Hyundai Coupe 2008 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2008, Model line: Coupe, Model: Hyundai Coupe 2008Pages: 407, PDF Size: 11.03 MB

Page 341 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

3

SF030B1-E

SERVICE HISTORY

It is important that all scheduled main- tenance services are recorded in thewarranty and service passport to en- sure that proof of maintenance is avail- able when warranty service is required.

NOTE:

Service schedules may change de-pending on individual country needs. Please ask your local Hyundai authorised repairer for acopy of the service schedule that relates to that country.

Page 342 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

4

DESCRIPTION ENGINE CONTROL SYSTEM MAINTENANCE ENGINE OIL & FILTER

DRIVE BELT 1.6L/2.0L (ALT, W/PUMP, P/STR'G) 2.7L (AUTO-TENSIONER, ALT, P/STR'G, A/CON)

FUEL FILTER (MPI) (1)FLUID LEAKS

TIMING BELT 2.7L

2.0L

TIMING BELT TENSIONER AND IDLER (2.0L)VACUUM HOSE CRANKCASE VENTILATION HOSE AIR CLEANER FILTER 3036

R II I I I

R

NO.

1 2 3 45 6 7 8 9

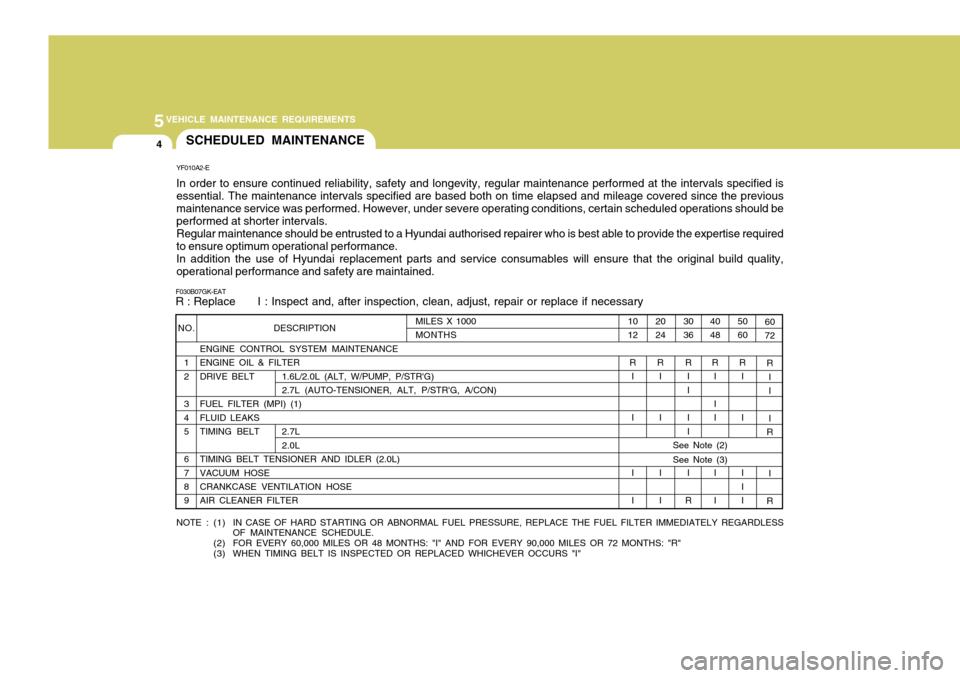

YF010A2-E In order to ensure continued reliability, safety and longevity, regular maintenance performed at the intervals specified is essential. The maintenance intervals specified are based both on time elapsed and mileage covered since the previous maintenance service was performed. However, under severe operating conditions, certain scheduled operations should beperformed at shorter intervals.Regular maintenance should be entrusted to a Hyundai authorised repairer who is best able to provide the expertise requiredto ensure optimum operational performance.In addition the use of Hyundai replacement parts and service consumables will ensure that the original build quality,operational performance and safety are maintained.

