maintenance schedule HYUNDAI ELANTRA 2021 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2021, Model line: ELANTRA, Model: HYUNDAI ELANTRA 2021Pages: 570, PDF Size: 52.21 MB

Page 495 of 570

09

9-9

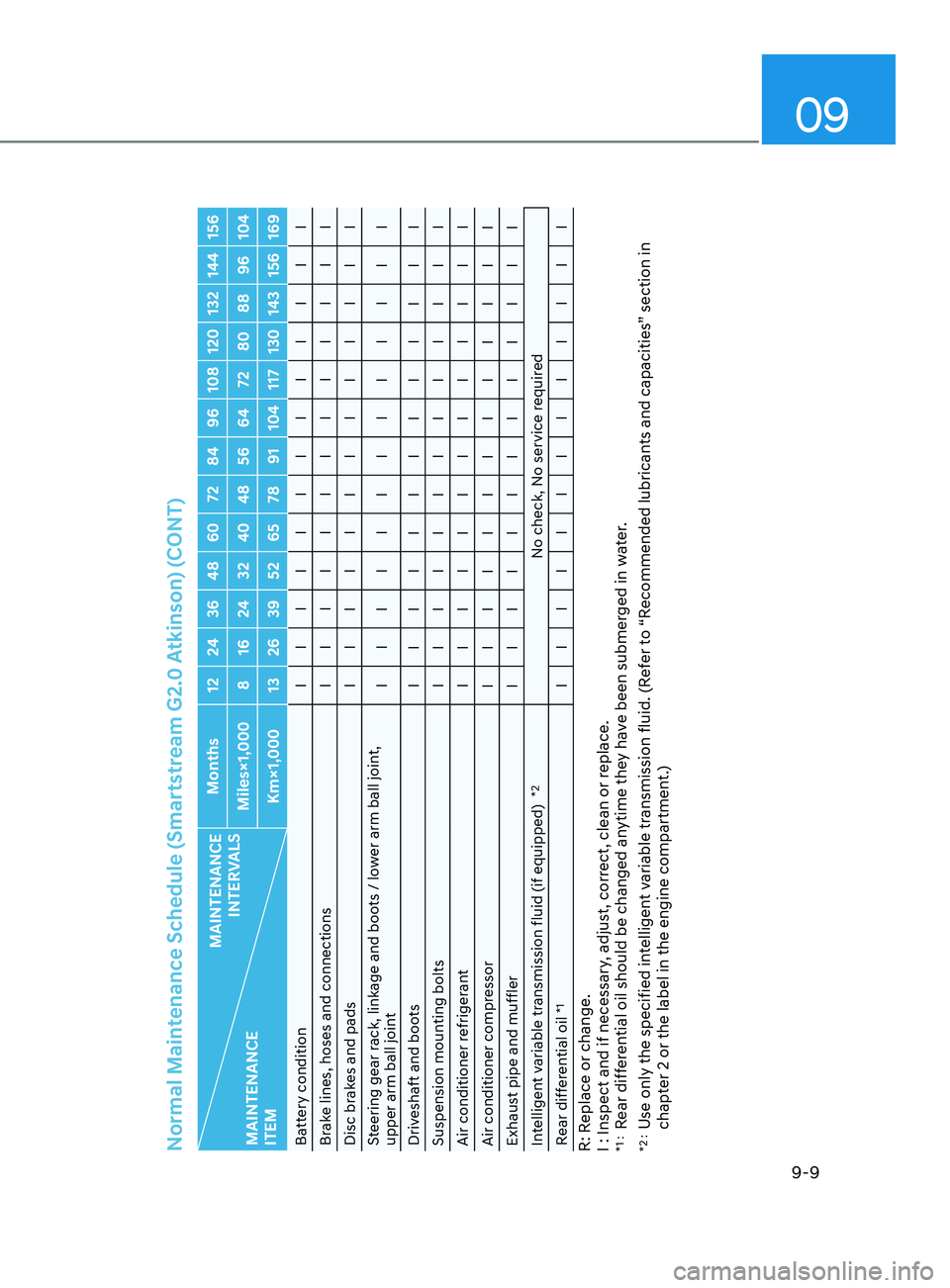

Normal Maintenance Schedule (Smartstream G2.0 Atkinson) (CONT)

MAINTENANCE INTERVALS

MAINTENANCE

ITEM Months 12 24 36 48 60 72 84 96 108 120 132 144 156

Miles×1,000 8 16 24 32 40 48 56 64 72 80 88 96 104 Km×1,000 13 26 39 52 65 78 91 104 117 130 143 156 169

Battery condition I I I I I I I I I I I I I

Brake lines, hoses and connections I I I I I I I I I I I I I

Disc brakes and pads I I I I I I I I I I I I I

Steering gear rack, linkage and boots / lower arm ball joint,

upper arm ball joint I I I I I I I I I I I I I

Driveshaft and boots I I I I I I I I I I I I I

Suspension mounting bolts I I I I I I I I I I I I I

Air conditioner refrigerant I I I I I I I I I I I I I

Air conditioner compressor I I I I I I I I I I I I I

Exhaust pipe and muffler I I I I I I I I I I I I I

Intelligent variable transmission fluid (if equipped)

*2

No check, No service required

Rear differential oil

*1

I I I I I I I I I I I I I

R: Replace or change.

