cooling HYUNDAI COUPE 2012 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2012, Model line: COUPE, Model: HYUNDAI COUPE 2012Pages: 391, PDF Size: 6.88 MB

Page 307 of 391

75

Maintenance

OWNER MAINTENANCE

G030000AEN

The following lists are vehicle checks and

inspections that should be performed by

the owner or an authorized HYUNDAI

dealer at the frequencies indicated to

help ensure safe, dependable operation

of your vehicle.

Any adverse conditions should be

brought to the attention of your dealer as

soon as possible.

These Owner Maintenance Checks are

generally not covered by warranties and

you may be charged for labor, parts and

lubricants used.Owner maintenance schedule

G030101AUN

When you stop for fuel:

Check the engine oil level.

Check the coolant level in coolantreservoir.

Check the windshield washer fluid level.

Look for low or under-inflated tires.

WARNING- Maintenance work

Performing maintenance work on

a vehicle can be dangerous. You

can be seriously injured while

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, have it done by an

authorized HYUNDAI dealer.

Working under the hood with the engine running is dangerous. It

becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine while work-

ing under the hood, make certain

that you remove all jewelry (espe-

cially rings, bracelets, watches,

and necklaces) and all neckties,

scarves, and similar loose cloth-

ing before getting near the

engine or cooling fans.

WARNING

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot coolant

and steam may blow out under

pressure. This could cause burns

or other serious injury.

procarmanuals.com

Page 316 of 391

Maintenance

14

7

G050600AUN

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

G050700AUN

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

G050800AEN

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is

recommended when the filter is

replaced.

G050900AUN

Spark plugs

Make sure to install new spark plugs of

the correct heat range.

G051000AEN

Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized HYUNDAI dealer should

perform the operation.

G051100AUN

Cooling system

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

G051200AUN

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

G051300ABK

Manual transmission fluid

(if equipped)

Inspect the manual transmission fluid

according to the maintenance schedule.

G051400ABK

Automatic transmission fluid

(if equipped)

Inspect the automatic transmission fluid

according to the maintenance schedule.

G051500AUN

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

procarmanuals.com

Page 319 of 391

717

Maintenance

G060200AEN-EU

Changing the engine oil and filter

Have engine oil and filter changed by an

authorized HYUNDAI dealer according to

the Maintenance Schedule at the begin-

ning of this section.

G070000AUN

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, at the

beginning of the winter season, and

before traveling to a colder climate.

Checking the coolant level

CALIFORNIA PROPOSI-

TION 65 WARNING

Engine oil contains chemicals

known to the State of California to

cause cancer, birth defects and

reproductive harm. Used engine oil

may cause irritation or cancer of

the skin if left in contact with the

skin for prolonged periods of time.

Always protect your skin by wash-

ing your hands thoroughly with

soap and warm water as soon as

possible after handling used oil.

ENGINE COOLANT

(Continued)

Turn the engine off and wait until it

cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the cool-

ing system. When you are sure all

the pressure has been released,

press down on the cap, using a

thick towel, and continue turning

counterclockwise to remove it.

Even if the engine is not operat- ing, do not remove the radiator

cap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

WARNING

Removing radiator

cap

Never attempt to remove the radi-ator cap while the engine is oper-

ating or hot. Doing so might lead

to cooling system and engine

damage and could result in seri-

ous personal injury from escap-

ing hot coolant or steam.

(Continued)