F030B07GK-EAT

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary50 60

R I I I I I 60 72

R I I I

R

I

R

40 48

R I I I I I

20 24

R I I I I

10 12

R I I I I

MILES X 1000 MONTHS

SCHEDULED MAINTENANCE

See Note (2) See Note (3)

NOTE : (1) IN CASE OF HARD STARTING OR ABNORMAL FUEL PRESSURE, REPLACE THE FUEL FILTER IMMEDIATELY REGARDLESS

OF MAINTENANCE SCHEDULE.

(2) FOR EVERY 60,000 MILES OR 48 MONTHS: "I" AND FOR EVERY 90,000 MILES OR 72 MONTHS: "R"

(3) WHEN TIMING BELT IS INSPECTED OR REPLACED WHICHEVER OCCURS "I"

Page 343 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

5

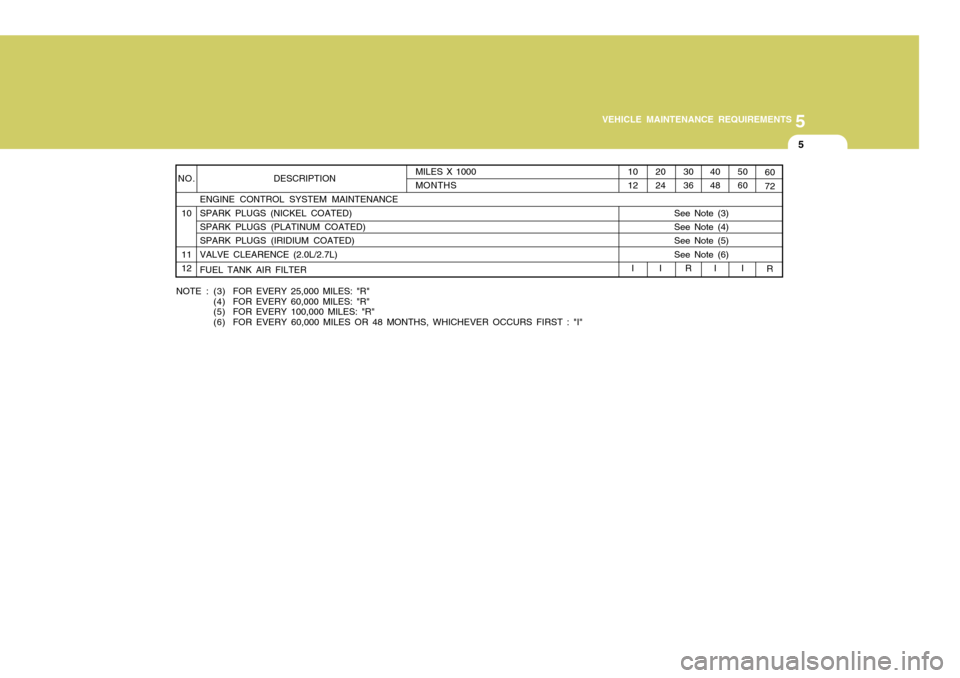

DESCRIPTION ENGINE CONTROL SYSTEM MAINTENANCE SPARK PLUGS (NICKEL COATED)SPARK PLUGS (PLATINUM COATED) SPARK PLUGS (IRIDIUM COATED) VALVE CLEARENCE (2.0L/2.7L) FUEL TANK AIR FILTER 30 36

R

NO.

10 11 12

50 60

I 6072

R

4048

I

2024

I

1012

I

MILES X 1000MONTHS

NOTE : (3) FOR EVERY 25,000 MILES: "R"

(4) FOR EVERY 60,000 MILES: "R"

(5) FOR EVERY 100,000 MILES: "R"

(6) FOR EVERY 60,000 MILES OR 48 MONTHS, WHICHEVER OCCURS FIRST : "I" See Note (3) See Note (4) See Note (5) See Note (6)

