brake rotor Hyundai Elantra 2008 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Elantra, Model: Hyundai Elantra 2008Pages: 360, PDF Size: 12.2 MB

Page 219 of 360

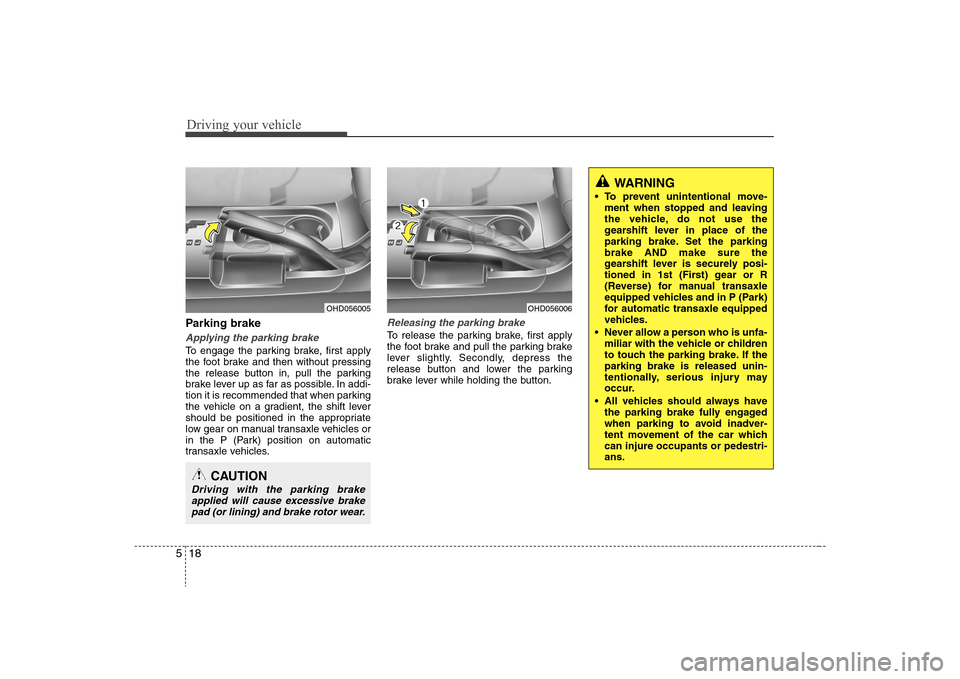

Driving your vehicle18 5Parking brake Applying the parking brakeTo engage the parking brake, first apply

the foot brake and then without pressing

the release button in, pull the parking

brake lever up as far as possible. In addi-

tion it is recommended that when parking

the vehicle on a gradient, the shift lever

should be positioned in the appropriate

low gear on manual transaxle vehicles or

in the P (Park) position on automatic

transaxle vehicles.

Releasing the parking brakeTo release the parking brake, first apply

the foot brake and pull the parking brake

lever slightly. Secondly, depress the

release button and lower the parking

brake lever while holding the button.

CAUTION

Driving with the parking brake

applied will cause excessive brake

pad (or lining) and brake rotor wear.

WARNING

To prevent unintentional move-

ment when stopped and leaving

the vehicle, do not use the

gearshift lever in place of the

parking brake. Set the parking

brake AND make sure the

gearshift lever is securely posi-

tioned in 1st (First) gear or R

(Reverse) for manual transaxle

equipped vehicles and in P (Park)

for automatic transaxle equipped

vehicles.

Never allow a person who is unfa-

miliar with the vehicle or children

to touch the parking brake. If the

parking brake is released unin-

tentionally, serious injury may

occur.

All vehicles should always have

the parking brake fully engaged

when parking to avoid inadver-

tent movement of the car which

can injure occupants or pedestri-

ans.

