Hyundai Elantra 2008 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2008, Model line: Elantra, Model: Hyundai Elantra 2008Pages: 360, PDF Size: 12.2 MB

Page 281 of 360

75

Maintenance

OWNER MAINTENANCE The following lists are vehicle checks and

inspections that should be performed by

the owner or an authorized Hyundai

dealer at the frequencies indicated to

help ensure safe, dependable operation

of your vehicle.

Any adverse conditions should be

brought to the attention of your dealer as

soon as possible.

These Owner Maintenance Checks are

generally not covered by warranties and

you may be charged for labor, parts and

lubricants used.

Owner maintenance schedule When you stop for fuel: Check the engine oil level.

Check coolant level in coolant reser-

voir.

Check the windshield washer fluid

level.

Look for low or under-inflated tires.

While operating your vehicle: Note any changes in the sound of the

exhaust or any smell of exhaust fumes

in the vehicle.

Check for vibrations in the steering

wheel. Notice any increased steering

effort or looseness in the steering

wheel, or change in its straight-ahead

position.

Notice if your vehicle constantly turns

slightly or “pulls” to one side when trav-

eling on smooth, level road.

When stopping, listen and check for

unusual sounds, pulling to one side,

increased brake pedal travel or “hard-

to-push” brake pedal.

If any slipping or changes in the oper-

ation of your transaxle occurs, check

the transaxle fluid level.

Check automatic transaxle P (Park)

function.

Check parking brake.

Check for fluid leaks under your vehicle

(water dripping from the air condition-

ing system during or after use is nor-

mal).

WARNING

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot coolant

and steam may blow out under

pressure. This could cause burns

or other serious injury.

Page 282 of 360

Maintenance6 7At least monthly: Check coolant level in the engine

coolant reservoir.

Check the operation of all exterior

lights, including the stoplights, turn sig-

nals and hazard warning flashers.

Check the inflation pressures of all

tires including the spare.

At least twice a year

(i.e., every Spring and Fall) : Check radiator, heater and air condi-

tioning hoses for leaks or damage.

Check windshield washer spray and

wiper operation. Clean wiper blades

with clean cloth dampened with wash-

er fluid.

Check headlight alignment.

Check muffler, exhaust pipes, shields

and clamps.

Check the lap/shoulder belts for wear

and function.

Check for worn tires and loose wheel

lug nuts.

At least once a year : Clean body and door drain holes.

Lubricate door hinges and checks, and

hood hinges.

Lubricate door and hood locks and

latches.

Lubricate door rubber weatherstrips.

Check the air conditioning system.

Inspect and lubricate automatic

transaxle linkage and controls.

Clean battery and terminals.

Check the brake (and clutch) fluid

level.

Page 283 of 360

77

Maintenance

SCHEDULED MAINTENANCE SERVICE Follow Normal Maintenance Schedule if

the vehicle is usually operated where

none of the following conditions apply. If

any of the following conditions apply, fol-

low Maintenance Under Severe Usage

Conditions.

Repeated short distance driving.

Driving in dusty conditions or sandy

areas.

Extensive use of brakes.

Driving in areas where salt or other

corrosive materials are being used.

Driving on rough or muddy roads.

Driving in mountainous areas.

Extended periods of idling or low

speed operation.

Driving for a prolonged period in cold

temperatures and/or extremely humid

climates.

More than 50% driving in heavy city

traffic during hot weather above 90°F

(32°C).

If your vehicle is operated under the

above conditions, you should inspect,

replace or refill more frequently than the

following Normal Maintenance Schedule.

After 120 month or 150,000 miles

(240,000 km) continue to follow the pre-

scribed maintenance intervals.