procarmanuals.com

Page 320 of 391

Maintenance

18

7

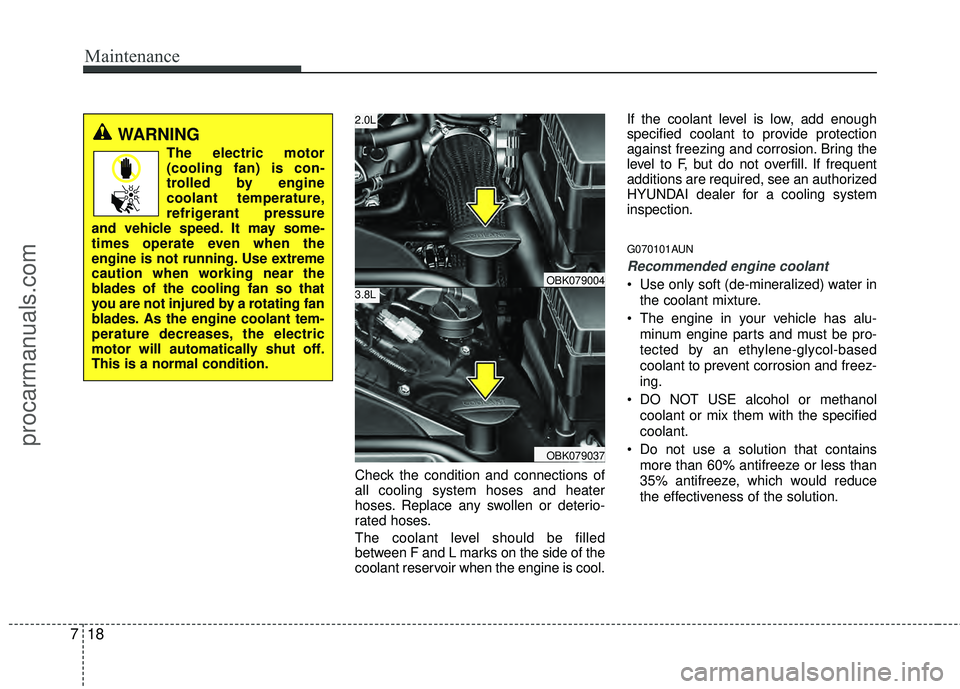

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine is cool. If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F, but do not overfill. If frequent

additions are required, see an authorized

HYUNDAI dealer for a cooling system

inspection.

G070101AUN

Recommended engine coolant

Use only soft (de-mineralized) water in

the coolant mixture.

The engine in your vehicle has alu- minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-

ing.

DO NOT USE alcohol or methanol coolant or mix them with the specified

coolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.OBK079004

OBK079037

2.0L

3.8L

WARNING

The electric motor

(cooling fan) is con-

trolled by engine

coolant temperature,

refrigerant pressure

and vehicle speed. It may some-

times operate even when the

engine is not running. Use extreme

caution when working near the

blades of the cooling fan so that

you are not injured by a rotating fan

blades. As the engine coolant tem-

perature decreases, the electric

motor will automatically shut off.

This is a normal condition.

procarmanuals.com

Page 356 of 391

Maintenance

54

7

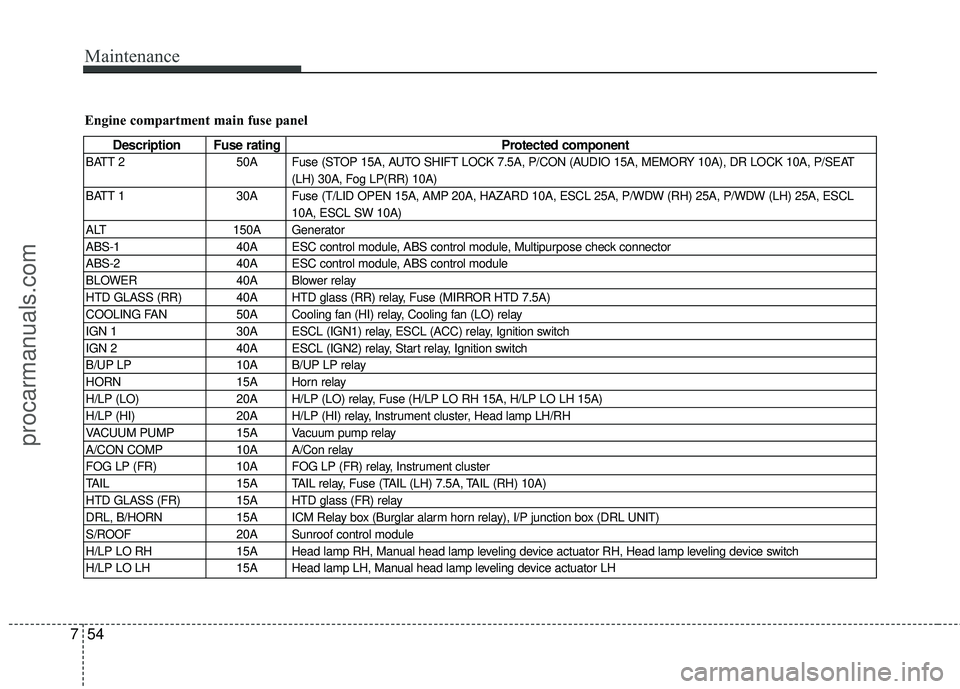

Engine compartment main fuse panel

Description Fuse rating Protected component

BATT 250A Fuse (STOP 15A, AUTO SHIFT LOCK 7.5A, P/CON (AUDIO 15A, MEMORY 10A), DR LOCK 10A, P/SEAT

(LH) 30A, Fog LP(RR) 10A)