I : Inspect and if necessary, adjust, correct, clean or replace.*1 : Rear differential oil should be changed anytime they have been submerged in water.

*2 : Use only the specified intelligent variable transmission fluid. (Refer to “Recommended lubricants and capacities” section in

chapter 2 or the label in the engine compartment.)

Page 496 of 570

Maintenance

9-10

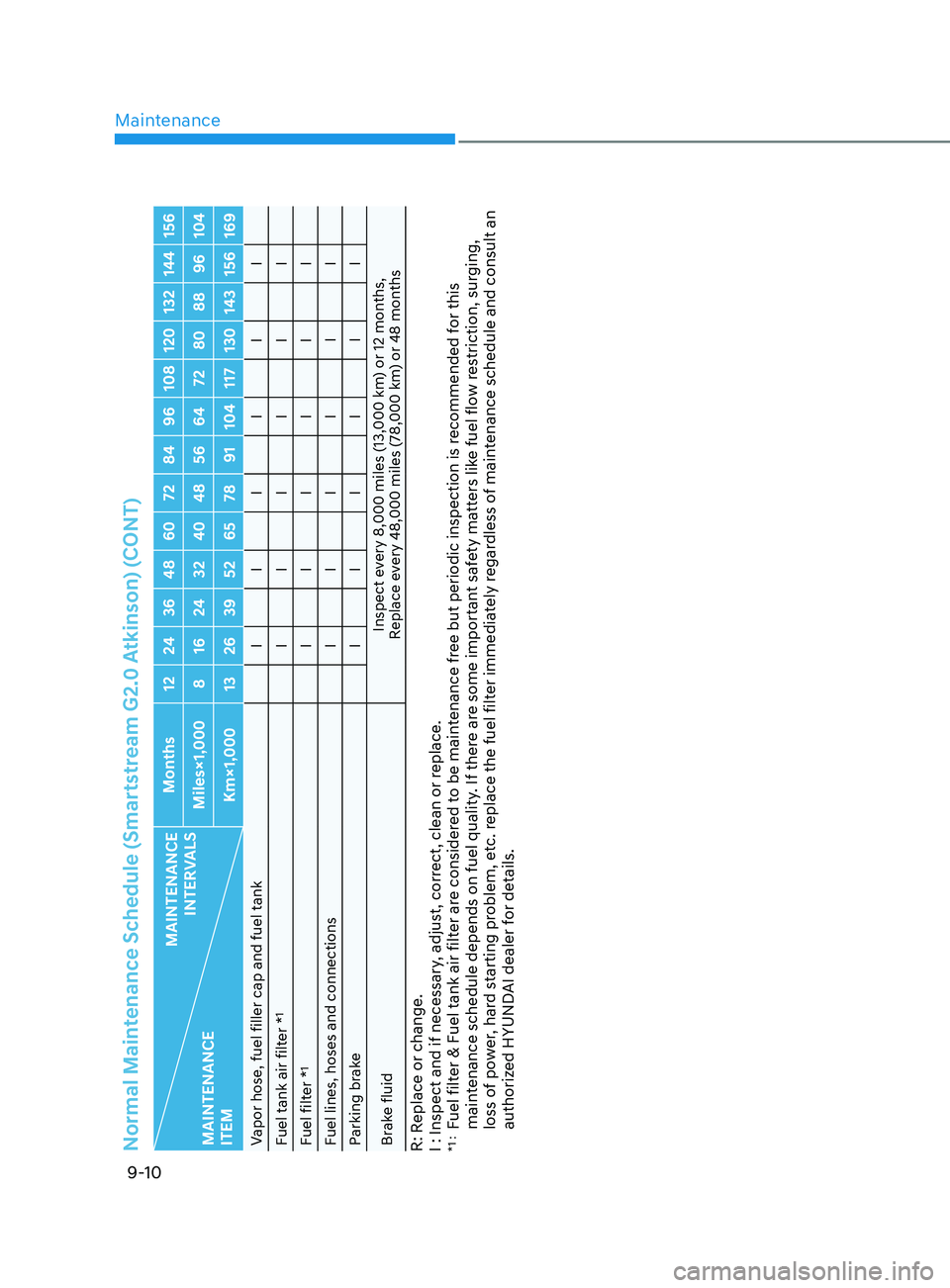

Normal Maintenance Schedule (Smartstream G2.0 Atkinson) (CONT)

MAINTENANCE INTERVALS

MAINTENANCE

ITEM Months 12 24 36 48 60 72 84 96 108 120 132 144 156

Miles×1,000 8 16 24 32 40 48 56 64 72 80 88 96 104 Km×1,000 13 26 39 52 65 78 91 104 117 130 143 156 169

Vapor hose, fuel filler cap and fuel tank I I I I I I

Fuel tank air filter *

1

I I I I I I

Fuel filter *

1

I I I I I I

Fuel lines, hoses and connections I I I I I I

Parking brake I I I I I I

Brake fluid Inspect every 8,000 miles (13,000 km) or 12 months,

Replace every 48,000 miles (78,000 km) or 48 months

R: Replace or change.