Page 284 of 360

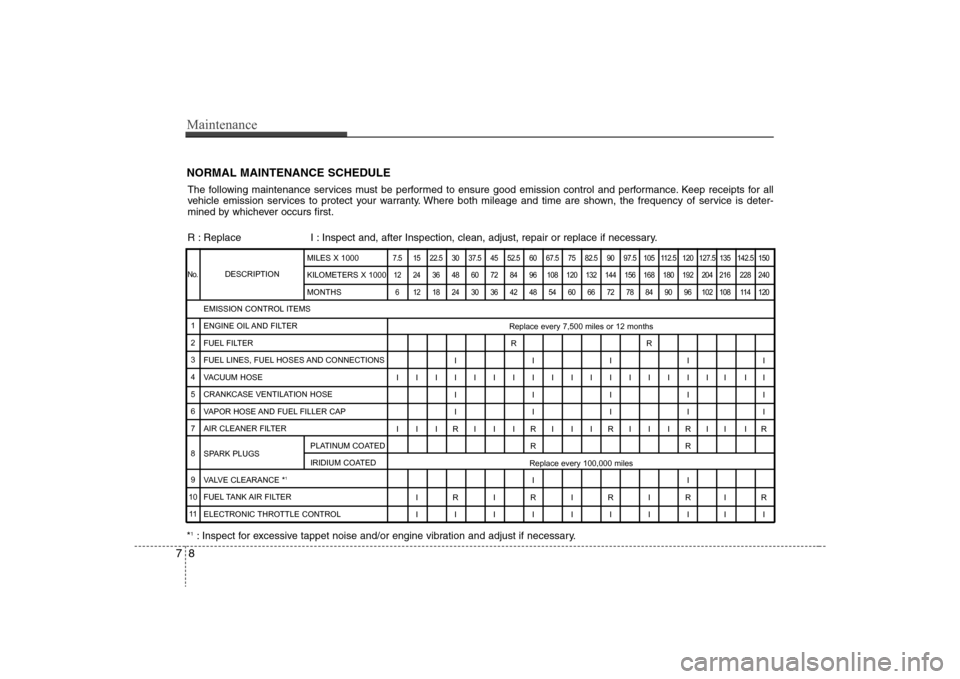

Maintenance8 7NORMAL MAINTENANCE SCHEDULEThe following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all

vehicle emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is deter-

mined by whichever occurs first.

R : Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120

Replace every 7,500 miles or 12 months

RR

IIIII

IIIIIIIIIIIIIIIIII II

IIIII

IIIII

I I IRI I IRI I IRI I IRII IR

RR

Replace every 100,000 miles

II

IRIRIRIRIR

IIIIIIIIII EMISSION CONTROL ITEMS

ENGINE OIL AND FILTER

FUEL FILTER

FUEL LINES, FUEL HOSES AND CONNECTIONS

VACUUM HOSE

CRANKCASE VENTILATION HOSE

VAPOR HOSE AND FUEL FILLER CAP

AIR CLEANER FILTER

SPARK PLUGSPLATINUM COATED

IRIDIUM COATED

VALVE CLEARANCE *

1

FUEL TANK AIR FILTER

ELECTRONIC THROTTLE CONTROL

No.1

2

3

4

5

6

7

8

9

10

11MILES X 1000

KILOMETERS X 1000

MONTHS*1: Inspect for excessive tappet noise and/or engine vibration and adjust if necessary.

Page 285 of 360

No.1

2

3

4

5

6

7

8

9

10

79

Maintenance

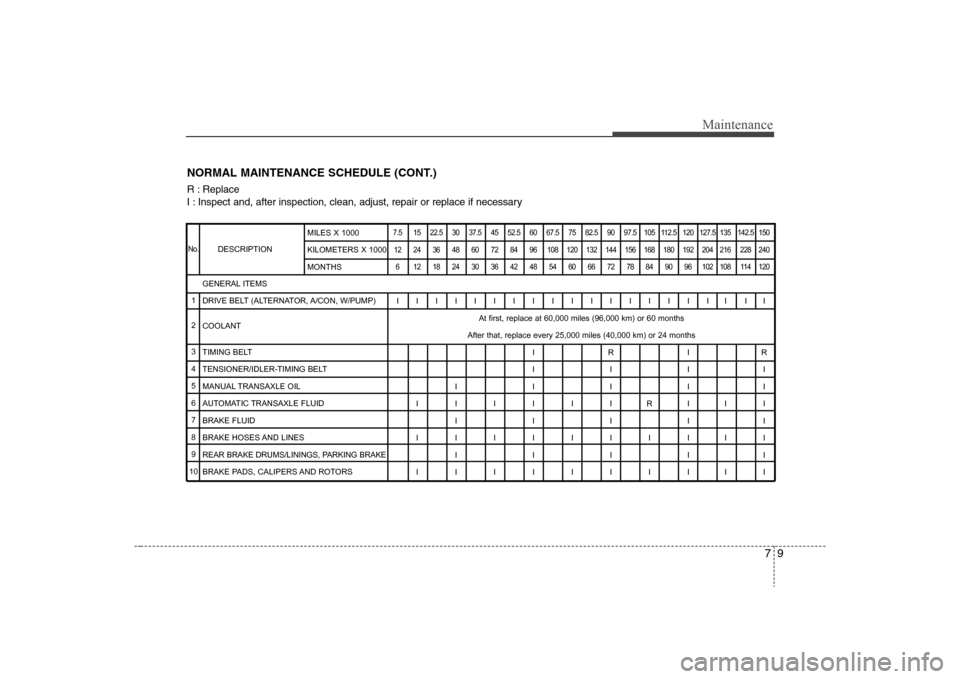

NORMAL MAINTENANCE SCHEDULE (CONT.)