BATT 1 30A Fuse (T/LID OPEN 15A, AMP 20A, HAZARD 10A, ESCL 25A, P/WDW (RH) 25A, P/WDW (LH) 25A, ESCL

10A, ESCL SW 10A)

ALT 150A Generator

ABS-1 40A ESC control module, ABS control module, Multipurpose check connector

ABS-2 40A ESC control module, ABS control module

BLOWER 40A Blower relay

HTD GLASS (RR) 40A HTD glass (RR) relay, Fuse (MIRROR HTD 7.5A)

COOLING FAN 50A Cooling fan (HI) relay, Cooling fan (LO) relay

IGN 1 30A ESCL (IGN1) relay, ESCL (ACC) relay, Ignition switch

IGN 2 40A ESCL (IGN2) relay, Start relay, Ignition switch

B/UP LP 10A B/UP LP relay

HORN 15A Horn relay

H/LP (LO) 20A H/LP (LO) relay, Fuse (H/LP LO RH 15A, H/LP LO LH 15A)

H/LP (HI) 20A H/LP (HI) relay, Instrument cluster, Head lamp LH/RH

VACUUM PUMP 15A Vacuum pump relay

A/CON COMP 10A A/Con relay

FOG LP (FR) 10A FOG LP (FR) relay, Instrument cluster

TAIL 15A TAIL relay, Fuse (TAIL (LH) 7.5A, TAIL (RH) 10A)

HTD GLASS (FR) 15A HTD glass (FR) relay

DRL, B/HORN 15A ICM Relay box (Burglar alarm horn relay), I/P junction box (DRL UNIT)

S/ROOF 20A Sunroof control module

H/LP LO RH 15A Head lamp RH, Manual head lamp leveling device actuator RH, Head lamp leveling device switch

H/LP LO LH 15A Head lamp LH, Manual head lamp leveling device actuator LH

procarmanuals.com

Page 357 of 391

755

Maintenance

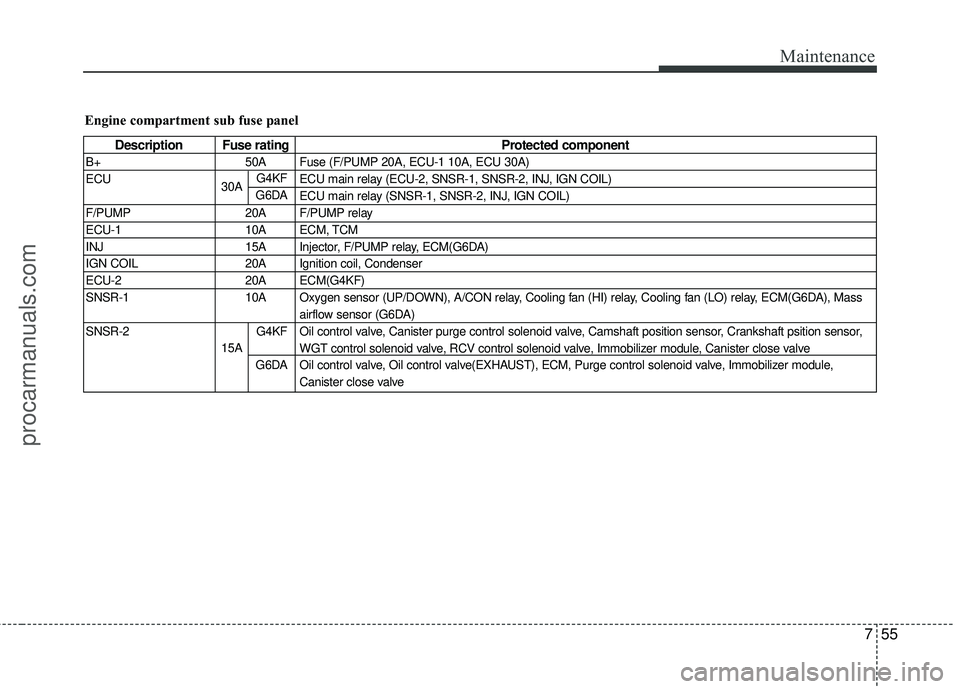

Engine compartment sub fuse panel

Description Fuse ratingProtected component

B+50A Fuse (F/PUMP 20A, ECU-1 10A, ECU 30A)