I : Inspect and if necessary, adjust, correct, clean or replace.*1 : Fuel filter & Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this

maintenance schedule depends on fuel quality. If there are some important safety matters like fuel flow restriction, surging,

loss of power, hard starting problem, etc. replace the fuel filter immediately regardless of maintenance schedule and consult an

authorized HYUNDAI dealer for details.

Page 499 of 570

09

9-13

Engine Oil and Filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the vehicle

is being driven in severe conditions,

more frequent oil and filter changes are

required.

Drive Belts

Inspect all drive belts for evidence

of cuts, cracks, excessive wear or oil

saturation and replace if necessary. Drive

belts should be checked periodically

for proper tension and adjusted as

necessary.

Fuel Filter

A clogged-up fuel filter may limit the

vehicle driving speed, damage the

emission system, and cause the hard

starting. When a considerable amount

of foreign substances are accumulated

in the fuel tank, the fuel filter should be

replaced.

Upon installing a new fuel filter, operate

the engine for several minutes, and

check the connections for any leakages.

Fuel filters should be installed by an

authorized HYUNDAI dealer.

Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and

connections for leakage and damage.

Have an authorized HYUNDAI dealer

replace any damaged or leaking parts

immediately.

Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

a new vapor hose or fuel filler cap is

correctly replaced.

Air Cleaner Filter

A genuine HYUNDAI air cleaner filter

is recommended when the filter is

replaced.

Spark Plugs

Make sure to install new spark plugs of

the correct heat range.

Cooling System

Check cooling system components, such

as radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

Explanation of SChEdulEd maintEnanCE itEmS

Page 500 of 570

Maintenance

9-14

Engine Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Intelligent variable transmission

fluid (if equipped)

Intelligent variable transmission fluid

should not be checked under normal

usage conditions.

We recommend that the Intelligent

variable transmission fluid is changed by

an authorized HYUNDAI dealer according

to the maintenance schedule.

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

Brake Fluid

Check the brake fluid level in the brake

fluid reservoir. The level should be

between the MIN and the MAX marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to DOT

4 specification.

Parking Brake

Inspect the parking brake system

including the parking brake pedal and

cables.

Brake Discs, Pads, Calipers and

Rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for

fluid leakage.

Suspension Mounting Bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the engine

off, check for excessive freeplay in the

steering wheel. Check the linkage for

bends or damage. Check the dust boots

and ball joints for deterioration, cracks,

or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if

necessary, repack the grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and damage.