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120IIIIIIIIIIIIIIIIII II

At first, replace at 60,000 miles (96,000 km) or 60 months

After that, replace every 25,000 miles (40,000 km) or 24 months

IRIR

IIII

IIIII

IIIIIIRIII

IIIII

IIIIIIIIII

IIIII

IIIIIIIIII GENERAL ITEMS

DRIVE BELT (ALTERNATOR, A/CON, W/PUMP)

COOLANT

TIMING BELT

TENSIONER/IDLER-TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORSMILES X 1000

KILOMETERS X 1000

MONTHS

R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 286 of 360

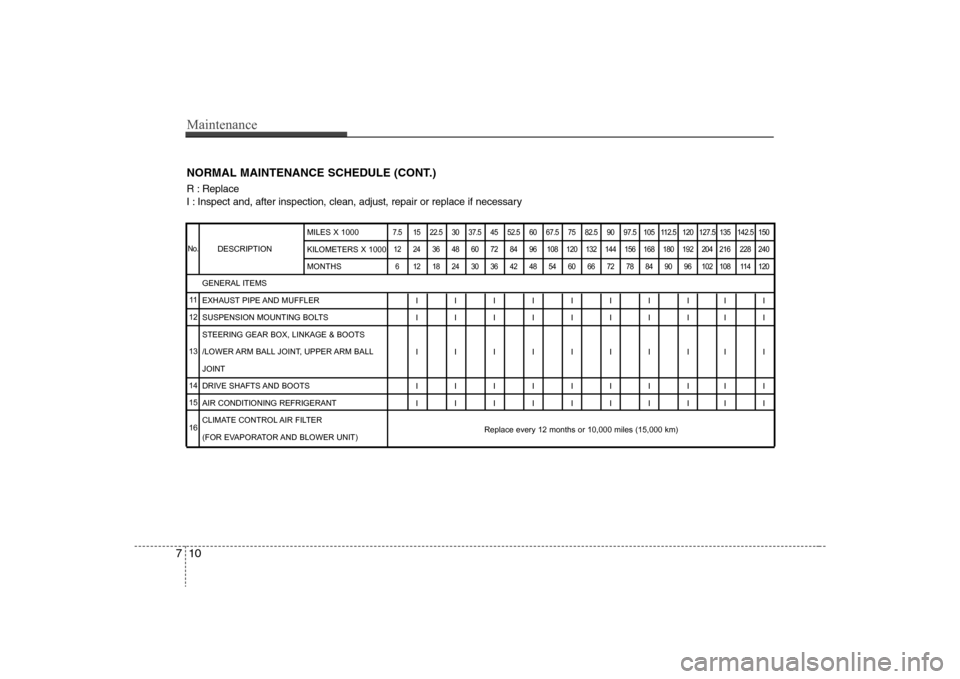

Maintenance10 7NORMAL MAINTENANCE SCHEDULE (CONT.)R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