OHD056005

OHD056006

Page 285 of 360

No.1

2

3

4

5

6

7

8

9

10

79

Maintenance

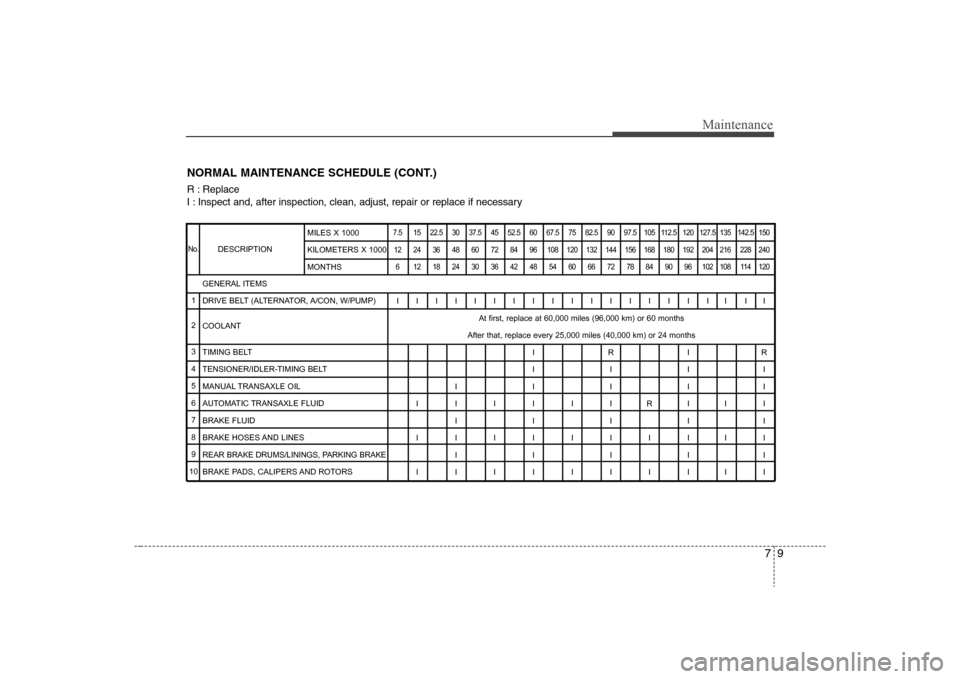

NORMAL MAINTENANCE SCHEDULE (CONT.)

DESCRIPTION

7.5 15 22.5 30 37.5 45 52.5 60 67.5 75 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

12 24 36 48 60 72 84 96 108 120 132 144 156 168 180 192 204 216 228 240

6 121824303642485460667278849096102108114120IIIIIIIIIIIIIIIIII II

At first, replace at 60,000 miles (96,000 km) or 60 months

After that, replace every 25,000 miles (40,000 km) or 24 months

IRIR

IIII

IIIII

IIIIIIRIII

IIIII

IIIIIIIIII

IIIII

IIIIIIIIII GENERAL ITEMS

DRIVE BELT (ALTERNATOR, A/CON, W/PUMP)

COOLANT

TIMING BELT

TENSIONER/IDLER-TIMING BELT

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORSMILES X 1000

KILOMETERS X 1000

MONTHS

R : Replace

I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 287 of 360

711

Maintenance

MAINTENANCE UNDER SEVERE USAGE CONDITIONSSEVERE DRIVING CONDITIONS

A - Repeatedly driving short distance of less than 5miles (8km) in nor-

mal temperature or less than 10miles (16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt- spread

roads

D - Driving in areas using salt or other corrosive materials or in very cold

weatherE - Driving in sandy areas

F - Driving in heavy traffic area over 90°F (32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 100 MPH (170 Km/h)

K - Frequently driving in stop-and-go conditionsENGINE OIL AND FILTER

AIR CLEANER FILTER

SPARK PLUGS

BRAKE PADS, CALIPERS AND ROTORS

REAR BRAKE DRUMS/LININGS, PARKING BRAKE

STEERING GEAR BOX, LINKAGE & BOOTS/

LOWER ARM BALL JOINT, UPPER ARM BALL JOINT

DRIVE SHAFTS AND BOOTS

TIMING BELT/IDLER/TENSIONER

MANUAL TRANSAXLE OIL

AUTOMATIC TRANSAXLE FLUID

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)R

R

R

I

I

I

I

R

R

R

REVERY 3,000 MILES (5,000 KM) OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 7,500 MILES (12,000 KM) OR 6 MONTHS

EVERY 60,000 MILES (96,000 KM) OR 48 MONTHS

EVERY 60,000 MILES (96,000 KM)

EVERY 30,000 MILES (48,000 KM)

MORE FREQUENTLY

A, B, C, D, E, F, G, H, I, KC, E

B, H

C, D, G, H

C, D, G, H

C, D, E, F, G, H, I

C, D, E, F, H

B, C, D, E, F, G

A, C, D, E, F, G, H, I, J

A, C, E, F, G, H, I

C, E

MAINTENANCE ITEMMAINTENANCE

OPERATIONMAINTENANCE

INTERVALSDRIVING

CONDITION

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart

below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Page 290 of 360

Maintenance14 7Manual transaxle fluid

(if equipped)Inspect the manual transaxle fluid

according to the maintenance schedule.✽ ✽

NOTICEIf the oil level is low, check for possible

leaks before adding oil. Do not overfill.Automatic transaxle fluid

(if equipped)The fluid level should be in the "HOT"

range of the dipstick, after the engine

and transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine run-

ning and the transaxle in neutral, with the

parking brake properly applied.Brake hoses and linesVisually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake fluidCheck brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4

specification.Rear disc brake / linings, parking

brakeCheck the rear disc brake and linings for

scoring, burning, leaking fluid, broken

parts, and excessive wear. Inspect the

parking brake system including the park-

ing brake lever and cables.Brake pads, calipers and rotorsCheck the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.Exhaust pipe and mufflerVisually inspect the exhaust pipes, muf-

fler and hangers for cracks, deterioration,

or damage. Start the engine and listen

carefully for any exhaust gas leakage.

Tighten connections or replace parts as

necessary.

Suspension mounting boltsCheck the suspension connections for

looseness or damage. Retighten to the

specified torque.Steering gear box, linkage &

boots/lower arm ball jointWith the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.Drive shafts and bootsCheck the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.Air conditioning refrigerant

(if equipped)Check the air conditioning lines and con-

nections for leakage and damage.