour turns dark- ish red gradually. It is a normal condition and you should not judgethe need to replace based upon the changing colour. You must replace the automatic transaxle fluid in accordance with intervals specified in the vehicle maintenances schedule in section 5.

WARNING:

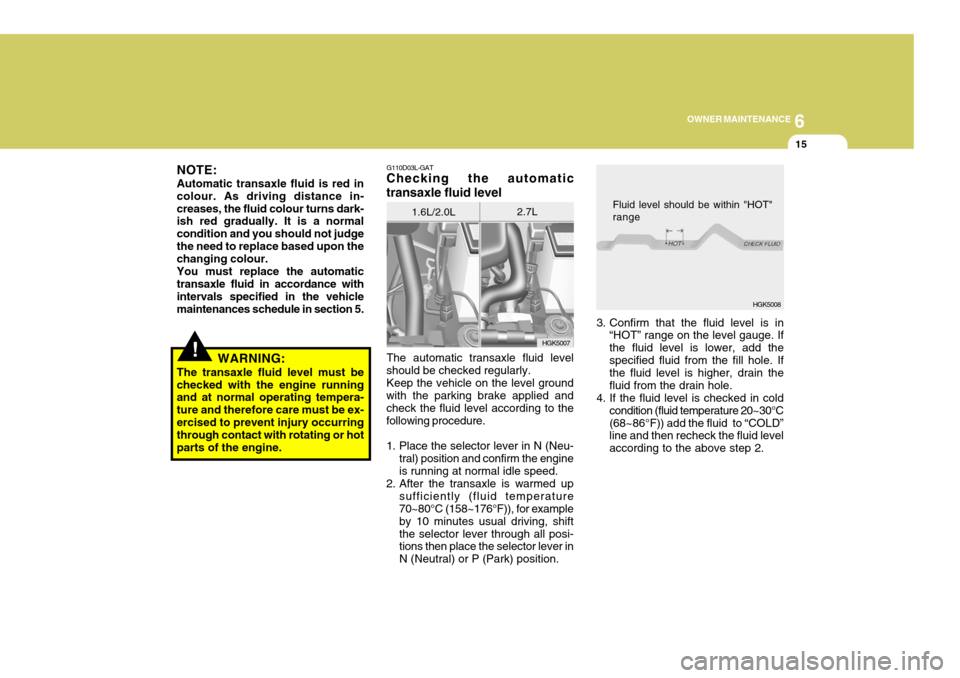

The transaxle fluid level must bechecked with the engine running and at normal operating tempera- ture and therefore care must be ex-ercised to prevent injury occurring through contact with rotating or hot parts of the engine. G110D03L-GAT

Checking the automatic transaxle fluid level

The automatic transaxle fluid level

should be checked regularly.

Keep the vehicle on the level ground

with the parking brake applied and check the fluid level according to the following procedure.

1. Place the selector lever in N (Neu- tral) position and confirm the engine is running at normal idle speed.

2. After the transaxle is warmed up sufficiently (fluid temperature70~80°C (158~176°F)), for example by 10 minutes usual driving, shiftthe selector lever through all posi- tions then place the selector lever in N (Neutral) or P (Park) position.

HGK5007

1.6L/2.0L

2.7L

HGK5008

Fluid level should be within "HOT" range

3. Confirm that the fluid level is in “HOT” range on the level gauge. If the fluid level is lower, add the specified fluid from the fill hole. If the fluid level is higher, drain thefluid from the drain hole.

4. If the fluid level is checked in cold condition (fluid temperature 20~30°C(68~86°F)) add the fluid to “COLD” line and then recheck the fluid level according to the above step 2.

Page 388 of 407

7EMISSION CONTROL SYSTEMS

2

SH010A1-E (Not all models) Depending upon the market for which the vehicle is destined, the emission control system will comprise one or more of the following emission controldevices.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. EMISSION CONTROL SYS- TEMS

DH010B1-E

1. Crankcase Emission Control

System

The positive crankcase ventilation (PCV) system is employed to prevent air pollution caused by blow-by gases being emitted from the crankcase. This system supplies fresh air to the crankcase through the air cleaner. In- side the crankcase, the fresh air mixeswith blow-by gases, then passes through the PCV valve into the intake system. When the engine is running, the fuelvapors absorbed in the canister aredrawn into the induction system through the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled by the ECU (Engine Control Unit); when the engine coolant tem- perature is low, and during idling, itcloses, so that evaporated fuel is not taken into the surge tank. After engine warm-up, during ordinary driving, itopens to introduce evaporated fuel to the surge tank.

JH010D1-E

3. Exhaust Emission Control

System

This system helps control oxides of

nitrogen by recirculating a portion of the exhaust gases into the intake manifold, thereby reducing cylinder combustion temperatures.

ZH010C1-E

2. Evaporative Emission

Control System

The Evaporative Emission Control System is designed to prevent fuelvapors from escaping into the atmo- sphere. Canister Whilst the engine is inoperative, fuel vapors generated inside the fuel tank are absorbed and stored in the canis- ter.

Page 404 of 407

10INDEX

4

L

Light Bulb Replacement .............................................. 6-25

Lubrication Chart .......................................................... 9-4

Luggage Net ............................................................... 1-77

M Maintenance Intervals Explanation of scheduled maintenance items

................................................................................. 5-8

Maintenance under severe usage conditions ............ 5-7

Scheduled maintenance ............................................ 5-4

Service requirements ................................................ 5-2

Map Light .................................................................... 1-66

Mirros Day-night inside rearview mirror ...............................1-69

Outside rearview mirror folding ................................1-69

Outsde rearview mirror heating ................................1-68

Multi Gauge ................................................................ 1-52

O Odometer .................................................................... 1-48

PParking Brake ............................................................. 1-70

Power Steering Fluid Level ......................................... 6-23

R Rear Seats Before folding the rear seats ................................... 1-18

Folding rear seatbacks ............................................ 1-18Rear seat entry ........................................................

1-16

Rear seat positions .................................................. 1-17

Rear Window Defogger ............................................... 1-59

Rear Window Wiper and Washer Switch ....................1-58

Running-In Your New Hyundai ..................................... 1-3

S Seats .......................................................................... 1-12

Seat Belts ................................................................... 1-19

3-Point type ............................................................. 1-22

Adjustable height ..................................................... 1-21

Adjusting your seat belt ........................................... 1-23

Care of seat belts .................................................... 1-21

Pre-tentioner seat belt ............................................. 1-29

Spectacle C ase .......................................................... 1-66

Speedometer ............................................................... 1-47

Starting Pr ocedures..................................................... 2-5

Steering Wheel Tilt Lever ........................................... 1-76

Stereo Sound System .............................................. 1-101

Sun Visor .................................................................... 1-75

Sunroof ....................................................................... 1-63

TTachometer ................................................................. 1-48

Theft Alarm System .................................................... 1-8

Towing

Emergency .............................................................. 3-13

If your vehicle must be towed ................................. 3-11

Trailer or vehicle towing ........................................... 2-20