IIIIIIIIII

Replace every 12 months or 10,000 miles (15,000 km) GENERAL ITEMS

EXHAUST PIPE AND MUFFLER

SUSPENSION MOUNTING BOLTS

STEERING GEAR BOX, LINKAGE & BOOTS

/LOWER ARM BALL JOINT, UPPER ARM BALL

JOINT

DRIVE SHAFTS AND BOOTS

AIR CONDITIONING REFRIGERANT

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)MILES X 1000

KILOMETERS X 1000

MONTHS

No.11

12

13

14

15

16

Page 287 of 360

711

Maintenance

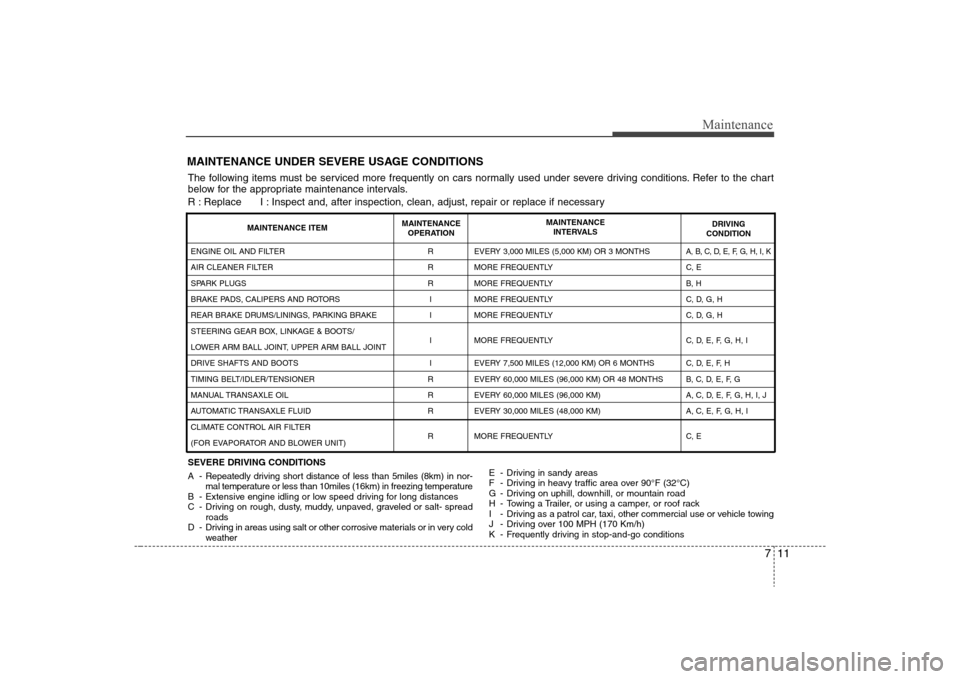

MAINTENANCE UNDER SEVERE USAGE CONDITIONSSEVERE DRIVING CONDITIONS

A - Repeatedly driving short distance of less than 5miles (8km) in nor-

mal temperature or less than 10miles (16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread

roads

D - Driving in areas using salt or other corrosive materials or in very cold

weatherE - Driving in sandy areas

F - Driving in heavy traffic area over 90°F (32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 100 MPH (170 Km/h)

K - Frequently driving in stop-and-go conditionsENGINE OIL AND FILTER

AIR CLEANER FILTER

SPARK PLUGS

BRAKE PADS, CALIPERS AND ROTORS

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

STEERING GEAR BOX, LINKAGE & BOOTS/

LOWER ARM BALL JOINT, UPPER ARM BALL JOINT

DRIVE SHAFTS AND BOOTS

TIMING BELT/IDLER/TENSIONER

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)R

R

R

I

I

I

I

R

R

R

REVERY 3,000 MILES (5,000 KM) OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 7,500 MILES (12,000 KM) OR 6 MONTHS

EVERY 60,000 MILES (96,000 KM) OR 48 MONTHS

EVERY 60,000 MILES (96,000 KM)

EVERY 30,000 MILES (48,000 KM)

MORE FREQUENTLY

A, B, C, D, E, F, G, H, I, KC, E

B, H

C, D, G, H

C, D, G, H

C, D, E, F, G, H, I

C, D, E, F, H

B, C, D, E, F, G

A, C, D, E, F, G, H, I, J

A, C, E, F, G, H, I

C, E

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE

INTERVALSDRIVING

CONDITION

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart

below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 288 of 360

Maintenance12 7EXPLANATION OF SCHEDULED MAINTENANCE ITEMSEngine oil and filterThe engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.Drive beltsInspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filterA clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by trained technicians.

Fuel lines, fuel hoses and con-

nectionsCheck the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

a trained technician replace any dam-

aged or leaking parts immediately.

Page 289 of 360

713

Maintenance

Timing beltInspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.Vapor hose and fuel filler capThe vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hosesInspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filterA Genuine Hyundai air cleaner filter is

recommended when the filter is

replaced.Spark plugsMake sure to install new spark plugs of

the correct heat range.Valve clearanceInspect excessive valve noise and/or

engine vibration and adjust if necessary.

A qualified technician should perform the

operation.Cooling systemCheck the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 290 of 360

Maintenance14 7Manual transaxle fluid

(if equipped)Inspect the manual transaxle fluid

according to the maintenance schedule.✽ ✽

NOTICEIf the oil level is low, check for possible

leaks before adding oil. Do not overfill.Automatic transaxle fluid

(if equipped)The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.Brake hoses and linesVisually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake fluidCheck brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4

specification.Rear disc brake / linings, parking

brakeCheck the rear disc brake and linings for

scoring, burning, leaking fluid, broken

parts, and excessive wear. Inspect the

parking brake system including the park-

ing brake lever and cables.Brake pads, calipers and rotorsCheck the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.Exhaust pipe and mufflerVisually inspect the exhaust pipes, muf-

fler and hangers for cracks, deterioration,

or damage. Start the engine and listen

carefully for any exhaust gas leakage.

Tighten connections or replace parts as

necessary.

Suspension mounting boltsCheck the suspension connections for

looseness or damage. Retighten to the

specified torque.Steering gear box, linkage &

boots/lower arm ball jointWith the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.Drive shafts and bootsCheck the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.Air conditioning refrigerant

(if equipped)Check the air conditioning lines and con-

nections for leakage and damage.