Page 501 of 570

09

9-15

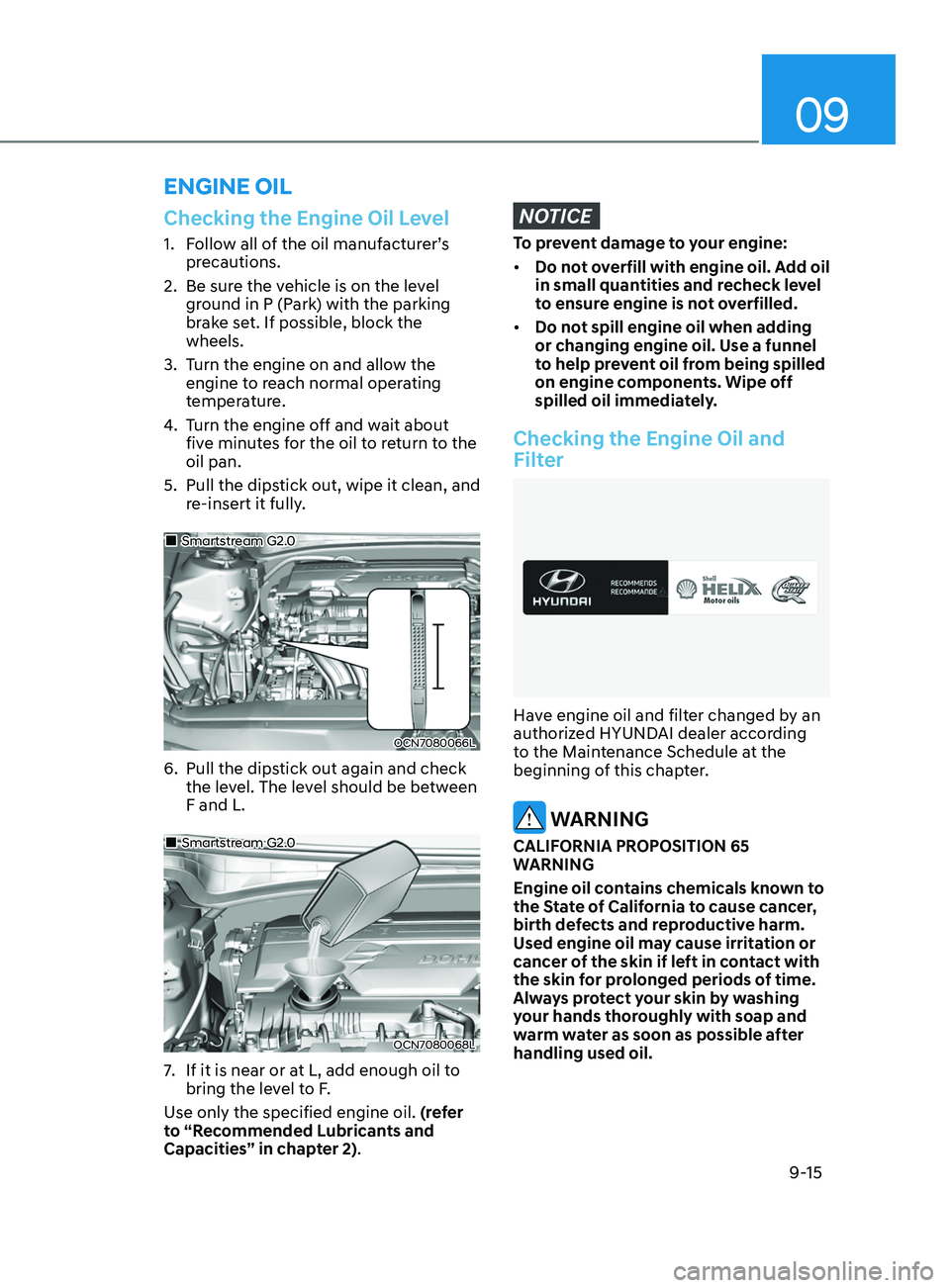

Checking the Engine Oil Level

1. Follow all of the oil manufacturer’s

precautions.

2.

Be sure the v

ehicle is on the level

ground in P (Park) with the parking

brake set. If possible, block the

wheels.

3.

Turn the engine on and allo

w the

engine to reach normal operating

temperature.

4.

Turn the engine o

ff and wait about

five minutes for the oil to return to the

oil pan.

5.

Pull the dipstick out, wipe it clean, and

r

e-insert it fully.

OCN7080066L

„„Smartstream G2.0

6. Pull the dipstick out again and check

the le vel. The level should be between

F and L.

OCN7080068L

„„Smartstream G2.0

7. If it is near or at L, add enough oil t o

bring the level to F.

Use only the specified engine oil. (refer

to “Recommended Lubricants and

Capacities” in chapter 2).

NOTICE

To prevent damage to your engine:

• Do not overfill with engine oil. Add oil

in small quantities and recheck level

to ensure engine is not overfilled.

• Do not spill engine oil when adding

or changing engine oil. Use a funnel

to help prevent oil from being spilled

on engine components. Wipe off

spilled oil immediately.

Checking the Engine Oil and

Filter

Have engine oil and filter changed by an

authorized HYUNDAI dealer according

to the Maintenance Schedule at the

beginning of this chapter.

WARNING

CALIFORNIA PROPOSITION 65

WARNING

Engine oil contains chemicals known to

the State of California to cause cancer,

birth defects and reproductive harm.

Used engine oil may cause irritation or

cancer of the skin if left in contact with

the skin for prolonged periods of time.

Always protect your skin by washing

your hands thoroughly with soap and

warm water as soon as possible after

handling used oil.

EnginE oil

Page 503 of 570

09

9-17

Recommended engine coolant

• When adding coolant, use only

distilled (deionized) water for your

vehicle and never mix hard water in

the coolant filled at the factory.

• An improper coolant mixture can

result in severe malfunction or engine

damage.

• The engine in your vehicle has

aluminum engine parts and must be

protected by an ethylene-glycol with

phosphate based coolant to prevent

corrosion and freezing.

• Do not use alcohol or methanol

coolant or mix them with the specified

coolant.

• Do not use a solution that contains

more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution.