ECU ECU main relay (ECU-2, SNSR-1, SNSR-2, INJ, IGN COIL)

ECU main relay (SNSR-1, SNSR-2, INJ, IGN COIL)

F/PUMP 20A F/PUMP relay

ECU-1 10A ECM, TCM

INJ 15A Injector, F/PUMP relay, ECM(G6DA)

IGN COIL 20A Ignition coil, Condenser

ECU-2 20A ECM(G4KF)

SNSR-1 10A Oxygen sensor (UP/DOWN), A/CON relay, Cooling fan (HI) relay, Cooling fan (LO) relay, ECM(G6DA), Mass

airflow sensor (G6DA)

SNSR-2 Oil control valve, Canister purge control solenoid valve, Camshaft position sensor, Crankshaft psition sensor,

WGT control solenoid valve, RCV control solenoid valve, Immobilizer module, Canister close valve

Oil control valve, Oil control valve(EXHAUST), ECM, Purge control solenoid valve, Immobilizer module,

Canister close valve

30A G4KF

G6DA

15A G4KF

G6DA

procarmanuals.com

Page 384 of 391

I3

Index

CareExterior care ··················\

··················\

··················\

········7-61

Interior care ··················\

··················\

··················\

·········7-66

Tire care··················\

··················\

··················\

···············7-33

Cargo capacity ··················\

··················\

··················\

·········5-47

Cargo weight ··················\

··················\

··················\

············5-51

Center console storage ··················\

··················\

···············4-92

Central door lock switch··················\

··················\

············4-17

Certification label ··················\

··················\

··················\

····5-49

Changing a tire with TPMS ··················\

··················\

·········6-7

Changing tires ··················\

··················\

··················\

··········6-13

Chains Tire chains··················\

··················\

··················\

··5-43, 7-45

Checking tire inflation pressure··················\

··················\

·7-34

Child restraint system ··················\

··················\

················3-25 Auto lock mode (Passenger seat belt) ··················\

·····3-27

Lower anchor system ··················\

··················\

············3-31

Tether anchor system··················\

··················\

·············3-29

Climate control system (Automatic) ··················\

···········4-79 Air conditioning ··················\

··················\

··················\

··4-84

Automatic heating and air conditioning··················\

··4-80

Manual heating and air conditioning ··················\

······4-81

Climate control system (Manual) ··················\

···············4-70 Air conditioning ··················\

··················\

··················\

··4-75

Heating and air conditioning··················\

··················\

·4-71 Climate control air filter··················\

··················\

···4-77, 7-25

Clock (Digital) ··················\

··················\

··················\

·········4-96

Combined instrument, see instrument cluster ···············4-42

Compact spare tire ··················\

··················\

··················\

···6-18

Compact spare tire replacement ··················\

··················\

7-38

Consumer information ··················\

··················\

·················8-8

Coolant ··················\

··················\

··················\

··················\

···7-17

Cooling fluid, see engine coolant ··················\

················7-18

Crankcase emission control system ··················\

·············7-67

Cruise control system ··················\

··················\

················5-32

Cup holder ··················\

··················\

··················\

···············4-94

Curtain air bag ··················\

··················\

··················\

·········3-50

Dashboard, see instrument cluster ··················\

···············4-42

Dashboard illumination, see instrument

panel illumination··················\

··················\

··················\

4-43

Defogging (Windshield) ··················\

··················\

············4-90

Defogging logic (Windshield) ··················\

··················\

···4-91

Defroster (Rear window) ··················\

··················\

···········4-69

Defrosting (Windshield) ··················\

··················\

············4-90

Digital clock··················\

··················\

··················\

·············4-96

Dimensions ··················\

··················\

··················\

················8-2

Display illumination, see instrument panel illumination··················\

··················\

··················\

4-43

Displays, see instrument cluster ··················\

··················\

4-42

D

procarmanuals.com