coolant Hyundai Elantra 2008 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Elantra, Model: Hyundai Elantra 2008Pages: 360, PDF Size: 12.2 MB

Page 281 of 360

75

Maintenance

OWNER MAINTENANCE The following lists are vehicle checks and

inspections that should be performed by

the owner or an authorized Hyundai

dealer at the frequencies indicated to

help ensure safe, dependable operation

of your vehicle.

Any adverse conditions should be

brought to the attention of your dealer as

soon as possible.

These Owner Maintenance Checks are

generally not covered by warranties and

you may be charged for labor, parts and

lubricants used.

Owner maintenance schedule When you stop for fuel: Check the engine oil level.

Check coolant level in coolant reser-

voir.

Check the windshield washer fluid

level.

Look for low or under-inflated tires.

While operating your vehicle: Note any changes in the sound of the

exhaust or any smell of exhaust fumes

in the vehicle.

Check for vibrations in the steering

wheel. Notice any increased steering

effort or looseness in the steering

wheel, or change in its straight-ahead

position.

Notice if your vehicle constantly turns

slightly or “pulls” to one side when trav-

eling on smooth, level road.

When stopping, listen and check for

unusual sounds, pulling to one side,

increased brake pedal travel or “hard-

to-push” brake pedal.

If any slipping or changes in the oper-

ation of your transaxle occurs, check

the transaxle fluid level.

Check automatic transaxle P (Park)

function.

Check parking brake.

Check for fluid leaks under your vehicle

(water dripping from the air condition-

ing system during or after use is nor-

mal).

WARNING

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot coolant

and steam may blow out under

pressure. This could cause burns

or other serious injury.

Page 282 of 360

Maintenance6 7At least monthly: Check coolant level in the engine

coolant reservoir.

Check the operation of all exterior

lights, including the stoplights, turn sig-

nals and hazard warning flashers.

Check the inflation pressures of all

tires including the spare.

At least twice a year

(i.e., every Spring and Fall) : Check radiator, heater and air condi-

tioning hoses for leaks or damage.

Check windshield washer spray and

wiper operation. Clean wiper blades

with clean cloth dampened with wash-

er fluid.

Check headlight alignment.

Check muffler, exhaust pipes, shields

and clamps.

Check the lap/shoulder belts for wear

and function.

Check for worn tires and loose wheel

lug nuts.

At least once a year : Clean body and door drain holes.

Lubricate door hinges and checks, and

hood hinges.

Lubricate door and hood locks and

latches.

Lubricate door rubber weatherstrips.

Check the air conditioning system.

Inspect and lubricate automatic

transaxle linkage and controls.

Clean battery and terminals.

Check the brake (and clutch) fluid

level.

Page 285 of 360

No.1

2

3

4

5

6

7

8

9

10

79

Maintenance

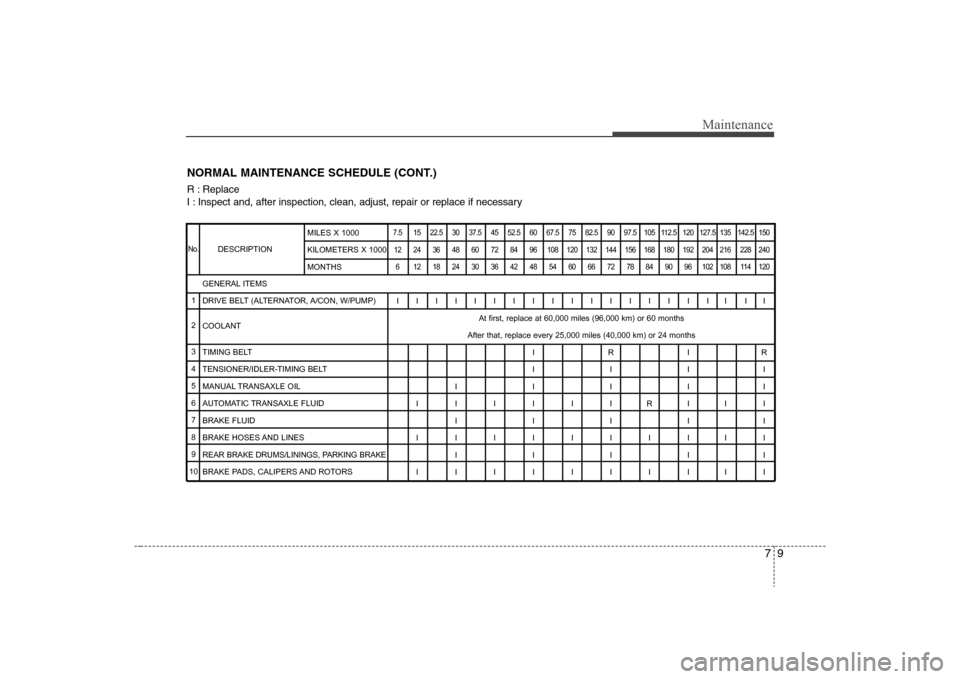

NORMAL MAINTENANCE SCHEDULE (CONT.)