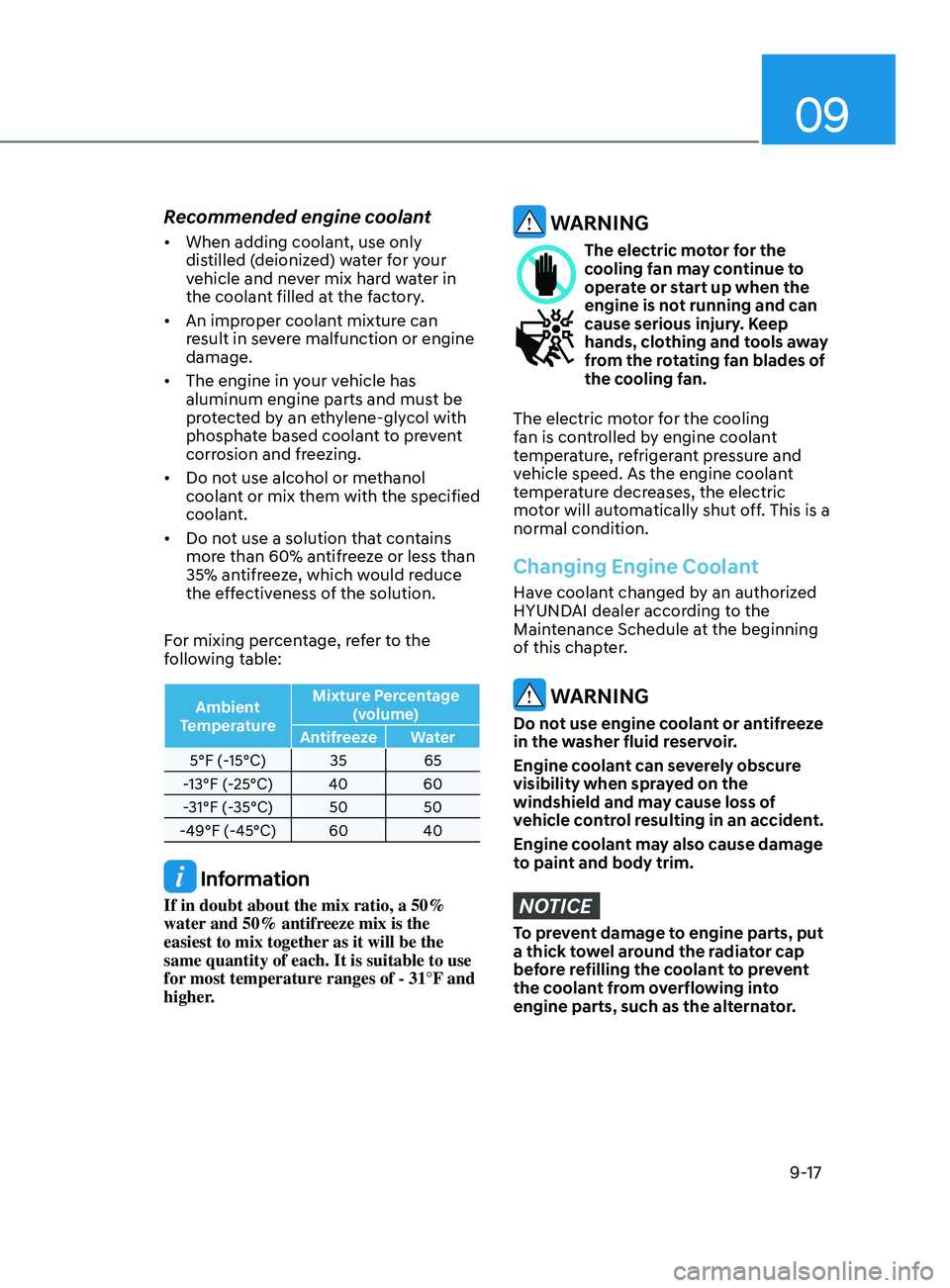

For mixing percentage, refer to the

following table:

Ambient

Temperature Mixture Percentage

(volume)

Antifreeze Water

5°F (-15°C) 35 65

-13°F (-25°C) 40 60

-31°F (-35°C) 50 50

-49°F (-45°C) 60 40

Information

If in doubt about the mix ratio, a 50%

water and 50% antifreeze mix is the

easiest to mix together as it will be the

same quantity of each. It is suitable to use

for most temperature ranges of - 31°F and

higher.

WARNING

The electric motor for the

cooling fan may continue to

operate or start up when the

engine is not running and can

cause serious injury. Keep

hands, clothing and tools away

from the rotating fan blades of

the cooling fan.

The electric motor for the cooling

fan is controlled by engine coolant

temperature, refrigerant pressure and

vehicle speed. As the engine coolant

temperature decreases, the electric

motor will automatically shut off. This is a

normal condition.

Changing Engine Coolant

Have coolant changed by an authorized

HYUNDAI dealer according to the

Maintenance Schedule at the beginning

of this chapter.

WARNING

Do not use engine coolant or antifreeze

in the washer fluid reservoir.

Engine coolant can severely obscure

visibility when sprayed on the

windshield and may cause loss of

vehicle control resulting in an accident.

Engine coolant may also cause damage

to paint and body trim.

NOTICE

To prevent damage to engine parts, put

a thick towel around the radiator cap

before refilling the coolant to prevent

the coolant from overflowing into

engine parts, such as the alternator.

Page 507 of 570

09

9-21

Filter Inspection

The cabin air filter should be replaced

according to the Maintenance Schedule.

If the vehicle is operated in severely

air-polluted cities or on dusty rough

roads for a long period, it should be

inspected more frequently and replaced

earlier. When you replace the cabin air

filter, replace it performing the following

procedure, and be careful to avoid

damaging other components.