Page 344 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

6

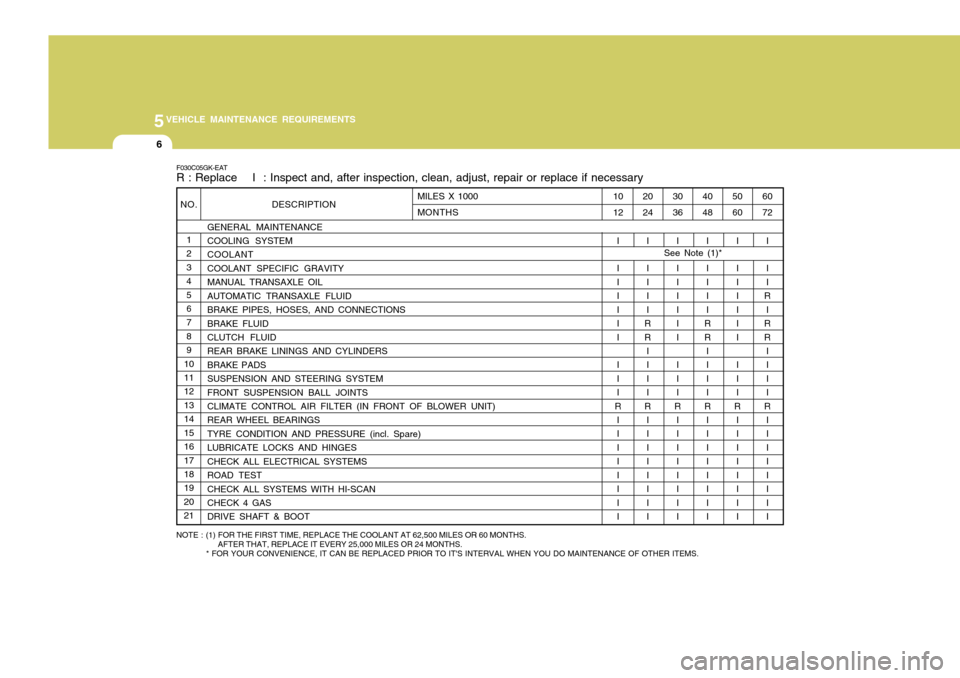

NO.1 2345 6 789

1011 12 1314151617 18 192021 DESCRIPTION

GENERAL MAINTENANCECOOLING SYSTEM COOLANT COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUID CLUTCH FLUID REAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSCLIMATE CONTROL AIR FILTER (IN FRONT OF BLOWER UNIT) REAR WHEEL BEARINGS TYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN CHECK 4 GAS DRIVE SHAFT & BOOT

F030C05GK-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

60 72

I I I

R

I

RR IIII

R I I IIIII I

50 60

I I IIIII I II

R

I I IIIII I

40 48

I I III

RR IIII

R I I IIIII I

30 36

I I IIIII I II

R I I IIIII I

20 24

I I III

RR IIII

R I I IIIII I

10 12

I I IIIII I II

R

I I IIIII I

MILES X 1000 MONTHS

NOTE : (1) FOR THE FIRST TIME, REPLACE THE COOLANT AT 62,500 MILES OR 60 MONTHS.

AFTER THAT, REPLACE IT EVERY 25,000 MILES OR 24 MONTHS.

* FOR YOUR CONVENIENCE, IT CAN BE REPLACED PRIOR TO IT'S INTERVAL WHEN YOU DO MAINTENANCE OF OTHER ITEMS. See Note (1)*

Page 345 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

7

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGS TIMING BELT BRAKE PADS, CALIPERS AND ROTORS REAR BRAKE DRUMS/LININGS, PARKING BRAKE STEERING GEAR BOX, LINKAGE & BOOTS/ LOWER ARM BALL JOINT DRIVE SHAFTS & BOOTS MANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID CLIMATE CONTROL AIR FILTER (IN FRONT OF BLOWER UNIT)

F040A04GK-EAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary MAINTENANCE UNDER SEVERE USAGE CONDITIONS

MAINTENANCE INTERVALS

A, B, C, D, E, F, G, H, I, K C, E B, H D, E, F, G B, D, E, F, G C, D, G, H C, D, G, H C, D, E, F C, D, E, F, G A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E

