fuel filter HYUNDAI ELANTRA GT 2019 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: ELANTRA GT, Model: HYUNDAI ELANTRA GT 2019Pages: 486, PDF Size: 78.59 MB

Page 381 of 486

7-8

Maintenance

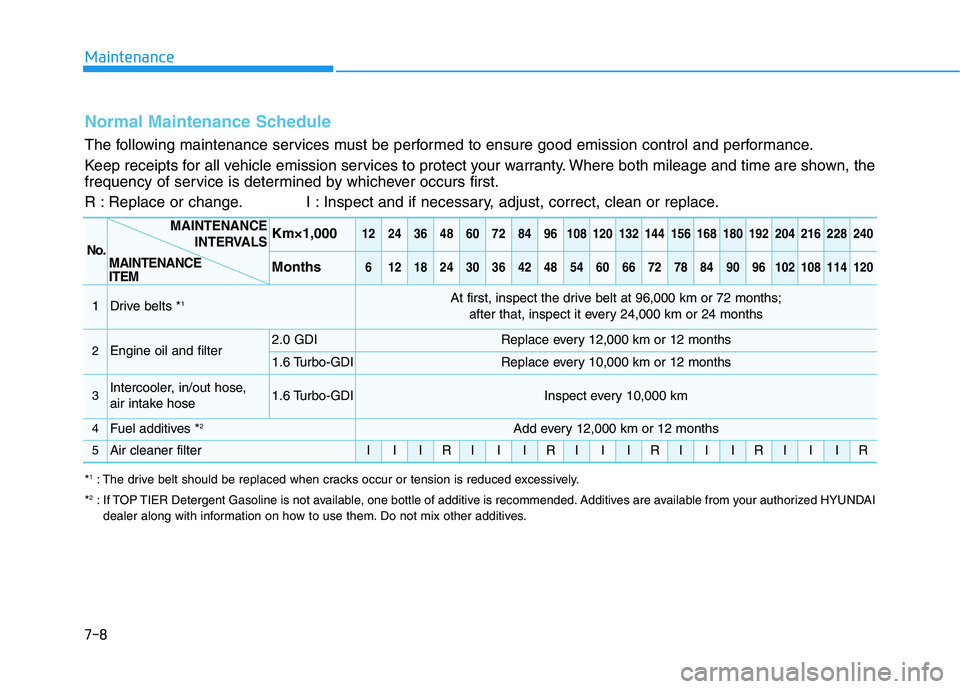

Normal Maintenance Schedule

The following maintenance services must be performed to ensure good emission control and performance.

Keep receipts for all vehicle emission services to protect your warranty. Where both mileage and time are shown, the

frequency of service is determined by whichever occurs first.

R : Replace or change. I : Inspect and if necessary, adjust, correct, clean or replace.

No.

Km×1,0001224364860728496108120132144156168180192204216228240

Months6121824303642485460667278849096102108114120

1Drive belts *1At first, inspect the drive belt at 96,000 km or 72 months;

after that, inspect it every 24,000 km or 24 months

2Engine oil and filter2.0 GDIReplace every 12,000 km or 12 months

1.6 Turbo-GDIReplace every 10,000 km or 12 months

3Intercooler, in/out hose,

air intake hose1.6 Turbo-GDIInspect every 10,000 km

4Fuel additives * 2Add every 12,000 km or 12 months

5Air cleaner filterIIIRIIIRIIIRIIIRIIIR

*

1

: The drive belt should be replaced when cracks occur or tension is reduced excessively.

* 2

: If TOP TIER Detergent Gasoline is not available, one bottle of additive is recommended. Additives are available from your authorized HYUNDAI

dealer along with information on how to use them. Do not mix other additives.