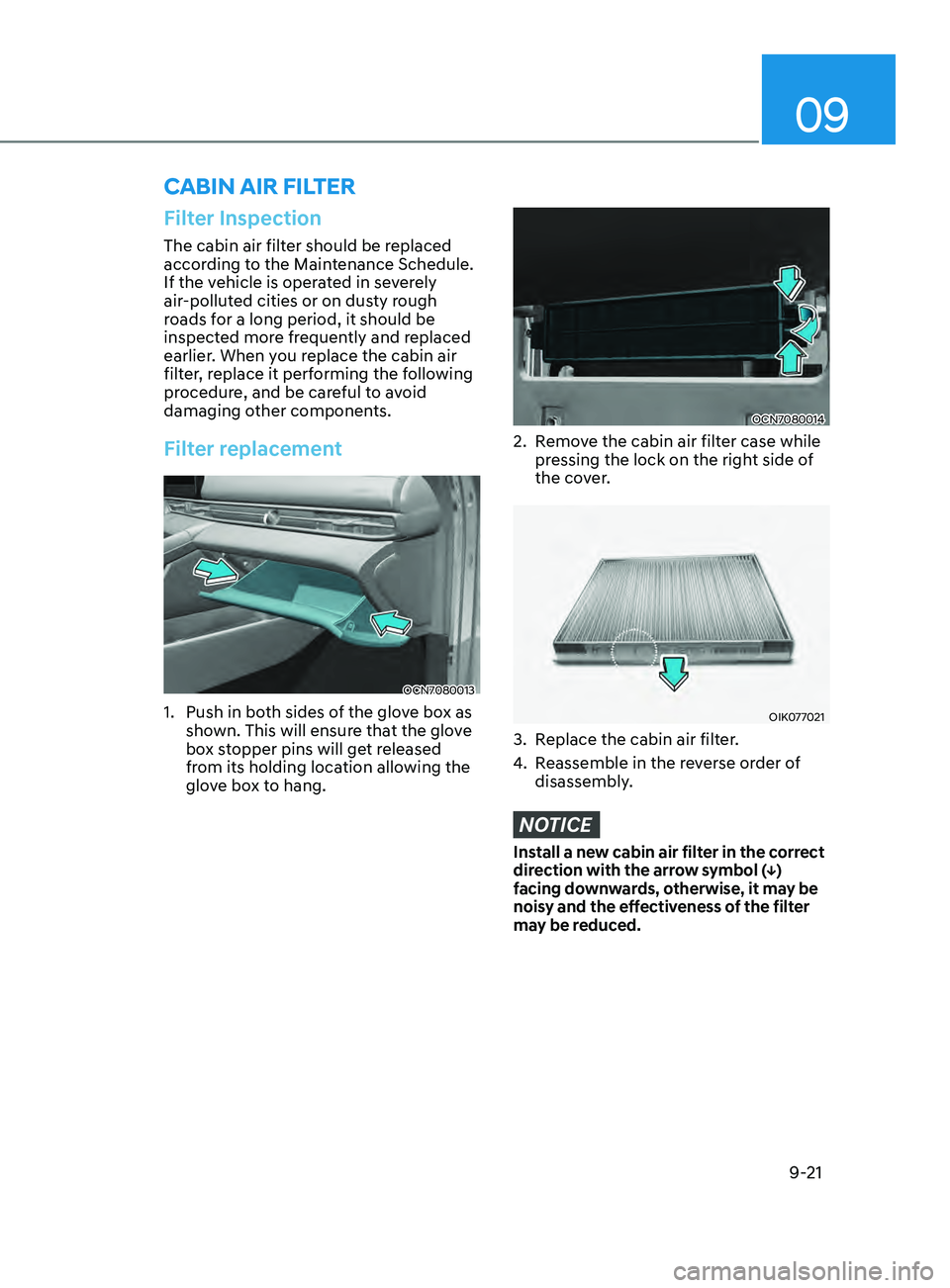

Filter replacement

OCN7080013

1. Push in both sides of the glove box as

shown. This will ensure that the glove

box stopper pins will get released

from its holding location allowing the

glove box to hang.

OCN7080014

2. Remove the cabin air filter case while

pr essing the lock on the right side of

the cover.

OIK077021

3. Replace the cabin air filter.

4.

Reassemble in the r

everse order of

disassembly.

NOTICE

Install a new cabin air filter in the correct

direction with the arrow symbol (↓)

facing downwards, otherwise, it may be

noisy and the effectiveness of the filter

may be reduced.