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120IIIIIIIIIIIIIIIIII II

At first, replace at 60,000 miles (96,000 km) or 60 months

After that, replace every 25,000 miles (40,000 km) or 24 months

IRIR

IIII

IIIII

IIIIIIRIII

IIIII

IIIIIIIIII

IIIII

IIIIIIIIII GENERAL ITEMS

DRIVE BELT (ALTERNATOR, A/CON, W/PUMP)

COOLANT

TIMING BELT

TENSIONER/IDLER-TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORSMILES X 1000

KILOMETERS X 1000

MONTHS

R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 289 of 360

713

Maintenance

Timing beltInspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.Vapor hose and fuel filler capThe vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hosesInspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filterA Genuine Hyundai air cleaner filter is

recommended when the filter is

replaced.Spark plugsMake sure to install new spark plugs of

the correct heat range.Valve clearanceInspect excessive valve noise and/or

engine vibration and adjust if necessary.

A qualified technician should perform the

operation.Cooling systemCheck the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 292 of 360

Maintenance16 7

The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant level at least once a year, at the

beginning of the winter season, and

before traveling to a colder climate.Checking the coolant level

WARNING

- Removing

radiator cap

Never attempt to remove the radi-

ator cap while the engine is oper-

ating or hot. Doing so might lead

to cooling system and engine

damage and could result in seri-

ous personal injury from escap-

ing hot coolant or steam.

(Continued)

(Continued)

Turn the engine off and wait until

it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the

cooling system. When you are

sure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not operat-

ing, do not remove the radiator

cap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

ENGINE COOLANT

PROPOSITION 65

WARNING

Used engine oil may cause irrita-

tion or cancer of the skin if left in

contact with the skin for prolonged

periods of time. Used engine oil

contains chemicals that have

caused cancer in laboratory ani-

mals. Always protect your skin by

washing your hands thoroughly

with soap and warm water as soon

as possible after handling used oil.

Page 293 of 360

717

Maintenance

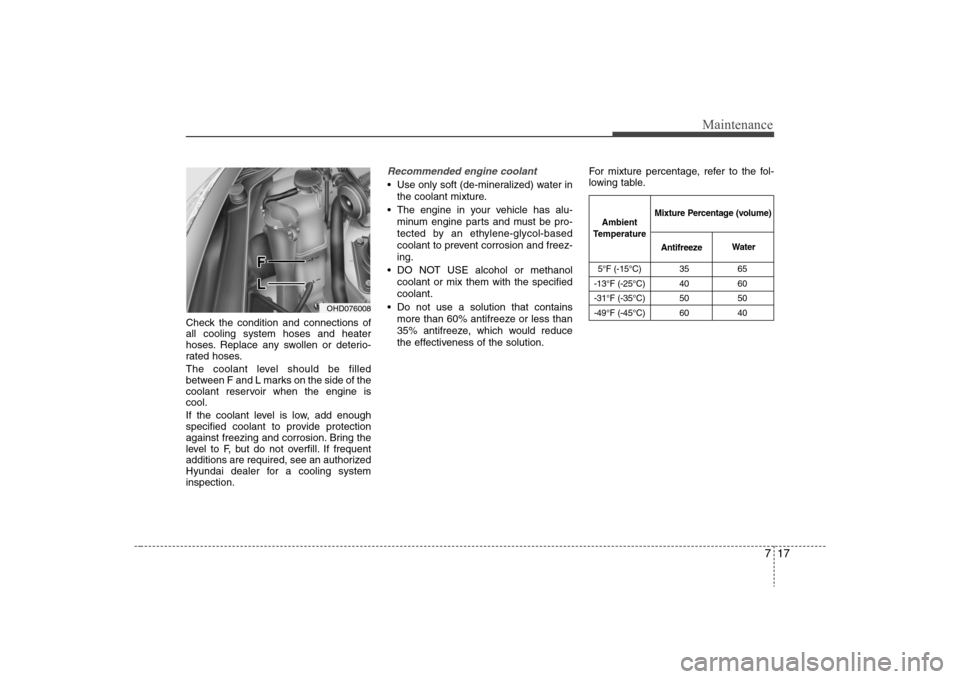

Check the condition and connections of

all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F and L marks on the side of the

coolant reservoir when the engine is

cool.

If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F, but do not overfill. If frequent

additions are required, see an authorized

Hyundai dealer for a cooling system

inspection.

Recommended engine coolant Use only soft (de-mineralized) water in

the coolant mixture.

The engine in your vehicle has alu-

minum engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-

ing.

DO NOT USE alcohol or methanol

coolant or mix them with the specified

coolant.