MAINTENANCE ITEM

DRIVING

CONDITION

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY MORE FREQUENTLY EVERY 37,000 MILES OR 48 MONTHS EVERY 60,000 MILES OR 48 MONTHS MORE FREQUENTLY MORE FREQUENTLY MORE FREQUENTLYEVERY 9,000 MILES OR 12 MONTHS EVERY 60,000 MILES EVERY 27,000 MILES MORE FREQUENTLYR R R R R II II

R R R

MAINTENANCE

OPERATION

SEVERE DRIVING CONDITIONSA - Repeatedly driving short distance of less than 5miles(8km) in normal temperature or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread roads

D - Driving in areas using salt or other corrosive materials or in very cold weather E - Driving in sandy areas

F - Driving in heavy traffic area over 32°C (90°F)G - Driving on uphill, downhill, or mountain roadH - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 100 MPH(170 Km/h) K - Frequently driving in stop-and-go conditions

2.7L 2.0L

Page 346 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

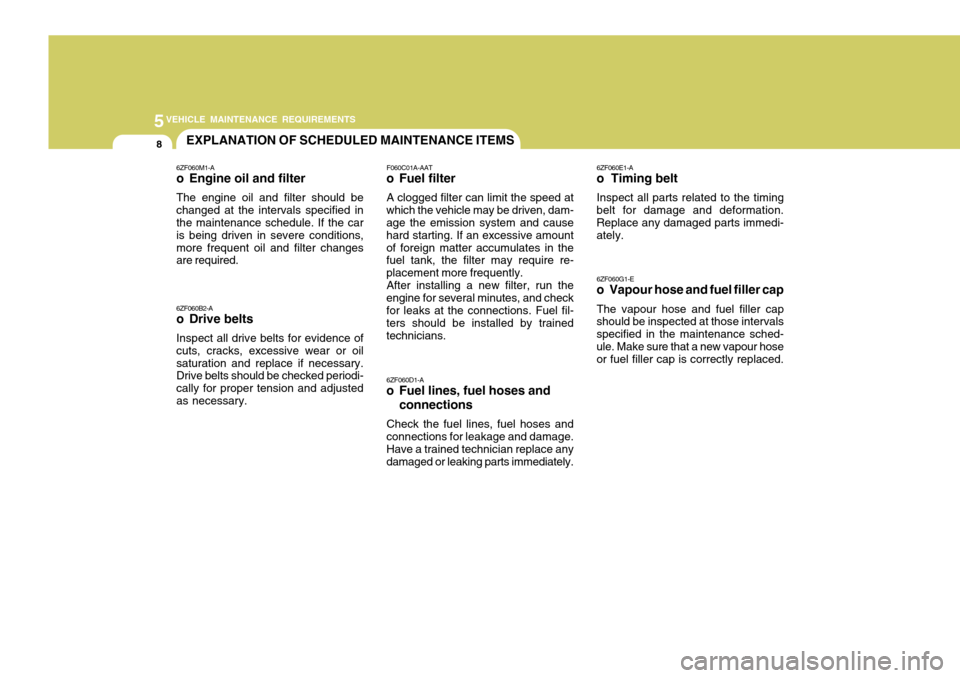

8EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked periodi- cally for proper tension and adjustedas necessary. 6ZF060D1-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately. 6ZF060E1-A

o Timing belt

Inspect all parts related to the timing

belt for damage and deformation. Replace any damaged parts immedi- ately.

6ZF060G1-E

o Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervalsspecified in the maintenance sched- ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

F060C01A-AAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians.

Page 347 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

9

6ZF060F2-A

o Crankcase ventilation hoses

Inspect the surface of hoses for evi- dence of heat and/or mechanical dam- age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Particu- lar attention should be paid to examin- ing those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold. Inspect the hose routing to assure that the hoses do not come in contact with any heat source, sharp edges or mov-ing component which might cause heat damage or mechanical wear. Inspect all hose connections, such as clampsand couplings, to make sure they are secure, and that no leaks are present. Hoses should be replaced immedi-ately if there is any evidence of dete- rioration or damage. 6ZF060H1-A

o Air cleaner filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re-placed.