CaBin air fil tEr

Page 515 of 570

09

9-29

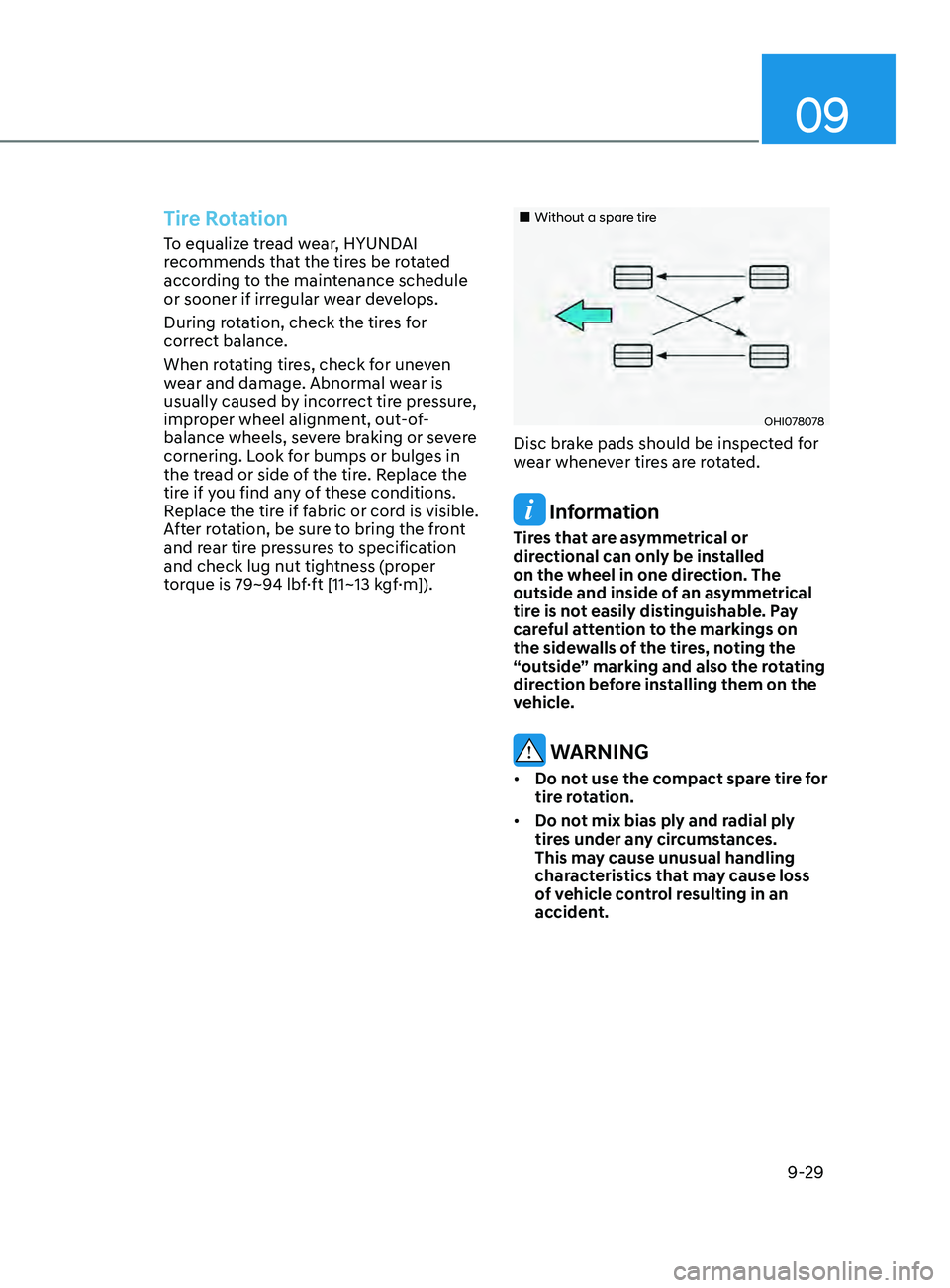

Tire Rotation

To equalize tread wear, HYUNDAI

recommends that the tires be rotated

according to the maintenance schedule

or sooner if irregular wear develops.

During rotation, check the tires for

correct balance.

When rotating tires, check for uneven

wear and damage. Abnormal wear is

usually caused by incorrect tire pressure,

improper wheel alignment, out-of-

balance wheels, severe braking or severe

cornering. Look for bumps or bulges in

the tread or side of the tire. Replace the

tire if you find any of these conditions.

Replace the tire if fabric or cord is visible.

After rotation, be sure to bring the front

and rear tire pressures to specification

and check lug nut tightness (proper

torque is 79~94 lbf·ft [11~13 kgf·m]).

„„Without a spare tire

OHI078078

Disc brake pads should be inspected for

wear whenever tires are rotated.

Information

Tires that are asymmetrical or

directional can only be installed

on the wheel in one direction. The

outside and inside of an asymmetrical

tire is not easily distinguishable. Pay

careful attention to the markings on

the sidewalls of the tires, noting the

“outside” marking and also the rotating

direction before installing them on the

vehicle.

WARNING

• Do not use the compact spare tire for

tire rotation.

• Do not mix bias ply and radial ply

tires under any circumstances.

This may cause unusual handling

characteristics that may cause loss

of vehicle control resulting in an

accident.

Page 554 of 570

Maintenance

9-68

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Owner’s

Handbook & Warranty Information

booklet in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations. There

are three emission control systems, as

follows.

(1)

Crank

case emission control system

(2)

Ev

aporative emission control system

(3)

Exhaust emission con

trol system

In order to ensure the proper function

of the emission control systems, it

is recommended that you have your

vehicle inspected and maintained

by an authorized HYUNDAI dealer in

accordance with the maintenance

schedule in this manual.

NOTICE

For the Inspection and Maintenance

Test (with Electronic Stability Control

(ESC) system)

• To prevent the vehicle from misfiring

during dynamometer testing, turn

the Electronic Stability Control

(ESC) system off by pressing the ESC

switch (ESC OFF light illuminated).

• After dynamometer testing is

completed, turn the ESC system back

on by pressing the ESC switch again.

1. Crankcase Emission Control

Sy

stem

The positive crankcase ventilation system

is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative Emission Control

System Including Onboard

Refueling Vapor Recovery

(ORVR)

The Evaporative Emission Control System

is designed to prevent fuel vapors from

escaping into the atmosphere. The

ORVR system is designed to allow the

vapors from the fuel tank to be loaded

into a canister while refueling at the gas

station, preventing the escape of fuel

vapors into the atmosphere.

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve

is controlled by the Engine Control

Module (ECM); when the engine coolant

temperature is low during idling, the

PCSV closes so that evaporated fuel

is not taken into the engine. After the

engine warms-up during ordinary

driving, the PCSV opens to introduce

evaporated fuel to the engine.