Do not use a solution that contains

more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.For mixture percentage, refer to the fol-

lowing table.

OHD076008

5°F (-15°C) 35 65

-13°F (-25°C) 40 60

-31°F (-35°C) 50 50

-49°F (-45°C) 60 40Ambient

TemperatureMixture Percentage (volume)

AntifreezeWater

Page 294 of 360

Maintenance18 7Changing the coolantHave coolant changed by an authorized

Hyundai dealer according to the

Maintenance Schedule at the beginning

of this section.

WARNING -

Radiator cap

Do not remove the radiator cap

when the engine and radiator are

hot. Scalding hot coolant and

steam may blow out under pres-

sure causing serious injury.

OHD076009

WARNING -

Coolant

Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

Radiator coolant can severely

obscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

Windshield Washer fluid agents

contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allow

sparks or flame to contact the

washer fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

Windshield washer fluid is poi-

sonous to humans and animals.

Do not drink and avoid contact-

ing windshield washer fluid.

Serious injury or death could

occur.

Page 298 of 360

Maintenance22 7WASHER FLUIDChecking the washer fluid level The reservoir is translucent so that you

can check the level with a quick visual

inspection.

Check the fluid level in the washer fluid

reservoir and add fluid if necessary. Plain

water may be used if washer fluid is not

available. However, use washer solvent

with antifreeze characteristics in cold cli-

mates to prevent freezing.

Checking the parking brake Check the stroke of the parking brake by

counting the number of “clicks’’ heard

while fully applying it from the released

position. Also, the parking brake alone

should securely hold the vehicle on a fair-

ly steep grade. If the stroke is more or

less than specified, have the parking

brake adjusted by an authorized Hyundai

dealer.

Stroke : 7 “clicks’’ at a force of

44 lbs (20 kg, 196 N).

WARNING -

Coolant

Do not use radiator coolant or

antifreeze in the washer fluid

reservoir.

Radiator coolant can severely

obscure visibility when sprayed

on the windshield and may cause

loss of vehicle control or damage

to paint and body trim.

Windshield Washer fluid agents

contain some amounts of alcohol

and can be flammable under cer-

tain circumstances. Do not allow

sparks or flame to contact the

washer fluid or the washer fluid

reservoir. Damage to the vehicle

or occupants could occur.

Windshield washer fluid is poi-

sonous to humans and animals.

Do not drink and avoid contact-

ing windshield washer fluid.

Serious injury or death could

occur.

OHD076013

OHD056005

PARKING BRAKE

Page 318 of 360

Maintenance42 7Cold Tire Pressure: The amount of

air pressure in a tire, measured in

pounds per square inch (psi) or kilo-

pascals (kPa) before a tire has built

up heat from driving.

Curb Weight: This means the weight

of a motor vehicle with standard and

optional equipment including the

maximum capacity of fuel, oil and

coolant, but without passengers and

cargo.

DOT Markings: A code molded into

the sidewall of a tire signifying that

the tire is in compliance with the U.S.

Department of Transportation motor

vehicle safety standards. The DOT

code includes the Tire Identification

Number (TIN), an alphanumeric des-

ignator which can also identify the

tire manufacturer, production plant,

brand and date of production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight

Rating for the Front Axle.

GAWR RR: Gross Axle Weight

Rating for the Rear Axle.Intended Outboard Sidewall: The

side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Load Index: An assigned number

ranging from 1 to 279 that corre-

sponds to the load carrying capacity

of a tire.

Maximum Inflation Pressure: The

maximum air pressure to which a

cold tire may be inflated. The maxi-

mum air pressure is molded onto the

sidewall.

Maximum Load Rating: The load

rating for a tire at the maximum per-

missible inflation pressure for that

tire.

Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight:The

number of occupants a vehicle is

designed to seat multiplied by 150

pounds (68 kg).Occupant Distribution: Designated

seating positions.

Outward Facing Sidewall:The side

of a asymmetrical tire that has a par-

ticular side that faces outward when

mounted on a vehicle. The outward

facing sidewall bears white lettering

or bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) Tire: A tire

used on passenger cars and some

light duty trucks and multipurpose

vehicles.

Recommended Inflation Pressure:

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and

upon which the tire beads are seat-

ed.

Sidewall: The portion of a tire

between the tread and the bead.

Page 341 of 360

765

Maintenance

EMISSION CONTROL SYSTEMThe emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Owner’s

Handbook & Warranty Information book-

let in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all emission

regulations.

There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized Hyundai dealer in accordance with

the maintenance schedule in this manu-

al.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com-

pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control

systemThe positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control

(including ORVR: Onboard

Refueling Vapor Recovery)

SystemThe Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be

loaded into a canister while refueling at

the gas station, preventing the escape of

fuel vapors into the atmosphere.)CanisterFuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.