MAINTENANCE

INTERVALS

MAINTENANCE ITEM

Page 384 of 486

7-11

7

Maintenance

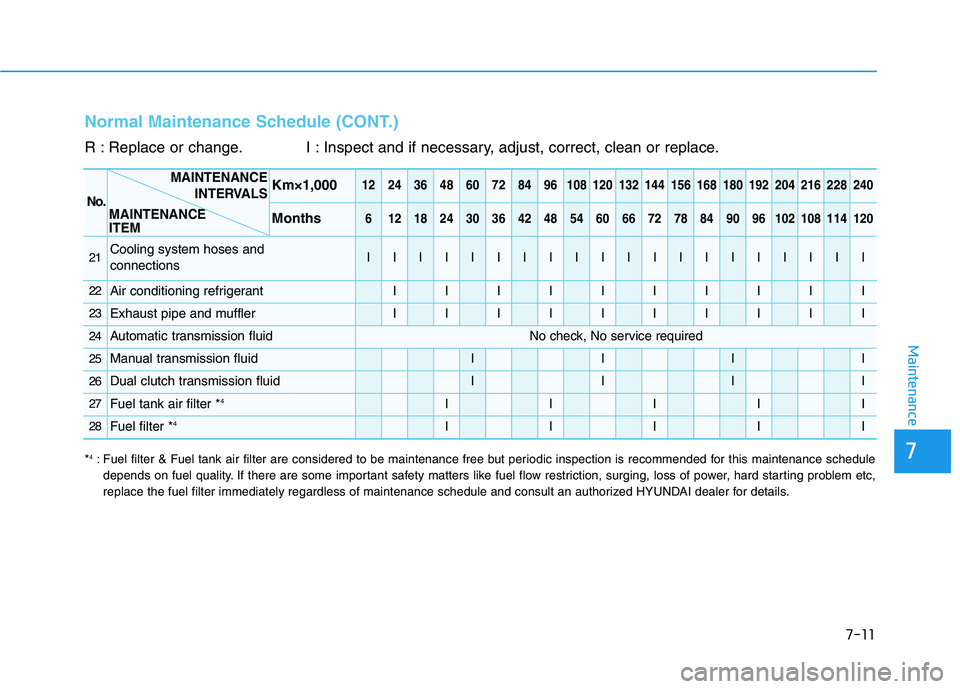

Normal Maintenance Schedule (CONT.)

R : Replace or change. I : Inspect and if necessary, adjust, correct, clean or replace.

No.

Km×1,0001224364860728496108120132144156168180192204216228240

Months6121824303642485460667278849096102108114120

21Cooling system hoses and connectionsIIIIIIIIIIIIIIIIIIII

22Air conditioning refrigerantIIIIIIIIII

23Exhaust pipe and mufflerIIIIIIIIII

24Automatic transmission fluidNo check, No service required

25Manual transmission fluidIIII

26Dual clutch transmission fluidIIII

27Fuel tank air filter *4IIIII

28Fuel filter *4IIIII

MAINTENANCE ITEM MAINTENANCE

INTERVALS

*4

: Fuel filter & Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this maintenance schedule

depends on fuel quality. If there are some important safety matters like fuel flow restriction, surging, loss of power, hard starting problem etc,

replace the fuel filter immediately regardless of maintenance schedule and consult an authorized HYUNDAI dealer for details.

Page 388 of 486

7-15

7

Maintenance

EEXX PPLLAA NN AATTIIOO NN OO FF SS CC HH EEDD UU LLEE DD MM AAIINN TTEENN AANN CCEE IITT EEMM SS

Engine Oil and Filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filterchanges are required.

Drive Belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel Filter

A clogged-up fuel filter may limit the

vehicle driving speed, damage theemission system, and cause the

hard starting. When a considerable

amount of foreign substances are

accumulated in the fuel tank, the fuelfilter should be replaced.

Upon installing a new fuel filter, oper-

ate the engine for several minutes,

and check the connections for any

leakages. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

Fuel Lines, Fuel Hoses and Connections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized HYUNDAI

dealer replace any damaged or leak-

ing parts immediately.

Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure a new vaporhose or fuel filler cap is correctlyreplaced.

Vacuum Crankcase Ventilation Hoses (if equipped)

Inspect the surface of hoses for evi- dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold. Inspect the hose routing to ensure that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component whichmight cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Page 457 of 486

7-84

Maintenance

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an emission control system to meet all

applicable emission regulations.There are three emission control

systems, as follows.

(1) Crankcase emission control sys-tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order to ensure the proper func-

tion of the emission control systems,

it is recommended that you have

your vehicle inspected and main-

tained by an authorized HYUNDAIdealer in accordance with the main-

tenance schedule in this manual. For the Inspection and

Maintenance Test (with Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch (ESCOFF light illuminated).

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase Emission Control

System

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative EmissionControl System Including

Onboard Refueling Vapor

Recovery (ORVR)

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere. The ORVR system is

designed to allow the vapors fromthe fuel tank to be loaded into a can-ister while refueling at the gas sta-

tion, preventing the escape of fuel

vapors into the atmosphere.

NOTICE

EEMM IISS SSIIOO NN CC OO NNTTRR OO LL SS YY SSTT EEMM