6ZF060J1-A

o Spark plugs

Make sure to install new spark plugs

of the correct heat range.

F060N02E-AAT

o Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces- sary. A qualified technician should perform the operation. 6ZF070B1-A

o Cooling system Check the cooling system part, such as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts. 6ZF070C1-A

o Coolant The coolant should be changed at the intervals specified in the mainte-nance schedule. 6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil ac- cording to the maintenance schedule. NOTE: If the oil level is low, check for possible leaks before adding oil. Do not overfill.

Page 348 of 407

5VEHICLE MAINTENANCE REQUIREMENTS

10

6ZF070F1-A o Brake hoses and lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately. A6ZF070G2-A

o Brake fluid & Clutch fluid

Check brake fluid level in the brake

fluid reservoir. The level should be between "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4.

6ZF070H1-A

o Rear brake drums and linings/

parking brake

Check the rear brake drums and lin-

ings for scoring, burning, leaking fluid,broken parts, and excessive wear. In- spect the parking brake system in-cluding the parking brake lever and cables. For detailed service proce- dures, refer to the Shop Manual. 6ZF070J1-A

o Brake pads, calipers and ro-

tors

Check the pads for excessive wear,

discs for run out and wear, and cali- pers for fluid leakage.

6ZF070K1-E

o Exhaust pipe and silencer

Visually inspect the exhaust pipes,

silencer and hangers for cracks, dete-rioration, or damage. Start the engine and listen carefully for any exhaustgas leakage. Tighten connections or replace parts as necessary.

6ZF070L1-A

o Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the specified torque.

F070E05A-EAT

o Automatic Transaxle Fluid

The fluid level should be in the "HOT"range of the dipstick, after the engine and transaxle are at normal operating temperature. Check the automatictransaxle fluid level with the engine running and the transaxle in neutral, with the parking brake properly ap-plied. Use Hyundai Genuine ATF SP- III, DIAMOND ATF SP-III, SK ATF SP-III or other brands approved byHyundai Motor Co., when adding or changing fluid. Refer to the chapter 6.

Page 349 of 407

5

VEHICLE MAINTENANCE REQUIREMENTS

11

6ZF070M1-A

o Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel. Check the linkage for bends or dam- age. Check the dust boots and ball joints for deterioration, cracks, or dam- age. Replace any damaged parts. 6ZF070N1-A

o Power steering pump,

belt and hoses

Check the power steering pump and hoses for leakage and damage. Re- place any damaged or leaking partsimmediately. Inspect the power steer- ing belt for evidence of cuts, cracks, excessive wear, oil contamination andproper tension. Replace or adjust it if necessary. 6ZF070P1-A

o Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, ordamage. Replace any damaged parts and, if necessary, repack the grease.

6ZF070Q1-A

o Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and damage. Check air conditioning performance according to the relevant shop manualif necessary.

Page 350 of 407

6

Engine Compartment .................................................... 6-2

Daily Operating Checks ............................................... 6-5

Maintenance Precautions ............................................. 6-5

Engine Oil ..................................................................... 6-6

Engine Coolant Checking and Replacing .................... 6-9

Changing the Air Cleaner Filter ...................................6-11

Manual Transaxle Lubricant .................... ....................6-14

Automatic Transaxle Fluid ........................................... 6-14

Brake System Checking ............................................. 6-16

Checking the Clutch Fluid ........................................... 6-17

Air Conditioning System Maintenance ........................ 6-17

Changing the Climate Control Air Filter .. ....................6-18

Fusible Links ............................................................... 6-20

Battery Mai ntenance ................................................... 6-21

Electric Cooling Fans .................................................. 6-23

Power Steering Fluid Level ......................................... 6-23

Headlight Aiming Adjustment ...................................... 6-24

Replacing Light Bulbs ................................................. 6-25

Bulb Wattage ............................................................... 6-33

Fuse Panel D escription ............................................... 6-34

OWNER MAINTENANCE

6