EmiSSion Control SyStEm

Page 561 of 570

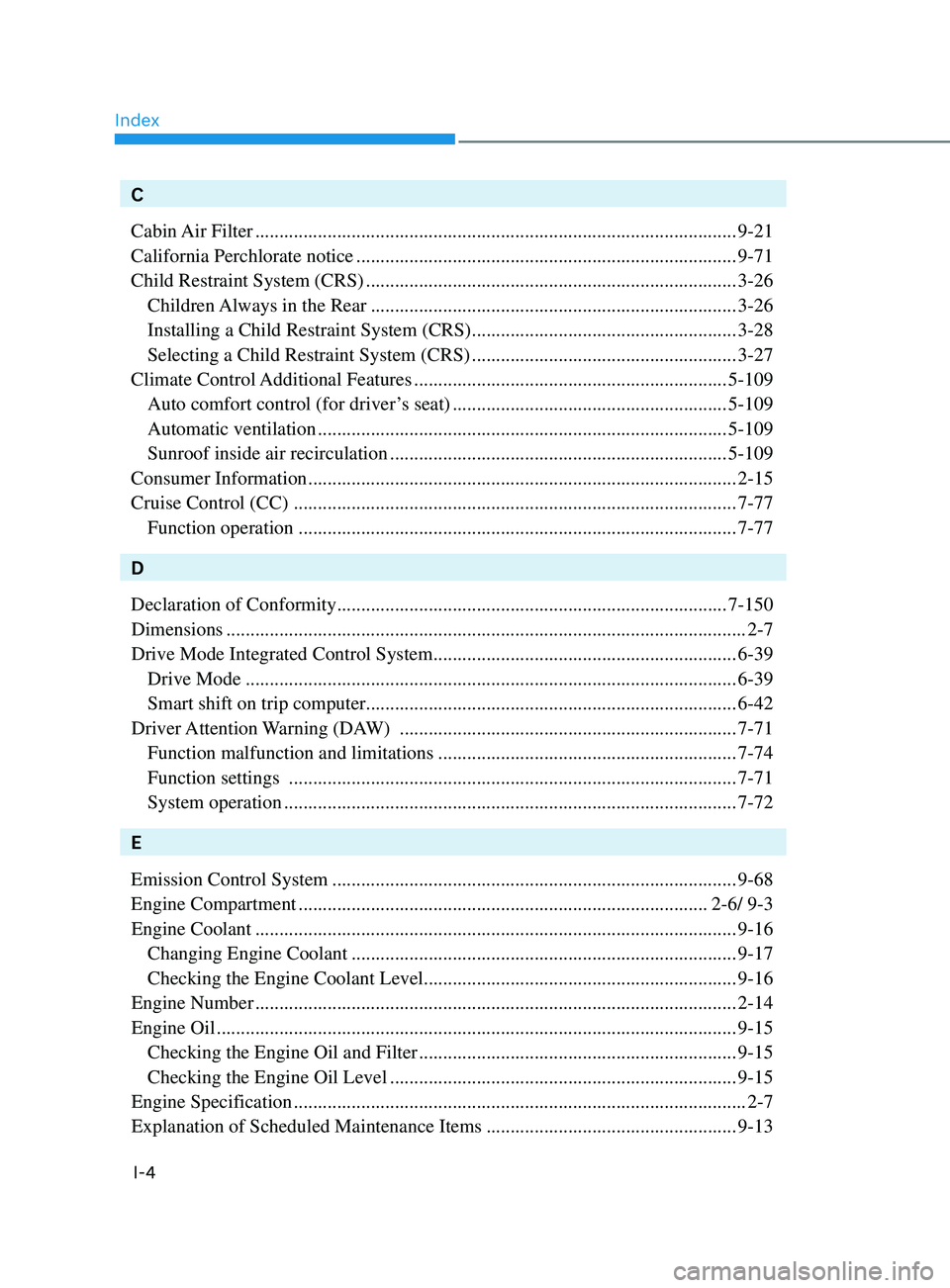

Index

I-4

C

Cabin Air Filter

........................................................................\

............................9-21

California Perchlorate notice

........................................................................\

....... 9-71

Child Restraint System (CRS)

........................................................................\

..... 3-26

Children Always in the Rear ........................................................................\

....3-26

Installing a Child Restraint System (CRS) .......................................................3-28

Selecting a Child Restraint System (CRS) .......................................................3-27

Climate Control

Additional Features

................................................................. 5-109

Auto comfort control (for driver’

s seat)

......................................................... 5-109

Automatic ventilation ........................................................................\

............. 5-109

Sunroof inside air recirculation ......................................................................5-109

Consumer Information

........................................................................\

................. 2-15

Cruise Control (CC)

........................................................................\

.................... 7-77

Function operation ........................................................................\

...................7-77

D

Declaration of Conformity

........................................................................\

......... 7-150

Dimensions

........................................................................\

.................................... 2-7

Drive Mode Integrated Control System

............................................................... 6-39

Drive Mode ........................................................................\

.............................. 6-39

Smart shift on trip computer ........................................................................\

.....6-42

Driver Attention

Warning (DAW)

...................................................................... 7-71

Function malfunction and limitations ..............................................................7-74

Function settings ........................................................................\

..................... 7-71

System operation ........................................................................\

...................... 7-72

E

Emission Control System

........................................................................\

............ 9-68

Engine Compartment

........................................................................\

............. 2-6/ 9-3

Engine Coolant

........................................................................\

............................ 9-16

Changing Engine Coolant ........................................................................\

........9-17

Checking the Engine Coolant Level .................................................................9-16

Engine Number

........................................................................\

............................ 2-14

Engine Oil

........................................................................\

.................................... 9-15

Checking the Engine Oil and Filter ..................................................................9-15

Checking the Engine Oil Level ........................................................................\

9-15

Engine Specification

........................................................................\

...................... 2-7

Explanation of Scheduled Maintenance Items

.................................................... 9-13